Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Jewelry

Tools & Equipment

What Grit Sandpaper For Jewelry

Published: December 20, 2023

Discover the best grit sandpaper for jewelry making with our comprehensive guide. Find the right tools and equipment for your jewelry projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of jewelry making, where every piece is a work of art and every detail matters. Whether you're a seasoned jewelry artisan or just starting out on your creative journey, you understand the importance of precision and finesse in crafting exquisite pieces. One essential tool that plays a significant role in achieving the desired finish is grit sandpaper.

In the realm of jewelry making, the choice of grit sandpaper can make a remarkable difference in the final outcome of your creations. Understanding the nuances of grit sandpaper and knowing which grit to use for specific jewelry-making tasks is crucial for achieving professional results.

In this comprehensive guide, we will delve into the realm of grit sandpaper for jewelry making. You will gain insights into the different grit levels, learn how to choose the right grit sandpaper for various jewelry-making applications, and discover the best practices for using grit sandpaper to elevate your craft. So, let's embark on this enlightening journey and unlock the secrets of harnessing the power of grit sandpaper in jewelry making.

Key Takeaways:

- Choose the right grit sandpaper for jewelry based on the imperfections, material type, desired finish, and abrasive material to achieve professional results in crafting exquisite pieces.

- Utilize grit sandpaper effectively by securing the workpiece, using progressive grits, maintaining consistent motion, and employing lubrication to transform raw materials into stunning works of art.

