Articles

How Many 12/2 Wires In 1/2 Inch Conduit

Modified: May 6, 2024

Discover how many 12/2 wires you can fit in a 1/2 conduit. Read our informative articles for expert insights and practical tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to this informative article on the topic of “How Many 12/2 Wires in 1/2 Conduit.” If you are involved in electrical installations or are planning a project that requires the use of electrical wiring, it is important to understand the capacity and limitations of various conduit sizes. In this article, we will specifically focus on the compatibility of 12/2 wires with 1/2 conduit.

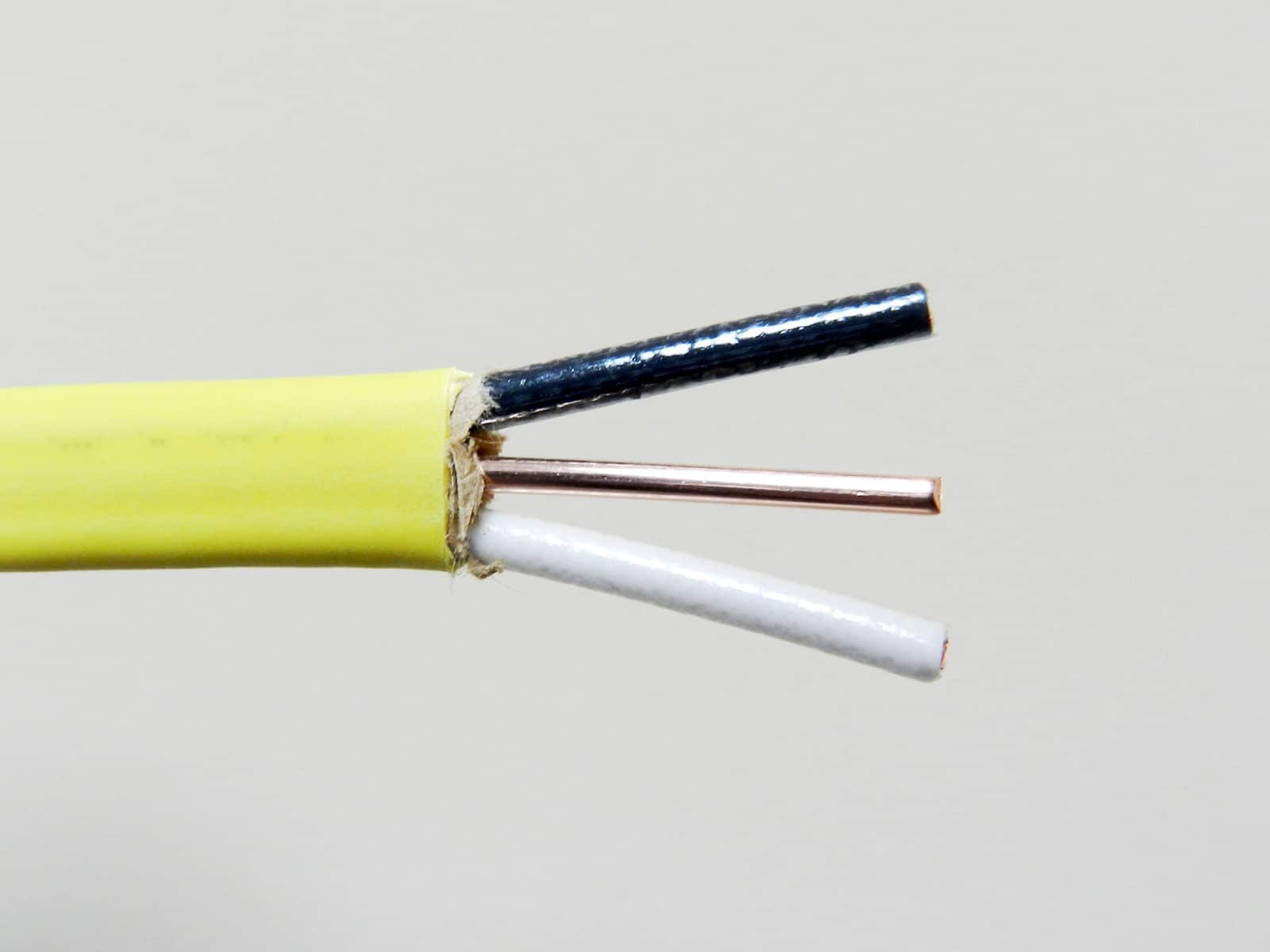

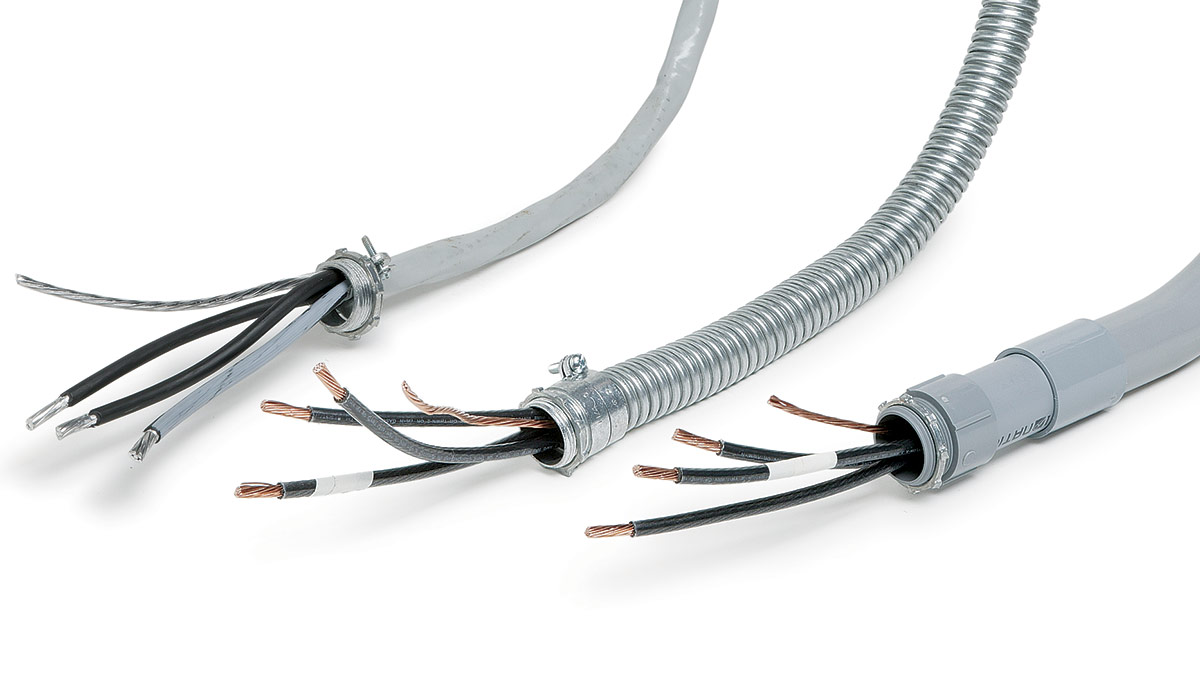

Before delving into the specifics, it is essential to have a basic understanding of what 12/2 wires and 1/2 conduit refer to. 12/2 wires, also known as Romex or NMD90, are a type of electrical wire commonly used for residential or light commercial applications. The “12” in 12/2 represents the gauge of the wire, indicating its size and capacity to handle electrical current. The “2” refers to the number of conductors present in the wire, which includes a neutral wire and a hot wire.

