Articles

How Much Is An HVAC Compressor

Modified: January 6, 2024

Find out the cost of HVAC compressor replacement in our informative articles. Learn how to budget for this important home improvement expense.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Overview of HVAC Compressors

When it comes to heating, ventilation, and air conditioning (HVAC) systems, the compressor plays a crucial role in maintaining indoor comfort. It is responsible for circulating refrigerant throughout the system and compressing it to facilitate the heat exchange process. Understanding the importance and functioning of HVAC compressors can help homeowners and businesses make informed decisions about their HVAC systems.

At its core, an HVAC compressor is a mechanical device that pumps refrigerant between the evaporator coil and the condenser coil to transfer heat. As refrigerant flows through the system, it changes state from a low-pressure gas to a high-pressure liquid, releasing heat in the process. This allows the system to cool or heat the indoor air, depending on the desired temperature.

Considering the vital role that compressors play in HVAC systems, it is crucial to choose the right one for your specific needs. Factors such as brand reputation, capacity, efficiency, features, and warranty can significantly impact the performance and cost of an HVAC compressor.

Brand: The brand of the compressor can influence the pricing, as well as the quality and reliability of the unit. Established brands often have a higher price tag due to their reputation for durability and customer satisfaction.

Capacity: The size or capacity of the compressor is determined by the cooling/heating load requirement of the space. A larger space will require a higher capacity compressor to maintain the desired temperature efficiently.

Efficiency: The efficiency of an HVAC compressor is measured by its Seasonal Energy Efficiency Ratio (SEER) or Energy Efficiency Ratio (EER) ratings. Higher efficiency ratings indicate a more energy-efficient unit, which can result in significant energy savings over time.

Features: Compressors may come with additional features such as variable-speed operation, noise reduction technology, advanced control systems, and enhanced reliability features. Manufacturers often add these features to differentiate their products from competitors.

Warranty: Warranty coverage can provide peace of mind by protecting against unexpected repairs or malfunctions. Be sure to consider the length and coverage of the warranty when comparing compressor options.

It’s essential to understand the average cost of HVAC compressors to make an informed purchasing decision. Whether you are a residential homeowner or a commercial property owner, the cost will vary based on the size and requirements of the system.

Key Takeaways:

- Invest in an energy-efficient HVAC compressor to enjoy long-term energy savings, reduce your carbon footprint, and contribute to a sustainable future while taking advantage of energy efficiency incentives to offset the upfront cost.

- Thorough research, comparison, and negotiation can help you find the best value for your investment in an HVAC compressor, ensuring optimal performance, longevity, and energy efficiency.

Read more: What Is A HVAC Compressor

Introduction

Heating, ventilation, and air conditioning (HVAC) systems are essential for maintaining a comfortable indoor environment. HVAC compressors are one of the key components of these systems, responsible for the circulation and compression of refrigerant to facilitate heat exchange. Understanding the role and importance of HVAC compressors is crucial for homeowners and businesses seeking to optimize their HVAC systems.

The primary function of an HVAC compressor is to transfer heat by circulating refrigerant between the evaporator coil and the condenser coil. As the refrigerant flows through the system, it undergoes changes in pressure and temperature, allowing it to absorb heat from the indoor air in the cooling mode or release heat into the indoor air in the heating mode.

Without a properly functioning compressor, an HVAC system would not be able to effectively cool or heat the indoor air, resulting in discomfort and reduced energy efficiency. Therefore, selecting the right compressor is vital to ensure optimal performance and energy savings.

When it comes to purchasing an HVAC compressor, there are several factors to consider. Brand reputation, capacity, efficiency, features, and warranty are all essential aspects that can impact the overall cost and performance of the compressor. Choosing a reputable brand ensures a higher level of reliability and customer satisfaction, albeit at a potentially higher cost. Determining the capacity of the compressor is crucial, as it needs to align with the cooling or heating load requirements of the space. An undersized compressor will struggle to maintain the desired temperature, while an oversized compressor may result in energy inefficiency and increased wear and tear.

Efficiency is another critical factor to consider when selecting an HVAC compressor. Compressors with higher efficiency ratings, such as a high SEER (Seasonal Energy Efficiency Ratio) or EER (Energy Efficiency Ratio), can provide substantial energy savings over time. Additionally, compressors with advanced features like variable-speed operation, noise reduction technology, and enhanced control systems can offer improved performance and durability.

Finally, the warranty coverage of the compressor is essential for protecting against unexpected repairs or component failures. Long warranty periods and comprehensive coverage can provide peace of mind and potentially save on future repair costs.

In the following sections, we will delve deeper into the factors that affect HVAC compressor pricing, average costs for residential and commercial units, additional costs to consider, and valuable tips for saving money when purchasing an HVAC compressor.

Importance of HVAC Compressors

HVAC compressors play a crucial role in the functioning of heating, ventilation, and air conditioning systems. They are responsible for the circulation and compression of refrigerant, which allows for efficient heat exchange and temperature control. Without a properly functioning compressor, an HVAC system would not be able to cool or heat the indoor air effectively.

By compressing the refrigerant, the HVAC compressor increases its pressure and temperature, allowing it to release or absorb heat as needed. This process enables the system to cool the indoor air during hot weather or heat it during colder months, providing a comfortable environment all year round.

In addition to temperature control, HVAC compressors also contribute to energy efficiency. Compressors with higher efficiency ratings, such as those with a high SEER (Seasonal Energy Efficiency Ratio) or EER (Energy Efficiency Ratio), can significantly reduce energy consumption and lower utility bills. These efficient compressors are designed to operate with minimal energy wastage, resulting in cost savings for homeowners and businesses.

Factors Affecting HVAC Compressor Pricing

Several factors influence the pricing of HVAC compressors. Understanding these factors can help potential buyers make informed decisions and find the most suitable compressor for their needs:

Brand: The brand of the HVAC compressor can have a significant impact on its price. Established and reputable brands often produce high-quality compressors with reliable performance, leading to higher price points. However, opting for a well-known brand can provide peace of mind and greater longevity.

Capacity: The size or capacity of the compressor affects its price. Compressors with larger capacities are generally more expensive than smaller ones. It is crucial to choose a compressor that matches the cooling or heating load requirements of the space, as an undersized compressor will struggle to maintain the desired temperature, while an oversized compressor can waste energy.