Read more: What Grit Sandpaper For Stairs

Understanding Grit Sandpaper

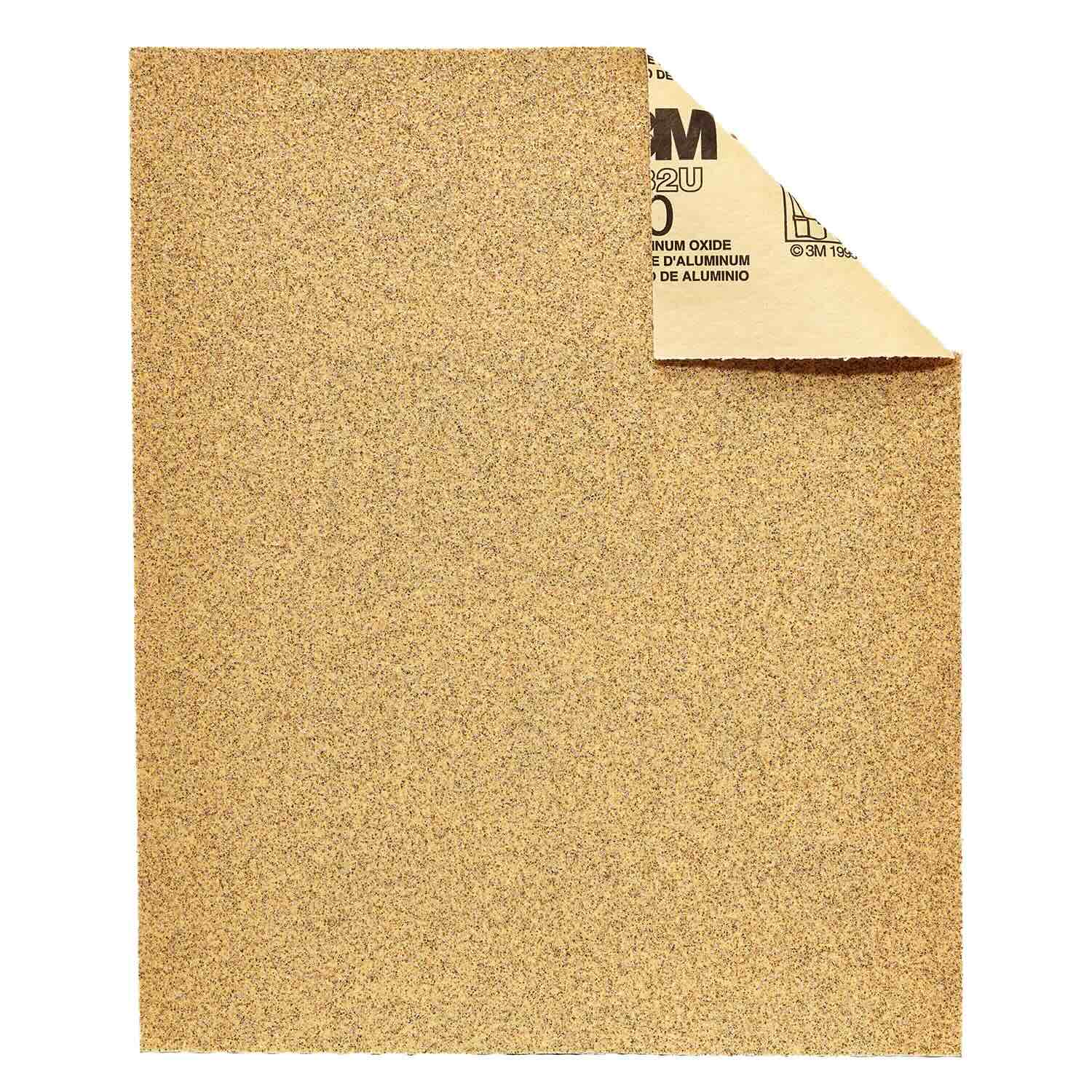

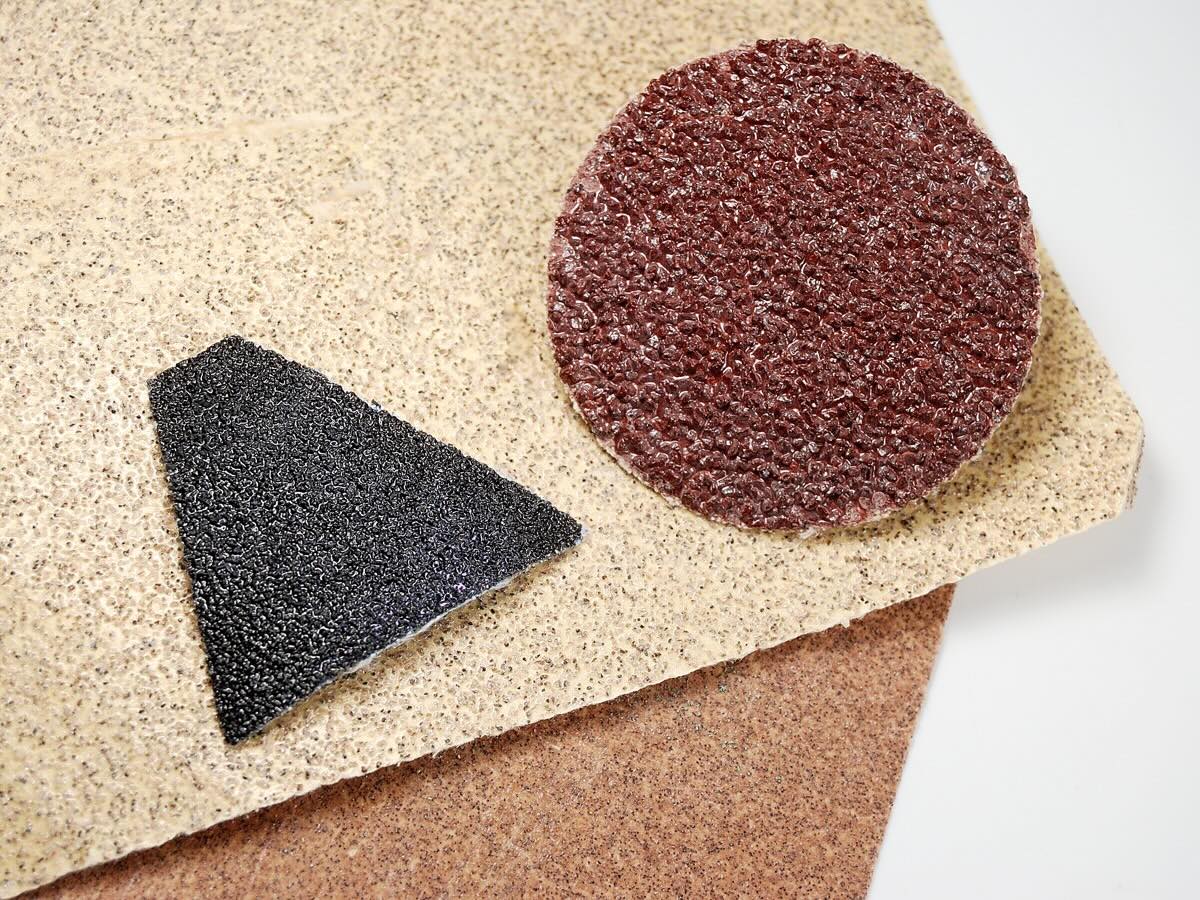

Grit sandpaper is a versatile abrasive material used in various industries, including woodworking, metalworking, and, of course, jewelry making. It consists of a backing material, such as paper or cloth, that is coated with abrasive particles. These particles, known as grit, are distributed across the surface of the backing in a uniform manner.

The grit of sandpaper refers to the number of abrasive particles per square inch. A higher grit number indicates a finer abrasive, while a lower grit number signifies a coarser abrasive. In the context of jewelry making, understanding the different grit levels is essential for achieving specific finishes and addressing various surface imperfections.

Common grit levels found in sandpaper range from coarse (e.g., 40-60 grit) to very fine (e.g., 400-600 grit and above). Coarse grit sandpaper is ideal for removing material quickly and addressing substantial imperfections, such as shaping metal or smoothing rough edges. On the other hand, fine grit sandpaper is suitable for refining surfaces, removing minor blemishes, and achieving a smooth, polished finish.

It’s important to note that the abrasive particles on sandpaper can be made from various materials, including aluminum oxide, silicon carbide, and diamond. Each material offers unique characteristics, such as durability, sharpness, and suitability for specific applications. When selecting sandpaper for jewelry making, considering the material of the abrasive particles is crucial for achieving the desired results.

