Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper To Polish Metal

Tools & Equipment

What Grit Sandpaper To Polish Metal

Modified: January 3, 2024

Discover the best grit sandpaper for polishing metal with our comprehensive guide. Get the right tools and equipment for a flawless finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

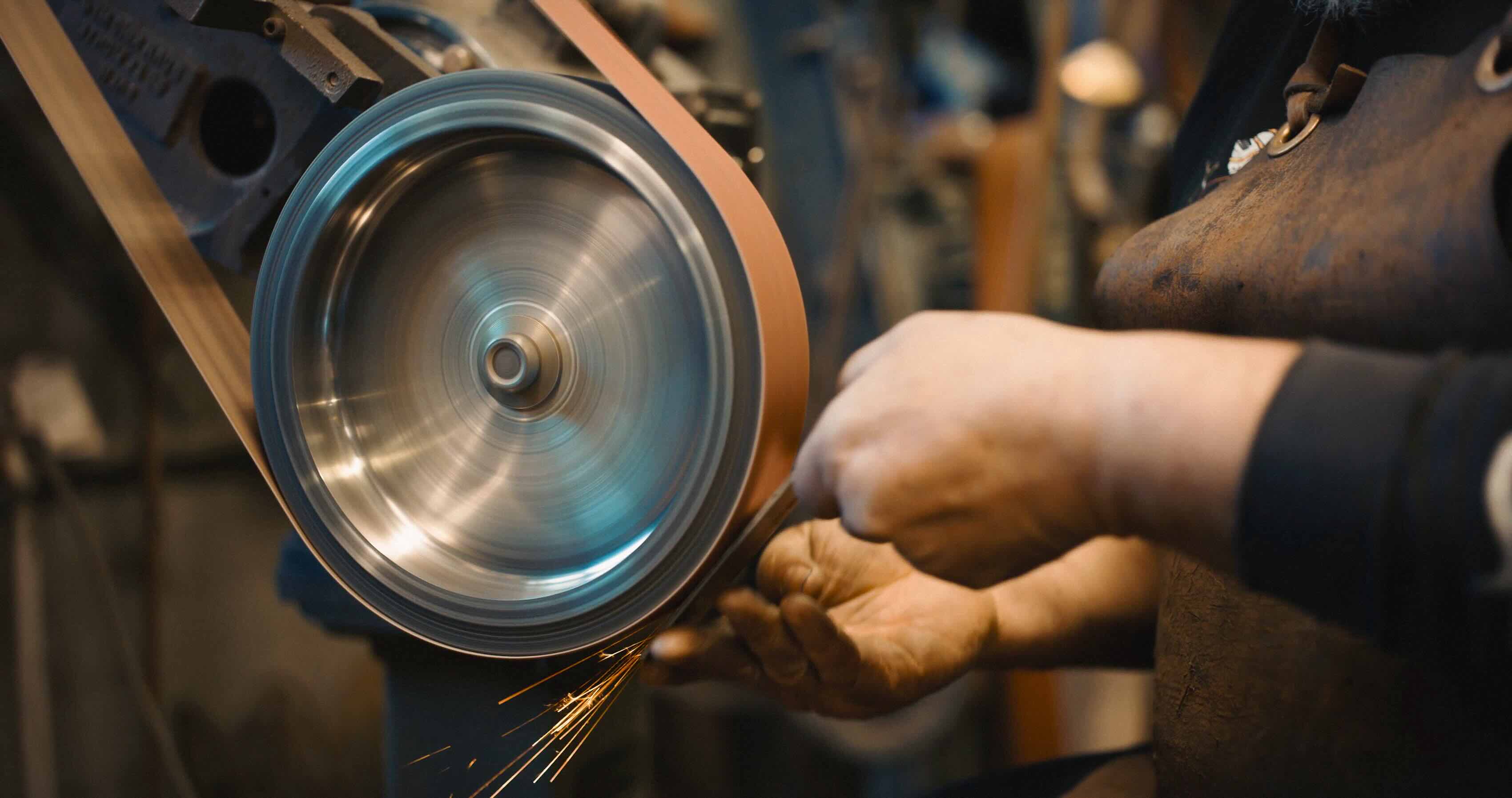

When it comes to metal polishing, the right grit sandpaper can make all the difference. Whether you're a seasoned metalworker or a DIY enthusiast, achieving a flawless, gleaming finish on metal surfaces requires the proper tools and techniques. Understanding the nuances of grit and selecting the appropriate sandpaper for your project is essential for achieving professional-looking results.