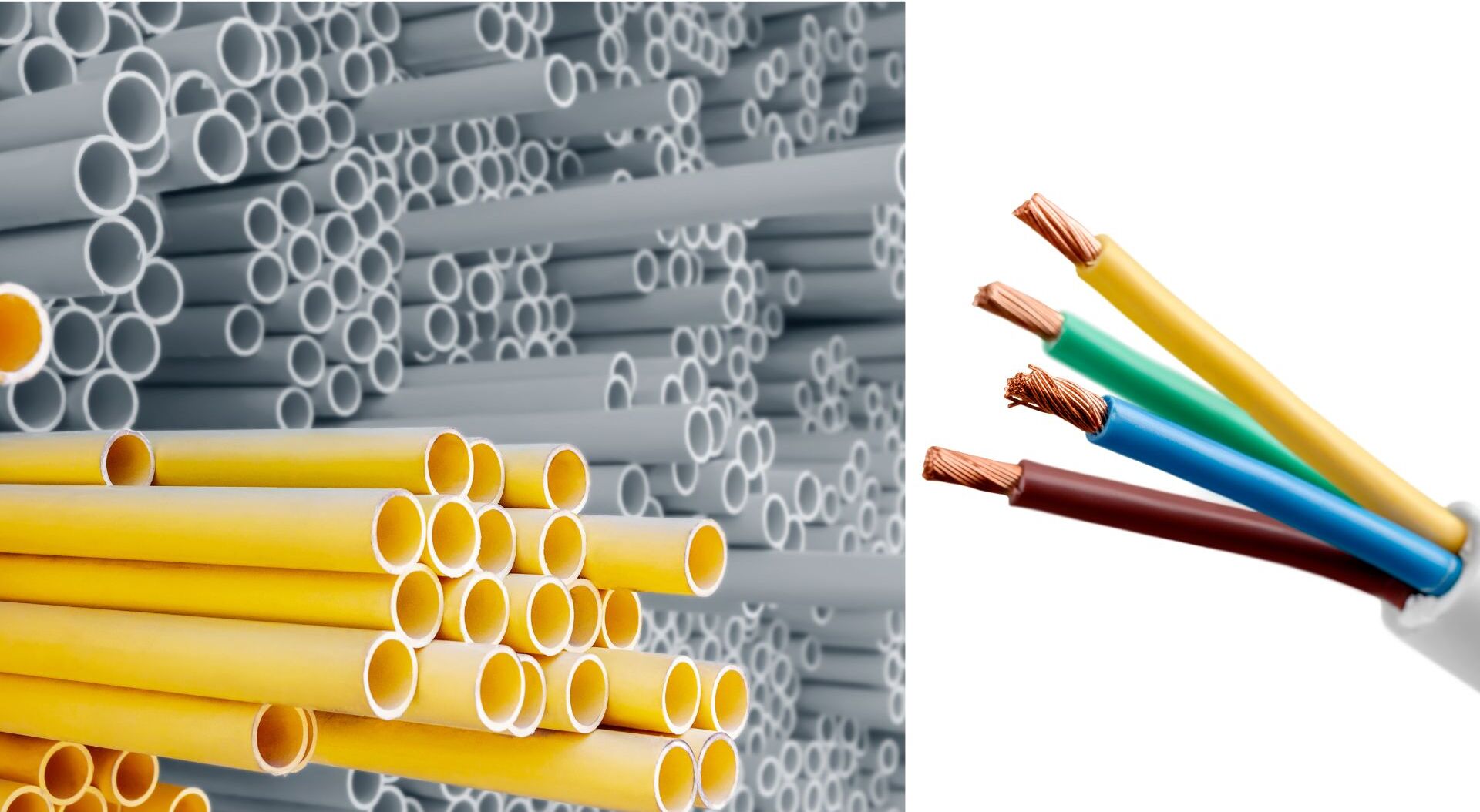

On the other hand, 1/2 conduit refers to the size of the electrical conduit, which is typically made of PVC or metal and is used to protect and route electrical wires. The measurement refers to the internal diameter of the conduit.

Now that we have a basic understanding of the components involved, let’s explore the compatibility between 12/2 wires and 1/2 conduit. Understanding this compatibility is crucial to ensure the efficient and safe installation of electrical systems.

