Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Polyurethane

Tools & Equipment

What Grit Sandpaper For Polyurethane

Modified: January 19, 2024

Discover the best grit sandpaper for polyurethane finishes and ensure a flawless result. Find the essential tools and equipment you need for a professional finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Are you looking to give your wooden furniture or floors a fresh new look? Perhaps you’ve heard about using grit sandpaper with polyurethane but aren’t quite sure where to begin. Well, you’ve come to the right place! In this comprehensive guide, we’ll delve into the world of grit sandpaper and polyurethane, exploring what they are, how they work, and how they can be used together to achieve stunning results.

Whether you’re a seasoned DIY enthusiast or a newcomer to the world of woodworking, understanding the role of grit sandpaper and polyurethane in refinishing projects is crucial. By the end of this article, you’ll have a clear grasp of these essential tools and be ready to tackle your next renovation or restoration project with confidence.

So, grab your safety goggles and roll up your sleeves as we embark on a journey through the fascinating realm of grit sandpaper and polyurethane!

Key Takeaways:

- Sandpaper grit determines smoothness. Coarse grit (40-60) for rough surfaces, fine grit (150-180) for smooth finish. Polyurethane protects and enhances wood, creating a glossy, satin, or matte finish.

- Sand wood with grit sandpaper before applying polyurethane. Start with coarse grit, progress to fine grit for a flawless finish. Sand between polyurethane coats for adhesion and a lustrous surface.

