Articles

How To Store Acid

Modified: December 7, 2023

Learn the proper methods on how to safely store acid in your home or workplace with these informative articles. Protect yourself and others from potential hazards.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to storing acid, whether it’s for laboratory use, industrial purposes, or even household cleaning, safety should be your top priority. Proper acid storage is essential to prevent accidents, ensure the longevity of the acid, and protect the environment. In this article, we will explore the importance of acid storage, safety precautions to take, choosing the right storage location, types of acid storage containers, labeling and documentation requirements, proper handling and transportation, regular maintenance, and emergency preparedness.

Acids can be corrosive, toxic, and pose serious health risks if mishandled or stored improperly. Whether it’s sulfuric acid, hydrochloric acid, or any other type of acid, it’s crucial to follow the necessary precautions to avoid accidents and maintain a safe environment.

In the following sections, we will provide in-depth information and guidelines on how to safely store acid, ensuring the well-being of yourself, others, and the environment. By adhering to these recommendations, you can minimize the risks associated with acid storage and handle it in a responsible and efficient manner.

Key Takeaways:

- Safety First

Proper acid storage is crucial for safety. Follow safety precautions, choose the right storage location, use appropriate containers, and maintain emergency preparedness to minimize risks and ensure compliance. - Diligent Maintenance

Regular maintenance and inspections are essential for the integrity of acid storage. Proper labeling, documentation, handling, and transportation are key to ensuring a safe working environment and minimizing potential hazards.

Read more: How To Store Muriatic Acid

Understanding Acid Storage

Before diving into the specifics of acid storage, it’s important to have a clear understanding of the nature of acids and how they can react with different materials. Acids are corrosive substances that can cause damage to living tissue, metals, and other materials. They can release toxic fumes, cause chemical burns, and even explode under certain conditions.