Efficiency: Energy efficiency ratings, such as SEER or EER, can influence the price of an HVAC compressor. Compressors with higher efficiency ratings tend to be more expensive upfront but offer greater long-term energy savings. Investing in a higher efficiency compressor can result in reduced energy consumption and lower utility costs over the lifespan of the unit.

Features: The presence of additional features can impact the price of an HVAC compressor. These features may include variable-speed operation, noise reduction technology, advanced control systems, or enhanced durability features. While these features can improve performance and convenience, they may come at a higher cost.

Warranty: The warranty coverage provided by the manufacturer is another factor to consider when assessing the price of an HVAC compressor. Longer warranty periods and comprehensive coverage can provide added value and protection against unexpected repairs or failures, impacting the overall value of the compressor.

By considering these factors, buyers can evaluate and compare different compressor options to find the best fit for their specific budget and requirements.

Brand

When it comes to purchasing an HVAC compressor, the brand of the unit is an important consideration. The brand represents the manufacturer’s reputation and reliability, which can significantly impact the performance and longevity of the compressor.

Opting for a well-known and reputable brand can provide several advantages. Established brands have often been in the industry for many years and have garnered a reputation for producing high-quality and reliable HVAC equipment. They invest in research and development to improve their products and stay up to date with the latest industry standards and technologies.

One of the advantages of choosing a reputable brand is the assurance of product quality. Established brands have stringent quality control processes in place to ensure that their compressors meet and exceed industry standards. This means that you can expect a reliable and durable compressor that will perform optimally for years to come.

In addition to quality, reputable brands often have a wide network of authorized dealers and service providers. This ensures that if you require any maintenance, repairs, or warranty services, you will have access to trained professionals who are familiar with the brand and its products. Having access to authorized service providers can help expedite the resolution of any issues and minimize downtime.

Another benefit of choosing a well-known brand is the availability of replacement parts. Over time, HVAC compressors may require repair or replacement of certain components. Reputable brands typically have a robust supply chain and readily available spare parts, making it easier and more convenient to maintain and service the unit.

While reputable brands offer many advantages, it is worth noting that they often come with a higher price tag compared to lesser-known or generic brands. This higher cost can be attributed to the brand’s investment in research and development, quality assurance processes, and their commitment to customer satisfaction.

However, it is important to note that going for a lesser-known brand solely based on a lower price is not always the best option. Cheaper or generic brands may lack the same level of reliability, warranty coverage, and customer support that established brands provide. Investing in a reputable brand can save you money in the long run by ensuring a longer lifespan for your HVAC compressor and minimizing potential repairs or replacement costs.

When considering the brand of an HVAC compressor, it is recommended to research customer reviews and ratings, consult with HVAC professionals, and compare different options. By doing so, you can make an informed decision that aligns with your budget, needs, and expectations for performance and reliability.

Read more: How To Check HVAC Compressor

Capacity

The capacity of an HVAC compressor is a crucial factor to consider when choosing the right unit for your heating and cooling needs. The capacity refers to the cooling or heating load that the compressor can handle, and it is measured in British Thermal Units per hour (BTU/h).

Choosing the correct capacity compressor is essential in order to maintain a comfortable indoor environment efficiently. An undersized compressor will struggle to keep up with the demand, leading to inadequate cooling or heating and potential issues such as increased energy consumption, frequent cycling, and reduced system lifespan. On the other hand, an oversized compressor can result in short cycling, which leads to energy inefficiency, temperature fluctuations, and increased wear and tear on the system.

Determining the appropriate capacity for your HVAC compressor involves evaluating the size of the space you want to cool or heat, as well as other factors such as insulation, window sizes, and local climate conditions. An HVAC professional can perform a load calculation to calculate the precise capacity needed for your specific requirements.

Residential HVAC compressors typically range in capacity from 18,000 BTU/h to 60,000 BTU/h, depending on the size of the home. Smaller homes or individual rooms may only require a 1.5-ton (18,000 BTU/h) or 2-ton (24,000 BTU/h) compressor, while larger homes may necessitate a 3-ton (36,000 BTU/h) or 5-ton (60,000 BTU/h) unit.

Commercial HVAC compressors have higher capacities to handle the cooling or heating demands of larger spaces. The capacity of commercial units can range from 60,000 BTU/h to several hundred thousand BTU/h, with the exact capacity depending on factors such as building size, occupancy, usage, and specific requirements of the space.

It is important to note that selecting the appropriate capacity for your HVAC compressor is not a task to be undertaken lightly. Inaccurate sizing can lead to significant issues and inefficiencies in your HVAC system, which may result in increased energy costs and reduced comfort levels. It is advisable to consult with a qualified HVAC professional who can perform a proper load calculation and provide guidance on the ideal capacity for your specific needs.

By ensuring that your HVAC compressor is appropriately sized, you can enjoy optimal performance, energy efficiency, and indoor comfort. A well-matched compressor will operate more efficiently, resulting in lower energy consumption and reduced utility bills, while also effectively maintaining the desired temperature in your home or commercial space.

Efficiency

When selecting an HVAC compressor, it is essential to consider its efficiency. Efficiency refers to how effectively the compressor converts electrical energy into cooling or heating output. Higher efficiency compressors can significantly impact energy consumption, utility bills, and overall environmental sustainability.

The efficiency of an HVAC compressor is typically measured by two key ratings: the Seasonal Energy Efficiency Ratio (SEER) and the Energy Efficiency Ratio (EER). These ratings provide valuable information on how efficiently the compressor can cool or heat a space.

The SEER rating measures the cooling efficiency of an HVAC system over an entire cooling season. The higher the SEER rating, the more efficient the system. In many countries, including the United States, a minimum SEER rating is required for new HVAC installations. Higher SEER ratings often come with a higher price tag, but they can result in significant energy savings over time.

The EER rating, on the other hand, measures the cooling efficiency of an HVAC system at a specific outdoor temperature. It provides a snapshot of the system’s performance at a given moment. Higher EER ratings indicate better efficiency and can result in lower energy consumption.

Efficiency is crucial for reducing energy consumption and minimizing utility costs. High-efficiency compressors can keep cooling or heating demands in check without wasting excessive energy. They are designed to operate more efficiently, with features such as variable-speed operation, advanced heat exchange design, and improved control systems.

By opting for a high-efficiency compressor, you can not only reduce your carbon footprint but also enjoy long-term energy savings. Lower energy consumption directly translates into lower utility bills, which can make a significant difference over the lifespan of the compressor.