Read more: What Grit Sandpaper To Remove Polyurethane

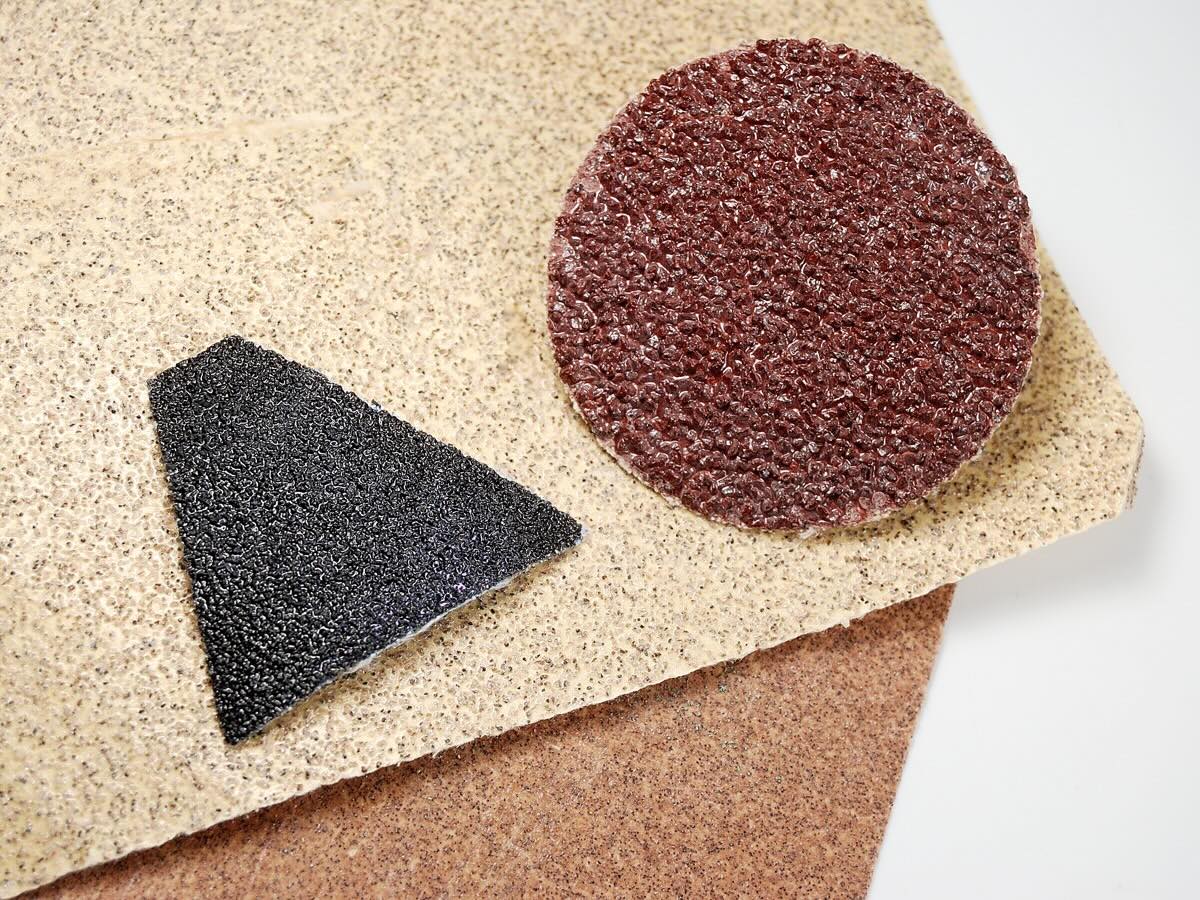

Understanding Grit Sandpaper

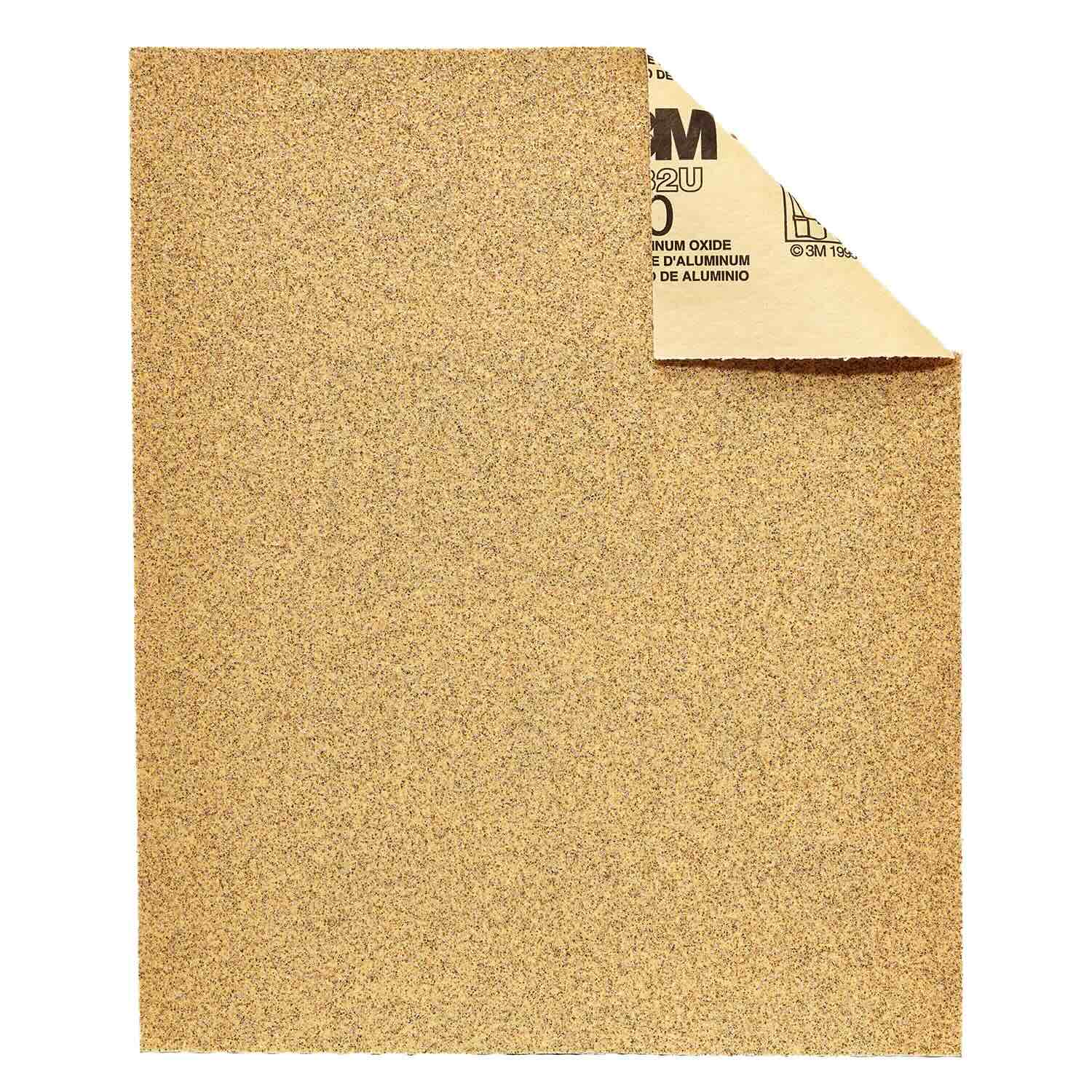

Grit sandpaper is a fundamental tool in the world of woodworking and refinishing. It consists of a backing material coated with abrasive particles that are graded according to their coarseness. These abrasive particles, often made of aluminum oxide or silicon carbide, are what make sandpaper effective in smoothing and shaping various surfaces.

