Articles

How Long Does Spray Foam Insulation Off Gas

Modified: October 18, 2024

Get all the essential information about how long spray foam insulation off gases in this informative article. Learn more about the off-gassing process and its duration.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Spray foam insulation has gained popularity in recent years as an effective way to improve energy efficiency and reduce heating and cooling costs in homes and commercial buildings. However, one concern that many homeowners have when considering spray foam insulation is the potential off-gassing of chemicals.

In this article, we will explore what spray foam insulation is, the process of off-gassing, factors that can affect the duration of off-gassing, and potential health risks associated with off-gassing. We will also provide some tips on how to minimize off-gassing effects.

Understanding these aspects can help homeowners make informed decisions about whether to choose spray foam insulation and how to mitigate potential risks.

Key Takeaways:

- Understanding the factors influencing off-gassing duration in spray foam insulation, such as type, temperature, and ventilation, can help homeowners anticipate and mitigate potential health risks.

- Minimizing off-gassing effects through proper curing time, ventilation, and sealing techniques can create a healthier indoor environment while enjoying the energy-saving benefits of spray foam insulation.

Read more: How To Clean Spray Foam Insulation

What is spray foam insulation?

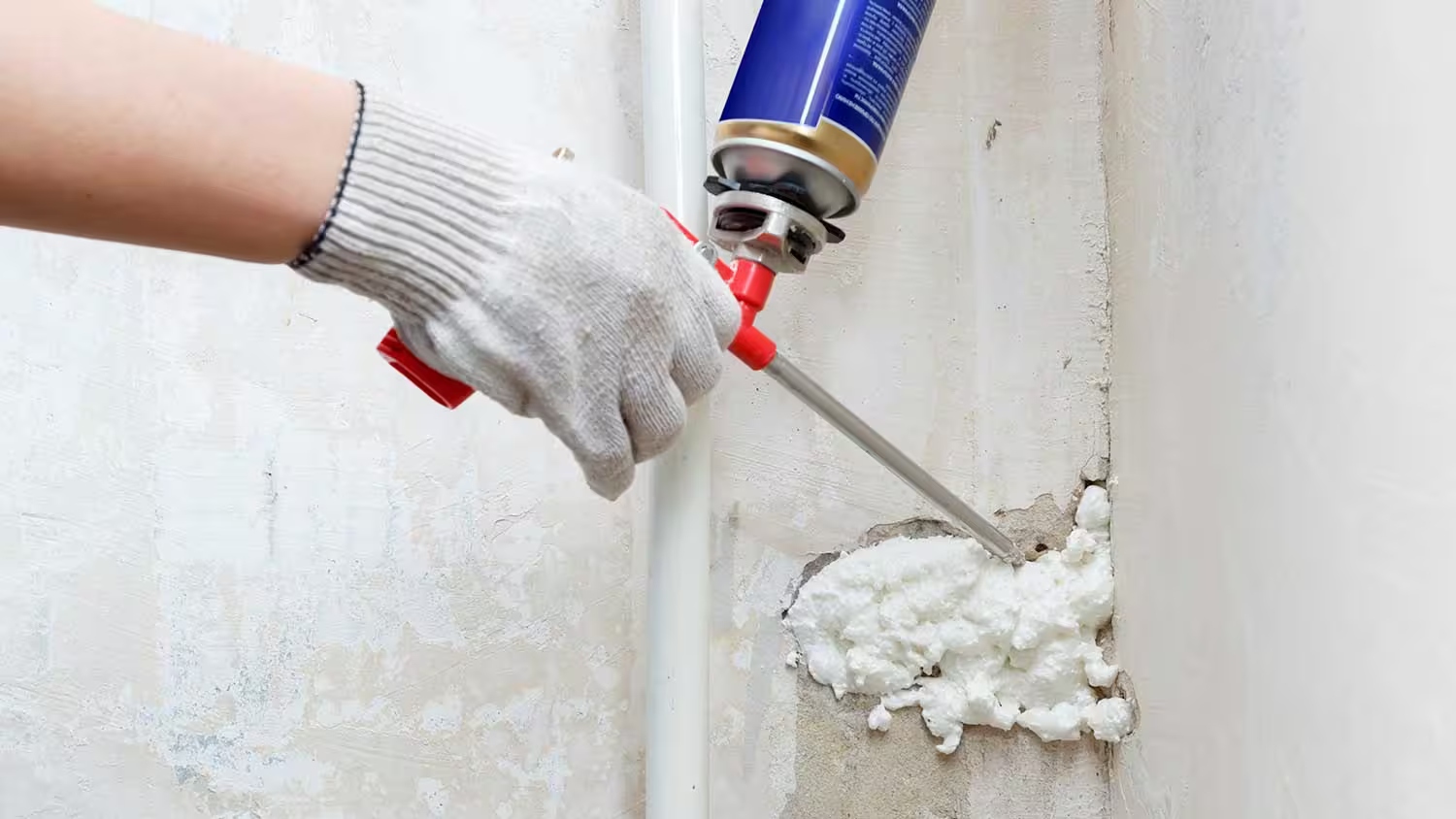

Spray foam insulation is a type of insulation material that is applied as a liquid and expands into a foam-like substance. It is typically made from two components – polyols and isocyanates – that are mixed at the time of application.

Once the two components are mixed, a chemical reaction occurs, causing the mixture to expand and harden. This process allows the spray foam insulation to fill gaps, cracks, and voids, creating an airtight and thermal barrier.

There are two main types of spray foam insulation: open-cell and closed-cell. Open-cell spray foam has a lower density and is more flexible, while closed-cell spray foam has a higher density and is rigid. Both types offer excellent insulation properties, with closed-cell foam providing a higher R-value per inch.

One of the key advantages of spray foam insulation is its ability to form a tight seal, preventing air leakage and heat transfer. This can result in significant energy savings and improved comfort levels in buildings. Additionally, spray foam insulation has a long lifespan and can help reduce noise transmission.

It is important to note that spray foam insulation should be installed by trained professionals due to the precise mixing and application process. Improper installation can lead to performance issues and health risks, including off-gassing.