It is important to note that while high-efficiency compressors may come with a higher upfront cost, the long-term energy savings often outweigh the initial investment. Additionally, many governments and utility companies offer incentives, rebates, or tax credits for purchasing and installing energy-efficient HVAC equipment. These incentives can further offset the cost and provide additional financial benefits.

When considering the efficiency of an HVAC compressor, it is essential to balance the upfront cost with potential long-term savings. If you reside in a region with high energy costs and long cooling or heating seasons, investing in a high-efficiency compressor can prove to be a wise decision over time.

Consulting with a qualified HVAC professional and considering the SEER and EER ratings can assist you in making an informed decision about the efficiency of an HVAC compressor. By selecting a compressor with higher efficiency, you can enjoy comfortable indoor temperatures while minimizing energy waste and reducing your environmental impact.

Features

When considering an HVAC compressor for your heating and cooling needs, it is important to evaluate the features that come with the unit. Features can enhance the performance, convenience, and overall value of the compressor. While some features may be considered optional, others can significantly impact the functionality and efficiency of the system.

Here are some features commonly found in HVAC compressors:

Variable-Speed Operation: Compressors with variable-speed motors can adjust the speed at which they operate based on the cooling or heating demands of the space. This allows for more precise temperature control and can result in energy savings by operating at lower speeds when less cooling or heating is required.

Noise Reduction Technology: HVAC compressors can produce noise during operation. Compressors with noise reduction technology are designed to minimize noise levels, providing quieter operation. This can be particularly beneficial in residential settings or areas where noise restrictions exist.

Advanced Control Systems: Some compressors come equipped with advanced control systems that allow for enhanced functionality and customization. These systems may include programmable thermostats, Wi-Fi connectivity, and smartphone apps, enabling you to control and monitor the compressor remotely for increased convenience and energy management.

Enhanced Durability Features: Certain compressors are designed with added durability features to extend the lifespan and reliability of the unit. These features might include corrosion-resistant coatings, robust construction, or advanced protection against harsh weather conditions.

Smart Energy Management: Some compressors incorporate energy management features that optimize the operation of the system to reduce energy consumption without sacrificing comfort. These features can include intelligent temperature setbacks, adaptive control algorithms, and energy monitoring capabilities.

Advanced Diagnostic Capabilities: Compressors with advanced diagnostic features can provide valuable information about the system’s performance, efficiency, and any potential issues. This allows for proactive maintenance and troubleshooting, reducing downtime and potential repairs.

It is worth noting that while these features can enhance the performance and convenience of an HVAC compressor, they may also come at an additional cost. It is essential to evaluate the value these features provide in relation to your specific needs and budget.

When considering the features of an HVAC compressor, it is advisable to assess which features align with your requirements and preferences. Some features may be more important in certain situations, such as noise reduction technology for residential applications, while others may be more relevant for commercial settings, such as enhanced diagnostic capabilities for proactive maintenance.

Consulting with an HVAC professional can help determine which features are most beneficial for your specific needs and ensure that the chosen compressor maximizes efficiency, comfort, and overall system performance.

Warranty

When purchasing an HVAC compressor, it is essential to consider the warranty coverage provided by the manufacturer. The warranty offers protection against unexpected repairs or component failures, providing peace of mind and potentially saving you significant costs in the future.

Warranty coverage varies between manufacturers and specific compressor models. It is important to review the warranty terms and conditions to understand what is covered, the duration of coverage, and any limitations or exclusions. Here are some key aspects to consider:

Length of Warranty: The length of the warranty can vary, typically ranging from 5 to 10 years for residential compressors. Some manufacturers may offer longer warranty periods, especially for premium or high-efficiency models. Longer warranty coverage can provide greater protection and indicate the manufacturer’s confidence in the product’s quality and performance.

Parts and Labor Coverage: Warranty coverage may include both parts and labor or may only cover specific components. It is important to clarify what is included in the warranty coverage to understand potential out-of-pocket expenses for labor costs associated with repairs.

Conditions and Limitations: Warranties often have conditions and limitations that need to be adhered to. For example, regular maintenance may be required to maintain the warranty validity. Failure to meet these conditions can void the warranty coverage. Understanding any specific requirements or restrictions can help ensure that the warranty remains valid throughout the coverage period.

Transferability: Some warranties may be transferable to subsequent homeowners if you decide to sell your property. This can be an appealing feature, as it adds value to the property and provides assurance to the new owner.

Manufacturer Reputation: It is worth considering the reputation of the HVAC manufacturer in relation to warranty support and customer service. A reputable manufacturer with positive customer feedback is more likely to provide prompt and reliable warranty support, ensuring a smoother resolution in the event of any issues with the compressor.

Purchasing an HVAC compressor with a comprehensive warranty can offer peace of mind and protect against unexpected repair costs. Additionally, it is advisable to keep records of regular maintenance and adhere to the manufacturer’s recommended service schedules to maintain warranty eligibility.

Read more: How Much Is An Air Conditioning Compressor

Average Cost of HVAC Compressors

The cost of an HVAC compressor can vary depending on several factors, including the brand, capacity, efficiency, features, and warranty coverage. It is important to consider these factors when determining the overall cost of the compressor.

Residential HVAC compressors typically range in cost from $1,500 to $4,000, depending on the brand, capacity, and efficiency. Higher capacity and higher efficiency compressors tend to have a higher price tag. Premium or well-known brands may also command higher prices due to their reputation for quality and reliability.

Commercial HVAC compressors have a wider price range, with costs varying based on the capacity and specific requirements of the space. Commercial compressors can range from $3,000 to over $10,000, or even higher for larger and more complex systems.

It is essential to consider the long-term costs when evaluating the price of an HVAC compressor. Energy-efficient compressors with higher initial costs can provide significant savings in terms of reduced energy consumption and lower utility bills over the lifespan of the unit. Additionally, taking into account any potential energy efficiency incentives, rebates, or tax credits can help offset the upfront cost of the compressor.

When selecting an HVAC compressor, it is recommended to obtain multiple quotes from reputable contractors, compare prices, and consider the overall value in terms of performance, warranty coverage, and long-term energy savings. Working with a qualified HVAC professional can help ensure that you choose a compressor that meets your specific needs within your budget.

When considering the cost of an HVAC compressor, it’s important to factor in the size of the unit, the brand, and any additional features. Additionally, labor costs for installation should be included in your budget. Always get multiple quotes from reputable HVAC professionals to ensure you’re getting a fair price.