The “grit” in sandpaper refers to the number of abrasive particles per square inch. The higher the grit number, the finer the sandpaper and the smoother the finish it produces. Conversely, lower grit numbers indicate coarser sandpaper, which is ideal for removing material quickly or smoothing rough surfaces.

Common grit ranges include:

- Coarse Grits (40-60): Ideal for heavy material removal, such as smoothing rough wood or removing old finishes.

- Medium Grits (80-120): Suitable for general sanding and preparing surfaces for finishing.

- Fine Grits (150-180): Used for light sanding between coats of finish or for achieving a smooth surface before applying a final finish.

- Very Fine Grits (220-240+): Perfect for achieving a glass-like smoothness on surfaces, particularly when working with delicate materials.

Understanding the right grit to use for each stage of a project is crucial for achieving the desired results. It’s important to start with a coarser grit to remove imperfections or old finishes and gradually progress to finer grits for a smooth, polished surface.

Now that we have a better understanding of grit sandpaper, let’s explore the world of polyurethane and its role in woodworking and refinishing projects.

What is Polyurethane?

Polyurethane is a versatile and durable finish that is commonly used to protect and enhance wooden surfaces. Available in various forms, including oil-based and water-based, polyurethane offers excellent resistance to scratches, heat, and moisture, making it an ideal choice for sealing and finishing furniture, floors, and other wooden items.

Oil-based polyurethane, known for its rich amber hue and long-lasting durability, penetrates deep into the wood, providing a warm and traditional finish. On the other hand, water-based polyurethane, with its clear and quick-drying properties, offers a more neutral appearance and emits fewer fumes during application.

One of the key benefits of polyurethane is its ability to add a protective layer to wood while enhancing its natural beauty. Whether you’re looking to achieve a glossy, satin, or matte finish, polyurethane can be tailored to meet your specific aesthetic preferences.

When applying polyurethane, it’s essential to prepare the surface properly and apply thin, even coats to achieve a smooth and professional finish. Sanding between coats is often necessary to promote adhesion and create a flawless final result.

Now that we’ve explored the characteristics and applications of polyurethane, let’s delve into the synergy between grit sandpaper and polyurethane and how they work together to elevate woodworking and refinishing projects.

Use 220-320 grit sandpaper before applying polyurethane to smooth the surface and remove any imperfections. This will help the polyurethane adhere better and result in a smoother finish.

Using Grit Sandpaper with Polyurethane

When it comes to applying polyurethane to wooden surfaces, the role of grit sandpaper is paramount in achieving a flawless and professional finish. Whether you’re refinishing a tabletop, restoring hardwood floors, or adding a protective coat to cabinets, the synergy between grit sandpaper and polyurethane is essential for a successful outcome.

