Home> Electrical Wire Gauge

Electrical Wire Gauge: Your Ultimate Guide to Wiring Basics

Discover the importance of Electrical Wire Gauge. Our comprehensive guide simplifies wire gauge basics, ensuring safety and efficiency in your projects.

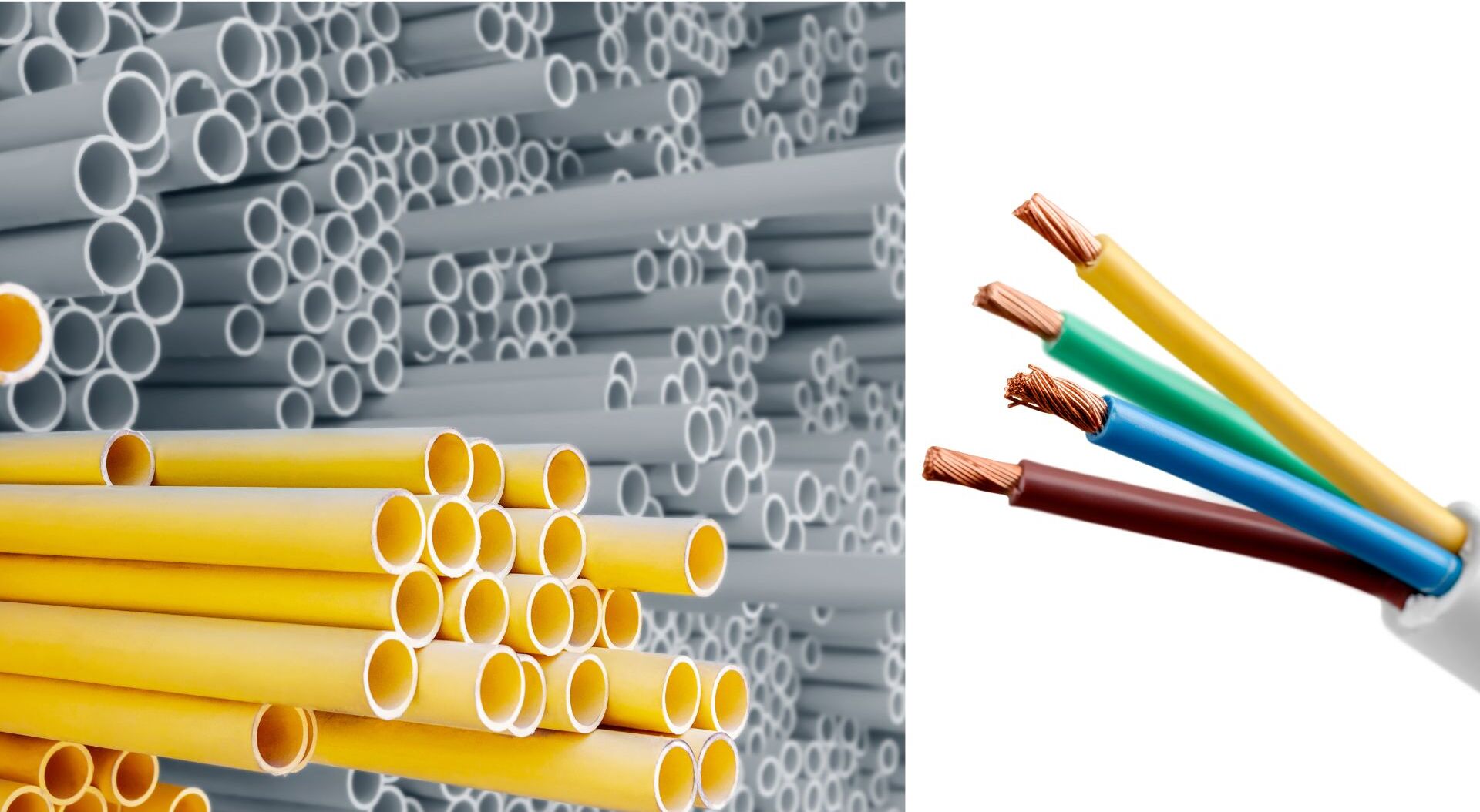

What Size Of Electrical Wire To Use For Your Electrical Installation

By: Samuel Turner • Articles

Our Helpful Guide To Understanding Electrical Cables And Wires

By: Sophia Turner • Articles