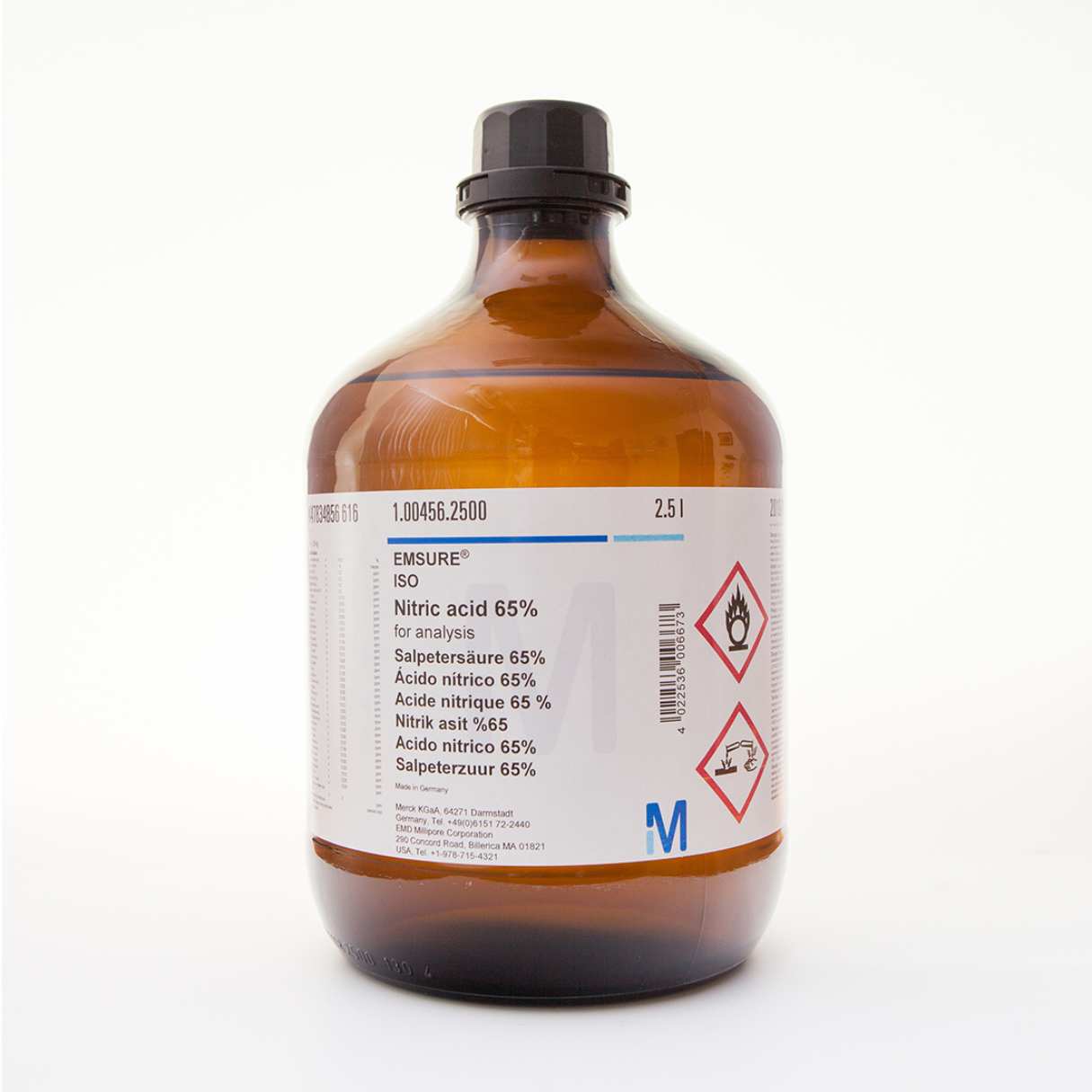

Acids are typically stored in liquid form, although there are some types that are stored in solid or gas form. The most common types of acids include sulfuric acid, hydrochloric acid, nitric acid, and acetic acid. Each type of acid has its own unique properties and requires specific precautions for safe storage.

Acid storage is essential for preventing leaks, spills, and contact with incompatible materials. When acids come into contact with substances such as bases, metals, or oxidizing agents, chemical reactions can occur, leading to hazardous situations. Therefore, storing acids in a controlled and safe environment is vital to minimize the potential risks.

Acid storage areas should be well-ventilated, away from extreme temperatures and direct sunlight, and free from any potential sources of ignition. Additionally, it is crucial to have proper containment measures in place to prevent leaks and spills from spreading and to facilitate easy cleanup.

Understanding the properties and potential hazards of the specific acid you are storing is also crucial. Different types of acids have varying levels of corrosiveness, toxicity, and reactivity. It is important to consult the material safety data sheet (MSDS) for the specific acid in question to understand its unique storage requirements and any special considerations.

In the next section, we will discuss the safety precautions that should be followed when storing acids to ensure the well-being of everyone involved.

Safety Precautions

When it comes to storing acids, safety should always be a top priority. Follow these essential safety precautions to minimize the risk of accidents and ensure the well-being of yourself and others:

- Wear appropriate personal protective equipment (PPE) when handling acids. This may include gloves, safety goggles, lab coats, and respiratory protection if necessary.

- Ensure that the storage area is well-ventilated to prevent the accumulation of fumes. If needed, use fume hoods or ventilation systems to remove any toxic fumes.

- Store acids in a dedicated storage room or cabinet that is separate from other chemicals. This will help prevent cross-contamination and reduce the risk of accidental spills or reactions.

- Keep all acid containers tightly sealed when not in use. This will prevent the release of fumes and minimize the risk of spills.

- Use secondary containment measures such as spill trays or containment basins to contain any potential leaks or spills. This will make cleanup easier and prevent the spread of hazardous materials.

- Avoid storing acids near heat sources, open flames, or electrical equipment. Acids can react violently with heat or ignition sources.

- Make sure to properly secure acid containers to prevent them from falling or being knocked over. This will reduce the risk of spills and breakage.