Now that we understand what spray foam insulation is, let’s explore the concept of off-gassing and its implications.

Off-gassing in spray foam insulation

Off-gassing refers to the release of volatile organic compounds (VOCs) from materials or products into the surrounding air. When it comes to spray foam insulation, off-gassing can occur during and after the curing process. The VOCs released during off-gassing include various chemicals such as isocyanates, blowing agents, and flame retardants.

During the installation of spray foam insulation, the mixture of polyols and isocyanates undergoes a chemical reaction and expands to form the foam. This process releases these VOCs into the air. Additionally, some blowing agents used in the manufacturing process can contribute to off-gassing.

After the initial installation, the curing process continues as the foam hardens and dries. This can lead to a period of off-gassing that may last for several days or weeks. The intensity of off-gassing can vary depending on factors such as humidity, temperature, ventilation, and the type of spray foam used.

It is important to note that off-gassing in spray foam insulation can occur in both open-cell and closed-cell foam, although closed-cell foam tends to have a lower off-gassing potential due to its denser nature.

The off-gassing of chemicals from spray foam insulation can give rise to a distinct odor, often described as a “chemical” or “sweet” smell. This odor can be more noticeable in the immediate aftermath of the installation but usually dissipates over time as the off-gassing diminishes.

However, it is essential to consider the potential health risks associated with off-gassing from spray foam insulation, especially for individuals who are sensitive to chemicals or have respiratory conditions.

In the next section, we will discuss the factors that can affect the duration and intensity of off-gassing in spray foam insulation.

Factors affecting off-gassing duration

The duration and intensity of off-gassing in spray foam insulation can be influenced by several factors. Understanding these factors can help homeowners anticipate the potential duration of off-gassing and take appropriate measures to mitigate any associated risks. Here are some key factors to consider:

- Type of spray foam: The composition and formulation of the spray foam insulation can impact off-gassing. Closed-cell spray foam generally has a faster curing time and lower off-gassing potential compared to open-cell spray foam. However, the specific brand and formulation can also play a role, so it’s important to consult with the manufacturer or installer for information specific to the product being used.

