Articles

How Many Wires In 1/2 Inch Flex Conduit

Modified: October 22, 2024

Discover the answers to how many wires can fit in a 1/2 flex conduit with this informative article. Learn about wire capacity and installation tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to electrical installations, choosing the right conduit size is crucial for ensuring efficiency and safety. The conduit acts as a protective housing for electrical wires, keeping them safe from physical damage and providing a clean and organized solution for wire management.

One commonly used conduit size is 1/2 flex conduit, which is flexible and versatile, making it ideal for a variety of applications. But have you ever wondered how many wires can fit inside a 1/2 flex conduit? In this article, we will explore the capacity of 1/2 flex conduit and discuss the factors that influence the maximum number of wires it can accommodate.

Key Takeaways:

- Choosing the right conduit size, such as 1/2 flex conduit, is crucial for efficient and safe electrical installations. Understanding wire capacity and following installation guidelines are essential for optimal wire management and system functionality.

- Adhering to electrical codes and consulting qualified electricians ensures that 1/2 flex conduit installations meet safety standards and local regulations. Proper planning, measuring, securing, and using appropriate fittings and connectors are key to a secure and reliable installation.

Read more: How Many 12/2 Wires In 1/2 Inch Conduit

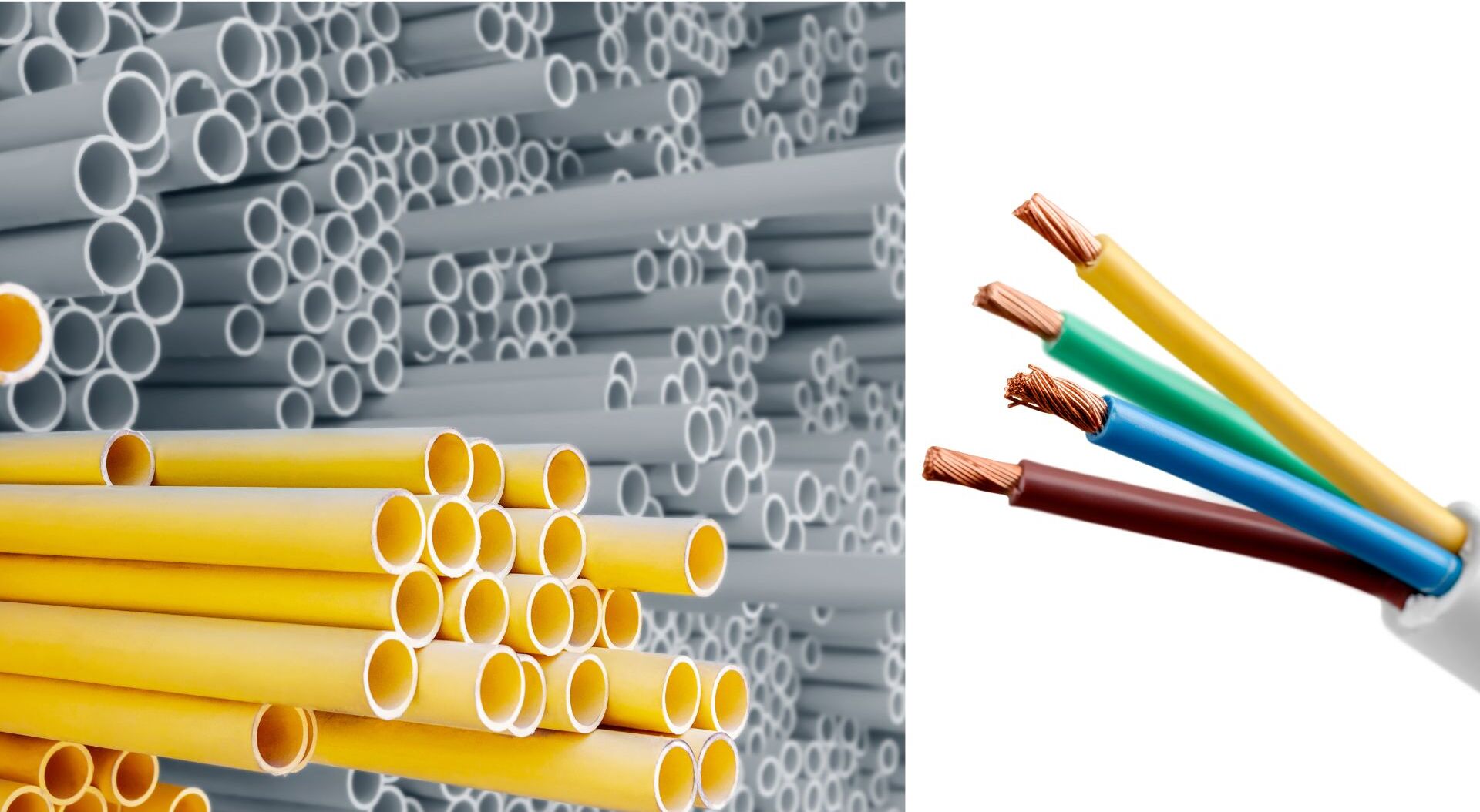

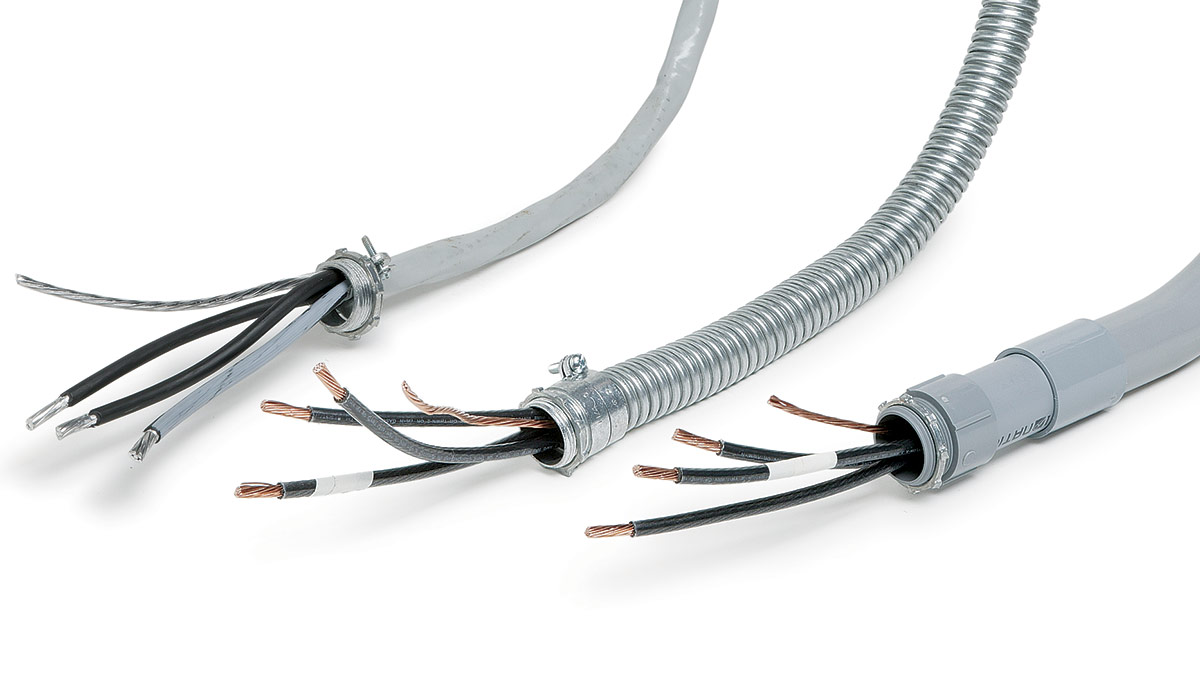

What is 1/2 Flex Conduit?

1/2 flex conduit, also known as flexible metal conduit or FMC, is a tubular conduit made of a flexible metal material, typically steel or aluminum. It is commonly used in electrical installations to protect and route electrical wires in both residential and commercial buildings.

Compared to rigid metal conduit (RMC) or electrical metallic tubing (EMT), 1/2 flex conduit offers greater flexibility and ease of installation. Its bendable nature allows electricians to navigate through tight spaces and around obstacles, making it an excellent choice for applications that require maneuverability.

1/2 flex conduit consists of a corrugated metal tube with a smooth inner lining. It is available in various lengths, and fittings such as connectors, couplings, and elbows can be used to join sections together. Additionally, 1/2 flex conduit is compatible with standard electrical boxes and fittings, making it interoperable with other electrical components.

It is important to note that 1/2 flex conduit should not be confused with liquid-tight flexible metal conduit (LFMC). LFMC has an additional outer covering that provides protection against liquids, whereas 1/2 flex conduit does not have this feature.

