Articles

What Are Calipers Used To Measure

Modified: May 6, 2024

Discover the versatility of calipers as measuring tools in this informative article. Explore how calipers are used to measure various objects and their importance in precision measurements.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of precision measurement! In the realm of science, engineering, and craftsmanship, accurate measurements are essential. Whether you’re designing a new product, building a structure, or creating intricate artwork, having the ability to measure with accuracy is paramount. One such tool that plays a crucial role in this process is the caliper.

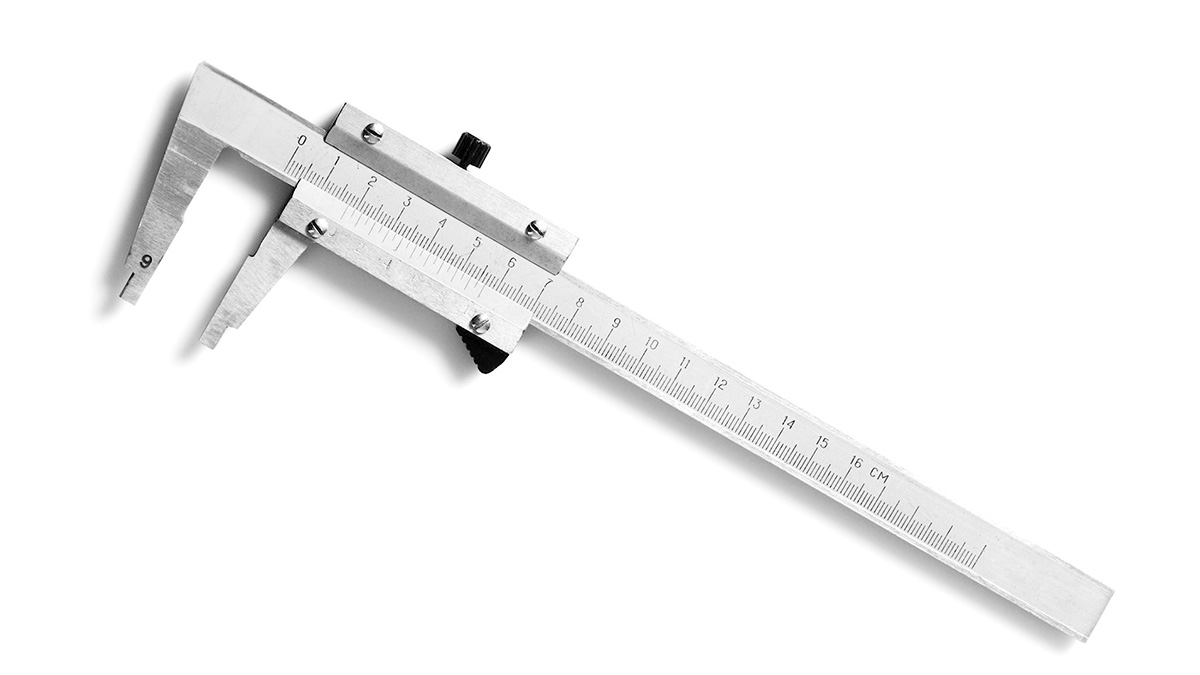

Calipers are versatile instruments utilized to measure distances and dimensions with great precision. They have been used for centuries and come in various forms, each serving a unique purpose. In this article, we will explore the world of calipers, delving into their types, applications, and the art of using them effectively.

So, let’s embark on a fascinating journey to understand the intricacies of calipers and how they contribute to the world of measurement.

Key Takeaways:

- Calipers are versatile, precision measurement tools used in engineering, woodworking, and medical fields. They come in various types, such as vernier, digital, and dial calipers, each serving specific measurement needs.

- Precision and accuracy are crucial when using calipers. Regular calibration and maintenance ensure reliable measurements. Calipers find applications in engineering, woodworking, metalworking, jewelry making, and medical fields, contributing to the highest standards in various industries.

Read more: How To Use Calipers To Measure

Definition of Calipers

Calipers are precision measurement tools consisting of two fixed legs or jaws and a movable arm or slide. They are designed to accurately measure distances between two points, diameters, and depths of objects. The primary purpose of calipers is to provide precise measurements with minimal error margins.