In this comprehensive guide, we'll delve into the intricacies of grit sandpaper and its pivotal role in the metal polishing process. By the end of this article, you'll have a firm grasp of how to choose the right grit sandpaper for metal polishing, empowering you to elevate your metalworking endeavors to new heights of excellence. Let's embark on this enlightening journey into the world of metal polishing and discover the transformative power of grit sandpaper.

Key Takeaways:

- Choose the right grit sandpaper based on the metal’s condition and type for a flawless finish. Start with coarser grits for imperfections and progress to finer grits for a mirror-like shine.

- Understanding grit sandpaper is crucial for achieving professional metal polishing results. Employ a progressive grit sequence and adapt to the metal type for optimal polishing.

Read more: What Grit Sandpaper To Polish Headlights

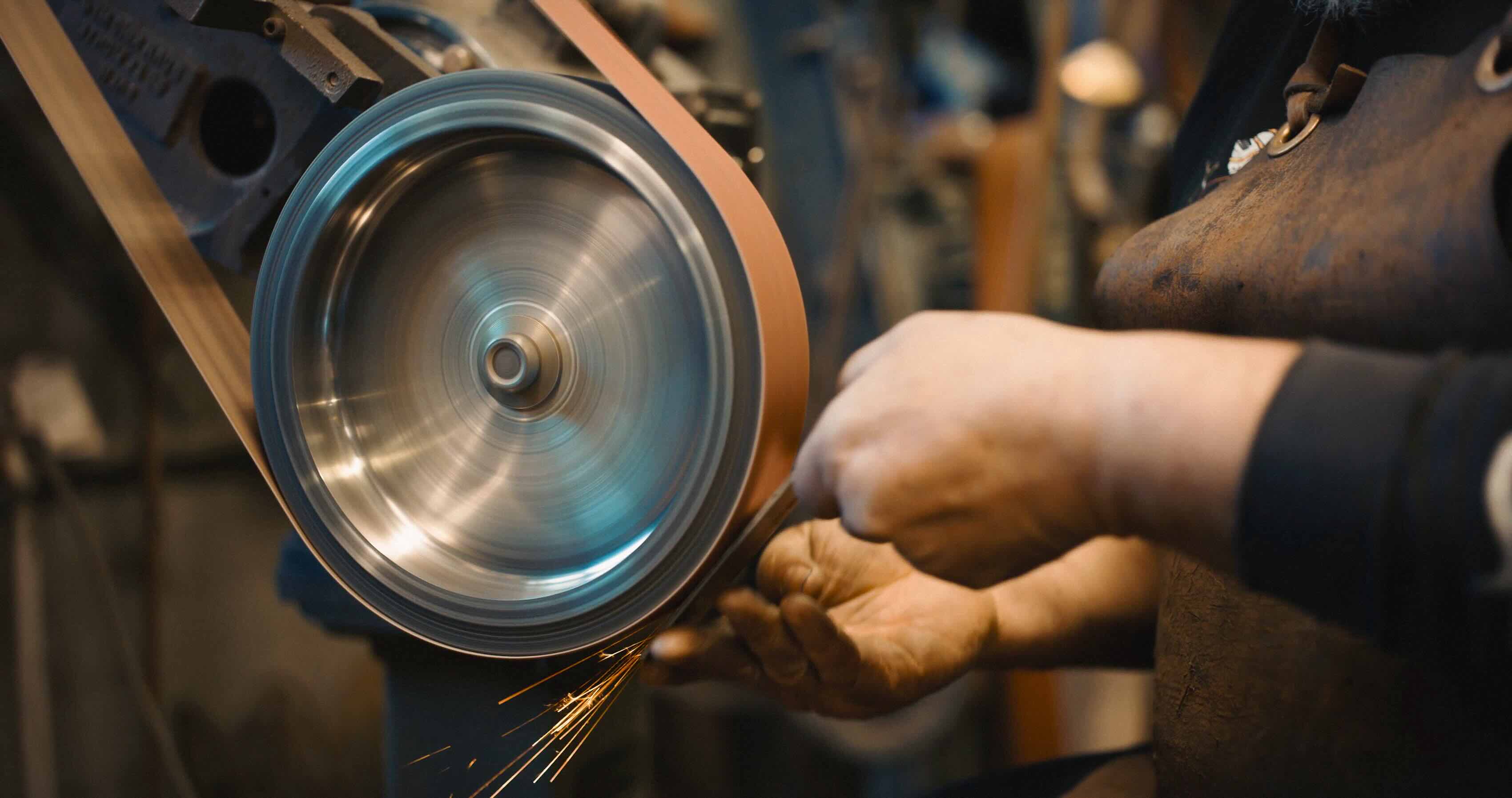