Residential Units

When it comes to residential HVAC compressors, the cost can vary depending on factors such as the brand, capacity, efficiency, features, and warranty coverage. Understanding the average cost of residential units can help homeowners make informed decisions when it comes to investing in HVAC systems. It is important to note that the prices mentioned here are estimates and can vary depending on specific factors.

The cost of residential HVAC compressors typically ranges from $1,500 to $4,000. However, the final price will depend on various factors, such as the size of the home, climate conditions, installation requirements, and any additional accessories or features.

Generally, smaller residential units with lower capacity, such as 1.5-ton (18,000 BTU/h) or 2-ton (24,000 BTU/h) compressors, tend to be more affordable. These compressors are suitable for smaller spaces and have a lower cooling or heating load requirement. Prices for these units can range from around $1,500 to $2,500, depending on brand, efficiency, and warranty coverage.

For larger homes or spaces with higher cooling or heating demands, larger capacity compressors are necessary. Compressors with capacities of 3 tons (36,000 BTU/h) or 5 tons (60,000 BTU/h) are commonly used in residential applications. Their prices can range from $2,500 to $4,000 or more, depending on the brand, efficiency rating, and additional features.

It is essential to consider the efficiency of the residential unit when evaluating the cost. High-efficiency compressors often come with a higher price tag but can provide significant energy savings over time. These units have higher SEER (Seasonal Energy Efficiency Ratio) or EER (Energy Efficiency Ratio) ratings, indicating their ability to operate more efficiently and reduce energy consumption. While a high-efficiency compressor may have a higher upfront cost, the long-term energy savings can make it a worthwhile investment.

It is also important to factor in the warranty coverage when assessing the cost of residential HVAC compressors. Longer warranty periods and comprehensive coverage can provide additional value and protection against unexpected repairs or component failures.

When purchasing a residential HVAC compressor, it is recommended to consult with an HVAC professional who can assess the specific requirements of your home and provide guidance on the most suitable unit within your budget. They can perform a load calculation to determine the appropriate capacity needed and help you choose a compressor with the right features and efficiency for optimal performance and long-term energy savings.

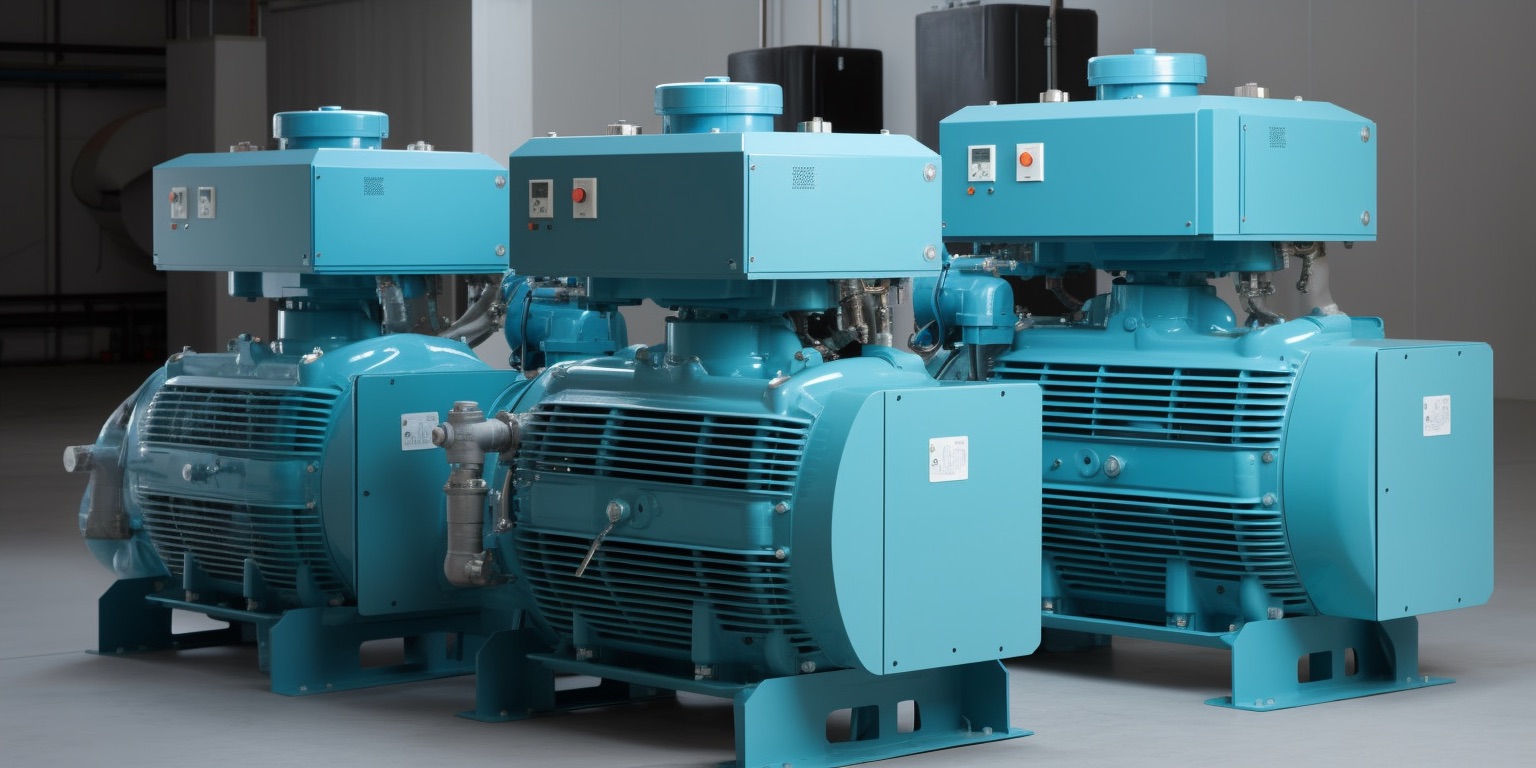

Commercial Units

Commercial HVAC systems are designed to meet the cooling and heating demands of larger spaces, such as office buildings, retail stores, warehouses, or industrial facilities. The cost of commercial HVAC compressors can vary significantly depending on factors such as brand, capacity, efficiency, features, and installation requirements. Understanding the average cost of commercial units can help businesses make informed decisions when it comes to investing in their HVAC systems. It is important to note that the prices mentioned here are estimates and can vary depending on specific factors.

