Articles

What Is EPS Insulation

Modified: February 28, 2024

Learn all about EPS insulation in our informative articles. Discover the benefits, installation process, and cost of EPS insulation for your home.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to keeping our homes comfortable and energy-efficient, insulation plays a vital role. It helps to regulate the temperature inside the house, prevents heat transfer, and reduces energy consumption. One popular type of insulation that has gained significant popularity is EPS insulation.

EPS stands for Expanded Polystyrene, which is a lightweight and rigid foam material. It is widely used in construction as an insulation solution due to its excellent thermal performance and versatility. EPS insulation is made from expanded polystyrene beads that are fused together, creating a durable and energy-efficient material.

In this article, we will delve into the world of EPS insulation and explore its different components, advantages, applications, challenges, and environmental impact. By the end of this article, you will have a comprehensive understanding of EPS insulation and its potential benefits for your home or building.

Key Takeaways:

- EPS insulation offers exceptional thermal performance, ease of installation, and resistance to moisture and pests, making it a practical choice for improving energy efficiency and creating comfortable living and working environments.

- While EPS insulation presents environmental challenges, its energy-saving properties, recyclability, and ongoing industry efforts to enhance sustainability contribute to a more eco-friendly future for insulation solutions.

Read more: What Is Insulation

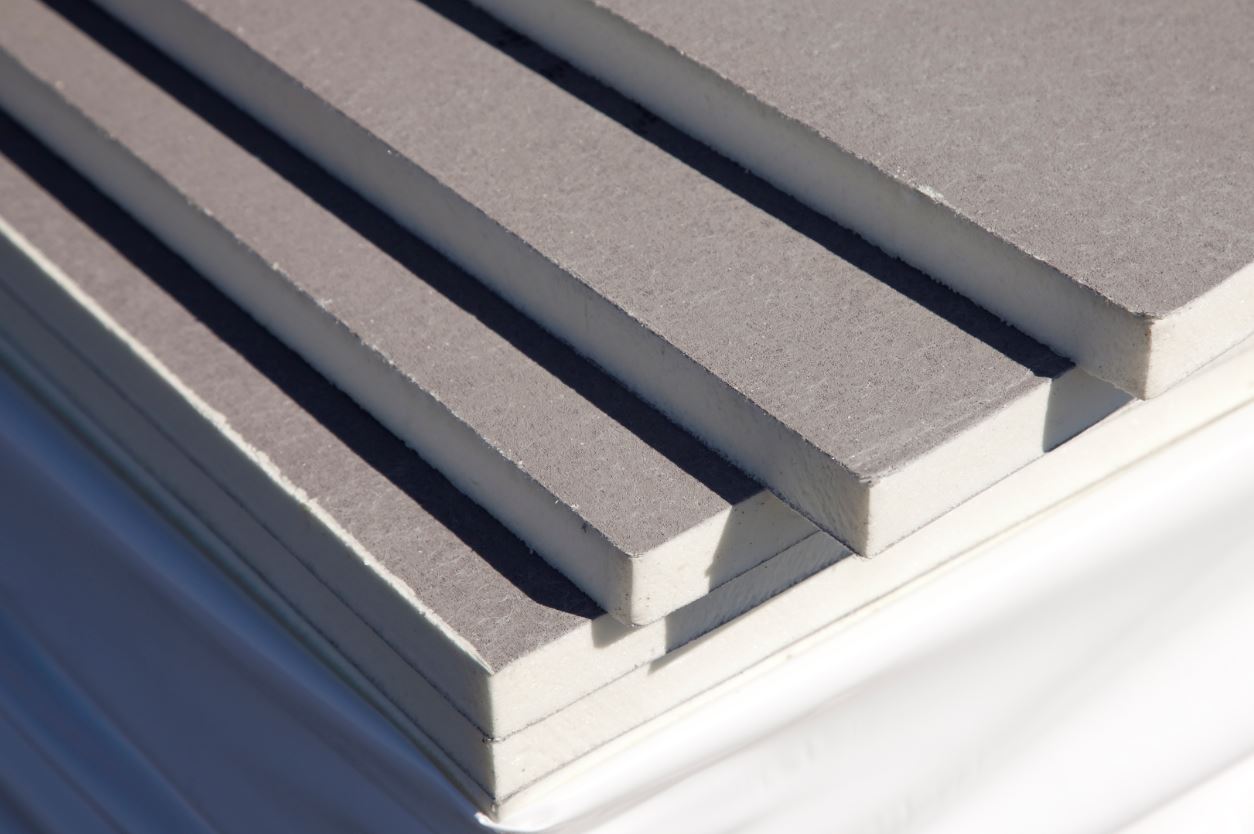

Definition of EPS Insulation

EPS insulation is a type of thermal insulation that is made from expanded polystyrene foam. It is composed of small beads of polystyrene, which are expanded using steam and then fused together to form rigid panels or blocks. The resulting product is lightweight, durable, and provides excellent thermal insulation properties.

