Articles

How Much Does HVAC Ductwork Cost

Modified: January 8, 2024

Find out the average cost of HVAC ductwork installation and repairs in our informative articles. Get the information you need to plan your project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on the cost of HVAC ductwork. If you’re considering installing or replacing ductwork in your home or commercial space, it’s important to understand the factors that affect the cost and the different types of ductwork available. HVAC ductwork plays a crucial role in distributing heated or cooled air throughout a building, ensuring optimal comfort and air quality.

The cost of HVAC ductwork can vary depending on several factors, including the size of the space, the complexity of the duct design, the type of material used, and the labor involved. In this article, we will explore the different factors that can influence the cost of HVAC ductwork installation or replacement, as well as provide you with an overview of the various types of ductwork available in the market.

Whether you’re a homeowner looking to upgrade your existing ductwork, or a contractor seeking to understand the cost breakdown for a new construction project, this guide will equip you with the knowledge you need.

In the following sections, we will delve into the factors that affect HVAC ductwork cost, explore the different types of ductwork, discuss material options and costs, and provide insight into installation, maintenance, and repair expenses. By the end of this guide, you’ll have a clear understanding of the overall cost considerations associated with HVAC ductwork.

Remember, proper installation and maintenance of ductwork are crucial to ensure the efficient operation of your HVAC system. Neglecting this vital component can result in poor air circulation, increased energy consumption, and reduced comfort levels. Therefore, investing in high-quality ductwork and hiring experienced professionals for installation and maintenance is essential for long-term performance and cost-effectiveness.

Now, let’s dive deeper into the factors that can impact the cost of HVAC ductwork.

Key Takeaways:

- Proper installation and maintenance of HVAC ductwork are crucial for efficient operation, energy savings, and comfort. Investing in high-quality materials and professional installation can lead to long-term cost-effectiveness.

- The cost of HVAC ductwork varies based on factors like space size, material type, and labor. Understanding these factors and considering maintenance and repair costs is essential for informed decision-making.

Factors Affecting HVAC Ductwork Cost

The cost of HVAC ductwork can vary based on several factors that influence the complexity and scope of the installation. Understanding these factors will help you estimate the overall cost and make informed decisions. Here are the key factors that affect the cost of HVAC ductwork:

- Size and Layout of Space: The size and layout of the building or room where the ductwork will be installed play a significant role in determining the cost. Larger spaces with multiple levels or complex layouts may require more ductwork and additional labor, leading to higher costs.

- Number of Vents and Returns: The number of vents, also known as supply registers, and returns, which pull air back into the HVAC system, affects the cost of ductwork. The more vents and returns required, the more materials and labor will be needed, resulting in higher costs.

- Accessibility: The accessibility of the space where the ductwork will be installed can impact the cost. If the area is difficult to access or requires special equipment or tools for installation, it may add to the overall cost of labor and materials.

- Ductwork Design Complexity: The complexity of the ductwork design can influence the cost. Simple straight-line designs are generally more cost-effective compared to intricate designs with bends, angles, or custom configurations that require additional fabrication and installation time.

- Insulation Requirements: Insulating the ductwork is essential for energy efficiency and preventing condensation. If your project requires insulated ductwork, the cost will be higher compared to uninsulated ductwork. The type and thickness of insulation chosen will also affect the overall price.

- Quality of Ductwork Material: The material used for the ductwork also affects the cost. There are various options available, including sheet metal, fiberglass, flexible ducts, and plastic. Each material has its own benefits and price point, with sheet metal being the most durable and expensive option.

- Local Labor and Material Costs: The cost of HVAC ductwork can also be influenced by regional variations in labor and material prices. Factors like availability of skilled labor, market competition, and local building codes can impact the overall cost of the project.

It’s important to note that while cost is a significant consideration, it’s equally crucial to prioritize quality and efficiency when it comes to HVAC ductwork. Investing in high-quality materials and professional installation can save you money in the long run by ensuring optimal performance, energy efficiency, and longevity of your HVAC system.