Understanding Grit

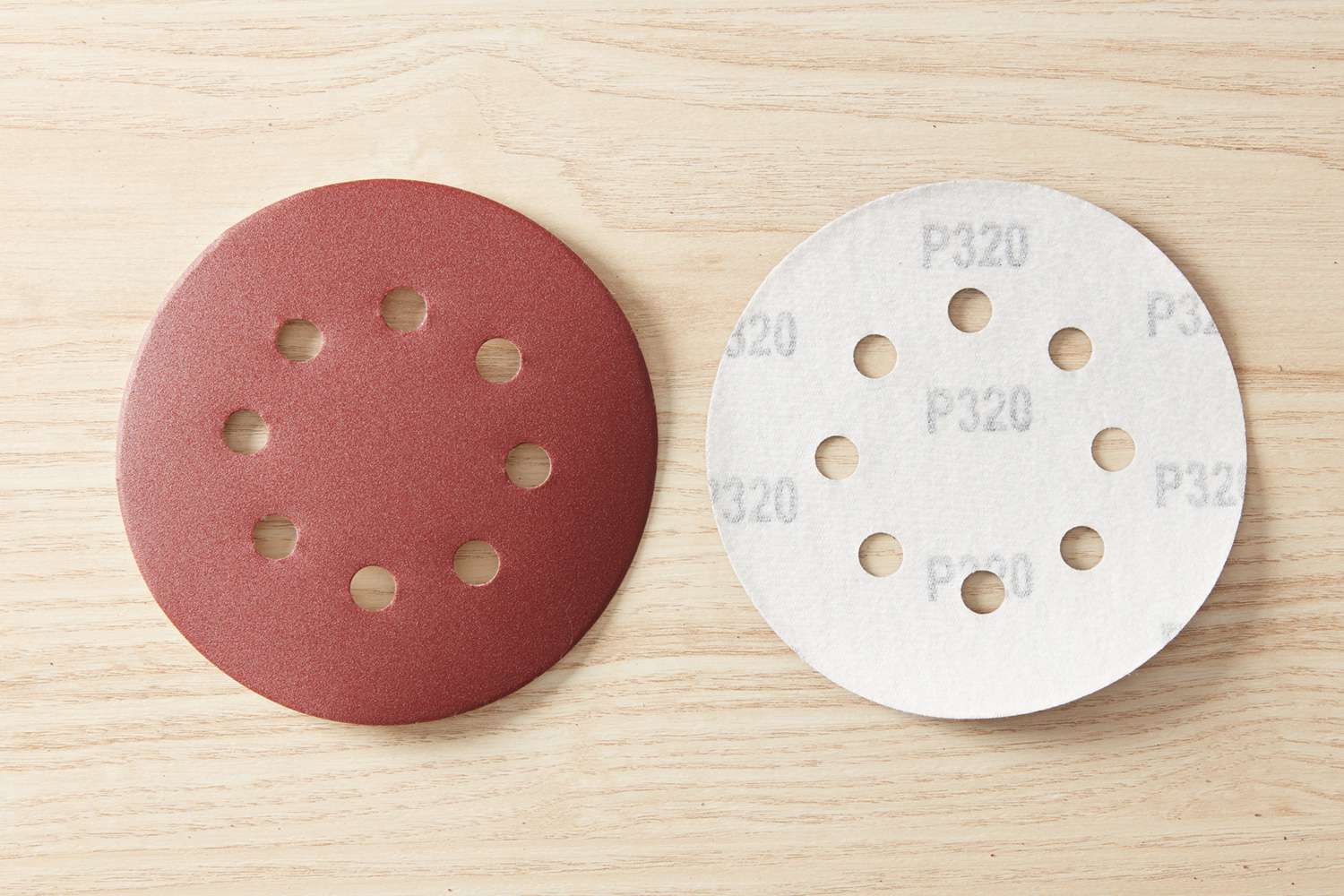

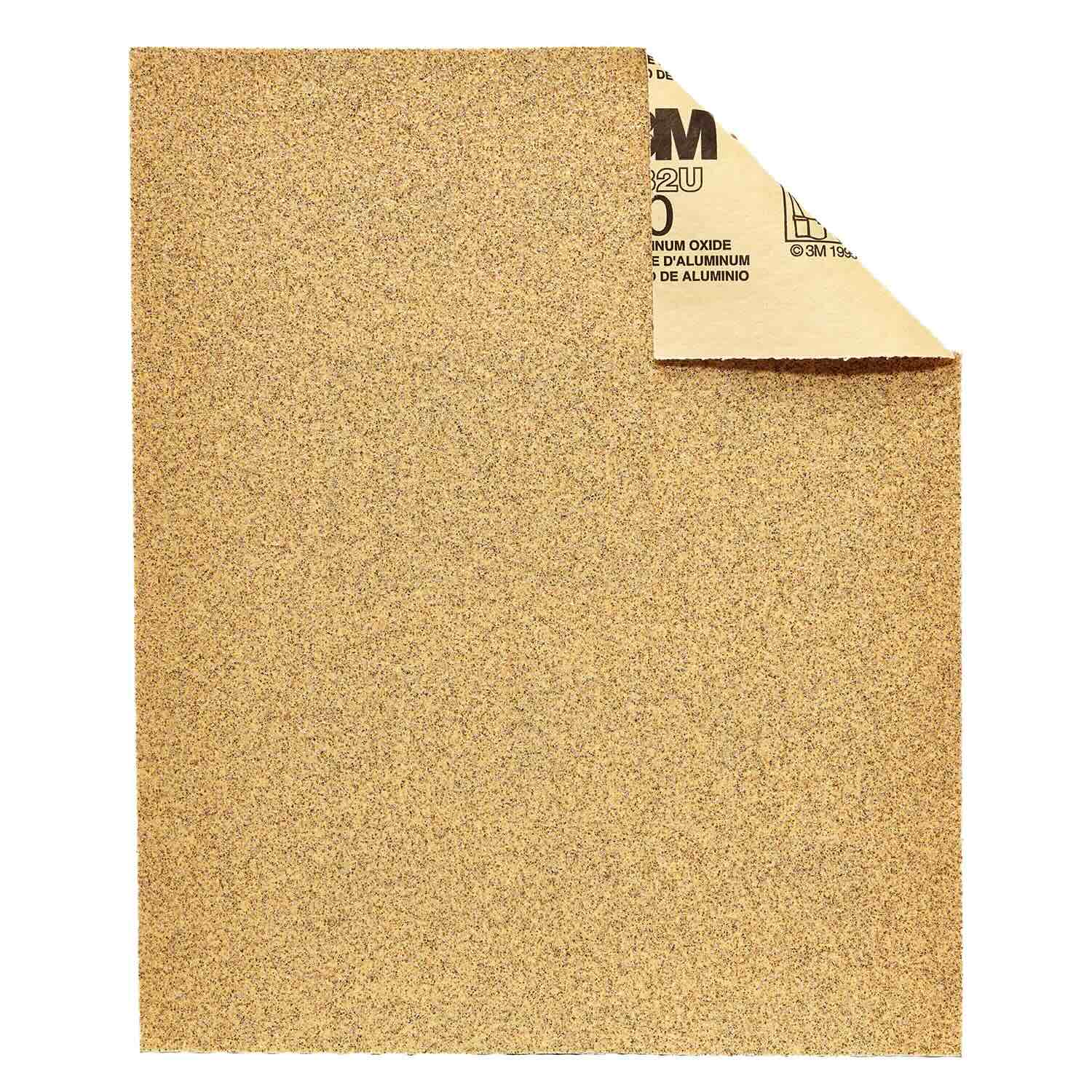

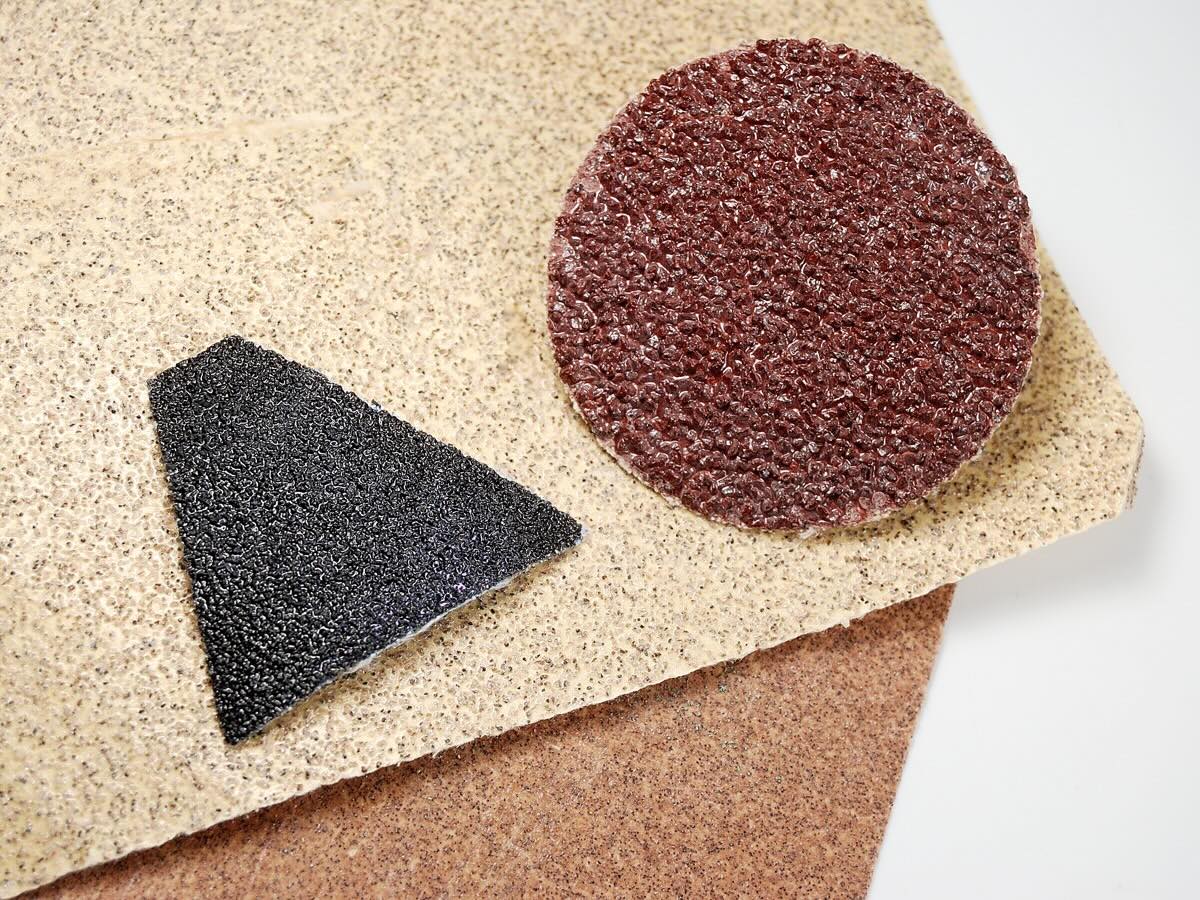

Grit, in the context of sandpaper, refers to the coarseness or fineness of the abrasive particles embedded in the paper. It is a crucial factor that determines the sandpaper’s effectiveness in removing imperfections, smoothing surfaces, and achieving the desired level of polish on metal.

Typically, grit is measured by the number of abrasive particles per square inch of sandpaper. The higher the grit number, the finer the particles and the smoother the sandpaper. Conversely, lower grit numbers indicate coarser particles, suitable for heavy material removal and surface leveling.

Common grit ranges for sandpaper include:

- Coarse Grit (40-60): Ideal for rapid material removal, shaping, and smoothing rough surfaces. This grit range is suitable for initial metal preparation before finer polishing.