- Regularly inspect storage areas for any signs of leaks, corrosion, or damage. If any issues are identified, take immediate action to address them and replace damaged containers if necessary.

- Train all personnel on proper handling and storage procedures for acids. Knowledge of the specific hazards associated with the acids being stored is essential for safe handling.

- Have a well-planned and documented emergency response plan in place, including procedures for handling spills, leaks, or other accidents. Ensure that all personnel are aware of the plan and know how to respond in case of an emergency.

By following these safety precautions, you can significantly reduce the risk of accidents and ensure the safe storage of acids. It’s important to remember that specific safety requirements may vary depending on the type of acid being stored, so it’s crucial to refer to the MSDS and any applicable regulations or guidelines.

In the next section, we will discuss the importance of choosing the right storage location for acids.

Choosing the Right Storage Location

When it comes to storing acids, choosing the right location is crucial to ensure safety and compliance with regulations. Consider the following factors when determining the ideal storage location for your acids:

- Separation: Acids should be stored away from incompatible substances. Ensure that they are kept separate from bases, oxidizers, flammable materials, and reactive chemicals to prevent the risk of chemical reactions or spills.

- Ventilation: Acid storage areas should be well-ventilated to prevent the buildup of toxic fumes. If possible, choose a location with natural ventilation or install mechanical ventilation systems to maintain a constant airflow.

- Temperature control: Storing acids at the correct temperature is essential. Some acids are sensitive to extreme temperatures and may need to be stored in climate-controlled areas. Avoid storing acids near heat sources or in areas prone to high temperatures.

- Accessibility: Ensure that the storage area is easily accessible for authorized personnel. This will allow for convenient inspection, maintenance, and retrieval of the acids when needed.

- Security: Keep acids in a secure area to prevent unauthorized access or tampering. Consider installing surveillance systems or locks to protect the storage area from theft or vandalism.

- Spill containment: Choose a location with proper spill containment measures in place. This could include using secondary containment trays or basins to capture any spills and prevent them from spreading.

- Environmental considerations: Take into account the potential impact of an acid spill on the surrounding environment. Avoid storing acids in areas where a spill could contaminate water sources or cause harm to local ecosystems.

In addition to these factors, it’s important to comply with any local, state, or federal regulations that may govern the storage of acids. Be aware of any permitting requirements or specific guidelines that apply to your industry or the type and quantity of acids being stored. Consulting with relevant regulatory authorities or environmental agencies can help ensure compliance.

By carefully considering these factors and adhering to regulations, you can choose the right storage location for your acids, minimizing the risk of accidents and ensuring compliance with safety standards.

In the next section, we will explore the different types of acid storage containers available and their features.

Types of Acid Storage Containers

Choosing the appropriate storage containers for acids is essential to maintain their integrity and prevent leaks or spills. Here are some common types of acid storage containers:

- Glass Bottles: Glass is a common choice for storing small quantities of acids. It is resistant to most acids, but certain acids, such as hydrofluoric acid, can corrode glass. Ensure that the glass bottles are made of acid-resistant glass and have secure caps or stoppers.

- Plastic Containers: High-density polyethylene (HDPE) and polypropylene (PP) containers are commonly used for acid storage. These plastics are resistant to a wide range of acids and provide excellent chemical resistance. Make sure to choose containers specifically designed for acid storage and that are labeled as such.

- Drums: For larger quantities of acids, storage drums made of special acid-resistant materials like polyethylene or stainless steel may be used. These drums are typically designed with appropriate closures, such as bungs or screw caps, to ensure secure containment.

- Secondary Containment Systems: In addition to primary acid storage containers, secondary containment systems, such as spill containment pallets or basins, are crucial. These systems help contain any potential leaks or spills, preventing them from spreading and minimizing environmental impact.

- Acid Cabinets: Acid storage cabinets are specifically designed to store acids safely. They are typically made of corrosion-resistant materials and feature leak-proof construction, ventilation systems, and built-in spill containment trays. Acid cabinets help reduce the risk of spills and provide additional protection for both the acid and the surrounding environment.