The expanded polystyrene material used in EPS insulation is a type of plastic that is manufactured from petroleum. It is known for its low thermal conductivity, meaning that it does not easily conduct heat. This property makes EPS insulation an effective barrier against heat transfer, helping to keep buildings cool in the summer and warm in the winter.

EPS insulation is available in various forms, including rigid panels, blocks, and molded shapes. These different forms allow for flexibility in installation and can be customized to fit specific building requirements. The panels or blocks can be easily cut and shaped to fit walls, roofs, floors, and other areas that need insulation.

One of the key features of EPS insulation is its closed-cell structure. This structure consists of tiny, interconnected cells that trap air and slow down the transfer of heat. The trapped air acts as an insulating layer, reducing the flow of heat and providing thermal resistance. EPS insulation typically has a high R-value, which is a measure of its thermal resistance.

EPS insulation is also known for its long-term durability. It is resistant to moisture, mold, and pests, making it a reliable choice for insulation in various environments. Additionally, it is lightweight and easy to handle, making installation quick and efficient.

Overall, EPS insulation is a versatile and effective solution for thermal insulation in both residential and commercial buildings. Its unique properties make it an excellent choice for improving energy efficiency and reducing heating and cooling costs.

Components of EPS Insulation

EPS insulation is primarily composed of expanded polystyrene (EPS) foam, but it may also include other components that enhance its performance and durability. Let’s take a closer look at the main components of EPS insulation:

1. Expanded Polystyrene (EPS) Foam:

The main component of EPS insulation is the expanded polystyrene foam. It is made from polystyrene beads that are expanded using steam, causing them to expand and fuse together. The resulting foam has a closed-cell structure, which provides excellent insulation properties. EPS foam is lightweight, rigid, and resistant to moisture, making it an ideal material for insulation.

2. Flame Retardants:

To improve the fire resistance of EPS insulation, flame retardants are often added during the manufacturing process. These additives help reduce the flammability of the material, making it safer in the event of a fire. Flame retardants are carefully selected and added in the appropriate quantities to meet safety regulations and standards.

Read more: What Is Insulation Made Of

3. Adhesives and Binding Agents:

During the production of EPS insulation panels or blocks, adhesives and binding agents may be used to fuse the expanded polystyrene beads together. These substances help create a strong and durable structure, ensuring that the insulation remains intact over time. The adhesives and binding agents used are typically designed to be chemically stable and resistant to moisture, ensuring the longevity of the insulation.

4. Protective Coatings:

In some cases, EPS insulation may be coated with protective layers to enhance its durability and resistance to external elements. These coatings can provide additional moisture resistance, improve thermal performance, and protect the insulation from UV rays. Common protective coatings include vapor barriers, reflective coatings, or other specialized coatings depending on the specific application and environmental conditions.

By carefully selecting and combining these components, EPS insulation manufacturers are able to create a high-quality and dependable insulation product. The combination of EPS foam, flame retardants, adhesives, binding agents, and protective coatings ensures that the insulation delivers optimal thermal performance, durability, and safety.

Advantages of EPS Insulation

EPS insulation offers numerous advantages that make it a popular choice for both residential and commercial applications. Let’s explore some of the key benefits of EPS insulation:

1. Excellent Thermal Insulation:

EPS insulation has a high thermal resistance, also known as the R-value. It effectively reduces heat transfer, keeping buildings cool in hot weather and warm in cold weather. This helps to improve energy efficiency and reduce heating and cooling costs.

Read more: What Is FSK Insulation

2. Lightweight and Easy to Install:

EPS insulation is lightweight, making it easy to handle and install. The panels or blocks can be easily cut and shaped to fit various areas, reducing installation time and effort. Its lightweight nature also minimizes the load on the structure, making it suitable for both new construction and retrofit applications.

3. Moisture Resistant:

EPS insulation is resistant to moisture absorption, which helps to prevent mold growth and maintain the integrity of the insulation. This makes it a suitable choice for humid environments or areas prone to water damage, such as basements and crawl spaces.