- Temperature and humidity: Higher temperatures and humidity levels can accelerate the curing process, potentially leading to a shorter duration of off-gassing. On the other hand, lower temperatures and humidity levels can slow down the curing process, resulting in a longer off-gassing period.

- Ventilation: Adequate ventilation can help expedite the dissipation of VOCs and reduce off-gassing duration. It is crucial to ensure proper airflow during and after the installation of spray foam insulation. Opening windows and using fans can facilitate air exchange and promote faster off-gassing.

- Surface area and thickness: The size of the sprayed area and the thickness of the foam can impact off-gassing. Larger surface areas and thicker foam layers may require more time for complete curing and off-gassing.

- Curing time: Each spray foam insulation product has a recommended curing time provided by the manufacturer. It is essential to follow these guidelines and allow the foam sufficient time to cure before occupying the space. Rushing the process can potentially lead to prolonged off-gassing.

It is important to note that while these factors can influence off-gassing duration, there is no precise timeline that applies universally. The duration of off-gassing can vary significantly depending on the specific circumstances and variables involved.

In the next section, we will delve into the question that homeowners often ask: “How long does spray foam insulation off-gas?”

When installing spray foam insulation, ensure proper ventilation for at least 24 hours to allow off-gassing of any harmful chemicals. Keep the area well-ventilated during and after installation.

How long does spray foam insulation off-gas?

The duration of off-gassing in spray foam insulation can vary depending on several factors, as mentioned earlier. Generally, the off-gassing period can range from a few days to several weeks. However, it’s important to note that the intensity of off-gassing typically diminishes over time.

During the initial stages of installation, the off-gassing may be more noticeable and have a stronger odor. This is when the majority of VOCs are released into the air. Over time, as the foam cures and the off-gassing diminishes, the odor should gradually dissipate.

The specific duration of off-gassing depends on factors such as the type of spray foam insulation, temperature, humidity, ventilation, and the thickness of the foam layer. Closed-cell spray foam insulation generally has a faster off-gassing period compared to open-cell foam, but it is essential to refer to the manufacturer’s guidelines for the specific product being used.

It’s important to allow sufficient time for the foam to fully cure and off-gas before occupying the space. Rushing the process can potentially expose occupants to a higher concentration of VOCs, which can pose health risks.

It’s also worth mentioning that some homeowners may still notice a faint odor even after the main off-gassing period has ended. This residual odor is typically harmless and should dissipate over time. However, if the odor persists or is a cause for concern, it’s recommended to consult with the manufacturer or a professional for further guidance.

In the next section, we will explore the potential health risks associated with off-gassing from spray foam insulation.

Read more: How To Spray Foam Insulation In Attic

Potential health risks of off-gassing

While spray foam insulation is generally considered safe, the off-gassing of volatile organic compounds (VOCs) can pose potential health risks, especially for individuals who are sensitive to chemicals or have respiratory conditions. The main health concerns associated with off-gassing include:

- Irritation of the respiratory system: Off-gassing from spray foam insulation can cause respiratory irritation, resulting in symptoms such as coughing, wheezing, chest tightness, and shortness of breath. These symptoms are more likely to occur in individuals with pre-existing respiratory conditions like asthma or allergies.

- Eye and skin irritation: Exposure to VOCs released during off-gassing can cause eye and skin irritation. This can manifest as redness, itching, and discomfort. It is important to avoid direct contact with uncured or recently installed spray foam insulation to minimize the risk of irritation.

- Allergic reactions: Some individuals may be allergic to certain chemicals present in spray foam insulation. This can result in allergic reactions such as sneezing, nasal congestion, runny nose, itching, and skin rashes. If you have a known sensitivity or allergy to certain chemicals, it is recommended to consult with a healthcare professional or allergist before the installation of spray foam insulation.

- Chemical sensitivity: Some individuals may have heightened sensitivity to chemical exposures. Even low levels of off-gassing from spray foam insulation can trigger symptoms such as headaches, dizziness, nausea, fatigue, and difficulty concentrating. If you experience these symptoms and suspect a chemical sensitivity, it is important to seek medical advice.