Now that we have a foundational understanding of grit sandpaper, let’s explore the intricacies of choosing the right grit sandpaper for different jewelry-making tasks, ensuring that each piece you create reflects the highest level of craftsmanship and artistry.

Choosing the Right Grit Sandpaper for Jewelry

When it comes to jewelry making, the selection of the right grit sandpaper is a critical decision that directly influences the quality and appearance of the final piece. Different jewelry-making tasks require specific grit levels to achieve the desired finish and address particular surface imperfections. Let’s explore the key considerations for choosing the right grit sandpaper for various jewelry-making applications.

- Surface Imperfections: Assess the nature of the surface imperfections you need to address. For smoothing rough metal edges or removing substantial material, start with a coarser grit, such as 40 or 60. If you’re refining the surface and eliminating minor blemishes, transition to finer grits, such as 220 or 400.

- Material Type: Consider the type of material you are working with. For softer metals like gold or silver, finer grit sandpaper is generally preferred to avoid excessive abrasion. Conversely, harder metals such as stainless steel may require coarser grits to effectively shape and refine the surface.

- Surface Finish: Determine the desired finish for your jewelry piece. If you aim to achieve a mirror-like polish, you will need to progress through a series of increasingly finer grits, culminating in ultra-fine grits like 600 or higher to attain a lustrous sheen.