Key Takeaways:

- Understanding the compatibility and capacity of 12/2 wires in 1/2 conduit is crucial for safe electrical installations. Consider factors like wire diameter, insulation thickness, and conduit type to determine the maximum number of wires that can fit.

- Prioritize safety when using 1/2 conduit for 12/2 wires by adhering to maximum fill capacity, ensuring proper wire sizing, and following professional installation practices. Consider insulation integrity, secure conduit anchoring, and proper wire pulling techniques for a reliable electrical system.

Read more: How Many Wires In A 3/4 Inch Conduit

Understanding 12/2 Wires and 1/2 Conduit

In order to determine how many 12/2 wires can fit within a 1/2 conduit, it’s important to have a clear understanding of the specifications and characteristics of both the wire and the conduit.

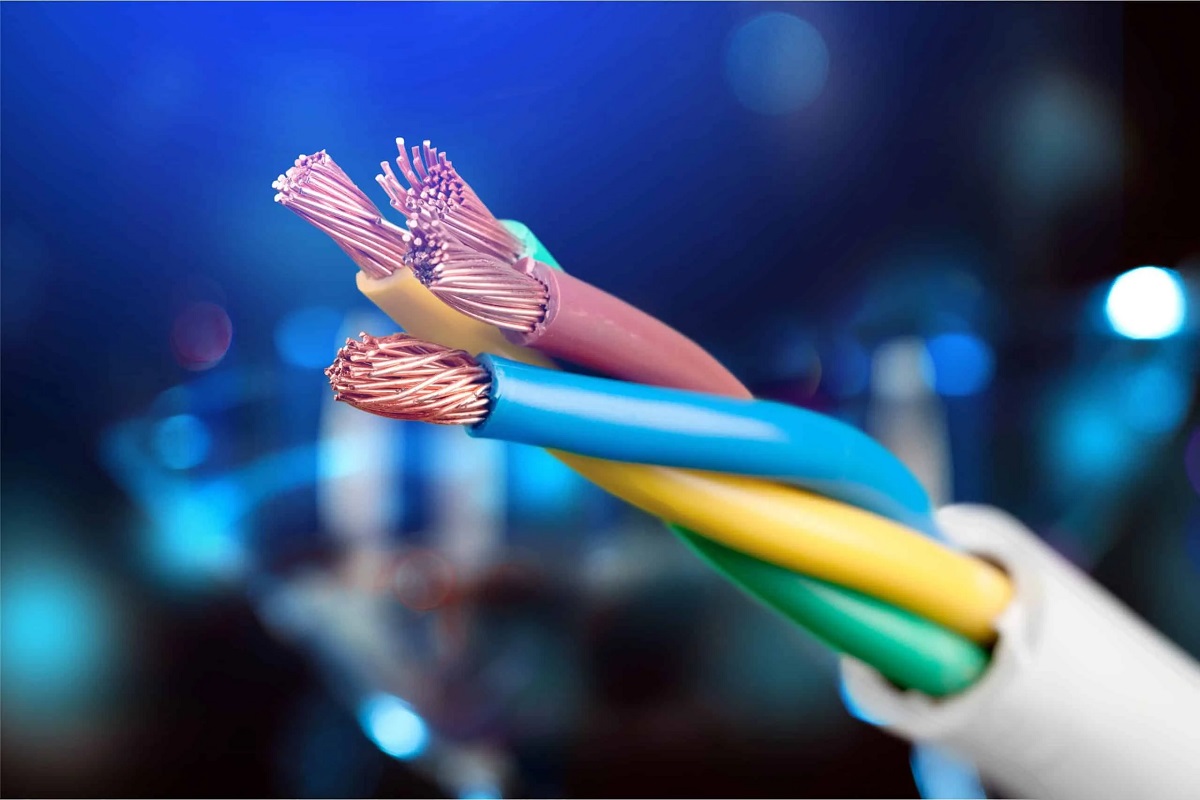

Firstly, 12/2 wires are commonly used in electrical installations to provide power to various devices and fixtures. The “12” in 12/2 refers to the gauge of the wire, which indicates its size and capacity to handle electrical current. A 12-gauge wire is capable of carrying up to 20 amps of electrical current.