To minimize the potential health risks associated with off-gassing, it is crucial to follow safety precautions and allow proper time for the foam to fully cure and off-gas before occupying the space. Adequate ventilation, such as opening windows and using fans, can help expedite the dissipation of VOCs.

If you have concerns about the health effects of off-gassing or experience persistent symptoms, it is recommended to consult with a healthcare professional who can provide personalized guidance based on your specific situation.

In the next section, we will provide some tips to minimize off-gassing effects and promote a healthy indoor environment.

Tips to minimize off-gassing

While off-gassing from spray foam insulation cannot be completely eliminated, there are several steps you can take to minimize its effects and promote a healthier indoor environment. Here are some tips:

- Allow sufficient curing time: Follow the manufacturer’s guidelines and allow the spray foam insulation ample time to cure before occupying the space. Rushing the process can lead to prolonged off-gassing, so patience is crucial.

- Improve ventilation: Ensure proper airflow by opening windows and using fans to facilitate the exchange of indoor and outdoor air. Ventilation helps to dissipate VOCs and reduce the concentration of off-gassing chemicals.

- Use exhaust fans: Install and utilize exhaust fans in bathrooms, kitchens, and other areas with high moisture levels to help remove any lingering VOCs and promote fresh air circulation.

- Seal the foam: Covering the spray foam insulation with an airtight barrier such as drywall can help minimize exposure to off-gassing chemicals. This can be particularly important in areas where the foam is exposed such as unfinished basements or crawl spaces.

- Clean the area: Regularly clean the area with a damp cloth or mop to remove any dust or particles that may have come in contact with the uncured or recently installed foam. This can help reduce the potential for inhalation or skin contact with off-gassing chemicals.

- Monitor indoor humidity levels: Maintaining optimal humidity levels (between 30-50%) can help accelerate the curing process and minimize off-gassing. Use a hygrometer to monitor humidity levels and employ dehumidifiers or humidifiers as necessary.

- Consider professional testing: If you have specific concerns about the off-gassing of spray foam insulation, you may consider consulting with professionals who specialize in indoor air quality testing. They can assess the levels of VOCs and provide recommendations for mitigation if necessary.

Remember, it is always essential to prioritize safety and take appropriate measures to protect yourself and your family. If you have specific health concerns or are particularly sensitive to chemicals, it is advisable to consult with a healthcare professional or specialist for personalized guidance.

In the next section, we will conclude our article on spray foam insulation off-gassing.

Conclusion

Spray foam insulation is a popular choice for improving energy efficiency and reducing heating and cooling costs in buildings. However, it is important to be aware of the potential off-gassing of volatile organic compounds (VOCs) associated with spray foam insulation.

During the installation and curing process, spray foam insulation can release VOCs into the air, leading to off-gassing. The duration and intensity of off-gassing can vary depending on factors such as the type of spray foam, temperature, humidity, ventilation, and the thickness of the foam layer.

While off-gassing can pose potential health risks, these risks can be minimized by allowing sufficient curing time, improving ventilation, sealing the foam, keeping the area clean, monitoring indoor humidity levels, and considering professional testing.

It is important to note that proper installation by trained professionals is crucial to minimize off-gassing and ensure the effectiveness of the insulation. If you have specific health concerns or are particularly sensitive to chemicals, it is always best to consult with healthcare professionals or specialists for personalized guidance.

By understanding the factors affecting off-gassing and implementing the appropriate measures, you can enjoy the benefits of spray foam insulation while minimizing potential risks and creating a healthier indoor environment.

Remember, each situation is unique, and it is important to consult with experts and manufacturers for specific recommendations and guidance based on your circumstances.

We hope this article has provided you with valuable insights into the concept of spray foam insulation off-gassing and how to minimize its effects. Make informed decisions and prioritize your well-being when considering spray foam insulation for your home or commercial space.

Frequently Asked Questions about How Long Does Spray Foam Insulation Off Gas

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Does Spray Foam Insulation Off Gas”