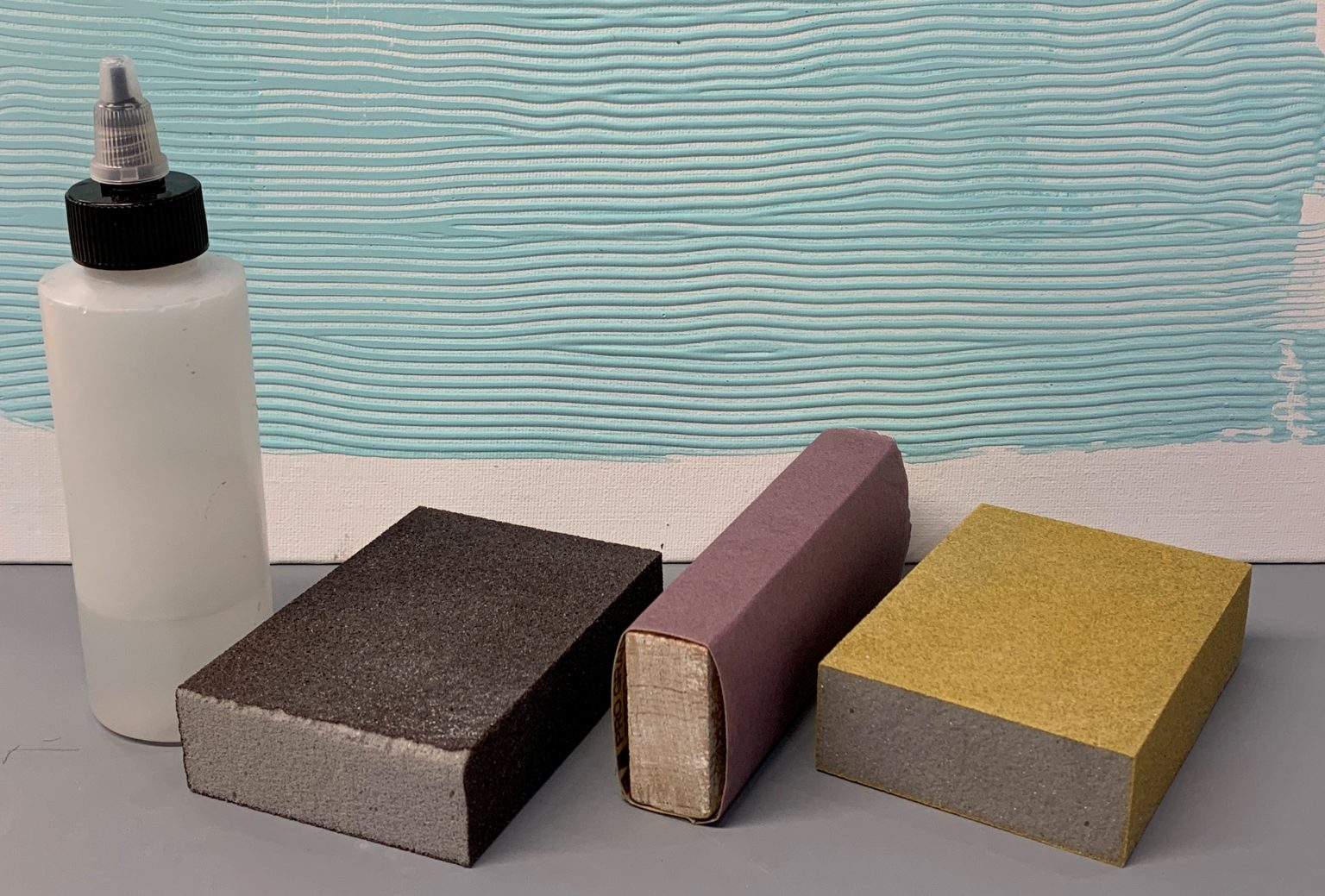

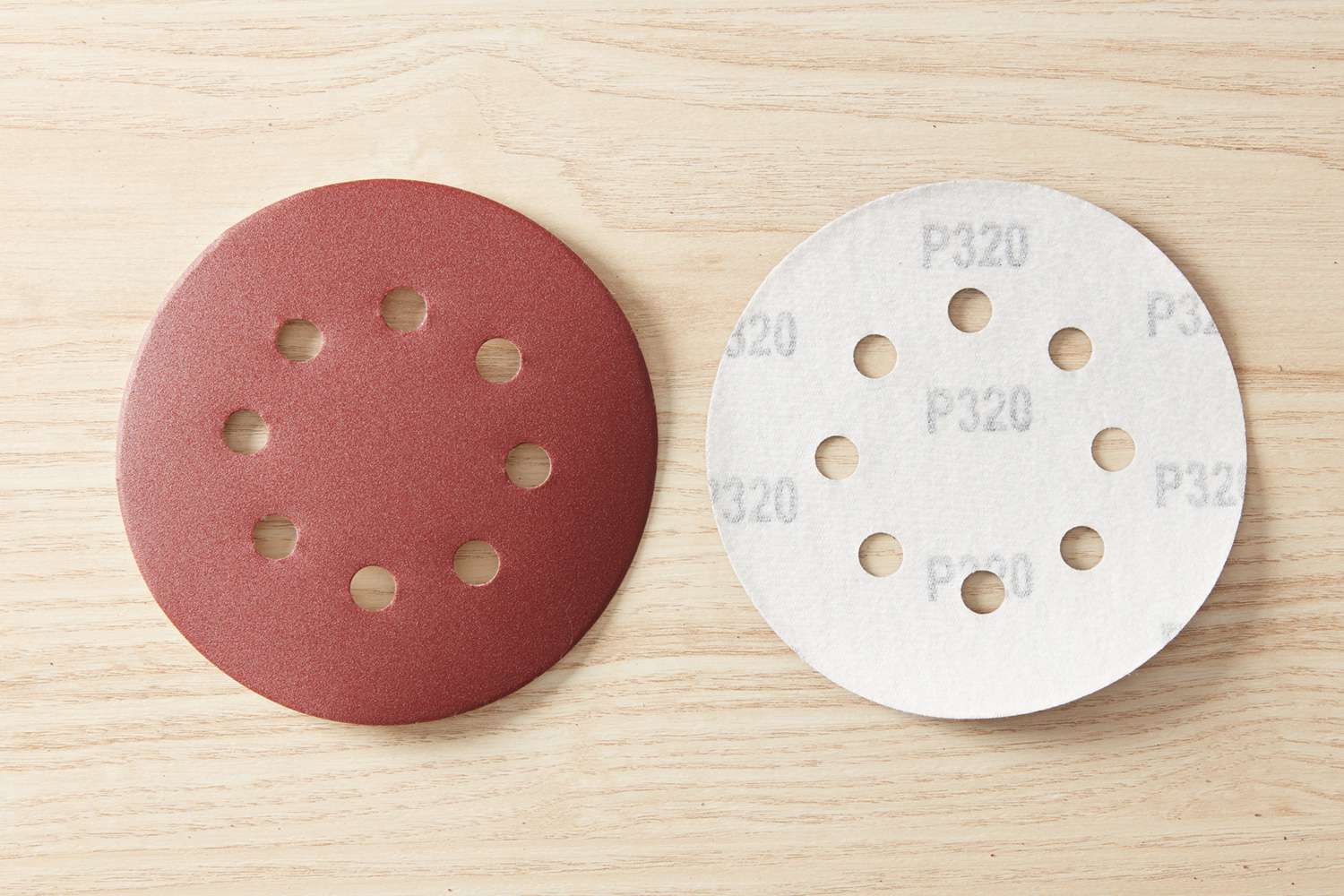

- Detail Work: For intricate detailing or reaching small, confined areas, consider using sandpaper in various grits, including fine-grit sanding pads or flexible sanding sheets. These specialized options enable precise and delicate sanding, ensuring that no detail is overlooked.