- Medium Grit (80-120): Effective for removing scratches, refining surfaces, and preparing the metal for finer polishing stages.

- Fine Grit (150-240): Used for smoothing and pre-polishing metal surfaces, eliminating minor imperfections, and preparing the metal for a mirror-like finish.

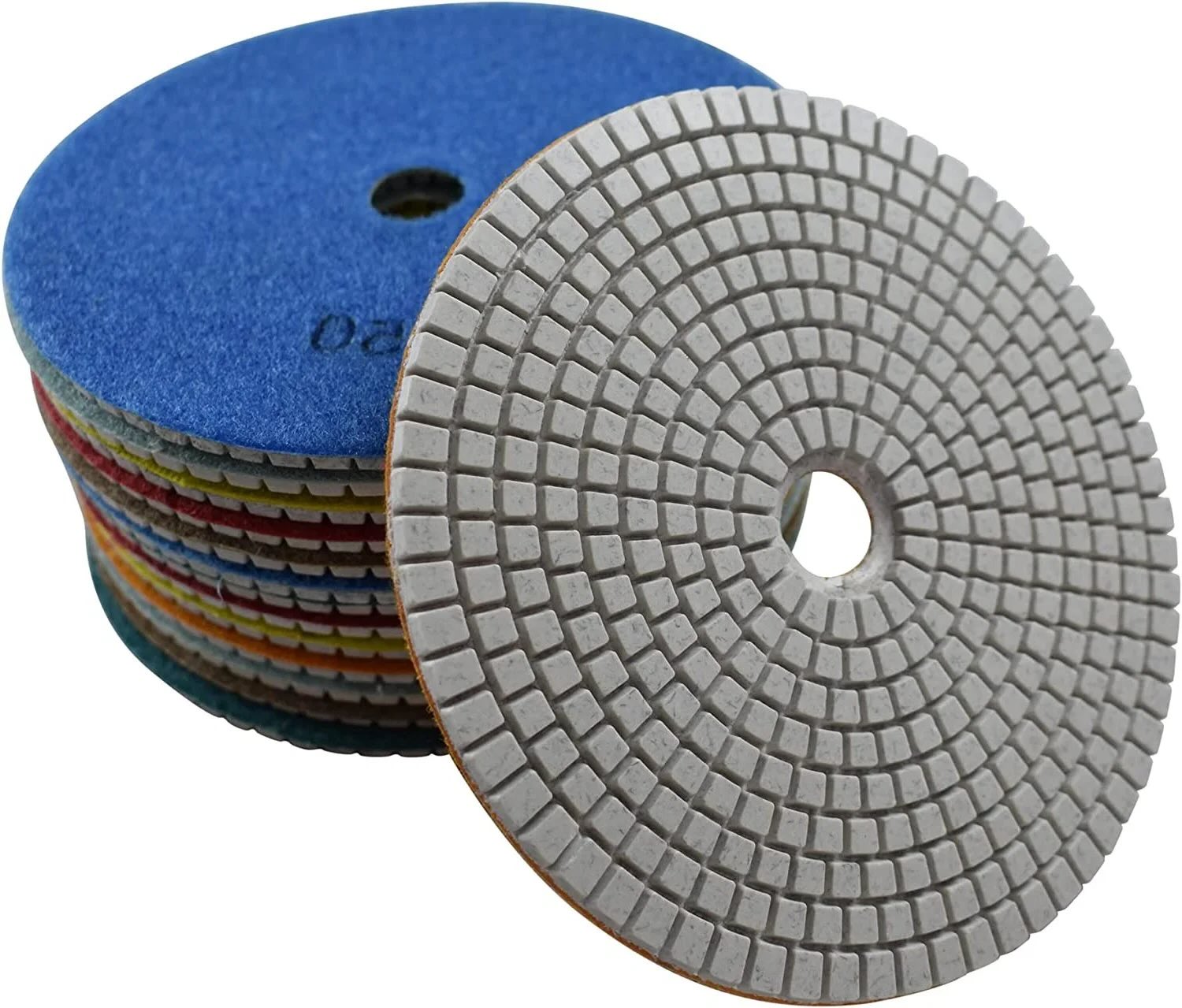

- Very Fine Grit (280-400+): Designed for achieving a high-gloss finish, removing fine scratches, and refining metal to a pristine, lustrous state.