The “2” in 12/2 refers to the number of conductors within the wire. In the case of a 12/2 wire, there are two conductors: a black or colored conductor, known as the hot wire, and a white conductor, known as the neutral wire. These conductors are typically insulated, providing protection against electrical shock and preventing interference between circuits.

On the other hand, 1/2 conduit refers to the size of the electrical conduit. This measurement refers to the internal diameter of the conduit. A 1/2 conduit has an internal diameter of approximately 0.62 inches.

Now that we have a basic understanding of the wire and conduit, we can explore how they relate to each other and their compatibility. When considering the number of 12/2 wires that can fit inside a 1/2 conduit, it’s important to take into account the space available within the conduit, the diameter of the wires, and any applicable electrical codes.

Generally, the maximum recommended fill capacity for conduit is 40%, meaning that the conduit should not be filled to more than 40% of its internal area. This allows for proper airflow, reduces the risk of overheating, and facilitates easy wire pulling during installation.

Additionally, electrical codes often specify the acceptable fill capacity for different wire sizes and conduit diameters. These codes are in place to ensure safe and efficient installation practices.

It’s important to note that different types of conduit may have different fill capacities. PVC conduit, for example, typically has a larger fill capacity compared to metal conduit. Therefore, it’s essential to refer to the appropriate electrical codes and guidelines specific to the type of conduit being used.

With a basic understanding of 12/2 wires and 1/2 conduit established, we can now move on to determining the capacity of the conduit and factors that affect the number of wires that can safely fit within it.

Determining the Capacity of 1/2 Conduit

Before determining the number of 12/2 wires that can fit inside a 1/2 conduit, it is crucial to understand the capacity of the conduit itself. The capacity of a conduit refers to the maximum number of wires it can safely and efficiently accommodate.

The capacity of a conduit is dictated by several factors, including its size, material, and any applicable electrical codes or regulations. In the case of a 1/2 conduit, the internal diameter is approximately 0.62 inches.

To determine the capacity of a 1/2 conduit, it is important to refer to industry-standard tables or guidelines provided by electrical codes. These tables provide information on the maximum number of wires that can safely fit within a particular conduit size.

For example, according to the National Electrical Code (NEC), a 1/2 conduit can accommodate up to 9 12-gauge wires. Keep in mind that this number includes all the conductors within the wire, including the hot, neutral, and ground wires.

The capacity of a 1/2 conduit may vary slightly depending on the type of conduit material used. PVC conduit, for instance, may have a slightly larger fill capacity compared to metal conduit due to its smoother interior surface.

It is crucial to always consult the relevant electrical codes and guidelines specific to your area and the type of conduit being used to ensure compliance with safety standards.

Additionally, when determining the capacity of a conduit, factors such as the insulation thickness of the wires, bundling or grouping of the wires, and any other special considerations must be taken into account.

It’s important to note that exceeding the maximum fill capacity of a conduit can lead to several issues, including increased risk of overheating, difficulty in wire pulling during installation, and decreased performance of the electrical system. It is crucial to adhere to the recommended maximum fill capacity to ensure the safety and efficiency of the installation.

Now that we have a clearer understanding of the capacity of a 1/2 conduit, we can delve into the factors that affect the number of 12/2 wires that can safely fit within it.

Factors Affecting the Number of 12/2 Wires in 1/2 Conduit

When determining the number of 12/2 wires that can fit inside a 1/2 conduit, several factors come into play. These factors can affect the overall capacity and functionality of the conduit, as well as the safety of the electrical installation.

- Wire Diameter: The diameter of the 12/2 wire plays a significant role in determining the number of wires that can fit inside a 1/2 conduit. Thicker wires may take up more space, reducing the overall capacity of the conduit.

