Articles

What Are Some Types Of Basic Hand Tools

Modified: January 24, 2024

Discover the different types of basic hand tools in this informative article. Find out how these essential tools can help you with your DIY projects and repairs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

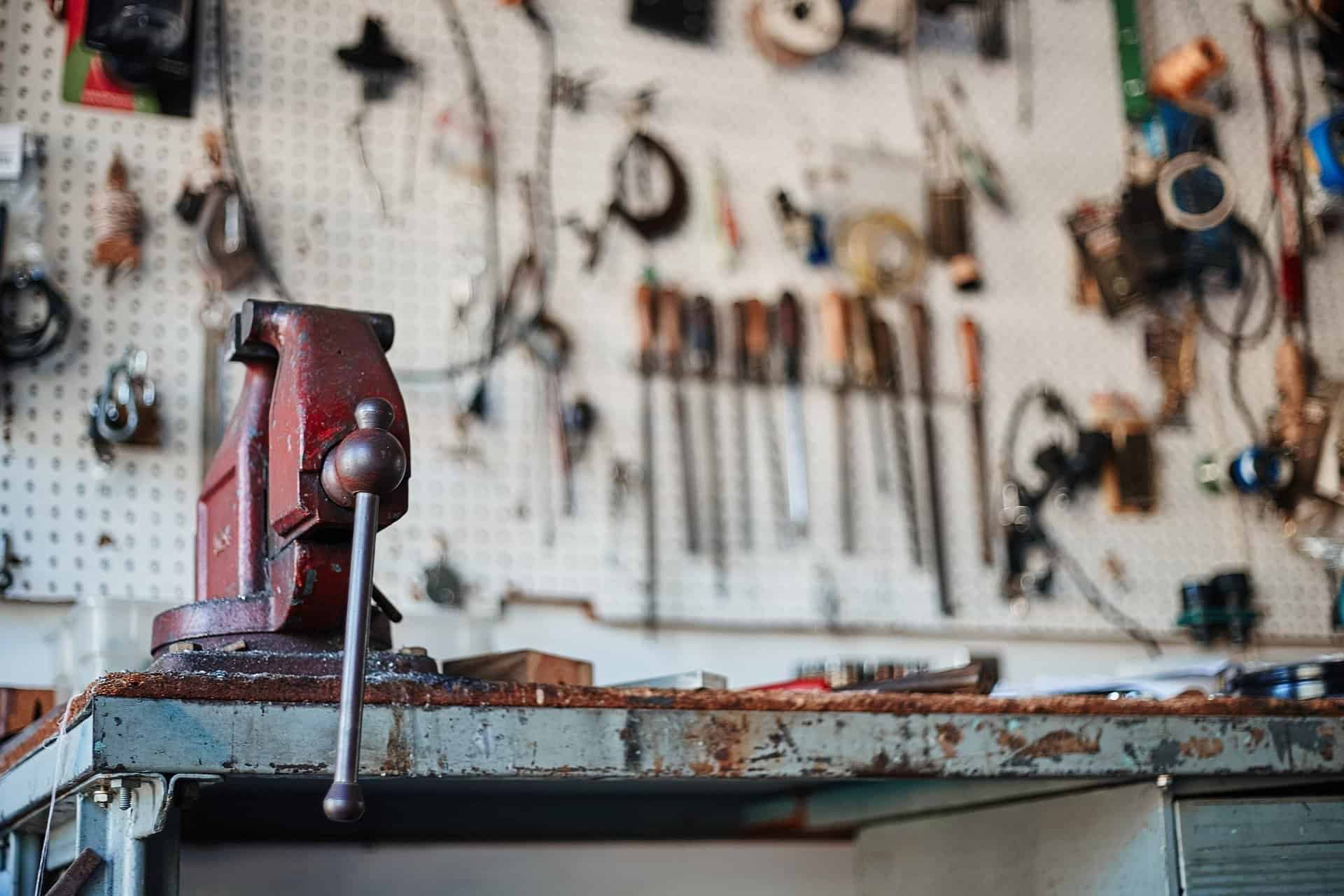

Hand tools are essential for any DIY enthusiast or professional tradesperson. These simple yet powerful tools empower individuals to tackle a wide range of tasks, from construction and repairs to woodworking and plumbing. By understanding the different types of basic hand tools available, you can equip yourself with the right tools for the job and enhance your efficiency and productivity.

While power tools have become increasingly popular in recent years, basic hand tools have stood the test of time. They are reliable, easy to use, and require minimal maintenance. Whether you are a beginner or an experienced handyman, having a collection of basic hand tools at your disposal is a must.