Overall, the flexibility, durability, and compatibility of 1/2 flex conduit make it a popular choice among electricians for various electrical installations.

Understanding Conduit Sizes

Conduit sizes are standardized measurements that indicate the diameter of the conduit opening and the maximum number of wires it can accommodate. The size of a conduit is denoted in inches and is typically measured based on the diameter of the conduit’s inner opening.

Conduit sizes range from 1/2 inch to 6 inches or larger, with each size having its own maximum wire capacity. It is important to choose the right conduit size for your specific electrical installation to ensure the wires have enough space for proper airflow and to prevent overheating.

When selecting a conduit size, consider not only the number of wires but also the type and gauge of the wires. Different wire types, such as THHN/THWN or NM cable, may have varying circumferences or insulation thickness, which can affect the number of wires that can fit within a given conduit size.

Additionally, the National Electrical Code (NEC) provides guidelines on the maximum fill capacity of conduits based on various factors, including the conduit material, wire type, and installation method. It is important to consult the NEC or a qualified electrician to ensure compliance with local electrical codes and safety standards.

By understanding conduit sizes and their corresponding wire capacities, you can select the appropriate size for your electrical installation, allowing for proper wire management and ensuring a safe and efficient electrical system.

Importance of Wire Capacity

The wire capacity of a conduit refers to the maximum number of wires that can safely fit inside it. It is essential to adhere to the recommended wire capacity for several reasons:

1. Prevention of Overheating: When wires are packed tightly in a conduit, there is limited airflow around them. This can restrict heat dissipation and result in the wires overheating. Overheating can lead to insulation damage, increased electrical resistance, and potential fire hazards.

2. Avoidance of Voltage Drop: When too many wires are squeezed into a conduit, it can cause increased electrical resistance. This resistance can result in voltage drop, meaning the voltage supplied to the end of the circuit decreases. Voltage drop can lead to inefficient electrical equipment performance and may cause lights to dim or appliances to malfunction.

3. Ease of Wire Installation: Conduit systems should be designed to facilitate the installation of wires. If the conduit is filled beyond its capacity, it becomes challenging to insert or remove the wires when necessary for maintenance or upgrades. Adhering to the recommended wire capacity ensures easy access to wires and simplifies future modifications.

4. Compliance with Electrical Codes: Electrical codes, such as the National Electrical Code (NEC), provide guidelines regarding the maximum fill capacity of conduits. Adhering to these codes is crucial to ensure electrical safety and compliance with local regulations. Failure to comply with these codes can result in fines, failed inspections, or invalidated insurance claims.

5. Enhanced Wire Protection: Proper wire capacity allows for adequate spacing between wires, providing protection against physical damage, abrasion, or accidental contact. This protects the wires from potential wear and tear, ensuring continued functionality and reducing the risk of electrical faults.

It is important to calculate and consider the wire capacity of a conduit before installation to avoid potential dangers and ensure the longevity of the electrical system. Consulting electrical codes and working with a qualified electrician can help determine the appropriate wire capacity for your specific application.

When determining how many wires can fit in a 1/2″ flex conduit, remember to follow the NEC guidelines for conduit fill. For 1/2″ flex conduit, the maximum fill is typically 4-6 conductors, depending on the wire gauge and type. Always consult the NEC and local codes for specific requirements.

Factors Affecting Wire Capacity in 1/2 Flex Conduit

The wire capacity of a 1/2 flex conduit is influenced by several factors that determine the maximum number of wires it can accommodate. These factors include:

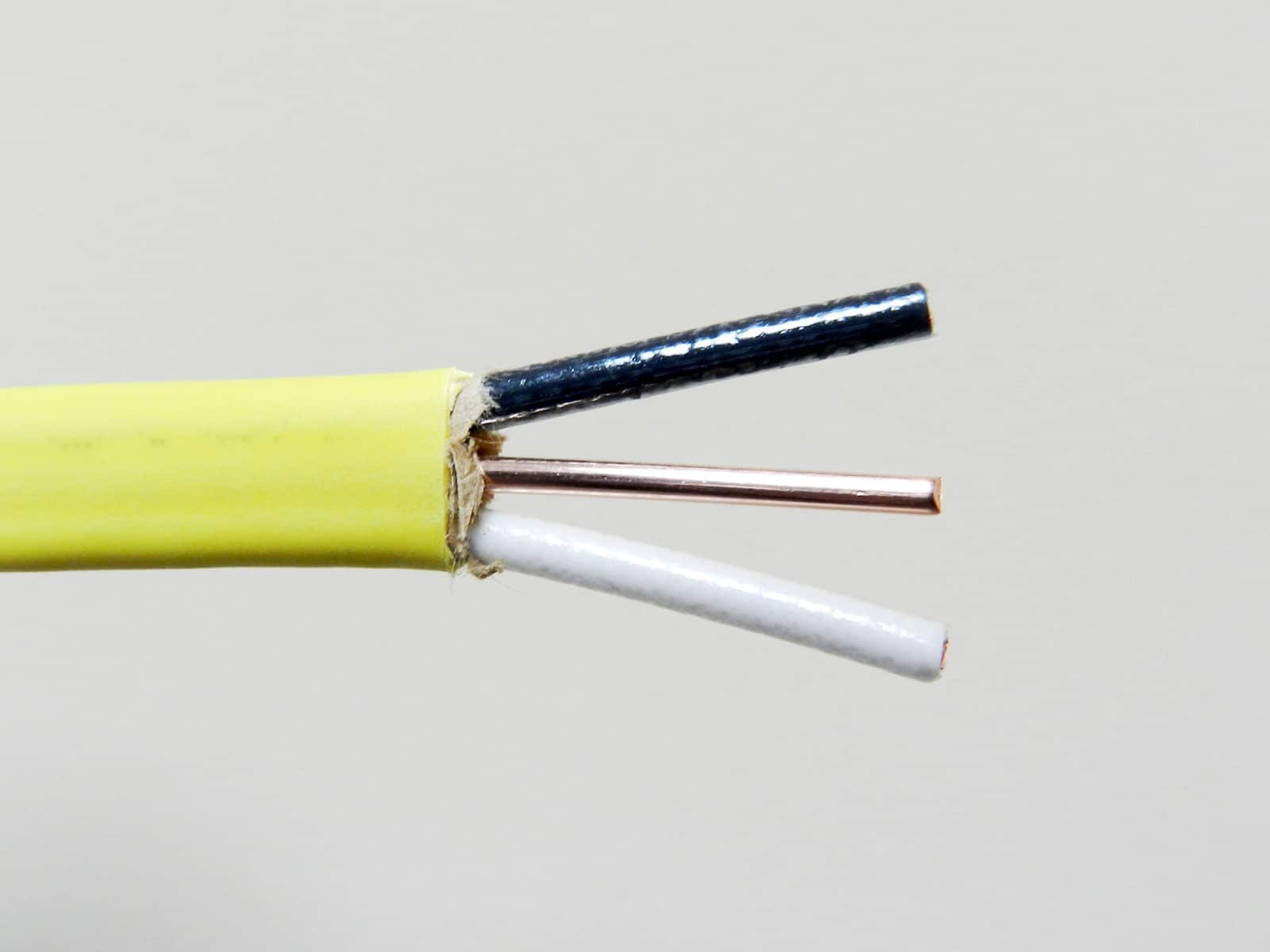

1. Wire Size and Gauge: The size of the wires being used plays a significant role in determining the wire capacity of a conduit. Larger wire gauges have a larger diameter, requiring more space within the conduit. Smaller wire sizes may allow for more wires to fit within the same conduit size.

2. Wire Type: Different wire types have varying thicknesses and insulation materials, which can affect the overall diameter of the wire. For example, THHN/THWN wires may have a thinner insulation layer compared to NM cables. Understanding the dimensions of the specific wire type being used is essential in determining the wire capacity.

3. Conduit Fill Ratio: Electrical codes, such as the NEC, provide guidelines regarding the maximum conduit fill ratio. This ratio specifies the maximum percentage of the conduit cross-sectional area that can be occupied by wires. Adhering to the recommended fill ratio ensures adequate spacing between wires, preventing overheating and reducing the risk of insulation damage.

4. Bend Radius: The flexibility of 1/2 flex conduit can be affected by bending the conduit at sharp angles or too tightly. When dealing with bends, it is important to consider the impact on the wire fill capacity. Bends that exceed the recommended radius can reduce the available space for wires and may require the use of fittings specifically designed for tight bends.