Calipers can be mechanical or digital, with the latter being more modern and convenient to use. They are typically made of sturdy materials such as stainless steel or hardened alloys to ensure durability and accuracy.

Calipers are indispensable in a wide range of fields, including engineering, manufacturing, woodworking, metalworking, and even in the field of medicine. They are widely used by professionals and hobbyists alike, enabling them to achieve precise measurements and maintain high levels of accuracy in their projects.

The beauty of calipers lies in their versatility. Depending on the specific use case, calipers come in different types, each tailored to suit a particular purpose. Let’s take a closer look at some of the most common types of calipers.

Types of Calipers

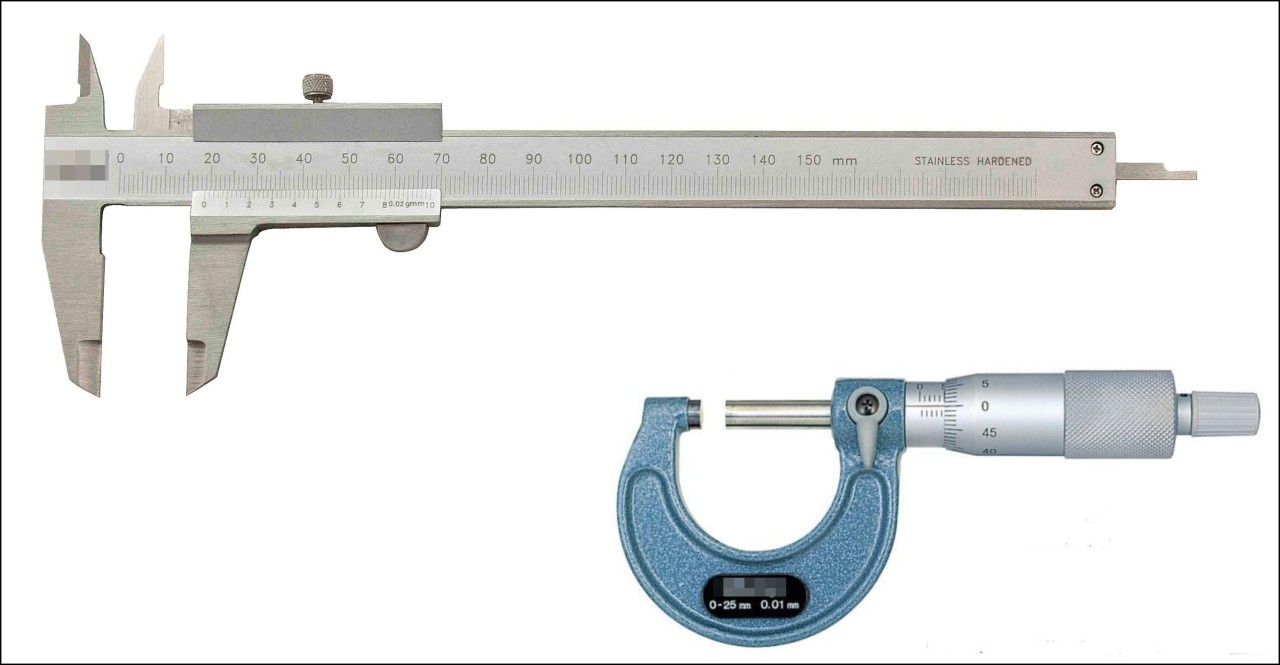

Calipers come in various forms, each designed to cater to specific measurement needs. Here are some of the most commonly used types of calipers:

- Vernier Caliper: The Vernier caliper is a classic mechanical caliper that utilizes a sliding vernier scale to provide precise measurements. It consists of two jaws, an upper scale with a main scale, and a sliding vernier scale for fine measurements. Vernier calipers are known for their accuracy and are widely used in a range of applications.

- Digital Caliper: Digital calipers are modern calipers equipped with a digital display that provides precise measurements. They are user-friendly, with an easy-to-read digital readout that eliminates the need for manual reading and reduces errors. Digital calipers are highly accurate and can switch between metric and imperial units with ease.

- Dial Caliper: Dial calipers, also known as dial indicators, feature a dial gauge that displays the measurements. They are designed with a spindle connected to the primary scale and a rotating dial pointer that indicates the measurements. Dial calipers are known for their ease of use and their ability to provide precise readings.

