Articles

Why Is Spray Foam Insulation Bad

Modified: December 7, 2023

Discover the truth behind spray foam insulation. Read articles that explore the drawbacks and potential dangers of this popular insulation choice.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to insulating buildings and homes, spray foam insulation has gained popularity in recent years. It is widely marketed as an effective solution for reducing energy consumption, improving indoor comfort, and lowering utility bills. However, despite its benefits, many experts are raising concerns about the potential negative impacts of spray foam insulation. In this article, we will explore some of the reasons why spray foam insulation may not be as beneficial as it seems.

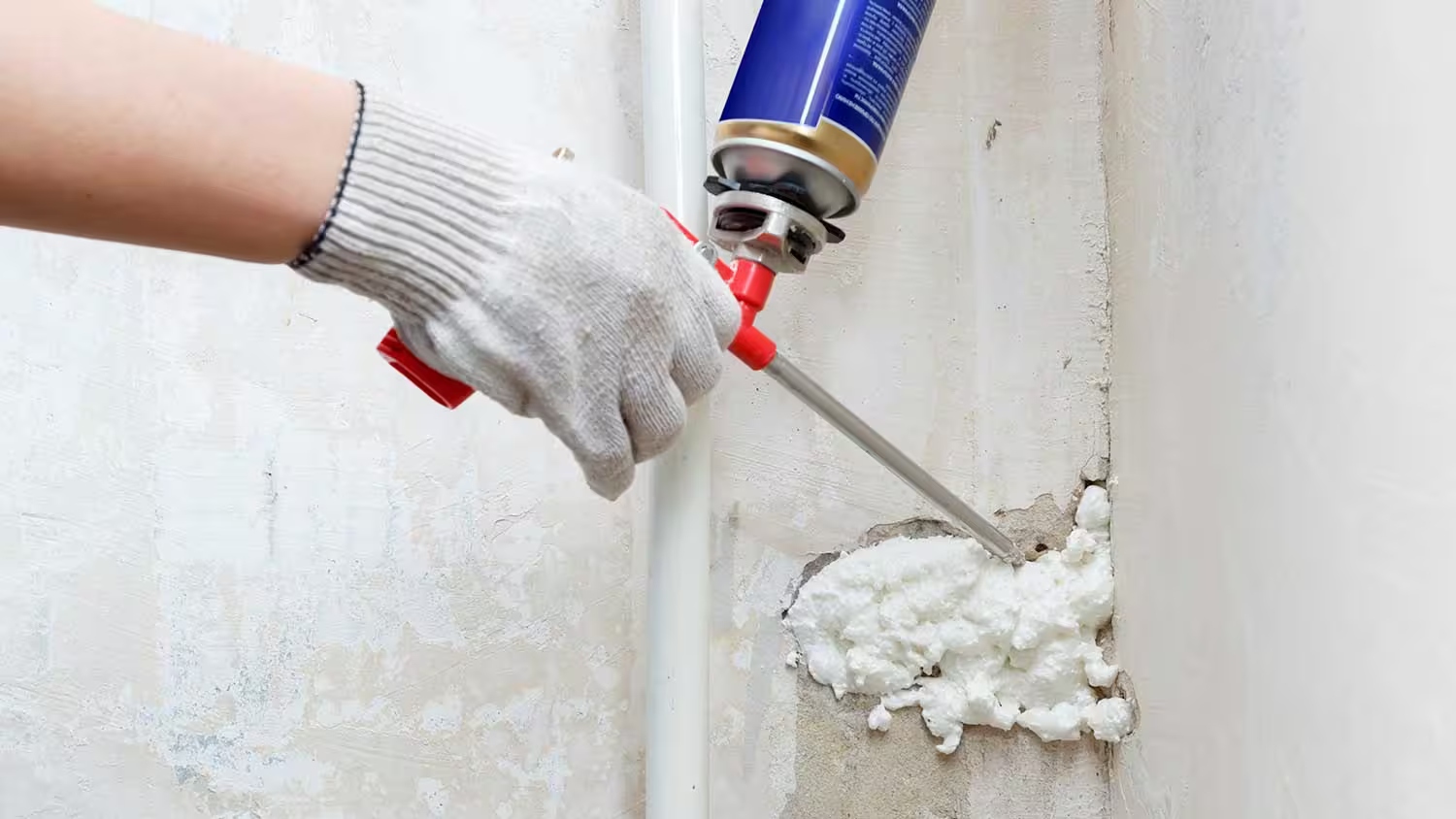

Before diving into the drawbacks of this insulation method, it’s important to understand the basics. Spray foam insulation is a two-component mixture that is sprayed onto surfaces. It expands and hardens to form a thick layer of insulation material, which fills gaps and seals air leaks. This insulation type is known for its excellent insulating properties and air-tight seal, which can help improve energy efficiency.