- Conduit Type: Different types of conduits have varying fill capacities. PVC conduits, for example, generally have a larger capacity compared to metal conduits. It is important to consult the appropriate electrical codes and guidelines specific to the conduit type being used.

- Insulation Thickness: The thickness of the insulation on the 12/2 wires can influence the amount of space they occupy within the conduit. Thicker insulation may reduce the overall capacity of the conduit.

- Bundling or Grouping of Wires: When multiple 12/2 wires are bundled or grouped together, they may occupy more space within the conduit. Bundling wires tightly can decrease airflow and increase the risk of overheating. It is important to follow electrical codes and guidelines regarding wire bundling to ensure safe installation.

- Special Considerations: In some cases, special consideration may need to be given to factors such as the presence of conduit bends, junction boxes, or other wire terminations. These factors can impact the available space within the conduit and affect the number of 12/2 wires that can be safely installed.

It is important to note that exceeding the recommended fill capacity of a conduit can lead to several safety hazards, including overheating, wire insulation damage, and reduced performance of the electrical system. Adhering to the appropriate guidelines and electrical codes is crucial to ensure the safe and efficient installation of the wires within the 1/2 conduit.

Now that we have explored the factors that affect the number of 12/2 wires in a 1/2 conduit, let’s move on to understanding how to calculate the maximum number of 12/2 wires that can safely fit within the conduit.

When determining how many 12/2 wires can fit in a 1/2″ conduit, it’s important to consider the fill capacity. According to NEC guidelines, a 1/2″ conduit can typically accommodate up to 4 12/2 wires. Always consult local codes and regulations for specific requirements.

Calculating the Maximum Number of 12/2 Wires in 1/2 Conduit

When determining the maximum number of 12/2 wires that can fit inside a 1/2 conduit, it is important to consider the available space within the conduit and comply with relevant electrical codes and guidelines. Calculating this maximum number involves taking into account the fill capacity of the conduit and the diameter of the wires.

Here is a step-by-step process for calculating the maximum number of 12/2 wires in a 1/2 conduit:

- Determine the fill capacity: Check the relevant electrical codes, guidelines, or industry-standard tables to find the fill capacity for a 1/2 conduit. This value represents the maximum fill percentage for the conduit.

- Calculate the fill area: Measure the internal diameter of the 1/2 conduit. Use this measurement to calculate the internal cross-sectional area of the conduit. The formula for calculating the area of a circle is A = πr^2, where A is the area and r is the radius. In this case, the radius is half of the diameter.

- Determine the area occupied by a single 12/2 wire: Measure the diameter of a single 12/2 wire. Use this measurement to calculate the cross-sectional area of the wire. Again, utilize the formula A = πr^2, where A is the area and r is the radius.

- Calculate the maximum number of wires: Divide the fill area of the conduit by the area occupied by a single 12/2 wire. Round down the result to the nearest whole number to account for installation requirements and safety considerations.

Keep in mind that the calculated maximum number of wires represents an estimate based on the available space within the conduit and the assumptions made during the calculation. It is essential to consult electrical codes and guidelines specific to your area and the type of conduit being used.

Additionally, it is important to consider factors such as insulation thickness, wire bundling, and any other special considerations that may affect the capacity of the conduit. Adhering to the recommended fill capacity and installation practices ensures the safety and efficiency of the electrical system.

Now that we have calculated the maximum number of 12/2 wires that can fit within a 1/2 conduit, let’s move on to discussing some safety considerations when using this combination.

Read more: How Many 12 GA Wires In 1/2 Inch Conduit

Safety Considerations When Using 1/2 Conduit for 12/2 Wires

When using a 1/2 conduit for 12/2 wires, there are several safety considerations that should be taken into account to ensure the proper installation and functioning of the electrical system. These considerations help to mitigate risks, prevent hazards, and maintain the overall safety of the installation.