- Inside Caliper: Inside calipers, as the name suggests, are used to measure the internal dimensions of an object or a hole. They consist of two jaws that can be adjusted to fit inside the object being measured, allowing for accurate internal measurements.

- Outside Caliper: Outside calipers are used to measure the external dimensions of an object. They are designed with two jaws that can be adjusted to fit around the object being measured, providing accurate external measurements.

Each type of caliper has its own unique advantages and applications, allowing professionals and enthusiasts to choose the most suitable one based on their specific needs.

Vernier Caliper

The Vernier caliper is a mechanical tool known for its precision and versatility in measuring distances and dimensions. Named after its inventor, Pierre Vernier, this type of caliper has been widely used for centuries and remains a staple in the field of precision measurement.

The Vernier caliper consists of a main scale and a sliding vernier scale. The main scale is fixed and typically features markings in centimeters or inches. The vernier scale is mounted on the sliding jaw of the caliper and features smaller divisions than the main scale.

When using a Vernier caliper, the jaws are adjusted to fit around the object being measured. The main scale is read first, indicating the whole number measurement, while the vernier scale is then observed to determine the fractional part of the measurement. The alignment of the smallest division on the vernier scale with a division on the main scale provides the additional precision required for accurate readings.

One of the key advantages of the Vernier caliper is its ability to provide measurements with high accuracy. The vernier scale allows for finer incremental measurements compared to a standard ruler or tape measure. With careful observation and practice, precise measurements up to a hundredth of a millimeter or thousandth of an inch can be achieved.

Vernier calipers are widely used in various industries and fields, including engineering, machining, metalworking, and even in laboratory settings. They are particularly useful when measuring small objects or components with tight tolerances. Additionally, Vernier calipers are often utilized in educational settings to teach students about the importance of precision measurement and how to read and interpret measurements accurately.

Overall, the Vernier caliper is a trusted and reliable tool for obtaining accurate measurements. Its simplicity, durability, and precision make it an essential instrument in any professional or hobbyist’s toolbox.

Digital Caliper

The digital caliper is a modern and advanced variation of the traditional mechanical caliper. Equipped with a digital display, this type of caliper offers precise and easy-to-read measurements, making it a popular choice among professionals and hobbyists alike.

One of the key features of the digital caliper is its digital display, which eliminates the need for manual reading and interpretation of measurements. The display typically shows the measurements in either metric or imperial units and provides decimal or fractional readings, depending on the user’s preference. This makes it incredibly convenient and accurate, reducing the chances of human error in measurement readings.

Using a digital caliper is straightforward. The jaws are adjusted to fit around the object being measured, and the measurement value is instantly displayed on the digital screen. Some digital calipers even come with additional features such as hold functions, allowing users to freeze the measurement value, and conversion options between different units of measurement.

One of the major advantages of digital calipers is their precision. Digital calipers can provide measurements with a high degree of accuracy, often within a thousandth of an inch or a hundredth of a millimeter. This level of precision makes them ideal for tasks that require precise measurements, such as machining, woodworking, and engineering applications.

In addition to their accuracy, digital calipers offer other advantages as well. They are generally more durable than their mechanical counterparts due to the use of high-quality materials and electronic components. Some digital calipers even have a water-resistant or dustproof design, making them suitable for use in various environments.

Furthermore, digital calipers are highly versatile and can switch between different measuring modes and zero settings. This allows for easy measurements of inside, outside, step, and depth dimensions. Some models also include a data output port, enabling connectivity to a computer or data logging system for further analysis and record-keeping.

Whether you’re an engineer, machinist, hobbyist, or student, the digital caliper is a valuable tool that combines accuracy, convenience, and versatility. Its ease of use, clear digital display, and high precision make it an essential instrument for any project that demands precise measurements.

Read more: How Accurate Are Digital Calipers

Dial Caliper

The dial caliper, also known as a dial indicator or dial gauge, is a measuring instrument that provides precise and easy-to-read measurements. Unlike the traditional vernier or digital calipers, the dial caliper utilizes a dial gauge to display the measurement values. This type of caliper offers several advantages, making it a popular choice among professionals and enthusiasts.