Next, let’s explore the different types of HVAC ductwork available in the market.

Types of HVAC Ductwork

When it comes to HVAC ductwork, there are several types to choose from, each with its own benefits and considerations. The type of ductwork you select will depend on factors such as cost, space constraints, installation requirements, and personal preferences. Here are the most common types of HVAC ductwork:

- Sheet Metal Ducts: Sheet metal ducts are the most common type of ductwork and have been used for decades. They are made from galvanized steel or aluminum sheets that are cut, formed, and assembled to create ducts of various shapes and sizes. Sheet metal ducts provide excellent durability, fire resistance, and the ability to handle high air pressures. However, they can be more expensive and require professional fabrication and installation.

- Fiberglass Duct Board: Fiberglass duct board is a lightweight and pre-insulated type of ductwork made from compressed fiberglass layers. It is easy to handle and can be shaped and cut on-site to fit the required dimensions. Fiberglass duct board is a cost-effective option and provides good insulation and sound absorption. However, it is more prone to damage and may require additional sealing to prevent air leaks.

- Flexible Ducts: Flexible ducts, also known as flex ducts, are made of a wire coil covered with a plastic or metalized film. They are often used in situations where rigid ductwork is not feasible due to space constraints or the need for flexibility. Flexible ducts can be easily bent and routed around obstacles, making installation more convenient. However, they have a higher chance of airflow restrictions if not installed properly and may need additional support to maintain their shape and prevent sagging.

- Plastic Ducts: Plastic ducts, typically made from PVC or high-density polyethylene (HDPE), are becoming increasingly popular due to their affordability and corrosion resistance. Plastic ducts are lightweight, easy to install, and require minimal maintenance. They are commonly used in applications that involve moisture or chemical exposure. However, plastic ducts may have limitations in high-temperature environments and may not be suitable for all HVAC systems.

- Fabric Ducts: Fabric ducts, also known as textile ducts or air socks, are an alternative to traditional metal ductwork. They are constructed from permeable fabric materials and distribute air through hundreds of small holes along their length. Fabric ducts offer advantages such as even air distribution, low pressure losses, and ease of installation and maintenance. They are commonly used in commercial and industrial settings, such as warehouses and gymnasiums.

Each type of ductwork has its own advantages and limitations, so it’s essential to consider your specific requirements and consult with HVAC professionals to determine the best option for your project.

Now that we have explored the types of HVAC ductwork available, let’s move on to discussing the material options and costs associated with ductwork.

Material Options and Costs

When it comes to HVAC ductwork, there are various materials to choose from, each with its own cost and performance factors. The material you select for your ductwork will depend on factors such as budget, desired durability, insulation requirements, and aesthetic preferences. Here are the most common material options for HVAC ductwork and their associated costs:

- Sheet Metal: Sheet metal, typically galvanized steel or aluminum, is a durable and long-lasting option for ductwork. It provides excellent strength and can handle high air pressures. The cost of sheet metal ductwork can vary based on the thickness of the metal and the complexity of the fabrication. On average, sheet metal ductwork can range from $9 to $17 per linear foot.

- Fiberglass Duct Board: Fiberglass duct board is a cost-effective option that offers good insulation properties. It consists of compressed layers of fiberglass and is available in pre-cut or custom sizes. The cost of fiberglass duct board is typically lower compared to sheet metal ductwork and can range from $4 to $8 per square foot.

- Flexible Ducts: Flexible ducts are a convenient and economical option for ductwork installations that require flexibility. They are made of a wire coil covered with a plastic or metalized film. The cost of flexible ductwork is generally lower compared to other materials and can range from $1 to $5 per linear foot.

- Plastic Ducts: Plastic ducts, such as PVC or HDPE, are lightweight, corrosion-resistant, and easy to install. They are an affordable option for ductwork, and the cost can range from $2 to $6 per linear foot.

- Fabric Ducts: Fabric ducts offer a unique alternative to traditional ductwork, with advantages such as even air distribution and low pressure losses. The cost of fabric ductwork varies depending on factors such as the fabric material, length of the duct, and additional accessories. On average, fabric ductwork can range from $7 to $15 per linear foot.