When selecting acid storage containers, it is important to consider the specific properties of the acid, such as corrosiveness, concentration, and temperature sensitivity, as well as any regulatory requirements. Consult the MSDS for the acid being stored to determine the appropriate container material and features.

Proper labeling of the containers is also crucial. Clearly mark each container with the name of the acid, concentration, date of receipt, and any other relevant information. This helps identify the contents and provides valuable information for handling and emergency response.

Remember to regularly inspect the containers for any signs of damage or deterioration. Replace any containers that show signs of wear or compromise to ensure the integrity of the storage system.

In the next section, we will discuss the importance of proper labeling and documentation when storing acids.

Store acid in a cool, dry, well-ventilated area away from direct sunlight and incompatible materials. Use a designated acid storage cabinet or secondary containment to prevent spills. Keep the containers tightly closed and labeled with the appropriate hazard warnings.

Read more: How To Store Hydrochloric Acid

Proper Labeling and Documentation

Proper labeling and documentation are essential aspects of acid storage. Clear and accurate labeling helps identify the contents of acid storage containers and provides important information for safe handling and emergency response. Here are some key considerations for labeling and documentation:

- Labeling: Each acid storage container should be labeled with the name of the acid, concentration, hazard warning symbols, and any other relevant information. Use durable, chemical-resistant labels that will not easily fade or peel. Ensure that the labels are prominently displayed and easily visible.

- MSDS: Material Safety Data Sheets (MSDS) provide detailed information about the hazards, handling, and storage requirements of acids. Every acid should have an accompanying MSDS, which outlines important safety instructions, emergency procedures, and first aid measures. Keep all MSDS readily accessible to personnel who handle or store acids.

- Inventory Records: Maintain accurate inventory records of the acids being stored, including the quantity, date of receipt, expiration dates, and any other pertinent information. This can help with tracking and ensuring that the oldest stock is used first.

- Emergency Procedures: Develop and document clear emergency procedures for acid spills, leaks, and other accidents. Make sure all personnel are trained on these procedures and have easy access to the documentation. Ensure that emergency contact numbers and spill response supplies are readily available in the vicinity of the acid storage area.

- Inspection and Maintenance Logs: Maintain a logbook or electronic record to document regular inspections and maintenance activities related to the acid storage area. Document any repairs or maintenance performed, as well as any issues identified during inspections. This helps ensure that the storage area is being properly maintained and provides a record of compliance.

Proper labeling and documentation not only promote safe handling and storage of acids but also assist in regulatory compliance. They provide crucial information for emergency response teams, help prevent mix-ups or accidental misuse, and facilitate inventory management.

Regularly review and update labeling and documentation as needed to ensure accuracy and compliance with any changes in regulations or safety requirements. By maintaining proper labeling and documentation, you can enhance the safety and efficiency of your acid storage practices.

In the next section, we will discuss proper handling and transportation of acids to ensure safety at all stages of storage.

Handling and Transporting Acid Safely

Proper handling and transportation of acids are crucial to prevent accidents and minimize the risk of exposure to hazards. Whether you are moving acids within a laboratory, industrial facility, or transporting them to another location, following these guidelines is essential:

- Personal Protective Equipment (PPE): Always wear appropriate PPE when handling or transporting acids. This includes gloves, safety goggles, lab coats, and closed-toe footwear. Depending on the specific acid and the task at hand, respiratory protection may also be necessary.

- Avoid Splashes and Spills: When handling acids, ensure that the containers are properly sealed and that the lids or caps are securely fastened. Avoid shaking or jerking the containers, as this can cause splashes or spills. Slow and careful movements are essential to minimize the risk of accidents.

- Proper Lifting Techniques: Use proper lifting techniques to avoid strain or injury when moving heavy containers of acid. Lift with your legs, not your back, and get assistance if necessary. Use hand trucks or carts when moving large quantities of acids to minimize the risk of dropping or spilling.