In this article, we will explore some of the most commonly used types of basic hand tools and their applications. From screwdrivers and wrenches to hammers and saws, each tool has its own unique purpose and functionality. So, let’s dive in and discover the essential hand tools that every toolbox should have.

Key Takeaways:

- Basic hand tools, such as screwdrivers, pliers, and wrenches, are essential for a wide range of tasks. Investing in high-quality tools and understanding their applications enhances efficiency and productivity.

- Safety, proper maintenance, and choosing the right tool for the job are crucial when using hand tools. With a well-stocked toolbox and the right knowledge, DIY enthusiasts and professionals can tackle any task with confidence and skill.

Read more: What Are Some Of The Hand Tools For Saws

Screwdrivers

Screwdrivers are versatile hand tools designed for inserting and removing screws. They consist of a handle and a shaft with a shaped tip called a bit. The bit corresponds to the type of screw head it can work with, such as flathead, Phillips, or Torx.

Flathead screwdrivers have a straight, single-slot bit and are commonly used for screws with a straight, single-slot head. They are ideal for basic household tasks, such as tightening or loosening screws on electrical outlets or light switch covers.

Phillips screwdrivers have a cross-shaped bit and are used for screws with a cross-shaped head, commonly found on electronics and appliances. They provide better grip and torque, preventing the screwdriver from slipping out of the screw head.

Torx screwdrivers are designed for screws with a star-shaped head, often used in automotive and electronics industries. The star-shaped pattern provides better torque and reduces the risk of stripping the screw head.

Screwdrivers come in various sizes and lengths to accommodate different screw types and applications. It’s essential to select the right screwdriver size to avoid damaging the screw head or surrounding materials.

When using a screwdriver, make sure to apply steady pressure and avoid overtightening, as it can lead to stripping the screw or damaging the material. For stubborn or rusted screws, applying lubricant or using a screwdriver with a greater handle for increased torque can help.

In addition to the traditional manual screwdrivers, electric and cordless screwdrivers are also available. These power-driven versions make it easier to insert or remove screws quickly and effortlessly, especially for larger projects or repetitive tasks.

Screwdrivers are indispensable tools for many common DIY tasks, including assembling furniture, installing shelves, repairing appliances, and working on electronics. Having a set of screwdrivers in different sizes and types will ensure you’re prepared for any screw-related job that comes your way.

Pliers

Pliers are versatile hand tools that are designed to grip, bend, twist, and cut various materials. They consist of two handles connected by a pivot, with jaws at the end of each handle. The jaws can be flat, curved, or shaped to perform specific tasks.

One of the most common types of pliers is the combination pliers. They have a flat and serrated gripping surface in the jaws, making them suitable for gripping and holding objects securely. Combination pliers can be used for general tasks such as twisting wire, bending metal, or even cutting through thin wires or nails.

Needle-nose pliers are another popular type. They have long, slender jaws that taper to a pointed tip, making them ideal for working in tight spaces or manipulating small objects. They are commonly used in electronics repair, jewelry-making, and intricate DIY projects where precision is required.

For heavier-duty tasks, such as plumbing or automotive work, adjustable or slip-joint pliers are commonly used. They have adjustable jaws that can be set to different widths to accommodate various sizes of nuts, bolts, or pipes. The slip-joint mechanism allows the user to adjust the handle position for gripping objects of different sizes.

Other specialized types of pliers include wire-cutting pliers, also known as diagonal cutters or side cutters, which have a sharp cutting edge for cutting through wire or cable. There are also locking pliers, commonly known as Vise-Grips, which have a built-in locking mechanism that allows them to securely hold objects without the need for continuous grip pressure.

Pliers are designed to provide a firm grip on objects, preventing slippage and ensuring precise control. When using pliers, it is important to choose the right size and type for the task at hand. Applying excessive force or using the wrong type of pliers can damage the material or result in an inefficient work process.

Whether you’re an electrician, plumber, mechanic, or simply someone who enjoys DIY projects, having a good set of pliers is essential. They are versatile tools that can be used in a wide range of applications, from gripping and shaping materials to cutting and twisting wires. Make sure to invest in high-quality pliers to ensure durability and reliable performance for all your projects.

Wrenches

Wrenches are essential hand tools designed for tightening or loosening nuts, bolts, and other fasteners. They come in various sizes and types, each suited for different applications and fastener types. Wrenches are commonly made of durable steel and have a handle with a fixed or adjustable jaw at one end.