The cost of commercial HVAC compressors typically ranges from $3,000 to over $10,000, depending on the capacity and specific requirements of the space. Larger commercial units with higher cooling or heating capacity will generally tend to have higher prices. The final cost will also depend on factors such as brand reputation, efficiency rating, warranty coverage, and any additional features or customization options.

For commercial applications, the range of available compressors is vast, covering a wide range of cooling and heating capacities. Capacities for commercial compressors can start from around 60,000 BTU/h and go up to several hundred thousand BTU/h, depending on the size and requirements of the space.

As with residential units, it is essential to consider the efficiency of commercial compressors when evaluating cost. High-efficiency compressors may have a higher upfront cost but can result in significant energy savings over time. These units often have higher SEER (Seasonal Energy Efficiency Ratio) or EER (Energy Efficiency Ratio) ratings, indicating their ability to operate more efficiently and reduce energy consumption.

In addition to the cost of the compressor, there are other factors to consider when calculating the overall cost of commercial HVAC systems. These include:

Installation Costs: The installation of commercial HVAC systems can be more complex compared to residential systems. It may require customization, additional components, ductwork, zoning systems, and professional installation services. The cost of installation can vary depending on the specific requirements of the space.

Maintenance Costs: Commercial HVAC systems require regular maintenance to ensure optimal performance and longevity. Maintenance costs may include filter replacements, cleaning, inspection, and ongoing professional maintenance services to keep the system running efficiently and prevent any potential breakdowns or issues.

Energy Efficiency Ratings: Considering energy efficiency ratings is crucial for commercial units, as they can have a significant impact on energy consumption and operating costs. Energy-efficient compressors may have a higher initial cost but can result in substantial long-term savings through reduced energy consumption and lower utility bills.

Longevity and Lifespan: Commercial HVAC compressors are designed to withstand heavy usage and operate for extended periods. It is important to consider the expected lifespan of the compressor when evaluating its cost. Quality brands with reliable performance may have a higher upfront cost but can provide better longevity and reduce the need for premature replacement or repairs.

When considering commercial HVAC compressors, it is recommended to consult with experienced HVAC professionals who specialize in commercial systems. They can assess the specific requirements of the space, provide accurate load calculations, and guide you in choosing the right compressor that meets the demands of your business while ensuring efficient and reliable operation.

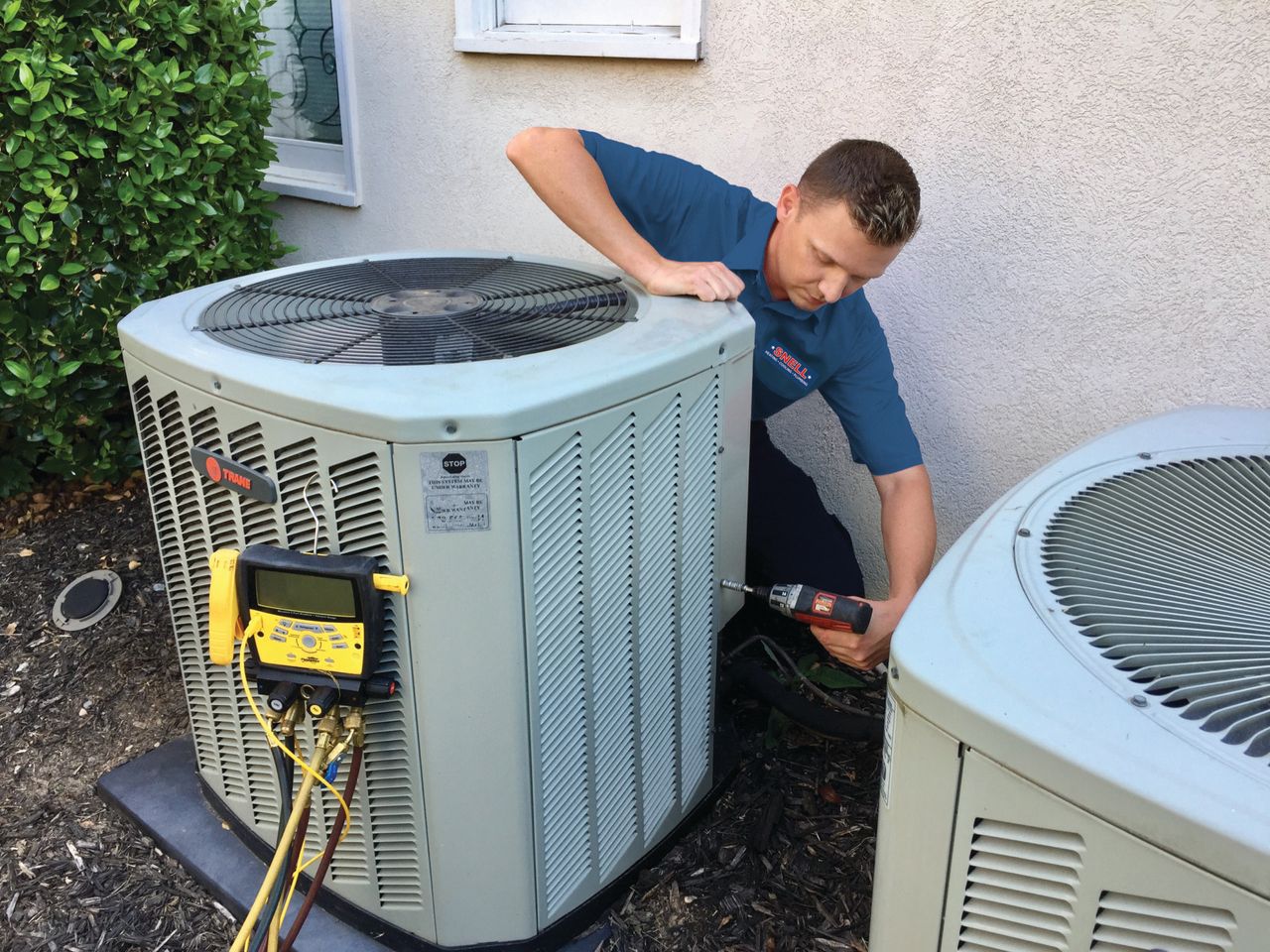

Installation Costs

When it comes to HVAC systems, installation plays a crucial role in ensuring optimal performance and efficiency. The installation of an HVAC compressor requires professional expertise to ensure proper sizing, placement, and connection to the existing system. It is important to consider installation costs when budgeting for a new HVAC compressor. The actual installation costs can vary depending on factors such as the complexity of the installation, the specific requirements of the space, and any additional components or customization needed.