Understanding the characteristics of different grit ranges is essential for selecting the appropriate sandpaper to address specific imperfections and achieve the desired level of smoothness and shine on metal surfaces. By mastering the concept of grit, you can navigate the vast array of sandpaper options with confidence, knowing precisely which grits will yield the best results for your metal polishing project.

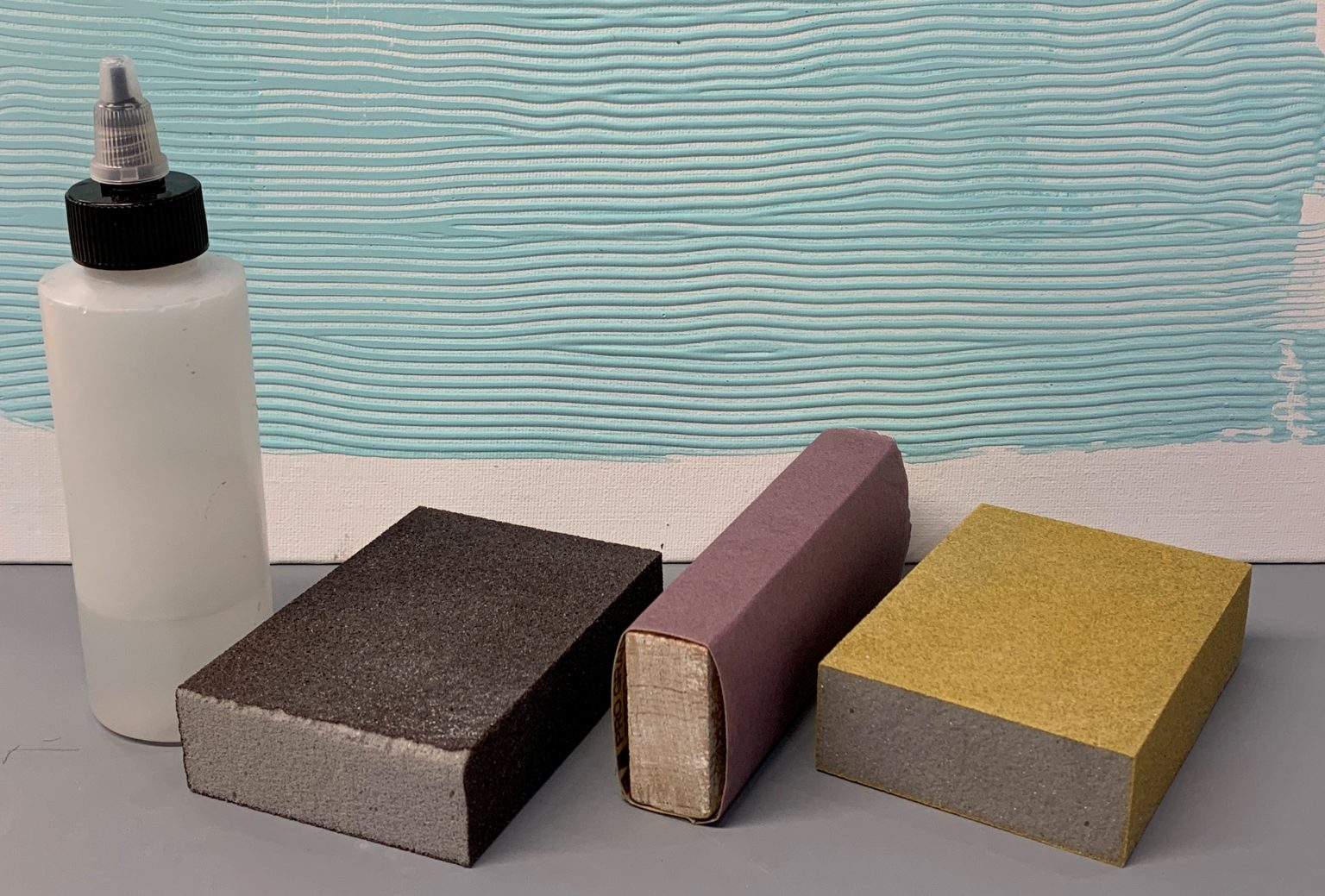

Choosing the Right Grit Sandpaper for Metal Polishing

When embarking on a metal polishing endeavor, selecting the right grit sandpaper is pivotal to the success of your project. The key lies in understanding the specific requirements of the metal surface and identifying the appropriate grits to address imperfections, refine the finish, and achieve the desired level of luster. Let’s explore the essential considerations for choosing the right grit sandpaper for metal polishing:

Assessing the Metal Surface

Before selecting a grit sandpaper, it’s crucial to assess the condition of the metal surface. If the metal exhibits deep scratches, prominent imperfections, or uneven surfaces, a coarser grit (e.g., 40-80) is recommended to efficiently level the surface and remove substantial material. Conversely, for surfaces with minor imperfections or those that have undergone initial preparation, transitioning to medium or fine grits (e.g., 120-240) is the next step in the polishing process.

Progressive Grit Sequencing

For optimal results, employing a progressive grit sequence is paramount. Initiating the polishing process with a coarse grit to address major imperfections and gradually transitioning to finer grits allows for systematic refinement of the metal surface. This methodical approach ensures that each grit level builds upon the previous one, culminating in a flawlessly polished finish.

Read more: What Grit Sandpaper To Polish Aluminum

Consideration of Polishing Stages

Understanding the distinct stages of metal polishing is instrumental in selecting the appropriate grit sandpaper. Coarse grits are employed in the initial stages to rectify significant flaws and prepare the surface for subsequent polishing. As the polishing process advances, finer grits are utilized to progressively refine the surface, eliminate minor blemishes, and impart a dazzling sheen to the metal.

Adaptation to Metal Type

Different metals possess unique characteristics that influence the selection of grit sandpaper. For softer metals such as aluminum, utilizing finer grits earlier in the polishing process is advantageous to prevent deep scratches and preserve the metal’s integrity. In contrast, harder metals like stainless steel may necessitate the initial use of coarser grits to effectively address surface irregularities before transitioning to finer grits for a pristine finish.

Finishing Touches

As the metal nears its desired level of polish, employing very fine grits (e.g., 280-400+) is essential for achieving a mirror-like, immaculate finish. These ultra-fine grits meticulously refine the surface, eradicate any remaining imperfections, and elevate the metal to a state of unparalleled brilliance.

By considering the condition of the metal surface, implementing a progressive grit sequence, adapting to the metal type, and recognizing the distinct polishing stages, you can confidently select the right grit sandpaper for metal polishing. This strategic approach ensures that each abrasive action brings the metal closer to its ultimate radiance, culminating in a flawlessly polished masterpiece.

Conclusion

In the realm of metal polishing, the significance of choosing the right grit sandpaper cannot be overstated. The art of transforming metal surfaces from raw to resplendent hinges upon the judicious selection of grits, each contributing to the gradual refinement and ultimate magnificence of the polished piece. As we conclude our exploration of grit sandpaper and its role in metal polishing, it is evident that a nuanced understanding of grit is the cornerstone of achieving impeccable results.

By comprehending the intricacies of grit and its correlation with the metal surface, one gains the insight to orchestrate a symphony of abrasion and refinement, culminating in a harmonious union of form and finish. The journey from coarse to fine grits mirrors the evolution of the metal surface, as it transcends its initial state to embody a captivating radiance. Each grit represents a stage in the metamorphosis, an incremental step towards perfection.

Choosing the right grit sandpaper for metal polishing is an art form in itself, demanding a discerning eye and a deft touch. It is a testament to the meticulous craftsmanship and unwavering dedication of metalworkers and artisans who strive to unveil the inherent splendor within each metal canvas.

As you embark on your next metal polishing endeavor, armed with the knowledge of grit and its transformative prowess, may you navigate the spectrum of sandpaper with confidence and clarity. Let each stroke of the abrasive particles be imbued with purpose, guiding the metal on its odyssey from roughness to refinement, from dullness to brilliance.

In the realm of metal polishing, the right grit sandpaper is not merely a tool; it is a conduit for metamorphosis, a catalyst for metamorphosis, a catalyst for unveiling the latent beauty that resides within the metal. Embrace the journey, honor the process, and revel in the revelation of metal transformed, polished to perfection.

Frequently Asked Questions about What Grit Sandpaper To Polish Metal

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper To Polish Metal”