4. Versatile and Flexible:

EPS insulation comes in various forms, including rigid panels and blocks. It can be easily customized and shaped to fit different areas, such as walls, roofs, and floors. This versatility allows for seamless integration into different architectural designs and construction projects.

5. Durable and Long-lasting:

EPS insulation is known for its durability. It can withstand normal wear and tear without losing its insulating properties. It is resistant to pests, such as termites, rodents, and insects, which can damage other types of insulation. This longevity ensures that the insulation remains effective for years to come.

Read more: What Is Tapered Insulation

6. Environmentally Friendly:

EPS insulation is manufactured using low-energy processes, and it is recyclable and non-toxic. It does not emit harmful gases during its lifespan or contribute to ozone depletion. Additionally, EPS insulation can be reused or recycled at the end of its life, reducing waste and environmental impact.

Overall, the advantages of EPS insulation make it a practical and efficient choice for a wide range of insulation needs. Its thermal performance, ease of installation, durability, and environmental benefits make it a preferred option in the construction industry.

Applications of EPS Insulation

EPS insulation is widely used in various construction and building applications due to its excellent thermal insulation properties and versatility. Let’s explore some of the common applications of EPS insulation:

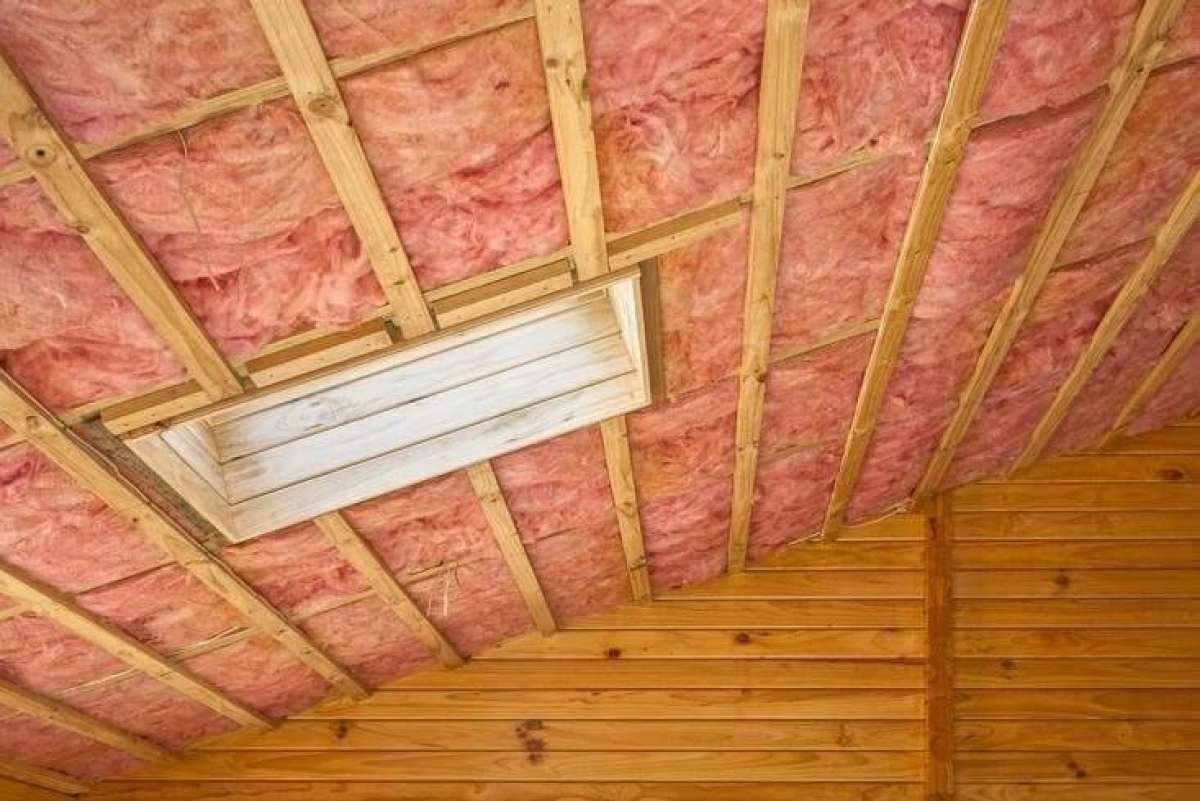

1. Walls and Roofs:

EPS insulation is commonly used in both exterior and interior walls as well as roofs. It provides effective insulation, reducing heat transfer and improving energy efficiency. EPS panels or blocks can be installed between wall studs or roof rafters, creating a thermal barrier that helps maintain a comfortable indoor temperature.