In general, the installation costs for an HVAC compressor can range from several hundred dollars to several thousand dollars. This wide range depends on various factors, including:

System Type and Complexity: The type of HVAC system being installed can impact the installation costs. For example, installing a split system that incorporates both indoor and outdoor components may involve more complex installation procedures compared to a packaged system. Additionally, more complex systems with multiple zones, ductwork modifications, or additional components such as humidifiers or air filtration systems can lead to higher installation costs.

Ductwork Requirements: Assessing the ductwork is an important aspect of HVAC installation. The condition of existing ductwork and any necessary modifications, repairs, or replacements can influence installation costs. In some cases, the installation of a new compressor may require reconfiguring or extending the ductwork, which can add to the overall installation expenses.

Electrical Connections: An HVAC compressor requires proper electrical wiring to function effectively. The complexity of electrical connections, including any necessary upgrades or modifications to the electrical system, can impact the installation costs. It is important to ensure that the electrical connections are handled by a qualified electrician to comply with safety regulations and ensure proper operation of the compressor.

Permits and Local Codes: Depending on your location, obtaining permits and meeting local building codes may be required for HVAC system installations. Permit fees and compliance with code requirements can add to the overall installation costs. Working with a licensed HVAC professional ensures that the installation meets all necessary regulations and requirements and can help navigate the permit process.

Additional Components or Accessories: Installing additional components or accessories, such as thermostats, zone control systems, or air purifiers, can incur additional costs. These additions can enhance the functionality and efficiency of the HVAC system but need to be considered when budgeting for installation.

It is important to note that while installation costs can add to the overall expense of installing an HVAC compressor, professional installation is crucial for ensuring optimal performance and avoiding potential issues or safety hazards. Improper installation can lead to reduced efficiency, inadequate cooling or heating, increased energy consumption, and even system malfunctions.

When budgeting for an HVAC compressor installation, it is recommended to obtain multiple quotes from reputable contractors. These quotes should include a breakdown of the specific installation tasks, additional costs, and any necessary parts or permits. By comparing quotes and assessing the expertise and reputation of the contractors, you can make an informed decision while considering both the quality of installation and the overall costs involved.

Read more: What Is A Scroll Compressor For HVAC

Maintenance Costs

Maintenance is a crucial aspect of keeping an HVAC compressor in optimal condition, ensuring its efficiency, performance, and longevity. Regular maintenance not only helps prevent unexpected breakdowns but also enhances energy efficiency and reduces the overall operating costs. It is important to consider maintenance costs when budgeting for an HVAC compressor. The actual maintenance costs can vary depending on factors such as the type of maintenance required, the frequency of service, and any additional components or repairs needed.

The maintenance costs for HVAC compressors typically range from a few hundred dollars to several hundred dollars per year. However, it should be noted that the exact costs can vary depending on the specific needs of the compressor and the maintenance plan provided by the HVAC professional. Here are some aspects to consider regarding maintenance costs:

Regular Service Visits: Regular service visits involve routine maintenance tasks performed by HVAC professionals. These visits typically include activities such as inspecting the compressor, cleaning the coils, changing or cleaning air filters, lubricating moving parts, and checking refrigerant levels. The frequency of service visits can vary depending on factors such as system usage and manufacturer recommendations.

Seasonal Maintenance: Many HVAC systems benefit from seasonal maintenance, especially during the transition between cooling and heating seasons. These maintenance visits ensure that the compressor and the entire system are prepared for the upcoming season, optimizing performance and reducing the risk of issues.

Filter Replacements: Air filters play a significant role in maintaining air quality and system efficiency. Regularly replacing or cleaning air filters is essential to keep the HVAC compressor running smoothly. The cost of replacement filters can vary based on factors such as filter type, brand, and required frequency of replacement.

Repair Costs: While regular maintenance helps prevent major breakdowns, there may still be occasions when repairs are necessary. Repair costs can vary depending on the specific issue and the complexity of the repair required. It is important to address any repair needs promptly to prevent further damage and ensure the optimal performance of the compressor.

Additional Components or Parts: As the compressor ages, certain components or parts may require replacement or repair. This can include items such as fan blades, motors, capacitors, or electrical switches. The cost of these additional components should be considered when budgeting for maintenance.

It is worth noting that investing in regular maintenance can help prevent costly repairs or the need for premature replacement of the HVAC compressor. A well-maintained compressor operates more efficiently, reducing energy consumption and extending the unit’s lifespan.

When budgeting for maintenance costs, it is advisable to discuss maintenance plans and pricing with qualified HVAC professionals. They can provide guidance on the specific maintenance needs of your compressor, suggest appropriate service intervals, and offer maintenance plans tailored to your requirements. Choosing a comprehensive maintenance plan can help ensure that your HVAC compressor receives regular, professional care and can contribute to its longevity and efficient operation.

Energy Efficiency RatingsEnergy efficiency ratings are an important consideration when selecting an HVAC compressor. These ratings provide valuable information about how efficiently the compressor converts electrical energy into cooling or heating output. By choosing a compressor with a high energy efficiency rating, you can reduce energy consumption, lower utility bills, and decrease your environmental impact. Understanding energy efficiency ratings can help you make an informed decision when purchasing an HVAC compressor.

There are two main energy efficiency ratings to be aware of:

Seasonal Energy Efficiency Ratio (SEER): The SEER rating measures the cooling efficiency of an HVAC system over an entire cooling season. It represents the ratio of the cooling output (measured in British Thermal Units, or BTUs) to the energy input (measured in watt-hours). Higher SEER ratings indicate higher efficiency. In many countries, including the United States, there is a minimum SEER requirement for new HVAC installations. Depending on the region and regulatory requirements, the minimum SEER rating typically ranges from 13 to 16. However, high-efficiency models can have SEER ratings of 18 or higher.

Energy Efficiency Ratio (EER): The EER rating measures the cooling efficiency of an HVAC system at a specific outdoor temperature. It represents the ratio of the cooling output to the energy input, similar to the SEER rating. However, the EER rating is measured at a specific outdoor temperature, typically 95°F (35°C). This rating is useful for assessing the compressor’s performance under peak load conditions. Just like the SEER rating, higher EER ratings indicate higher efficiency.