However, there are several key issues to consider before deciding to use spray foam insulation. From environmental concerns to health risks and installation challenges, it’s crucial to have a comprehensive understanding of the potential downsides. Let’s take a closer look at these concerns to determine whether spray foam insulation is the best choice for your needs.

Key Takeaways:

- Despite its insulation benefits, spray foam insulation poses environmental, health, fire, and moisture concerns. Exploring alternative materials like fiberglass, cellulose, or mineral wool can provide effective insulation with fewer drawbacks.

- The high cost, installation challenges, and potential drawbacks of spray foam insulation warrant consideration of alternative options. Natural fiber insulation and open-cell spray foam are eco-friendly alternatives worth exploring.

Read more: Why Use Spray Foam Insulation

Environmental Impact

One of the major concerns surrounding spray foam insulation is its environmental impact. The foam is primarily made from petrochemicals, which are non-renewable resources extracted from fossil fuels. The production and disposal of these materials contribute to greenhouse gas emissions and depletion of natural resources.

In addition, the blowing agents used in spray foam insulation can have a significant impact on the environment. Older formulations of spray foam insulation contained hydrofluorocarbons (HFCs), which have a high global warming potential. Although newer formulations use more environmentally friendly blowing agents, such as hydrofluoroolefins (HFOs), their long-term ecological impact is still being studied.

The installation process of spray foam insulation also raises environmental concerns. The foam must be applied using specialized equipment, which can release volatile organic compounds (VOCs) into the air. VOCs contribute to air pollution and can have harmful effects on both human health and the environment.

Furthermore, the disposal of spray foam insulation can be problematic. If the foam is exposed to fire or high temperatures, it can release toxic fumes. This makes it challenging to dispose of properly and may result in the foam ending up in landfills, where it can potentially leach harmful chemicals into the soil and groundwater.

Considering these environmental concerns, it’s important to explore alternative insulation options that have a lower environmental impact. This includes materials like cellulose insulation, which is made from recycled paper, or mineral wool insulation, which is made from natural and sustainable materials.

Health Concerns

While spray foam insulation provides efficient insulation and air sealing, it can also pose health risks to occupants if not installed or maintained properly. One of the primary concerns is related to off-gassing of volatile organic compounds (VOCs) during the installation process and the initial curing period.

During application, spray foam insulation emits fumes that contain chemicals called isocyanates. These chemicals can cause respiratory issues, allergic reactions, and irritation to the eyes, throat, and skin. Prolonged exposure to isocyanates can lead to more serious health problems, including asthma and other respiratory conditions.

It’s crucial to note that the risks associated with spray foam insulation are primarily during the installation process when the foam is being sprayed and expanding. Once the foam has fully cured, it is generally considered safe. However, if the foam is damaged or deteriorates over time, it can release particles into the air, increasing the risk of health issues.

Furthermore, certain individuals may be more susceptible to the health effects of spray foam insulation, especially those with respiratory conditions, allergies, or chemical sensitivities. It is important for anyone considering spray foam insulation to consult with a professional and discuss potential risks and precautions.

To minimize health risks, it is important to choose a reputable and experienced insulation contractor who follows industry best practices and safety guidelines. Adequate ventilation during installation and proper protective equipment, such as masks and goggles, are essential to reduce exposure to harmful chemicals.

If you are concerned about the potential health risks associated with spray foam insulation, alternative insulation materials such as fiberglass or cellulose may be a safer option. These materials have been used for many years and have a lower risk of off-gassing or releasing harmful particles into the air.

Fire Hazards

While spray foam insulation provides effective insulation properties, it is important to consider its fire hazards. Spray foam insulation is highly flammable and can contribute to the rapid spread of fire if not properly protected or treated with fire-resistant coatings.

Unlike traditional insulation materials, such as fiberglass or mineral wool, which are inherently non-combustible, spray foam insulation is made from petroleum-based materials that can easily ignite when exposed to flames or high temperatures.

In the event of a fire, spray foam insulation can release toxic fumes and smoke, posing a significant threat to occupants. These fumes and smoke can be harmful to breathe in and can hinder evacuation efforts. Additionally, the combustion of spray foam insulation can generate intense heat, exacerbating the fire and making it more difficult for firefighters to contain.