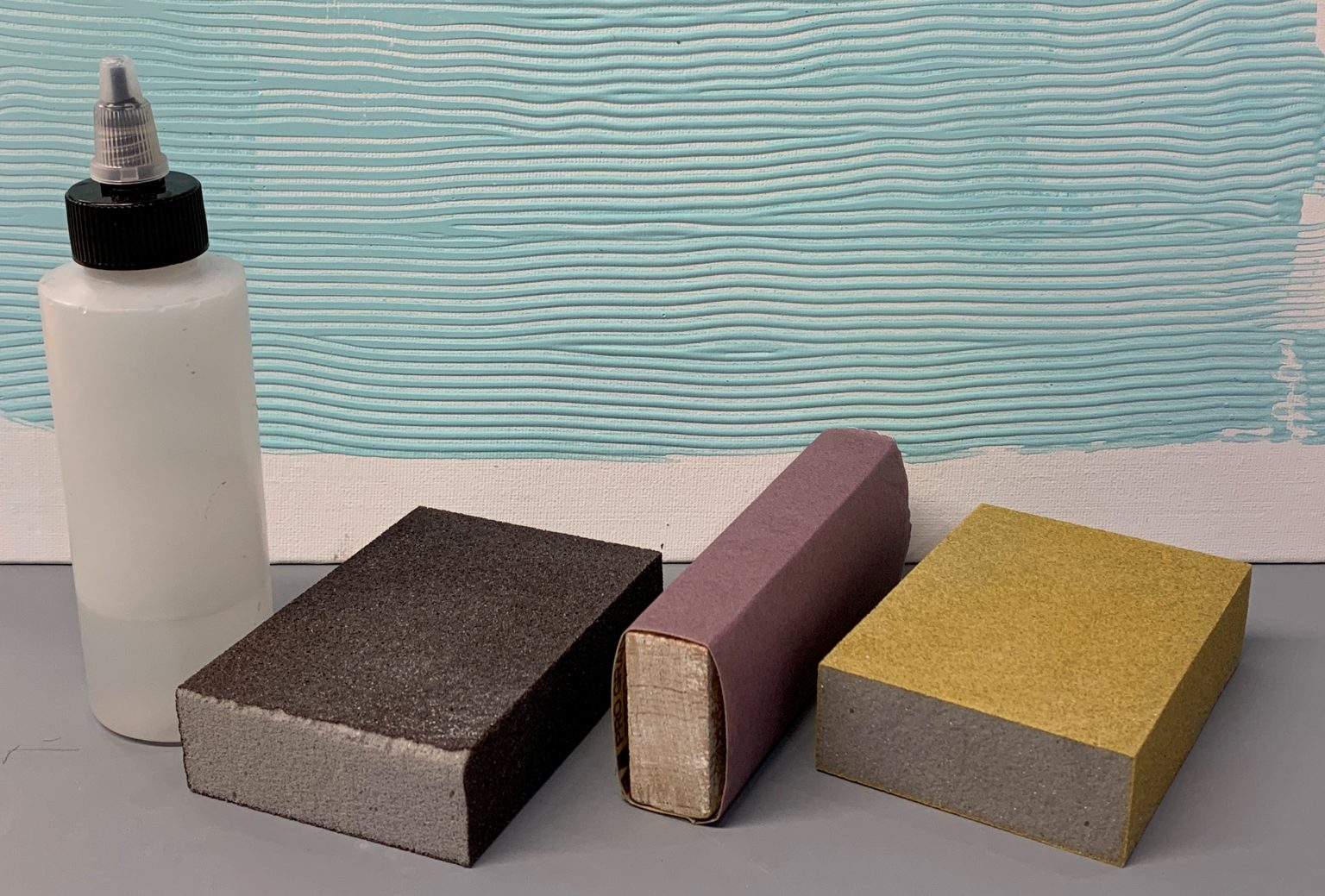

Before applying polyurethane, it’s crucial to prepare the wood surface properly. This often involves sanding the wood to remove any imperfections, old finishes, or blemishes. The choice of sandpaper grit depends on the condition of the wood and the desired level of smoothness. Coarser grits, such as 80 or 100, are typically used for initial sanding to remove old finishes and level the surface. As the process progresses, finer grits, such as 150 or 180, are employed to achieve a smooth and uniform substrate for the polyurethane application.