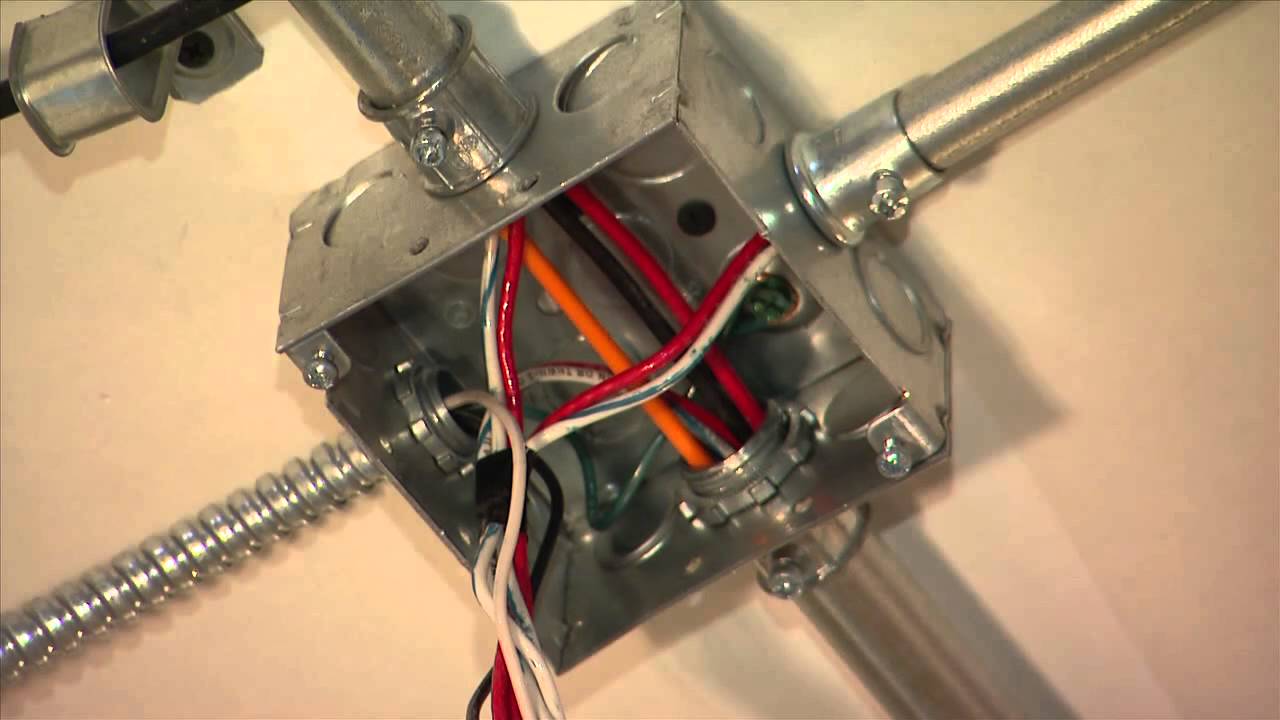

5. Number of Conductors: The number of conductors or circuits being run through the conduit also affects the wire capacity. Each circuit requires space within the conduit for both the hot and neutral wires, as well as any additional wires needed for grounding or other purposes.

When determining the wire capacity in a 1/2 flex conduit, it is important to consider these factors and ensure compliance with electrical codes and safety standards. Consulting with a qualified electrician or referencing the NEC can help in determining the maximum number of wires that can be safely installed within the conduit.

Read more: How Many Wires In A 3/4 Inch Conduit

Maximum Number of Wires Allowed in 1/2 Flex Conduit

The maximum number of wires that can be safely installed in a 1/2 flex conduit depends on various factors, including wire size, wire type, and conduit fill ratio. Adhering to recommended guidelines and electrical codes ensures proper wire management and promotes safety in electrical installations.

According to the National Electrical Code (NEC), the maximum conduit fill ratio for flexible metal conduit, including 1/2 flex conduit, is 40%. This means that the total area occupied by wires should not exceed 40% of the cross-sectional area of the conduit.

Calculating the exact number of wires that can fit within a 1/2 flex conduit depends on the specific wire sizes and insulation types. However, as a general guideline, here are examples of maximum wire counts based on typical wire sizes:

- For 14 AWG wires: The maximum recommended wire count is around 9 to 10 wires.

- For 12 AWG wires: The maximum recommended wire count is around 6 to 7 wires.

- For 10 AWG wires: The maximum recommended wire count is around 4 to 5 wires.