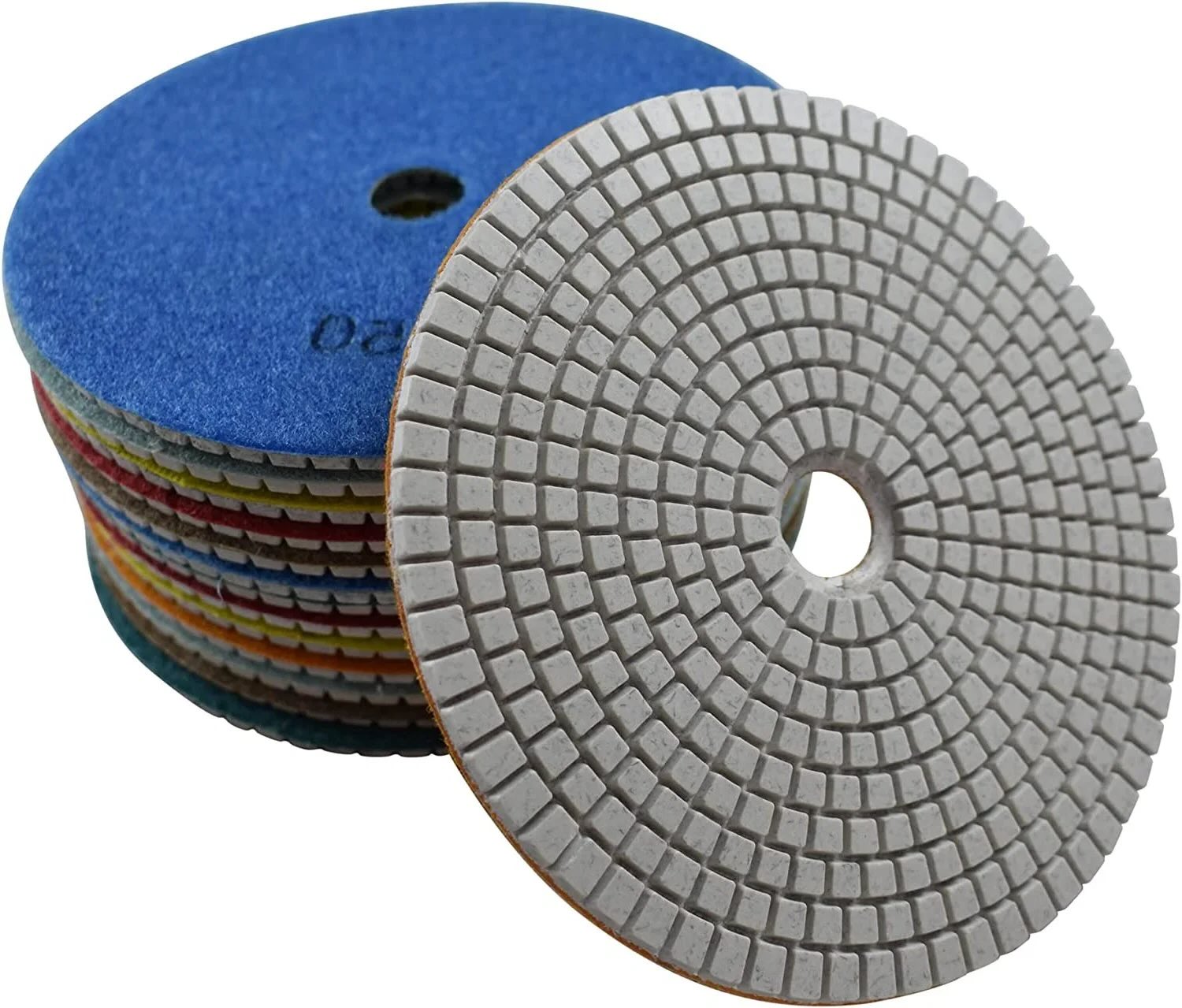

- Abrasive Material: Pay attention to the abrasive material of the sandpaper. Aluminum oxide is a versatile choice for general-purpose sanding, while silicon carbide excels in wet sanding applications. Diamond abrasive sandpaper offers exceptional durability and precision for demanding tasks.

By carefully considering these factors, you can make informed decisions when selecting the right grit sandpaper for your jewelry-making endeavors. Remember that the journey from rough metal to a dazzling piece of jewelry is a step-by-step process, and choosing the appropriate grit sandpaper at each stage is pivotal to achieving impeccable results.

Now that we’ve gained insights into choosing the right grit sandpaper, let’s delve into the best practices for using grit sandpaper effectively in jewelry making, ensuring that your creations exude unparalleled brilliance and craftsmanship.

Use 400-600 grit sandpaper for smoothing and shaping jewelry. It’s fine enough to avoid scratching the metal but coarse enough to remove imperfections.

Using Grit Sandpaper for Jewelry

Now that you’ve selected the appropriate grit sandpaper for your jewelry-making project, it’s time to delve into the art of using it effectively to refine and perfect your creations. Whether you’re shaping metal, refining surfaces, or achieving a flawless polish, employing the right techniques is crucial for harnessing the full potential of grit sandpaper.