The energy efficiency ratings provide a standardized way to evaluate the efficiency of HVAC compressors. However, it is important to note that these ratings are based on laboratory conditions and may not perfectly reflect real-world performance. Various factors such as climate, installation, ductwork, and overall system design can impact the actual efficiency of an HVAC system. Nonetheless, energy efficiency ratings offer a valuable benchmark for comparing different compressors.

Choosing a compressor with a higher energy efficiency rating can result in several benefits:

Energy Savings: Compressors with higher energy efficiency ratings consume less electricity to cool or heat a given space. This translates to lower energy consumption and reduced utility bills. The energy savings achieved by choosing a high-efficiency compressor can add up significantly over time.

Environmental Impact: Energy-efficient compressors help reduce greenhouse gas emissions associated with electricity generation. By consuming less energy, these compressors contribute to a smaller carbon footprint and environmental sustainability.

Long-Term Cost Savings: Although high-efficiency compressors may have a higher upfront cost, the energy savings they provide can result in long-term cost savings. The reduced energy consumption offsets the initial investment and can make the high-efficiency compressor a financially wise choice over the lifespan of the unit.

It is essential to note that energy efficiency incentives, rebates, or tax credits may be available in your region or from utility companies. These incentives can help offset the upfront cost of a high-efficiency compressor, making it a more cost-effective investment.

When considering the energy efficiency of an HVAC compressor, it is recommended to consult with HVAC professionals who can guide you towards the most efficient options. They can help you understand the energy efficiency ratings, assess your specific cooling or heating needs, and recommend compressors that balance efficiency, performance, and cost-effectiveness in line with your requirements.

Longevity and Lifespan

Considering the longevity and lifespan of an HVAC compressor is important when making a purchasing decision. The lifespan of a compressor can vary depending on factors such as brand, quality, maintenance, usage, and environmental conditions. Understanding the lifespan of an HVAC compressor can help you assess its value and factor in potential replacement costs over time.

On average, residential HVAC compressors have a lifespan of about 10 to 15 years. However, with proper maintenance and care, compressors can last even longer. Commercial HVAC compressors, which tend to be more durable due to their heavy-duty construction, can have a lifespan of 15 to 20 years or more.

To maximize the longevity of your HVAC compressor, consider the following:

Regular Maintenance: Routine maintenance is crucial for keeping the compressor in optimal condition. Regularly cleaning or changing air filters, inspecting and cleaning coils, lubricating moving parts, and checking refrigerant levels can help reduce wear and tear and prevent major breakdowns. Following the manufacturer’s recommended maintenance schedule and seeking professional maintenance services can extend the lifespan of the compressor.

Avoiding Overworking the Compressor: Excessive or constant use of the compressor can significantly impact its lifespan. Avoid setting the thermostat to extreme temperatures or running the system unnecessarily for extended periods. When possible, utilize energy-saving features and consider zoning options to enable better temperature control and reduce strain on the compressor.

Ensuring Proper Airflow: Proper airflow is essential for the efficient operation of the compressor. Ensure that the air ducts are clean, unobstructed, and properly sealed to allow for optimal airflow throughout the system. Restricted airflow can cause the compressor to work harder, leading to increased wear and tear.

Addressing Repairs Promptly: If you notice any issues or hear unusual sounds coming from the compressor, it is important to address them promptly. Ignoring or delaying necessary repairs can result in further damage and a shortened lifespan for the compressor. By promptly addressing repairs, you can prevent minor issues from escalating and avoid more costly repairs down the line.

Investing in Quality and Reputable Brands: Choosing a high-quality and reputable brand can contribute to the longevity of the compressor. Established brands often have a reputation for durability and reliability. While these brands may come with a higher upfront cost, their superior construction and components can result in a longer lifespan and reduced need for premature replacement.

Tips for Saving Money on HVAC Compressors

Purchasing an HVAC compressor can be a significant investment. However, there are several ways to save money without compromising on quality and performance. Consider the following tips:

Research and Comparison: Take the time to research different compressor brands, models, and features. Compare prices, energy efficiency ratings, warranty coverage, and customer reviews. By doing thorough research and making informed comparisons, you can find the best compressor that meets your needs and budget.

Negotiation: Don’t hesitate to negotiate the price with HVAC contractors or suppliers. They may be willing to offer discounts, especially during slower seasons or if you are purchasing additional services or products along with the compressor. Be prepared to negotiate and explore different options to secure a competitive price.

Energy Efficiency Incentives: Check for any energy efficiency incentives, rebates, or tax credits offered by local authorities or utility companies. These incentives can help offset the upfront cost of a high-efficiency compressor, making it a more cost-effective choice. Research and stay updated on available incentives and take advantage of them when making your purchase.

Proper Sizing: Ensure the compressor is correctly sized for your specific cooling or heating needs. An oversized compressor may cost more upfront and lead to increased energy consumption, while an undersized compressor may struggle to maintain the desired temperature efficiently. Proper sizing ensures optimal performance and can save you money in the long run.

Maintain Energy Efficiency: Once you have purchased and installed your HVAC compressor, focus on maintaining its energy efficiency. Regularly clean or replace air filters, seal air duct leaks, and schedule professional maintenance to ensure the compressor is operating at peak efficiency. By reducing energy waste, you can lower your utility bills and save money in the long term.

By considering these tips, you can make a cost-effective investment in an HVAC compressor while ensuring optimal performance, longevity, and energy efficiency.

Research and Comparison

When it comes to purchasing an HVAC compressor, conducting thorough research and making comparisons is essential. Investing time and effort into researching different compressor brands, models, and features can help you find the best fit for your needs and budget. By comparing various options, you can ensure that you make an informed decision and secure the best value for your investment.

Here are some key points to consider when conducting research and making comparisons:

Compressor Brands: Start by researching reputable compressor brands known for their quality, reliability, and customer satisfaction. Look into their track record, history, and reputation in the HVAC industry. Assessing customer reviews, forums, and ratings can provide insights into the experiences of other users.

Compressor Models: Within each brand, there might be multiple models available with varying features, capacities, and efficiencies. Compare the specifications, performance, and capabilities of different compressor models to see which ones align with your specific cooling or heating requirements.