To mitigate the fire risk associated with spray foam insulation, it is important to take necessary precautions during the installation process. This may include applying fire-resistant coatings or barriers over the foam to enhance its fire resistance. It is also crucial to ensure that electrical wiring and fixtures are properly installed and insulated to prevent potential fire hazards.

Choosing fire-resistant insulation materials with higher fire ratings, such as mineral wool or fiberglass, may be a safer alternative for areas where fire safety is a concern. These materials are designed to resist ignition and limit the spread of flames.

Ultimately, it is essential to consult with a professional and adhere to fire safety regulations and building codes when considering using spray foam insulation. By taking the necessary precautions and using additional fire-resistant measures, the fire hazards associated with spray foam insulation can be minimized.

Moisture and Mold Issues

While spray foam insulation is known for its air-sealing properties, it can also trap moisture within the wall cavities if not properly installed or if there are existing moisture issues in the building. Moisture that becomes trapped inside the walls can lead to a variety of problems, including mold growth.

Mold thrives in environments with high humidity and moisture levels. When moisture is sealed within the walls by the impermeable nature of spray foam insulation, it creates an ideal breeding ground for mold spores to grow and spread. Mold can not only damage the structural integrity of the building but also pose significant health risks to its occupants.

To prevent moisture-related issues and mold growth, it is crucial to address any existing moisture problems before installing spray foam insulation. This may involve fixing leaky pipes or addressing issues such as water intrusion from the exterior of the building.

In addition to addressing existing moisture issues, proper installation techniques are essential to avoid potential problems. It is crucial to ensure that the building is properly ventilated and that the foam is applied evenly and in the correct thickness. Proper installation can help minimize the risk of trapping moisture within the walls.

When considering insulation options, alternative materials like fiberglass or cellulose may be more suitable in areas with high moisture levels or a history of moisture-related issues. These materials allow moisture to pass through, reducing the risk of moisture accumulation and mold growth.

Regular maintenance and inspection of the insulation system and the building’s overall moisture management are also essential to identify and address any potential issues before they escalate.

By taking proper precautions and addressing moisture-related concerns, the risk of mold growth and other moisture-related problems associated with spray foam insulation can be minimized.

When considering spray foam insulation, be aware of potential health risks from off-gassing of chemicals and improper installation leading to moisture problems. Conduct thorough research and consult with professionals before making a decision.

Read more: How To Spray Foam Insulation

Cost and Installation Challenges

One of the significant drawbacks of spray foam insulation is its relatively high cost compared to other insulation materials. The cost of materials and professional installation for spray foam insulation can be significantly higher than alternative options, such as fiberglass or cellulose insulation.

The high cost of spray foam insulation can be attributed to several factors. Firstly, the materials used in spray foam insulation, such as polyurethane or polyisocyanurate, are more expensive compared to materials like fiberglass or cellulose. Additionally, the specialized equipment and training required for the proper installation of spray foam insulation contribute to the overall cost.

Moreover, the installation process itself can be challenging and time-consuming. Spray foam insulation requires precise application to ensure proper coverage and avoid any gaps or inadequate sealing. Improper installation can lead to reduced insulation performance and potential issues like air leakage or moisture problems.

Furthermore, the installation of spray foam insulation may require additional preparation of the building. This can include covering or protecting existing fixtures, electrical wiring, and plumbing to prevent the spray foam from adhering or causing damage during application.

It is essential to hire a professional and experienced insulation contractor who is knowledgeable in the proper installation techniques for spray foam insulation. This will help ensure an effective and efficient installation while minimizing the risk of potential problems.

In cases where cost is a significant consideration, alternative insulation materials like fiberglass or cellulose may be more budget-friendly options. These materials are widely available and generally have lower installation costs.

When weighing the cost and installation challenges associated with spray foam insulation, it is important to consider the long-term benefits in energy savings and improved comfort. A cost-benefit analysis can help determine whether the initial investment in spray foam insulation is worth the potential return on investment over time.

Durability and Maintenance

Spray foam insulation is known for its durability and long lifespan. When properly installed, it can last for several decades without significant degradation. However, there are certain factors that can impact the durability and maintenance requirements of spray foam insulation.

One factor to consider is the potential for physical damage to the foam insulation. Spray foam insulation is not as resistant to impact or compression as other insulation materials like fiberglass or mineral wool. Sharp objects or heavy weights that come into contact with the foam can cause it to deform or even puncture, compromising its insulation properties.

To ensure the long-term durability of spray foam insulation, it is important to protect it from potential damage. This can be done by applying a protective barrier or covering over the foam, particularly in high-traffic areas or locations where it may be susceptible to impact. Regular inspections should also be conducted to identify and address any signs of physical damage.