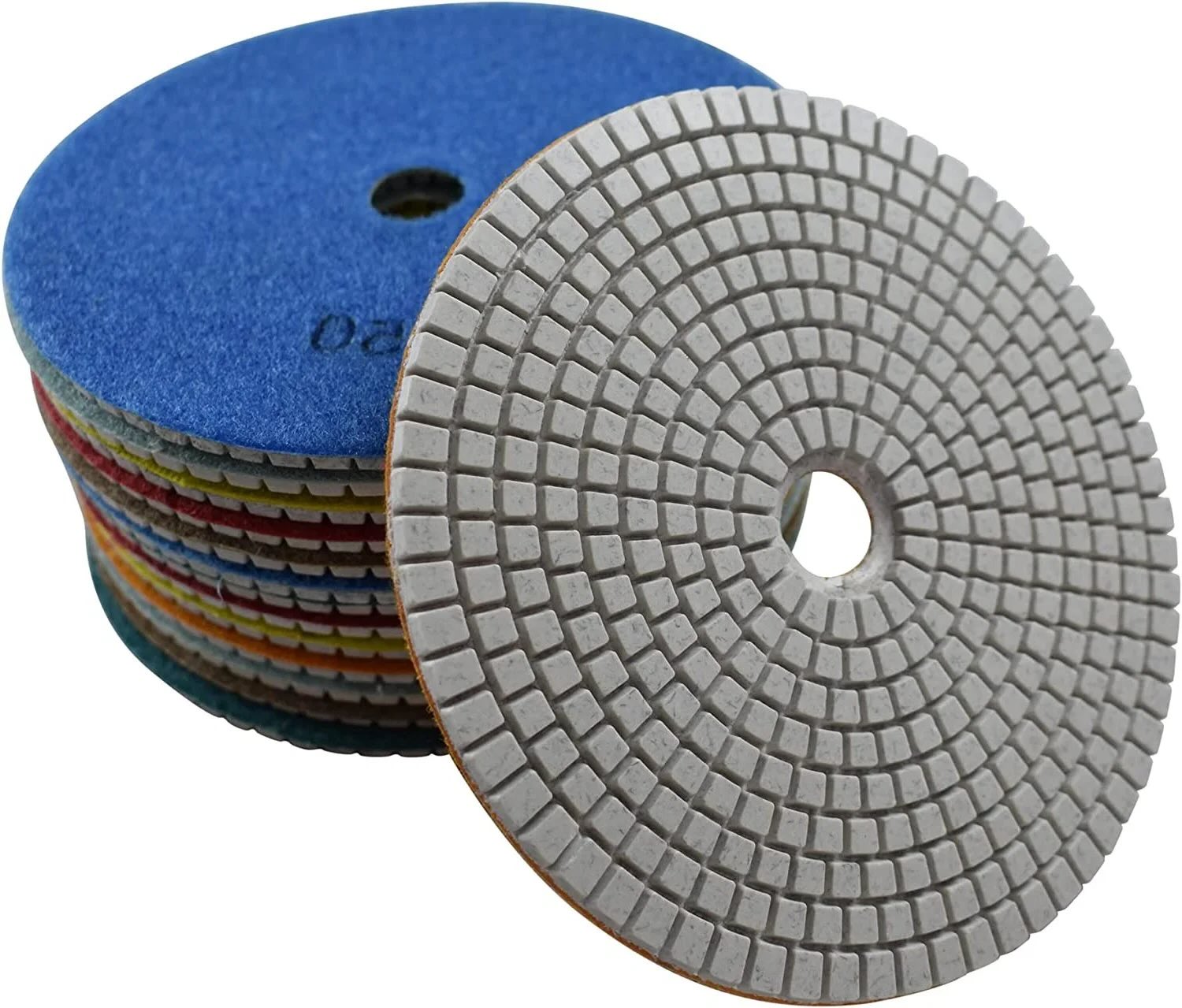

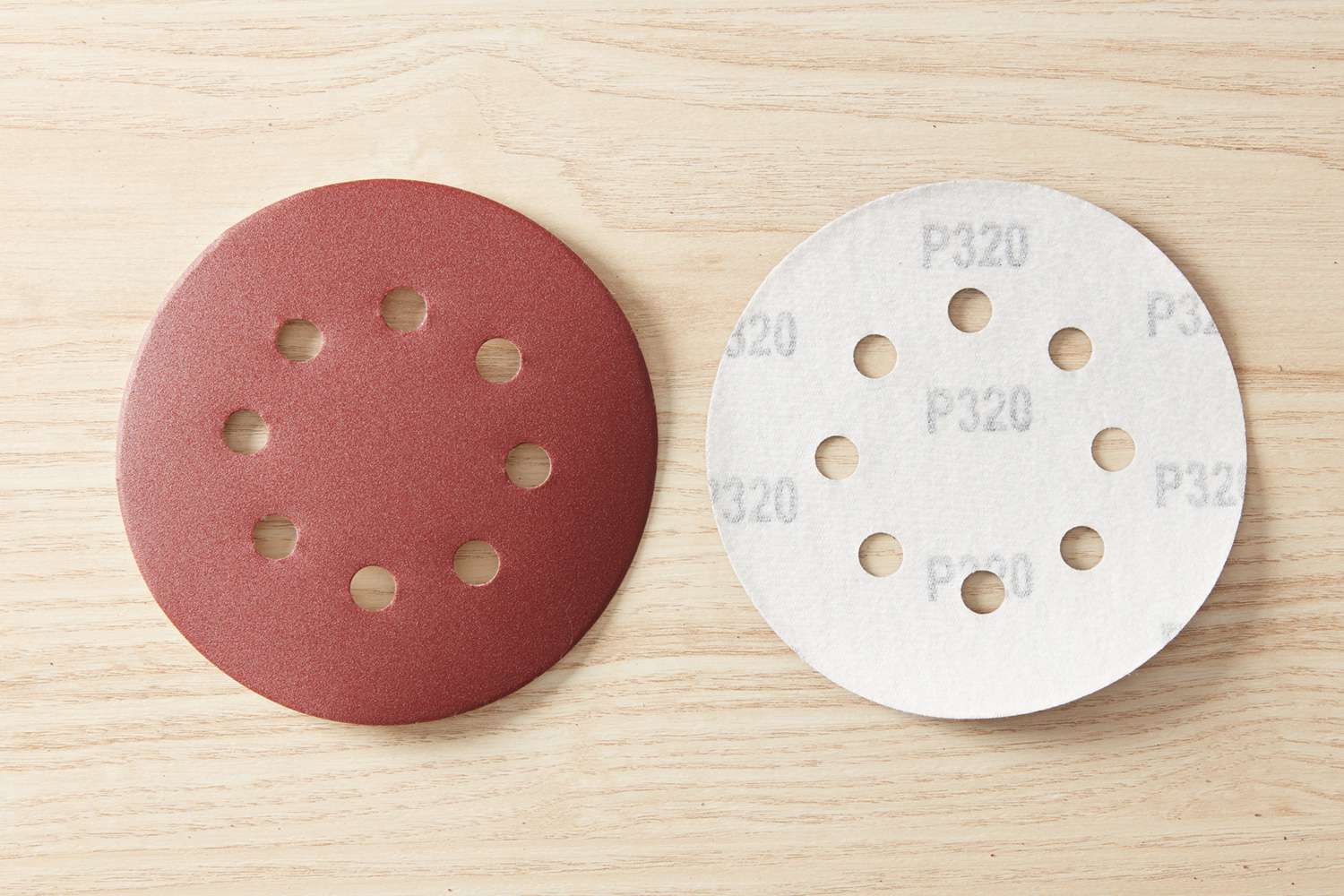

Once the wood surface has been sanded to the desired smoothness, it’s time to apply the polyurethane. Whether using an oil-based or water-based variant, the application process involves using a high-quality brush, foam applicator, or sprayer to apply thin, even coats of polyurethane. Sanding between coats with fine-grit sandpaper, such as 220 or 240, is essential to promote adhesion and eliminate any imperfections or dust particles that may have settled on the surface during application.

After the final coat of polyurethane has been applied and allowed to cure, a light sanding with ultra-fine grit sandpaper, such as 320 or 400, can be performed to achieve an exceptionally smooth and lustrous finish. This step helps to remove any minor imperfections and ensure a glass-like surface that accentuates the natural beauty of the wood.

By using the appropriate grit sandpaper in conjunction with polyurethane, woodworkers and DIY enthusiasts can achieve stunning results, from a silky-smooth tabletop to a gleaming hardwood floor, all while ensuring the longevity and resilience of the finished surface.

With a solid understanding of how grit sandpaper and polyurethane complement each other, you’re now equipped to embark on your next woodworking or refinishing project with confidence and precision.

Conclusion

In the realm of woodworking and refinishing, the partnership between grit sandpaper and polyurethane is a crucial element in achieving exceptional results. Understanding the nuances of grit sandpaper, from coarse to ultra-fine, empowers craftsmen and DIY enthusiasts to prepare wooden surfaces with precision and finesse.