It’s important to note that these are general price ranges, and the actual cost of ductwork materials can vary based on factors such as regional availability, quantity discounts, and the specific requirements of the project. Additionally, the installation and labor costs should also be factored into the overall budget for HVAC ductwork.

Now that we have discussed the material options and costs, let’s move on to understanding the installation cost of HVAC ductwork.

When budgeting for HVAC ductwork, consider factors such as the size of the space, the type of duct material, and the complexity of the installation. Get multiple quotes from reputable contractors to ensure you’re getting a fair price.

Ductwork Installation Cost

The installation cost of HVAC ductwork will depend on various factors, including the size of the space, the complexity of the duct design, the type of material used, and the labor involved. It’s important to note that the installation process requires the expertise of HVAC professionals to ensure proper functioning and efficiency. Here is an overview of the factors that can influence the overall cost of ductwork installation:

- Size and Layout of Space: The size and layout of the space where the ductwork will be installed will impact the installation cost. Larger spaces or spaces with multiple levels and complex layouts will require more ductwork and may involve additional labor, resulting in higher installation costs.

- Material Selection: The type of material selected for the ductwork will affect the installation cost. Some materials, such as sheet metal, may require more labor-intensive fabrication and installation processes, which can contribute to higher installation costs compared to other materials like flexible ducts.

- Complexity of Duct Design: The complexity of the ductwork design can also influence the installation cost. Designs with intricate configurations, bends, or custom fabrication requirements may require additional time and expertise, resulting in higher labor costs.

- Insulation Requirements: If insulation is required for the ductwork, it will add to the installation cost. Insulating the ducts helps improve energy efficiency and reduce heat loss or gain, but it involves additional material and labor expenses.

- Labor Charges: The labor charges for ductwork installation can vary depending on factors such as the region, the experience of the HVAC contractor, and the complexity of the installation. It’s important to obtain multiple quotes from reputable contractors to compare prices and choose the best option.

- Additional Components: The installation cost may also include the installation of additional components such as dampers, grilles, registers, and zone control systems. These components help regulate airflow and temperature and may add to the overall installation cost.

On average, the installation cost of HVAC ductwork can range from $6 to $15 per linear foot. However, it’s important to note that this is an estimate, and the actual installation cost may vary based on the factors mentioned above. Requesting quotes from HVAC professionals and discussing your specific requirements can help you get a more accurate cost estimation.

It’s crucial to invest in professional installation to ensure that the ductwork is properly sized, sealed, and connected to the HVAC system. Proper installation not only ensures optimal performance but also minimizes the risk of air leaks, energy loss, and compromised indoor air quality.

Now that we have covered the installation costs, let’s move on to discussing additional costs to consider in relation to HVAC ductwork.

Read more: How Much Does An HVAC Inspection Cost

Additional Costs to Consider

When budgeting for HVAC ductwork, there are several additional costs to consider beyond the installation itself. These costs may arise during the planning, construction, and maintenance phases of the project. Understanding these potential expenses will help you plan your budget effectively. Here are some additional costs to consider:

- Design and Consulting Fees: If you require custom ductwork design or need the assistance of an HVAC consultant, there may be additional fees associated with their services. These professionals can provide expert advice, conduct load calculations, and ensure that the ductwork meets your specific requirements.

- Permits and Inspections: Depending on your jurisdiction, you may need to obtain permits and schedule inspections for your ductwork installation. These administrative costs vary and should be factored into your budget.

- Demolition or Removal Costs: In cases where existing ductwork needs to be removed or demolished before installing new ducts, there may be additional costs associated with the demolition work, including labor and disposal fees.

- Zone Control Systems: Zone control systems allow you to divide your space into different temperature zones, providing better control over heating and cooling. If you choose to install a zone control system, there will be additional costs for the equipment, controls, and installation.