2. Floors and Foundations:

EPS insulation is also frequently used beneath concrete slabs, in crawl spaces, and under flooring systems. It helps to minimize heat loss through the floors and foundations, improving energy efficiency and ensuring a more comfortable living environment. The lightweight nature of EPS insulation makes it easy to install in basement walls and floors as well.

Read more: What Is A Batt Of Insulation

3. Insulated Concrete Forms (ICFs):

EPS insulation is a key component in insulated concrete forms (ICFs), which are used in constructing energy-efficient and durable buildings. ICFs are hollow foam blocks or panels that are stacked to form the walls of a structure. The EPS insulation provides both insulation and structural support, resulting in highly efficient and well-insulated buildings.

4. Pre-fabricated Building Systems:

EPS insulation is widely used in pre-fabricated building systems, where panels or modules are manufactured off-site and then assembled on-site. These systems provide rapid construction and energy efficiency. EPS insulation is incorporated into the panels, ensuring optimal thermal insulation for the entire structure.

5. Cold Storage and Refrigeration Facilities:

EPS insulation is an ideal choice for cold storage and refrigeration facilities due to its excellent insulation properties. It helps to maintain consistent temperatures and prevent thermal bridging, ensuring the integrity of temperature-sensitive products. EPS insulation is often used in walls, ceilings, and floors of cold rooms, walk-in freezers, and refrigerated trucks.

6. HVAC Ductwork:

EPS insulation is used to insulate HVAC (Heating, Ventilation, and Air Conditioning) ductwork. It helps to minimize heat loss or gain within the ducts, improving energy efficiency and preventing condensation. Properly insulated ductwork ensures more efficient distribution of conditioned air throughout a building.

These are just a few of the many applications of EPS insulation. Its versatility, thermal performance, and durability make it a suitable choice for a wide range of construction and insulation needs.

Read more: What Is Continuous Insulation

Challenges and Limitations of EPS Insulation

While EPS insulation offers many benefits, it is important to be aware of some of its challenges and limitations. Understanding these factors can help in making informed decisions when using EPS insulation. Here are some of the challenges and limitations associated with EPS insulation:

1. Vulnerability to Heat:

EPS insulation has a low melting point and is susceptible to damage when exposed to high temperatures. Direct contact with heat sources, such as open flames or hot surfaces, can cause the material to deform or even melt. Therefore, it is important to take precautions and ensure proper installation and placement of EPS insulation in areas where heat exposure is a concern.

2. Permeability to Water Vapor:

While EPS insulation is resistant to moisture, it is not completely impermeable to water vapor. Over time, small amounts of moisture may be absorbed into the EPS foam. This can lead to a gradual reduction in the insulation’s thermal performance. It is important to take measures to minimize moisture infiltration and ensure proper ventilation to mitigate the potential impact on the insulation’s effectiveness.

3. Limited Acoustic Insulation:

EPS insulation primarily offers thermal insulation properties and does not provide significant acoustic insulation. Sound waves can easily pass through the foam material, making it less effective in reducing noise transmission between rooms or from external sources. For applications requiring soundproofing, additional acoustic insulation materials may need to be incorporated alongside EPS insulation.

Read more: What Are Insulation Baffles

4. Environmental Considerations:

The production of EPS insulation involves the use of petroleum-based materials. While EPS foam itself is recyclable, the recycling process can be challenging due to the need for specialized facilities. End-of-life disposal of EPS insulation can pose environmental challenges, as improper disposal can lead to potential pollution or waste management issues. However, efforts are being made to improve the sustainability of EPS insulation through recycling initiatives and the development of bio-based alternatives.

5. Compression and Stability:

EPS insulation can experience compression over time, especially when subjected to heavy loads or pressure. This can impact its thermal performance as the air pockets within the foam cells can become compacted. To maintain its effectiveness, proper installation techniques and regular maintenance should be followed to ensure the insulation’s stability and structural integrity.

While EPS insulation has its limitations, many of these challenges can be addressed through proper installation techniques, regular inspection, and maintenance. It is important to consult with professionals or follow manufacturer guidelines to ensure the best use and longevity of EPS insulation in different applications.