In terms of maintenance, spray foam insulation generally requires minimal upkeep. Unlike other insulation materials that may require periodic inspection and replacement, spray foam insulation is not prone to settling or sagging over time.

However, if there are any issues with the spray foam insulation, such as damage or signs of degradation, it is crucial to address them promptly. Any gaps or compromised areas in the foam can lead to reduced insulation effectiveness or potential moisture infiltration.

Regular inspections of the insulation system are recommended to ensure its continued performance. This includes checking for any areas where the foam may have pulled away from surfaces or where gaps have formed. Any identified issues should be addressed by a professional to maintain the integrity of the insulation system.

Although spray foam insulation is generally low maintenance, it is important to consider the potential challenges of accessing the foam in case of any necessary repairs or modifications to the building. In some cases, accessing or removing the foam may require specialized equipment or professional assistance.

Overall, spray foam insulation offers durability and minimal maintenance requirements. However, proper care and maintenance are still necessary to ensure its long-term effectiveness and address any potential issues that may arise.

Alternatives to Spray Foam Insulation

While spray foam insulation offers some advantages, it is important to consider alternative insulation options that may be better suited to your needs. Here are a few alternatives to spray foam insulation:

1. Fiberglass Insulation: Fiberglass insulation is one of the most common and widely used insulation materials. It is made from glass fibers and is known for its affordability and ease of installation. Fiberglass insulation can be installed in batts or blown-in form and provides good thermal performance.

2. Cellulose Insulation: Cellulose insulation is made from recycled materials such as newspapers and cardboard. It offers excellent thermal performance and is environmentally friendly. Cellulose insulation is typically blown or sprayed into cavities and provides effective insulation and soundproofing.

3. Mineral Wool Insulation: Mineral wool insulation is made from natural minerals, such as basalt or rock wool. It is a non-combustible material that offers good thermal and acoustic insulation properties. Mineral wool insulation is available in batts or loose-fill form and is a popular choice for fire-resistant applications.

4. Spray Foam Alternatives: There are also alternative types of spray foam insulation that may have fewer drawbacks. For example, open-cell spray foam insulation has a lower environmental impact and is more breathable compared to closed-cell foam. It allows for moisture vapor to pass through, reducing the risk of trapped moisture and potential mold growth.

5. Natural Fiber Insulation: Natural fiber insulation, such as cotton, hemp, or sheep’s wool, is gaining popularity as an eco-friendly alternative to traditional insulation materials. These materials are renewable, biodegradable, and have good thermal and acoustic performance.

When considering insulation alternatives, it is important to evaluate factors such as cost, environmental impact, performance, and specific requirements for your building or home. Consulting with insulation professionals can help you determine the best insulation option based on your needs and priorities.

Overall, there are several alternatives to spray foam insulation, each with its own advantages and considerations. By exploring these alternatives, you can make an informed decision and choose the insulation option that best suits your requirements.

Conclusion

While spray foam insulation has gained popularity for its ability to provide excellent insulation and air sealing, it is important to weigh the potential drawbacks and consider alternative insulation options. The environmental impact, health concerns, fire hazards, moisture and mold issues, cost, and installation challenges associated with spray foam insulation should not be overlooked.

The production and disposal of spray foam insulation materials have environmental implications, and the chemicals used in the insulation can pose health risks during installation if proper precautions are not taken. The flammable nature of spray foam insulation also presents fire hazards that need to be addressed.

Moisture can become trapped within the walls when using spray foam insulation, leading to potential mold growth and related issues. The cost of spray foam insulation, including materials and professional installation, can be higher compared to alternative insulation materials. The installation process itself requires expertise and can be time-consuming.

Considering these factors, it may be beneficial to explore alternative insulation options. Fiberglass insulation, cellulose insulation, mineral wool insulation, or spray foam alternatives like open-cell foam can provide effective thermal performance without some of the drawbacks associated with spray foam insulation. Natural fiber insulation is also a sustainable and biodegradable option worth considering.

Ultimately, the choice of insulation material depends on various factors, such as budget, environmental impact, durability, and specific requirements for your building or home. Consulting with insulation professionals and conducting thorough research will help you make an informed decision that best suits your needs.

In conclusion, spray foam insulation may not always be the best choice due to its potential drawbacks. By considering alternative insulation materials and understanding the specific advantages and challenges of each option, you can select an insulation solution that meets your goals for energy efficiency, comfort, and long-term performance while addressing any concerns or limitations associated with spray foam insulation.

Frequently Asked Questions about Why Is Spray Foam Insulation Bad

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Is Spray Foam Insulation Bad”