- Duct Cleaning and Maintenance: Regular duct cleaning and maintenance are essential for ensuring the efficiency and longevity of your HVAC system. Consider the costs associated with professional duct cleaning and periodic maintenance to preserve optimal performance and air quality.

- Noise Reduction Measures: If noise reduction is a concern, especially for commercial spaces, additional costs may be incurred to implement noise reduction measures such as acoustic lining or vibration control devices.

- Upgrades and Customization: If you have specific customization requirements or wish to upgrade certain components of your ductwork, such as adding air purifiers or smart thermostats, these additions will contribute to the overall cost.

It’s important to consult with HVAC professionals and factor in these additional costs when planning your budget for HVAC ductwork. Obtaining multiple quotes from reputable contractors will help you compare prices and ensure that all potential expenses are considered.

Now that we have discussed the additional costs to consider, let’s move on to understanding the maintenance and repair costs associated with HVAC ductwork.

Maintenance and Repair Costs

Maintaining and repairing your HVAC ductwork is essential for the longevity and efficiency of your system. Regular maintenance helps prevent issues and ensures optimal performance, while repairs address any problems that may arise. Here are some maintenance and repair costs to consider:

- Regular Maintenance: Regular maintenance, such as duct cleaning, filter replacement, and system inspections, should be performed to keep your ductwork in good condition. The cost of maintenance will depend on factors such as the size of the system, the complexity of the ductwork, and the extent of the maintenance required. On average, the cost of professional duct cleaning can range from $300 to $500, depending on the size of the system.