Here are the best practices for using grit sandpaper in jewelry making:

- Secure the Workpiece: Before you begin sanding, ensure that the jewelry piece is firmly secured in place. This can be accomplished using a vise, clamps, or specialized jewelry-holding tools. A secure workpiece allows for precise and controlled sanding without the risk of slippage.

- Progressive Grits: When refining metal surfaces, start with a coarser grit to address any prominent imperfections or shaping requirements. Gradually progress to finer grits to achieve a smooth and polished finish. Each grit level builds upon the previous one, leading to a refined and flawless surface.

- Consistent Motion: Maintain a consistent sanding motion, moving the sandpaper back and forth in the same direction. This ensures uniform abrasion and prevents uneven surfaces. For curved or contoured jewelry pieces, consider using flexible sanding pads to conform to the shape of the metal.

- Use Lubrication: For certain metals, especially those prone to overheating during sanding, utilizing a lubricant such as water or mineral oil can prevent heat buildup and prolong the life of the sandpaper. Wet sanding also helps in capturing abrasive particles and minimizing airborne dust.

- Inspect and Repeat: After sanding with each grit, thoroughly inspect the surface for any remaining imperfections. If necessary, repeat the process with progressively finer grits until the desired level of refinement and smoothness is achieved.

- Final Polishing: Once the surface is refined to your satisfaction, transition to ultra-fine grits or specialized polishing compounds to achieve a mirror-like polish. This final step enhances the luster and brilliance of the jewelry piece, elevating it to a professional standard.

By adhering to these best practices, you can effectively utilize grit sandpaper to transform raw materials into stunning works of art. The meticulous application of sandpaper, combined with your creative vision, culminates in jewelry pieces that epitomize elegance and craftsmanship.

As we conclude our exploration of using grit sandpaper in jewelry making, it’s evident that this humble tool holds the power to elevate your creations to unparalleled heights. Let’s reflect on the invaluable role of grit sandpaper and its transformative impact on the art of jewelry making.

Conclusion

Embarking on the journey of jewelry making unveils a world where creativity intertwines with precision, and every stroke of grit sandpaper contributes to the realization of exquisite masterpieces. Throughout this enlightening guide, we’ve delved into the realm of grit sandpaper for jewelry making, unraveling its significance and the art of harnessing its potential to elevate your craft.

Understanding the nuances of grit sandpaper, from its composition to the varying grit levels, is foundational to achieving exceptional results in jewelry making. By discerning the specific requirements of each jewelry-making task, you can adeptly choose the right grit sandpaper, ensuring that every stroke contributes to the refinement and perfection of your creations.

From addressing surface imperfections to shaping metal and achieving a lustrous polish, the judicious use of grit sandpaper is an art in itself. Employing the best practices, including securing the workpiece, progressing through progressive grits, and employing consistent motion, empowers you to wield grit sandpaper as a transformative tool in your creative arsenal.

As you meticulously refine each jewelry piece, the transformative impact of grit sandpaper becomes evident, unveiling the brilliance and allure that define professional craftsmanship. Every stroke of sandpaper is a testament to your dedication to excellence, culminating in jewelry pieces that exude unparalleled elegance and artistry.

So, as you continue on your journey as a jewelry artisan, remember the profound impact of grit sandpaper and the artistry it embodies. Let its gentle abrasion and meticulous refinement be a reflection of your unwavering commitment to creating timeless pieces that resonate with beauty and sophistication.

May your creative endeavors be guided by the wisdom of selecting the right grit, the finesse of using it effectively, and the transformative power it holds. Embrace the art of jewelry making, knowing that with each stroke of grit sandpaper, you are sculpting not just metal, but a legacy of craftsmanship and creativity.

Now, armed with the knowledge and insight gained from this guide, venture forth and let your creations shimmer with the brilliance that only the art of jewelry making, guided by the wisdom of grit sandpaper, can bestow.

Frequently Asked Questions about What Grit Sandpaper For Jewelry

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Jewelry”