One of the most common types of wrenches is the open-end wrench. It has a U-shaped opening with smooth jaws and is used to tighten or loosen nuts and bolts with two opposite flat sides. Open-end wrenches are available in various sizes to accommodate different fastener sizes.

Another commonly used type is the combination wrench, which has an open-end on one side and a box-end on the other. The box-end has a closed and 6 or 12-point grip, allowing for better torque and preventing rounding off the corners of the fastener. Combination wrenches are versatile and ideal for accessible nuts and bolts.

For tight spaces or hard-to-reach fasteners, a ratchet wrench is a useful tool. It has a ratcheting mechanism that allows for continuous rotation in one direction, eliminating the need to reposition the wrench after each turn. Ratchet wrenches are available in both open-end and box-end styles, making them versatile for various fastener types.

Adjustable wrenches, also known as crescent wrenches, have an adjustable jaw that can be widened or narrowed to fit different fastener sizes. They are versatile and can be used on hexagonal, square, or even rounded fasteners. However, adjustable wrenches should be used with caution, as excessive force or incorrect fitting may cause slipping and damage to the fastener or wrench itself.

For plumbing applications, pipe wrenches are commonly used. They have serrated jaws that grip and rotate pipes or round objects securely. Pipe wrenches are available in various sizes to handle different pipe diameters and can be used for installation, removal, or tightening of pipes.

Wrenches are essential tools in automotive, construction, plumbing, and many other industries. Proper selection and use of the right wrench for the job are crucial to prevent damage to fasteners, minimize slippage, and ensure effective tightening or loosening. Always choose high-quality wrenches to guarantee durability and reliable performance.

Hammers

Hammers are indispensable hand tools used for striking or driving objects. They consist of a handle and a weighted head typically made of metal, providing the necessary force and impact. Hammers come in various shapes and sizes, each designed for specific tasks and materials.

The most common type of hammer is the claw hammer. It has a flat face for striking and a V-shaped claw on the opposite end for pulling out nails. Claw hammers are versatile and suitable for general tasks such as driving nails into wood, construction work, and home repairs.

Ball-peen hammers, also known as machinist hammers, have a rounded end on one side and a flat face on the other. They are commonly used in metalworking and mechanics for shaping or striking metal objects. The rounded end is ideal for shaping metal, while the flat face is used for striking or driving punches.

For heavier-duty tasks, such as demolition or construction, sledgehammers are the go-to choice. They have a large, heavy head and a long handle, allowing for powerful blows. Sledgehammers are commonly used for breaking concrete, driving stakes, or demolishing structures.

When working with delicate materials or requiring more precision, a rubber mallet is preferred. Rubber mallets have a rubber or plastic head, which reduces the risk of damaging the surface while still providing the necessary impact. They are commonly used in woodworking, assembling furniture, or installing delicate tiles.

Dead blow hammers are specialized hammers filled with sand or shot, ensuring a more controlled and consistent impact. They are commonly used in automotive or mechanics work, where accuracy and minimizing recoil are crucial.

It’s important to choose the right hammer for the task at hand to ensure efficient and effective results. Consider factors such as the material being struck and the force required. Using the wrong hammer can lead to damage or incomplete work.

When using a hammer, it’s essential to wear appropriate safety gear, such as safety goggles, to protect your eyes from flying debris. Additionally, always strike the object squarely to prevent accidental slips and injuries.

Hammers are versatile tools that can be found in every toolbox, whether it’s for professional use or DIY projects. With the right hammer in your hand, you can successfully drive nails, shape metal, or perform various construction and demolition tasks with ease and precision.

Saws

Saws are essential hand tools used for cutting through different materials, such as wood, metal, or plastic. They consist of a sharp-toothed blade attached to a handle or frame, allowing for controlled and precise cutting.

One of the most common types of hand saws is the crosscut saw. It has a straight blade with sharp teeth designed to cut across the grain of wood. Crosscut saws are suitable for making clean and accurate cuts in lumber or other wooden materials.

Rip saws, on the other hand, are designed for cutting along the grain of the wood. They have fewer teeth per inch compared to crosscut saws, allowing for more efficient cutting along the length of the wood grain. Rip saws are commonly used in woodworking and carpentry tasks.

If you need to cut through metal or plastic, a hacksaw is the tool to use. Hacksaws have a thin, narrow blade with small, fine teeth. They are ideal for cutting through pipes, rods, or other small metal or plastic objects. Hacksaws allow for precise and controlled cutting, making them suitable for various DIY and professional applications.