The dial caliper consists of a main scale, a sliding jaw, and a dial gauge. The main scale is fixed and features markings in either metric or imperial units. The sliding jaw is moved along the main scale to adjust the caliper to the desired measurement. The dial gauge, usually located on the face of the caliper, features a rotating pointer that indicates the measurement on a circular dial.

Using a dial caliper is straightforward. The jaws are adjusted to fit around the object being measured, and as the caliper is moved, the dial gauge rotates accordingly, providing a precise and easy-to-read measurement. The dial typically has different divisions, allowing for both coarse and fine measurements. Some dial calipers also feature a locking screw to hold the measurement in place for easy reading and recording.

One of the main advantages of the dial caliper is its ease of use. The dial gauge provides a visual representation of the measurement, allowing users to quickly obtain accurate readings. This makes it ideal for tasks where frequent measurements need to be taken or where precise measurements are critical, such as machining, metalworking, and quality control applications.

In addition to its ease of use, the dial caliper offers excellent durability. The construction of dial calipers is typically robust, with sturdy materials and high-quality craftsmanship. This ensures that the instrument can withstand demanding industrial environments and maintain accuracy and reliability over extended periods of use.

Furthermore, dial calipers are known for their repeatability. Once calibrated, they provide consistent and reliable measurements, making them suitable for tasks that require precise and repeatable results.

Dial calipers also have the advantage of being resistant to magnetic fields, making them suitable for use in environments where magnetic interference is a concern. This makes them a preferred choice in industries such as aerospace and automotive, where electronic devices may be affected by magnetic fields.

The dial caliper offers a balance between simplicity and accuracy, making it a versatile and practical tool for a wide range of applications. Whether you’re a machinist, engineer, or hobbyist, the dial caliper is a reliable and valuable instrument that can provide precise and easy-to-read measurements with ease.

When using calipers to measure, ensure that the object being measured is clean and free from any debris that could affect the accuracy of the measurement.

Inside Caliper

The inside caliper is a specialized measuring tool designed to measure the internal dimensions of an object or a hole accurately. Also known as internal calipers, this type of caliper is widely used in various industries and applications that require precise internal measurements.

An inside caliper consists of two legs or jaws that can be adjusted to fit inside an opening or around a feature being measured. These legs are connected by a pivot point or a fulcrum, allowing them to open or close according to the dimension being measured. The inside caliper functions similarly to a compass, with one leg serving as the stationary point and the other leg as the movable point.

When using the inside caliper, the legs are carefully adjusted to fit snugly inside the object or hole to be measured. Once in position, the caliper is gently opened, and the distance between the legs is read from the scale or measurement gauge on the outside of the caliper. This provides an accurate measurement of the internal dimension.

The inside caliper is particularly useful when measuring the diameter of tubes, holes, or cylindrical objects. It enables precise measurements, ensuring a secure and tight fit when components need to be assembled. Inside calipers can also be used to measure the depth of a hole or a pocket by adding a depth rod to one of the legs.

In addition to its primary function, the inside caliper can also be used for scribing arcs or circles on the inside of an object. By adjusting the legs to the desired radius, the inside caliper can be used to mark a precise curve.

Inside calipers come in different sizes, with larger ones used for measuring larger holes and smaller ones used for more delicate work. They are typically made of durable materials such as stainless steel or hardened alloys to ensure accuracy and longevity.

Whether you’re in the field of engineering, woodworking, metalworking, or even in artistic crafts, the inside caliper is an essential tool for obtaining precise internal measurements. Its versatility, accuracy, and ability to fit into tight spaces make it an indispensable instrument for various applications.

Outside Caliper

The outside caliper is a versatile measuring tool used to accurately measure the external dimensions of an object. Also known as external calipers, this type of caliper is widely used in industries and applications that require precise measurements of the outer dimensions of various objects.

An outside caliper consists of two legs or jaws that can be adjusted to fit around the outer surface of an object or feature to be measured. These legs are connected by a pivot point, allowing them to open or close according to the dimension being measured. The outside caliper functions similarly to a compass, where one leg serves as the fixed point and the other leg as the movable point.

When using the outside caliper, the jaws are carefully adjusted to fit snugly around the object or feature to be measured. Once in position, the caliper is gently closed, and the reading is taken from the scale or measurement gauge located on the outside of the caliper. This provides an accurate measurement of the external dimension.