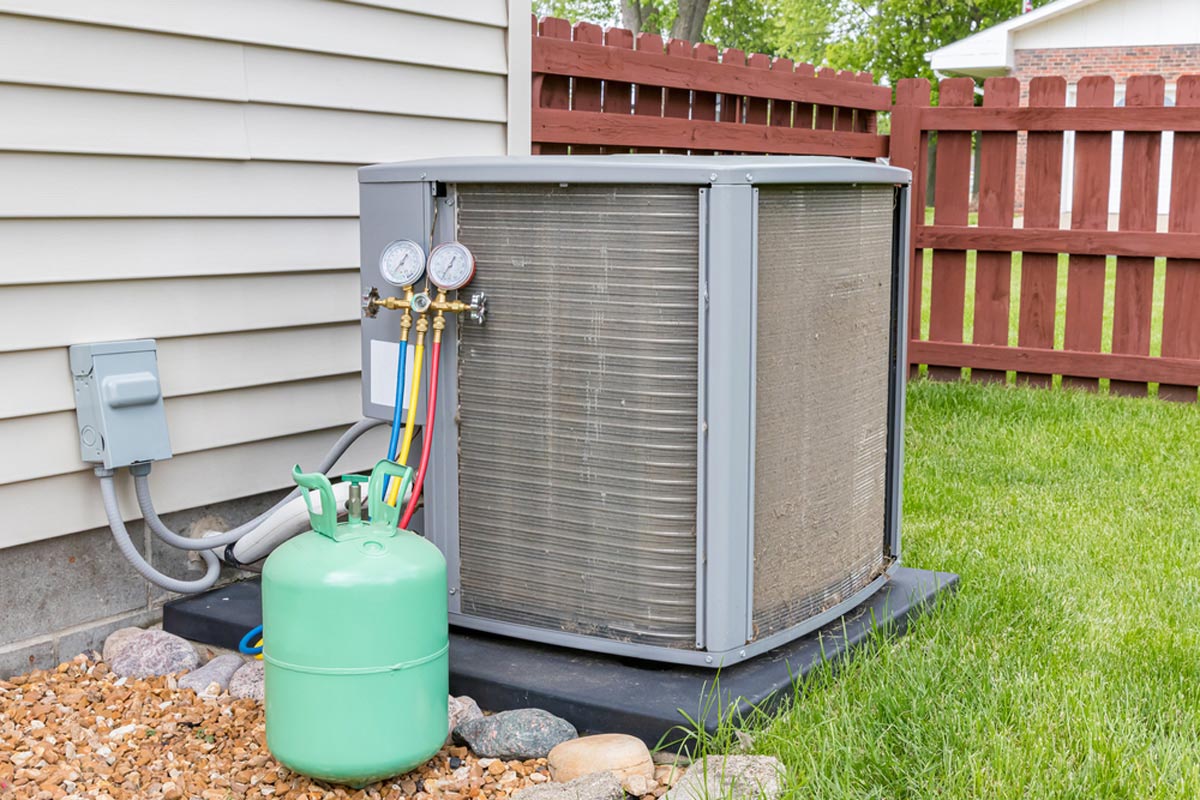

- Sealing and Insulation Repair: Over time, ductwork can develop leaks or insulation damage, affecting its efficiency. Repairing and sealing these leaks and replacing damaged insulation are essential to prevent energy loss and maintain proper airflow. The cost of sealing and insulation repair will vary depending on the extent of the damage and the size of the ductwork.

- Ductwork Replacement: In some cases, ductwork may need to be replaced due to extensive damage, corrosion, or age. The cost of ductwork replacement will depend on factors such as the size of the system, the material chosen, and the complexity of the installation. On average, the cost of ductwork replacement can range from $1,000 to $5,000 or more, depending on the scope of the project.

- Airflow Balancing: If you experience uneven airflow or hot and cold spots in your space, airflow balancing may be necessary. This involves adjusting dampers or registers to ensure proper airflow distribution. The cost of airflow balancing will depend on the complexity of the system and the time required for the HVAC technician to complete the task.

- Emergency Repairs: In the event of a ductwork failure or major issue, emergency repairs may be required. Emergency repair costs can vary significantly depending on the nature of the problem, the accessibility of the ductwork, and the time of the service call. It’s important to have a contingency plan and allocate funds for emergency repairs.

It’s recommended to schedule regular maintenance with trusted HVAC professionals to catch potential issues early and ensure the longevity of your ductwork. Keeping your ductwork in good condition will also contribute to energy efficiency, indoor air quality, and overall system performance.

Now that we have covered maintenance and repair costs, let’s wrap up our guide on the cost of HVAC ductwork.

Conclusion

In conclusion, the cost of HVAC ductwork can vary based on several factors, including the size and layout of the space, the complexity of the design, the type of material used, and the labor involved. Understanding these factors is crucial for estimating the overall cost and making informed decisions for your project.

When it comes to HVAC ductwork, there are various types to choose from, including sheet metal, fiberglass duct board, flexible ducts, plastic ducts, and fabric ducts. The material selection should be based on factors such as budget, durability, insulation requirements, and personal preferences.

In terms of costs, sheet metal ductwork tends to be the most expensive option, while flexible ducts and fiberglass duct board are more affordable. Plastic ducts and fabric ducts also offer cost-effective alternatives with their specific benefits and limitations.

It’s important to budget not only for the installation of the ductwork but also for additional costs such as design and consulting fees, permits and inspections, demolition or removal costs, zone control systems, and ongoing maintenance and repair expenses.

Maintaining and repairing your ductwork is essential for optimal performance and energy efficiency. Regular maintenance, including duct cleaning and filter replacement, will help prevent issues and ensure proper airflow. Repairing any leaks or insulation damage and addressing airflow imbalances are also important for maintaining efficiency and comfort levels.

Remember, investing in high-quality ductwork materials, professional installation, regular maintenance, and timely repairs will contribute to the longevity and efficiency of your HVAC system. It’s crucial to work with reputable HVAC professionals who can provide expert advice, perform proper installations, and address any maintenance or repair needs.

We hope that this comprehensive guide has provided you with valuable insights into the factors that affect the cost of HVAC ductwork. By understanding these factors and considering your specific requirements, you can make informed decisions and ensure the successful installation and performance of your HVAC ductwork.

If you have any further questions or need assistance with your HVAC project, don’t hesitate to reach out to experienced HVAC professionals in your area.

Frequently Asked Questions about How Much Does HVAC Ductwork Cost

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Does HVAC Ductwork Cost”