Polyurethane, with its protective and enhancing properties, serves as the final touch that seals and beautifies wood, ensuring its longevity and resilience. Whether it’s a glossy sheen on a tabletop, a satin finish on cabinets, or a durable coat on hardwood floors, polyurethane offers versatility and durability that elevate the natural beauty of wood.

The seamless integration of grit sandpaper and polyurethane involves a systematic approach, from initial sanding to the application of multiple coats of polyurethane, with intermittent sanding between layers. This meticulous process culminates in a smooth, flawless finish that accentuates the unique characteristics of the wood.

As you embark on your next woodworking or refinishing project, remember the symbiotic relationship between grit sandpaper and polyurethane. With the right tools, techniques, and a touch of creativity, you can transform ordinary wood surfaces into stunning focal points that exude elegance and craftsmanship.

So, whether you’re revitalizing an antique dresser, refinishing a cherished dining table, or adding a protective coat to a newly crafted piece, embrace the artistry of grit sandpaper and polyurethane. Let these essential tools guide you as you unleash your creativity and bring out the timeless allure of wood in all its glory.

Armed with the knowledge and insight gained from this guide, you’re ready to embark on your woodworking journey with confidence and finesse. The harmonious interplay of grit sandpaper and polyurethane awaits, promising to transform your woodworking endeavors into works of enduring beauty and craftsmanship.

Frequently Asked Questions about What Grit Sandpaper For Polyurethane

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Polyurethane”