The outside caliper is commonly used to measure the diameter, width, or thickness of various objects. It is particularly useful in applications such as machining, metalworking, carpentry, and fabrication, where precise measurements are essential for ensuring proper fits and alignments.

In addition to its primary function, the outside caliper can also be used for marking or transferring measurements. By adjusting the legs to a desired dimension, the outside caliper can be used as a guide to transfer the measurement to another object or to mark a line for cutting or shaping.

Outside calipers come in different sizes, with larger ones used for measuring larger objects and smaller ones used for more delicate work. They are typically made of durable materials such as stainless steel or hardened alloys to ensure accuracy and longevity.

Whether you’re a machinist, carpenter, metalworker, or even a DIY enthusiast, the outside caliper is an indispensable tool for obtaining precise external measurements. Its versatility, accuracy, and ease of use make it an essential instrument for a wide range of applications in various industries.

Use of Calipers in Measurement

Calipers are essential tools in the world of measurement, offering precise and accurate readings for a wide range of applications. They are commonly used in various industries such as engineering, manufacturing, woodworking, metalworking, and even in the field of medicine. Let’s explore some of the common uses of calipers in measurement:

- Dimensional Measurement: One of the primary uses of calipers is measuring dimensions such as length, width, diameter, and thickness. Calipers allow for precise measurements, ensuring components fit together properly, maintaining tolerances, and meeting design specifications.

- Quality Control: Calipers play a crucial role in quality control processes. They are used to check the accuracy and consistency of manufactured parts, ensuring they meet the required specifications and standards. Calipers are employed to measure critical dimensions and identify any variations or defects that may affect the product’s functionality or performance.

- Fitting and Alignment: In various industries, calipers are used for fitting and alignment purposes. For example, in carpentry, calipers help ensure proper alignment and fitting of joints, which is essential for sturdy and precise construction. In machining, calipers aid in aligning machine components and verifying the accuracy of workpieces.

- Machining and Metalworking: Calipers are indispensable tools in machining and metalworking applications. They enable accurate measurements of workpieces, including the diameter of holes, the thickness of materials, and the alignment of components. Calipers are commonly used in turning, milling, boring, and other machining operations to achieve high precision and quality.

- Art and Design: Calipers find value in artistic and design fields as well. Artists, sculptors, and designers use calipers to measure proportions, create symmetrical designs, and achieve accurate reproductions of objects. Calipers provide the necessary precision and control to bring artistic visions to life.

- Medical Applications: Calipers are also utilized in the medical field for various purposes. They are commonly used to measure body dimensions, such as the diameter of bones or the thickness of soft tissues. Calipers aid in diagnosing and monitoring health conditions, assessing growth rates, and ensuring proper prosthetic or orthotic fitting.

Calipers are reliable tools that offer accuracy, versatility, and ease of use in a broad range of measurement applications. Their importance cannot be overstated, as they contribute to the quality, precision, and efficiency of many industries and professions.

Read more: What Are Calipers

Precision and Accuracy of Calipers

When it comes to measurement tools, precision and accuracy are of utmost importance. Calipers are renowned for providing precise measurements with minimal error margins, making them highly valued in various industries. Let’s explore the concepts of precision and accuracy in relation to calipers:

Precision: Precision refers to the ability of a measuring instrument to provide consistent and repeatable results. A precise caliper can consistently produce the same measurement value when used repeatedly to measure the same dimension. Precision is crucial when working with tight tolerances and when small differences in measurement can have significant impacts on the final product or application.

Calipers achieve precision through several design features. The use of finely etched scales or digital readouts with high-resolution displays allows for reading measurements with great detail. Additionally, the use of high-quality materials and precision manufacturing techniques ensures smooth and precise movement of the caliper jaws, reducing any inaccuracies or variations in measurement results.

Accuracy: Accuracy refers to the closeness of a measured value to the true or accepted value. An accurate caliper provides measurements that are close to the actual dimensions being measured. Calibration and regular maintenance of calipers are essential to ensure accuracy. Calipers should be periodically checked or calibrated against known reference standards to verify their accuracy and make any necessary adjustments.