- Maximum Fill Capacity: It is crucial to adhere to the maximum fill capacity of the 1/2 conduit as specified by electrical codes and guidelines. Overfilling the conduit can lead to overheating, increased resistance, and potential damage to the wires and insulation.

- Proper Wire Sizing: Ensure that the 12/2 wires are sized appropriately for the electrical load they will be carrying. Undersized wires can result in excessive heat buildup and potential electrical fires. Consult electrical codes and guidelines to determine the correct wire gauges for specific applications.

- Insulation Integrity: It is important to inspect the insulation on the 12/2 wires to ensure that it is in good condition. Damaged or deteriorated insulation can pose a risk of electrical shock or short circuits. Replace any wires with compromised insulation before installation.

- Secure and Properly Anchored Conduit: Ensure that the 1/2 conduit is securely anchored and properly supported throughout the installation. This helps to prevent strain on the wires, reduces the risk of accidental disconnections, and ensures the durability and stability of the electrical system.

- Proper Wire Pulling Techniques: When pulling the 12/2 wires through the 1/2 conduit, use proper techniques to avoid excessive bending, twisting, or pulling. Excessive force can damage the wires or the conduit and compromise the overall integrity of the electrical system. Lubricants may be used to facilitate smooth wire pulling.

- Grounding and Bonding: Proper grounding and bonding of the electrical system are essential for electrical safety. Ensure that the grounding conductor is appropriately connected and bonded to the system’s grounding electrode or grounding bus. Follow electrical codes and guidelines for proper grounding and bonding techniques.

- Professional Installation: If you are not experienced or confident in your ability to install the 12/2 wires in the 1/2 conduit safely, it is recommended to seek the assistance of a licensed electrician. Professional installation ensures compliance with electrical codes, reduces the risk of potential hazards, and ensures the long-term safety of the electrical system.

By considering these safety considerations and following proper installation practices, you can ensure the safe and reliable operation of your electrical system when using a 1/2 conduit for 12/2 wires.

Now that we have discussed the safety considerations, let’s summarize the key points covered in this article.

Conclusion

In conclusion, understanding the compatibility and capacity of 12/2 wires in 1/2 conduit is essential for ensuring a safe and efficient electrical installation. By taking into account factors such as wire diameter, conduit type, insulation thickness, wire bundling, and special considerations, you can determine the maximum number of 12/2 wires that can fit within a 1/2 conduit.

It is important to consult relevant electrical codes and guidelines specific to your area and the type of conduit being used to ensure compliance with safety standards. Adhering to the recommended maximum fill capacity of the conduit helps prevent issues such as overheating, wire insulation damage, and decreased system performance.

When using a 1/2 conduit for 12/2 wires, it is important to consider safety considerations, including proper wire sizing, insulation integrity, secure conduit anchoring, proper wire pulling techniques, grounding and bonding, and professional installation when necessary. These measures help to mitigate risks, prevent hazards, and maintain the overall safety of the electrical installation.

If you are unsure about any aspect of the installation or lack the necessary expertise, it is always recommended to seek the assistance of a licensed electrician. They have the knowledge and experience to ensure proper installation practices and compliance with electrical codes, thus ensuring the long-term safety and functionality of the electrical system.

By understanding and following these considerations, you can confidently and safely utilize a 1/2 conduit for 12/2 wires in your electrical projects. Remember, safety should always be the top priority when working with electrical systems.

Thank you for reading this comprehensive article on “How Many 12/2 Wires in 1/2 Conduit.” We hope you found the information informative and valuable in your electrical endeavors.

If you've mastered how many 12/2 wires fit in a 1/2 inch conduit, why not expand your DIY skills further? Learn essential techniques for running overhead electrical wire to your garage with ease. Or, if you're planning to enhance your home's safety and aesthetics, discover the best methods for installing conduit in walls. Both guides are packed with practical advice to help you upgrade your home like a pro.

Frequently Asked Questions about How Many 12/2 Wires In 1/2 Inch Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many 12/2 Wires In 1/2 Inch Conduit”