Energy Efficiency Ratings: Pay attention to the energy efficiency ratings of the compressors you are considering. Look for high SEER (Seasonal Energy Efficiency Ratio) and EER (Energy Efficiency Ratio) ratings, as these indicate greater energy efficiency. Choosing a more efficient compressor can lead to energy savings and lower utility bills in the long run.

Warranty Coverage: Examine the warranty coverage provided by different compressor brands and models. Compare the length of the warranty, what it covers, and any limitations or exclusions. Longer warranty periods and comprehensive coverage can provide greater peace of mind and protect you against unexpected repair costs.

Price Comparison: Compare the prices of the compressors you are considering from different suppliers or contractors. Keep in mind that the price should not be the sole determining factor, as quality and performance also play vital roles. However, understanding the price range and assessing the overall value for your investment is important.

Additional Features: Take note of any additional features or benefits that different compressors offer. These can include energy-saving features, noise reduction technology, advanced control systems, or enhanced durability features. Consider which features are important to you and which ones align with your specific needs.

Reputable Contractors: Research and find reputable HVAC contractors who have experience with installing and servicing HVAC compressors. Look for certifications, licensing, and customer reviews to ensure that they can provide quality installation, maintenance, and support throughout the lifespan of the compressor.

By conducting thorough research and making informed comparisons, you can find an HVAC compressor that meets your needs, budget, and performance expectations. Taking the time to gather information and assess different options can lead to a more satisfying long-term investment and ensure that you receive the best value for your money.

Negotiation

When it comes to purchasing an HVAC compressor, negotiation can play a key role in getting the best price and value for your investment. By effectively negotiating with HVAC contractors or suppliers, you may be able to secure a more competitive price or obtain additional services or products along with the compressor. Here are some tips to help you navigate the negotiation process:

Do Your Research: Before entering into negotiations, make sure to do thorough research on the average market prices for HVAC compressors. This will give you an idea of the price range and help you determine a fair and reasonable target price. Researching different suppliers and their pricing can also provide you with leverage during negotiations.

Multiple Quotes: Obtain quotes from multiple HVAC contractors or suppliers. Having multiple quotes allows you to compare prices and services. It also gives you the advantage of negotiating by mentioning lower quotes received from other sources, encouraging the supplier to offer a more competitive price.

Know What You Want: Clearly define your requirements and expectations before entering into negotiations. Decide on the specific features, capacity, and efficiency rating you are looking for in an HVAC compressor. By knowing exactly what you want, you can effectively communicate your needs and negotiate accordingly.

Consider the Overall Value: Keep in mind that negotiation is not just about getting the lowest price; it’s also about maximizing overall value. Look for ways to negotiate additional services, such as installation, maintenance, or extended warranty coverage, as part of the package. Sometimes, suppliers may be willing to accommodate additional requests or provide discounts on bundled services.

Timing is Important: Consider the timing of your negotiations, as there may be specific periods or seasons when HVAC contractors are more willing to offer discounts or incentives. Contractor availability, slower business periods, or end-of-season promotions can work in your favor when negotiating a better price.

Be Polite and Professional: Approach negotiations with a polite and professional demeanor. Maintain a respectful tone and focus on finding a mutually beneficial agreement. Building a positive rapport with the supplier or contractor can improve your chances of getting a better deal.

Flexibility: In negotiations, be open to finding middle ground or alternative solutions. Sometimes, suppliers may not be able to meet your exact price expectations, but they may be able to offer other concessions or additional services that enhance the value of the deal. Flexibility can lead to a win-win outcome for both parties.

Negotiating the price of an HVAC compressor requires communication, research, and a willingness to find common ground. By leveraging your knowledge, considering the overall value, and maintaining a positive and flexible attitude, you can increase the chances of securing a better deal that meets your budget and requirements.

Energy Efficiency Incentives

Energy efficiency incentives are valuable tools that can help offset the upfront cost of an energy-efficient HVAC compressor while promoting sustainability and conservation efforts. Many governments, utility companies, and environmental organizations offer various incentives, rebates, or tax credits to encourage individuals and businesses to invest in energy-efficient HVAC systems. Understanding and taking advantage of these incentives can make a significant difference in your purchasing decision. Here are some key points to consider:

Financial Savings: Energy efficiency incentives provide financial savings by reducing the initial investment required for an energy-efficient HVAC compressor. These incentives can come in the form of cash rebates, tax credits, or subsidized installation programs. By reducing the upfront cost, you can achieve a faster return on investment and enjoy the long-term energy savings provided by an efficient compressor.

Promoting Sustainability: Energy-efficient HVAC systems help reduce greenhouse gas emissions and minimize the strain on natural resources. Governments and utility companies recognize the importance of promoting sustainable practices and offer incentives to encourage the adoption of energy-efficient technology. By taking advantage of these incentives, you contribute to a greener and more sustainable future.

Environmental Stewardship: Using energy-efficient HVAC compressors helps reduce your carbon footprint and environmental impact. By participating in energy efficiency incentive programs, you demonstrate your commitment to environmental stewardship and sustainability. You become a part of a collective effort to conserve energy and protect the planet for future generations.

Energy Savings: Energy-efficient HVAC compressors consume less electricity to deliver the same level of cooling or heating compared to less efficient models. Taking advantage of energy efficiency incentives allows you to enjoy long-term energy savings by reducing your utility bills. The savings can help offset the initial investment and result in significant cost reductions over the lifespan of the compressor.

Unleashing Market Demand: Energy efficiency incentives stimulate market demand for energy-efficient HVAC systems. As more individuals and businesses take advantage of these incentives, the demand for energy-efficient technology increases. This, in turn, drives innovation, leading to more advanced and efficient products becoming available in the market.

Conclusion

Investing in an energy-efficient HVAC compressor is a smart decision, both financially and environmentally. Energy efficiency incentives provide an opportunity to reduce the upfront cost and accelerate the adoption of energy-efficient technology. By taking advantage of these incentives, you contribute to sustainability efforts, enjoy long-term energy savings, and become a part of a global movement towards a greener future. Additionally, by conducting thorough research, evaluating different options, and considering factors such as brand reputation, capacity, efficiency, and warranty coverage, you can select the ideal HVAC compressor that meets your needs and budget. Consultation with qualified HVAC professionals can also provide valuable insights and ensure a successful installation. With the right choice and proper maintenance, your energy-efficient HVAC compressor can contribute to a comfortable indoor environment while saving energy and reducing your environmental impact.

Frequently Asked Questions about How Much Is An HVAC Compressor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Is An HVAC Compressor”