- Segregation During Transport: If acids need to be transported, separate them from other chemicals to prevent potential reactions. Acids should be stored in a secondary containment system during transportation to prevent leaks or spills from spreading.

- Secure Transportation: Ensure that the transportation vehicle or container is properly secured and stable. This will prevent the containers from shifting or falling during transit. Use proper restraints, such as straps or tie-downs, to secure the containers firmly.

- Monitor Environmental Conditions: Maintain awareness of temperature and humidity conditions during transportation. Extreme temperatures or fluctuations can affect the integrity of the containers and potentially lead to leaks or spills.

- Emergency Preparedness: Be prepared for any potential accidents or spills during transportation. Have spill response kits readily available, as well as emergency contact numbers and procedures. Properly train personnel on emergency response protocols and provide them with the necessary equipment to handle spills.

Remember to consult the MSDS for specific information on the handling and transportation requirements of the acid being dealt with. Follow all relevant regulatory guidelines and organizational policies to ensure compliance.

By following these guidelines and employing safe practices during handling and transportation, you can reduce the risk of accidents and ensure the safe movement of acids from one location to another.

In the next section, we will discuss the importance of regular maintenance and inspections to ensure the integrity of acid storage.

Regular Maintenance and Inspections

Regular maintenance and inspections are crucial for ensuring the integrity and safety of acid storage systems. By conducting routine checks, you can identify and address any issues or potential hazards before they escalate. Here are some key considerations for regular maintenance and inspections:

- Inspect Containers: Regularly inspect acid storage containers for signs of damage, corrosion, or deterioration. Look for any cracks, leaks, or discoloration that may indicate a compromised container. If any issues are found, replace the container immediately.

- Check Seals and Closures: Ensure that the lids, caps, or stoppers on acid containers are properly sealed and have not become loose or damaged. Check for any signs of leakage or evaporation around the closures. Tighten or replace seals as needed.

- Monitor Storage Area: Regularly check the acid storage area for any signs of leaks, spills, or environmental factors that could impact the integrity of the storage system. Look for any chemical stains, odors, or other indicators of incidents or potential risks.

- Inspect Secondary Containment Systems: If secondary containment systems, such as spill trays or basins, are in place, inspect them regularly for any signs of leaks or spills. Ensure that they are clean and free from any debris that could hinder their functionality.

- Review Inventory: Regularly review and update the inventory records to track the quantities, dates of receipt, and expiration dates of the acids stored. Remove any expired or outdated acids and properly dispose of them following the necessary protocols.

- Test Acid Purity: Depending on the specific application, testing the acid purity periodically may be necessary. Testing can help ensure that the acid’s properties remain within the required specifications.

- Document Inspections: Maintain a record of all maintenance and inspections conducted on the acid storage system. This documentation is valuable for regulatory compliance, maintaining a historical record, and identifying any trends or recurring issues.

- Training and Education: Regularly provide training and education to personnel involved in acid storage to ensure they are aware of proper handling, maintenance, and inspection protocols. Stay updated on any changes in regulations or best practices and communicate them to the relevant personnel.

If any issues or concerns are identified during inspections, take immediate action to rectify them and ensure the safety of the acid storage system. Prompt repairs, replacements, or adjustments can prevent accidents, leaks, and spills that may lead to environmental and safety hazards.

In the next section, we will discuss the importance of emergency preparedness when storing acids.

Emergency Preparedness

Having an effective emergency preparedness plan is crucial when storing acids. Accidents or incidents can occur unexpectedly, and being prepared can help minimize the risk of injuries, environmental damage, and property loss. Here are essential considerations for emergency preparedness:

- Develop an Emergency Response Plan: Create a comprehensive emergency response plan specifically tailored to acid storage. The plan should include procedures for spills, leaks, fires, injuries, and other potential incidents. Provide clear instructions and designate responsible individuals for each task.

- Training and Education: Ensure that all personnel involved in acid storage are properly trained on the emergency response plan. Conduct regular drills and exercises to reinforce knowledge and familiarity with emergency procedures. Keep training records up-to-date and easily accessible.