Factors that can affect the accuracy of calipers include wear and tear, dirt or debris that may interfere with the movement of the jaws, or improper handling of the instrument. Regular cleaning, lubrication, and proper storage are necessary to maintain the accuracy of calipers and ensure reliable measurement results.

It is important to note that precision does not guarantee accuracy. While a caliper may provide precise measurements consistently, it may still have inherent systematic errors that cause it to deviate from the true value. Calibration and verification against reference standards are necessary to establish the accuracy of a caliper.

When using calipers, it is crucial to consider both precision and accuracy. Precision ensures consistent and reliable results, while accuracy ensures that the measurements are true and align with the required specifications or standards. By using precise and accurate calipers, professionals can have confidence in the measurements they obtain, leading to better quality outcomes and successful projects.

Common Applications of Calipers

Calipers are versatile measuring tools that find application in various industries and fields where precision measurements are required. Let’s explore some of the common applications of calipers:

- Engineering and Manufacturing: Calipers are widely used in engineering and manufacturing industries. They play a crucial role in measuring and verifying critical dimensions of machined parts, ensuring they meet design specifications and tight tolerances.

- Woodworking and Carpentry: In woodworking and carpentry, calipers are used to measure and mark precise dimensions for cutting, joinery, and fitting. They ensure accurate and tight-fitting joints, allowing for sturdy and well-crafted furniture and structures.

- Metalworking and Fabrication: Calipers are instrumental in metalworking and fabrication applications, where precise measurements are vital for creating accurate metal components and assemblies. They enable precise marking and cutting of materials, ensuring proper fits and alignments in metal fabrication projects.

- Quality Control and Inspection: Calipers are essential tools in quality control and inspection processes across various industries. They are used to verify dimensions, tolerances, and alignments, ensuring that products meet the required quality standards before being released to the market.

- Jewelry Making: Precision is paramount in jewelry making, and calipers are indispensable tools in this field. They are used to measure gemstones, determine ring sizes, and create intricate designs with accuracy and precision.

- Medical and Healthcare: In the medical field, calipers are used for precise measurement of body dimensions and characteristics. They can be used to measure bone length, muscle thickness, or skinfold thickness, aiding in accurate diagnosis, treatment planning, and monitoring of various health conditions.

- Art and Design: Calipers find value in artistic and design fields as well. Artists, sculptors, and designers use calipers to measure proportions, transfer measurements, and create symmetrical designs. Calipers help ensure accurate proportions and precise replication of objects.

These are just a few examples of the wide range of applications in which calipers are utilized. Their accuracy, versatility, and ease of use make them invaluable tools in industries and fields that require precise measurements for successful outcomes.

Conclusion

Calipers are indispensable tools in the world of measurement, allowing professionals and enthusiasts to achieve precise and accurate results in various industries and fields. Whether it is engineering, woodworking, metalworking, or any other application that demands precision, calipers provide the necessary accuracy and reliability.

Throughout this article, we have explored the different types of calipers, including vernier calipers, digital calipers, dial calipers, inside calipers, and outside calipers. Each type serves specific measurement needs, but all share the common goal of providing accurate and precise measurements.

We have also delved into the importance of precision and accuracy when using calipers. Precision ensures consistent and repeatable measurements, while accuracy ensures that the measurements align with the true value. Regular calibration and maintenance are vital to guarantee the accuracy of calipers in order to obtain reliable results.

Calipers find applications in a wide range of industries such as engineering, manufacturing, woodworking, metalworking, jewelry making, medical fields, and even in art and design. From dimensional measurement to quality control and inspection, calipers play a significant role in ensuring the highest standards are met.

In conclusion, calipers are indispensable tools for professionals and enthusiasts alike. Their precision, versatility, and ease of use make them essential instruments in achieving accurate and reliable measurements. By utilizing calipers effectively and maintaining their accuracy through regular calibration, professionals can achieve outstanding results and ensure the success of their projects.

Now that you've got a handle on the basics and versatility of calipers, why not dive deeper into one of the most popular types? If precision in your projects is paramount, consider checking out our review on the latest and greatest dial calipers set to take 2024 by storm. Whether you're a seasoned engineer or just starting out, this guide will help you select the perfect tool for achieving flawless measurements every time.

Frequently Asked Questions about What Are Calipers Used To Measure

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Calipers Used To Measure”