It is important to note that these are general estimates, and the actual number of wires that can fit may vary depending on factors such as wire insulation thickness and wire type. In addition, local codes and regulations may dictate specific requirements for wire capacity in conduits.

It is crucial to consult the NEC or a qualified electrician to determine the exact maximum number of wires that can be safely installed in a 1/2 flex conduit based on your specific installation requirements. They will consider the factors mentioned earlier, provide accurate calculations, and ensure compliance with electrical codes and safety standards.

Installation Guidelines for 1/2 Flex Conduit

Proper installation of 1/2 flex conduit is important to ensure the integrity and safety of the electrical system. Here are some guidelines to follow when installing 1/2 flex conduit:

- Plan the Route: Determine the path the conduit will take, considering any obstacles or obstructions that may be encountered. This will help in determining the length of conduit, fittings, and connectors required for the installation.

- Measure and Cut: Measure and cut the 1/2 flex conduit to the required length using appropriate tools such as a hacksaw or conduit cutter. Ensure that the cuts are clean and straight to ensure a secure fit with fittings and connectors.

- Secure the Conduit: Use clamps or straps to secure the conduit to the building structure at regular intervals. This helps prevent the conduit from sagging or being subjected to excessive strain, ensuring long-term stability.

- Use Proper Fittings: Use fittings specifically designed for 1/2 flex conduit to join sections of conduit together or to make turns. This ensures a secure and watertight connection while maintaining the flexibility of the conduit.

- Install Connectors: Install connectors at both ends of the conduit to provide a smooth transition between the conduit and the electrical boxes. These connectors should be properly tightened to ensure a secure and reliable connection.

- Follow the Bend Radius: When bending the 1/2 flex conduit, adhere to the manufacturer’s recommended bend radius. Avoid bending the conduit too tightly, as this can cause damage to the conduit or restrict the wire capacity.

- Ensure Proper Grounding: Properly ground the conduit to provide a safe path for electrical currents in the event of a fault. Use grounding bushings and grounding screws to bond the conduit to the electrical system’s grounding conductor.

- Consider Expansion Joints: For long runs of 1/2 flex conduit, consider installing expansion joints to accommodate potential expansion and contraction due to temperature changes. This helps prevent stress on the conduit and ensures its long-term durability.

- Test and Inspect: After the installation is complete, thoroughly test the electrical system to ensure proper functionality. Inspect the conduit for any signs of damage or improper connections and address any issues promptly.

Following these guidelines when installing 1/2 flex conduit will help ensure a safe and effective electrical installation. However, it is always recommended to consult the National Electrical Code (NEC) and work with a qualified electrician to ensure compliance with local codes and regulations.

Conclusion

Choosing the right conduit size is crucial for a successful electrical installation, and understanding the wire capacity of 1/2 flex conduit is essential for proper wire management and safety. By considering factors such as wire size, wire type, conduit fill ratio, and installation guidelines, you can determine the maximum number of wires that can safely fit within a 1/2 flex conduit.

1/2 flex conduit offers flexibility and versatility, making it an ideal choice for various electrical applications. It provides protection for electrical wires and allows for easy installation in tight spaces. However, it is important to follow installation guidelines, including proper planning, measuring, securing, and using appropriate fittings and connectors, to ensure a secure and reliable installation.

By adhering to electrical codes, such as the National Electrical Code (NEC), and consulting with qualified electricians, you can ensure that your 1/2 flex conduit installation meets safety standards and local regulations. Following these guidelines will help prevent issues such as overheating, voltage drop, and physical damage to the wires, ensuring the longevity and efficiency of your electrical system.

Remember that each electrical installation is unique, and it is essential to consider specific requirements and consult professionals when in doubt. By being knowledgeable about conduit sizes, wire capacity, and proper installation techniques, you can create a safe and efficient electrical infrastructure.

In conclusion, understanding the wire capacity and following installation guidelines for 1/2 flex conduit plays a crucial role in maintaining electrical safety, optimizing wire management, and ensuring the proper functionality of your electrical system.

Curious about extending your electrical setup? Our latest piece guides you through running overhead electrical wiring to your garage efficiently. Perfect for those planning to power up remote spaces, this read is packed with practical advice, ensuring safety and compliance with electrical standards. Don't miss out on these essential installation tips that can save time and prevent common mistakes.

Frequently Asked Questions about How Many Wires In 1/2 Inch Flex Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many Wires In 1/2 Inch Flex Conduit”