- Emergency Communication: Establish a reliable means of communication during emergencies. Ensure that all personnel have access to communication devices and have a designated point of contact for reporting incidents. Identify communication protocols for contacting emergency services, such as fire departments or hazardous materials response teams.

- Emergency Shutdown Procedures: Clearly outline step-by-step procedures for shutting down acid-related equipment or systems in case of emergencies. Designate individuals responsible for executing these procedures and ensure that they are trained accordingly.

- Spill Response Kits: Keep spill response kits readily available near the acid storage area. The kits should include appropriate personal protective equipment, spill containment materials, neutralizing agents, absorbents, and emergency decontamination supplies. Regularly check and replenish the contents of the spill response kits as needed.

- Emergency Equipment and Resources: Identify and maintain the necessary emergency equipment, such as fire extinguishers, eye wash stations, safety showers, and ventilation systems. Inspect and test these resources regularly to ensure they are functioning correctly and accessible during emergencies.

- Evacuation Procedures: Establish evacuation procedures and designated assembly points in case of a large-scale emergency or when instructed by emergency personnel. Regularly communicate and practice evacuation procedures to ensure that all personnel are familiar with the process.

- Emergency Contacts: Maintain a list of emergency contacts, including relevant local authorities, emergency response teams, poison control centers, and safety personnel. Make sure this list is readily available and communicate it to all personnel involved in acid storage.

Regularly review and update the emergency response plan as needed. Consider conducting periodic audits or drills to assess the effectiveness of the plan and make improvements where necessary. Stay informed about any changes in regulations or best practices related to emergency preparedness and incorporate them into your plan.

By being well-prepared and proactive in your approach to emergency situations, you can effectively mitigate risks and minimize the potential impact of incidents involving acid storage.

Now, let’s conclude our article on how to store acid.

Read more: How To Store Oxalic Acid Powder

Conclusion

Proper storage of acids is critical to ensure safety, prevent accidents, and protect the environment. By following the guidelines and recommendations outlined in this article, you can establish effective acid storage practices that minimize risks and promote a safe working environment. Remember the following key points:

Understanding the nature of acids is essential in implementing proper storage methods. Acids can be corrosive, toxic, and reactive, requiring specific handling and storage precautions.

Adhering to safety precautions is crucial to protect yourself and others from the hazards associated with acids. Wear appropriate personal protective equipment, store acids separately from incompatible substances, and ensure proper ventilation in the storage area.

Choosing the right storage location is important to maintain the integrity of acids. Consider factors such as segregation, ventilation, temperature control, accessibility, and environmental impact when deciding where to store acids.

Selecting the appropriate acid storage containers is vital to prevent leaks, spills, and reactions. Glass bottles, plastic containers, drums, and acid cabinets are common options. Use secondary containment systems to further enhance safety.

Proper labeling and documentation provide crucial information for safe handling, emergency response, and regulatory compliance. Clearly label containers, maintain material safety data sheets (MSDS), and keep accurate inventory records.

Handle and transport acids with care, using appropriate personal protective equipment and following proper lifting techniques. Ensure segregation during transportation and be prepared for any emergencies that may arise.

Regular maintenance and inspections are necessary to ensure the integrity of acid storage systems. Regularly inspect containers, seals, storage areas, and secondary containment systems. Monitor acid purity and keep thorough records.

Develop and maintain an emergency preparedness plan specific to acid storage. Train personnel, establish communication protocols, prepare spill response kits, and have evacuation procedures in place.

By incorporating these practices into your acid storage processes, you can maintain a safe working environment, reduce the risk of accidents, and ensure compliance with regulations.

Remember to consult the specific guidelines and regulations applicable to your industry or location to ensure full compliance with acid storage requirements.

By prioritizing safety, adhering to proper storage methods, and staying prepared for emergencies, you can minimize risks and promote a secure environment in which to store and handle acids.

Frequently Asked Questions about How To Store Acid

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Acid”