Comparison with Other Types of Insulation

When considering insulation options for your home or building, it’s important to understand how EPS insulation compares to other types of insulation. Each insulation material has its own set of characteristics, advantages, and limitations. Here, we will compare EPS insulation with some commonly used insulation materials:

Fiberglass Insulation:

Fiberglass insulation is made from glass fibers and is one of the most commonly used insulation materials. It is known for its affordable price, availability, and ease of installation. Fiberglass insulation is effective in reducing heat transfer but has a lower R-value compared to EPS insulation. It can also be easily damaged by moisture and requires extra care during installation to prevent gaps or voids that can reduce its effectiveness.

Read more: What Is Bibs Insulation

Spray Foam Insulation:

Spray foam insulation is a type of polyurethane foam that is applied as a liquid and expands to fill the space. It provides excellent air sealing and can conform to irregular shapes and sizes. Spray foam insulation has a higher R-value than EPS insulation and provides superior thermal and air barrier properties. However, it is more expensive than EPS insulation and requires professional installation.

Cellulose Insulation:

Cellulose insulation is made from recycled paper fibers treated with fire retardants. It is a popular choice for those seeking an eco-friendly insulation option. Cellulose insulation has a moderate R-value and provides good thermal performance. However, it can be prone to settling over time, which can impact its effectiveness. It is also vulnerable to moisture absorption, which can lead to mold or deterioration if not properly installed or maintained.

Mineral Wool Insulation:

Mineral wool insulation is made from rock or slag fibers and is known for its fire-resistant properties. It has a higher R-value compared to EPS insulation and provides excellent soundproofing capabilities. Mineral wool insulation is durable, moisture-resistant, and can withstand high temperatures. However, it is heavier and more challenging to install compared to EPS insulation, requiring special equipment and expertise.

Polyisocyanurate (Polyiso) Insulation:

Polyisocyanurate insulation, commonly known as polyiso, is a high-performance insulation material. It has a high R-value per inch of thickness, providing excellent thermal resistance. Polyiso insulation offers good moisture resistance and can withstand temperature variations effectively. However, it is more expensive than EPS insulation and can be more difficult to install due to its rigidity and fragility.

When comparing insulation materials, factors such as cost, thermal performance, moisture resistance, ease of installation, and eco-friendliness should be considered. Every insulation material has its own strengths and weaknesses, and the choice ultimately depends on the specific requirements of the project and budget constraints.

Read more: What Is Insulation In A House

Installation and Maintenance of EPS Insulation

Proper installation and maintenance of EPS insulation are essential to ensure its effectiveness and longevity. Here are some key considerations for the installation and maintenance of EPS insulation:

Installation:

- Prepare the surface: Clean and prepare the surface where the EPS insulation will be installed. Ensure that the surface is free from dust, debris, and any other contaminants that may affect the adhesion of the insulation.

- Measure and cut: Measure the area accurately and cut the EPS insulation panels or blocks to fit the desired size and shape. Use appropriate tools, such as a utility knife or saw, to cut the insulation cleanly.

- Proper placement: Install the EPS insulation firmly against the surface, ensuring a snug fit. Secure the insulation using appropriate adhesive or mechanical fasteners, as recommended by the manufacturer. Pay attention to corners, edges, and joints to ensure proper insulation coverage.

- Sealing and covering: Use a suitable tape or sealant to seal any gaps or seams between the insulation panels to prevent air leakage. If necessary, cover the insulation with a protective layer, such as drywall or a vapor barrier, to enhance its durability and moisture resistance.

- Follow safety guidelines: When installing EPS insulation, follow safety guidelines, wear appropriate personal protective equipment (PPE), and ensure proper ventilation in enclosed spaces.

Maintenance:

- Regular inspection: Periodically inspect the EPS insulation for any signs of damage or deterioration. Look out for any moisture intrusion, pests, or physical damage that may impact its performance.

- Address any issues promptly: If any issues or damage are identified, take immediate action to repair or replace the damaged insulation. This ensures that the insulation continues to provide optimal thermal performance.

- Maintain ventilation: Ensure proper ventilation in the building to mitigate moisture buildup within the insulation. Good ventilation helps prevent condensation, mold growth, and potential damage to the insulation and surrounding areas.

- Avoid compressing the insulation: Avoid placing heavy objects or compressing the EPS insulation, as this can reduce its insulation properties. Educate occupants or workers about the importance of maintaining the integrity of the insulation.

- Follow manufacturer’s instructions: Always follow the manufacturer’s recommended maintenance guidelines for the specific EPS insulation product installed. This includes any specific cleaning or maintenance procedures to ensure optimal performance.

By following proper installation techniques and carrying out regular maintenance, EPS insulation can provide long-lasting thermal insulation for residential and commercial applications. Prioritizing installation quality and ongoing maintenance helps to maximize the benefits of EPS insulation and contribute to energy efficiency in buildings.

Environmental Impact of EPS Insulation

The environmental impact of EPS (Expanded Polystyrene) insulation is a topic of discussion and concern. While EPS insulation offers several advantages in terms of energy efficiency and thermal performance, it is important to consider its environmental implications. Let’s explore the environmental impact of EPS insulation:

Read more: What Is Heat Insulation

1. Manufacturing Process:

The production of EPS insulation involves the use of petroleum-based materials, which are derived from non-renewable sources. The manufacturing process requires energy and produces greenhouse gas emissions. However, advancements in manufacturing techniques have led to improved energy efficiency and reduced emissions associated with EPS production.

2. Recycling and Waste Management:

EPS insulation is recyclable, but the recycling process can be challenging due to its lightweight nature and the need for specialized facilities. However, efforts are being made to encourage EPS recycling and develop recycling technologies. Proper waste management practices should be followed to prevent EPS insulation from ending up in landfills, where it can take hundreds of years to decompose.

3. Environmental Performance:

EPS insulation contributes to energy efficiency by reducing heat transfer and lowering energy consumption for heating and cooling. This helps to minimize carbon emissions associated with energy production. Additionally, its long lifespan and durability can result in reduced material consumption and waste generation over time.

4. Environmental Solutions:

Various initiatives are being undertaken to address the environmental impact of EPS insulation. Some manufacturers are exploring the use of recycled or bio-based materials in the production of EPS, reducing reliance on petroleum derivatives. Additionally, efforts to improve recycling infrastructure and promote the use of recycled EPS can further reduce the environmental footprint of EPS insulation.

Read more: What Is Loft Insulation

5. Life Cycle Assessment:

A comprehensive life cycle assessment (LCA) can provide a holistic understanding of the environmental impact of EPS insulation. This assessment considers factors such as raw material extraction, production, transportation, installation, maintenance, and end-of-life disposal. It helps in identifying areas for improvement and making informed decisions about insulation choices.

It is essential to consider the overall energy savings and environmental benefits of using EPS insulation compared to its environmental impact. By considering energy efficiency gains, the recyclability of EPS insulation, and utilizing responsible waste management practices, the environmental impact can be mitigated.

As the construction industry continues to focus on sustainability and eco-friendly solutions, ongoing research and development in EPS insulation manufacturing, usage, and disposal methods pave the way for more environmentally friendly options.

Conclusion

EPS insulation, or Expanded Polystyrene insulation, provides an effective and versatile solution for thermal insulation in residential and commercial buildings. Its lightweight nature, excellent thermal performance, and durability make it a popular choice among builders, architects, and homeowners.

Throughout this article, we have explored various aspects of EPS insulation, including its definition, components, advantages, applications, challenges, and environmental impact. EPS insulation offers numerous benefits, such as exceptional thermal insulation, ease of installation, and resistance to moisture and pests.

Comparing EPS insulation with other types of insulation, it is clear that each material has its own unique characteristics and considerations. The choice of insulation depends on factors such as cost, thermal performance, environmental impact, and specific project requirements.

Proper installation and maintenance are crucial for the optimal performance of EPS insulation. Following recommended installation techniques, regular inspections, and addressing any issues promptly ensure that the insulation continues to deliver its thermal benefits effectively.

When considering the environmental impact of EPS insulation, it is important to recognize both its advantages and challenges. While EPS insulation is manufactured from petroleum-based materials and presents recycling challenges, it offers significant energy efficiency benefits, reduces carbon emissions, and can contribute to sustainable construction practices.

In conclusion, EPS insulation is a valuable solution for effective thermal insulation in buildings. Its energy-saving properties, ease of installation, and versatility make it a practical choice for improving energy efficiency and creating comfortable living and working environments. By considering the proper installation techniques, regular maintenance, and responsible waste management practices, the environmental impact of EPS insulation can be minimized. As the industry continues to innovate, efforts to enhance the sustainability and recyclability of EPS insulation are ongoing, ensuring a more eco-friendly future for insulation solutions.

Frequently Asked Questions about What Is EPS Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is EPS Insulation”