For cutting through large pieces of wood or boards, a handsaw or panel saw is commonly used. These saws have longer blades with larger teeth, allowing for faster and more efficient cutting. Handsaws are versatile and can be used for general woodworking tasks, while panel saws are designed for cutting large panels or sheets.

If you need to make curved or intricate cuts, a coping saw is the tool of choice. Coping saws have a thin, narrow blade stretched across a U-shaped frame. They are commonly used in woodworking, particularly for intricate designs or cutting curves.

When using a saw, it’s important to choose the right type of saw for the material and application. Using the wrong saw can lead to inefficient cutting or damage to the material. Always ensure the blade is sharp and in good condition, as a dull blade can cause rough cuts and require more effort.

Wearing appropriate safety gear, such as safety glasses or goggles, is essential when using saws to protect your eyes from flying debris. Additionally, always make sure to secure the material being cut properly and maintain a firm grip on the saw.

Having a collection of saws in your toolbox will ensure you have the right tool for any cutting task that comes your way. Whether you’re a woodworker, DIY enthusiast, or professional tradesperson, a good set of saws will help you achieve precise and clean cuts in various materials.

When using basic hand tools, always make sure to use the right tool for the job to avoid damaging the tool or the material you are working on. This will help you work more efficiently and safely.

Chisels

Chisels are versatile hand tools used for cutting or shaping a wide variety of materials, including wood, stone, or metal. They consist of a blade with a sharp cutting edge, typically made of steel, attached to a handle.

Woodworking chisels are commonly used for carving or sculpting wood. They come in different types, including bench chisels, mortise chisels, and carving chisels. Bench chisels have beveled edges and are used for general-purpose woodworking tasks, such as shaping or cutting joints. Mortise chisels, on the other hand, have thicker blades and are designed for cutting rectangular-shaped holes called mortises. Carving chisels have specialized shapes and are used for intricate woodcarving and detailing.

Cold chisels are specifically designed for cutting or shaping cold metal, such as steel or wrought iron. They have a wide, flat head and are commonly used in metalworking, automotive repair, or blacksmithing. Cold chisels are typically struck with a hammer to create clean and precise cuts or to shape metal objects.

For masonry or stone work, mason’s chisels are used. They have a strong and durable blade with a wide chisel edge, allowing for cutting or shaping various types of stone or masonry materials. Mason’s chisels are commonly used in construction, bricklaying, or sculpting stone.

When using a chisel, it’s important to maintain a proper grip and apply controlled force. Chisels should be sharp and in good condition to prevent slipping and ensure clean cuts. It’s recommended to use a mallet or hammer to strike the chisel, ensuring enough force without damaging the handle.

Chisels should be stored in a protective case or rack to prevent the cutting edge from becoming dull or damaged. Regular sharpening and maintenance are necessary to keep the blades in optimal condition.

Always wear appropriate safety gear, such as safety goggles or gloves, when using chisels to protect yourself from flying debris or accidental slips.

Whether you’re a woodworker, sculptor, or metalworker, having a set of high-quality chisels in your toolbox is essential. They are versatile tools that allow for precise cutting or shaping of different materials, opening up a world of creative possibilities in various DIY or professional applications.

Files

Files are hand tools used for shaping, smoothing, or refining surfaces of various materials, such as wood, metal, or plastic. They consist of a handle and a blade with rows of teeth or abrasive surfaces. The teeth or abrasive surfaces remove small amounts of material with each stroke, allowing for controlled and precise shaping or smoothing.

Hand files come in various shapes and sizes, each designed for specific tasks and materials. Some common types of hand files include flat files, round files, half-round files, and needle files.

Flat files have a rectangular shape and parallel cutting edges along the width of the file. They are commonly used for general-purpose filing, smoothing rough edges, or filing flat surfaces.

Round files, as the name implies, have a circular cross-section along with sharp teeth around the circumference. They are ideal for enlarging or shaping round holes or curves.

Half-round files have one flat side and one rounded side, which makes them versatile tools for both flat and curved surfaces. They are commonly used for filing concave or convex surfaces, fitting into tight corners, or removing material from both flat and curved areas.

Needle files are small, thin files with fine teeth and a narrow profile. They are used for intricate or delicate work, such as jewelry making, precision woodworking, or shaping small parts.

When using files, it’s important to have a firm grip on the handle and apply consistent and even pressure. Utilize long, smooth strokes to ensure an even and controlled removal of material. It’s also helpful to periodically clean files with a wire brush to remove debris and prevent clogging of the teeth.

Files are versatile tools that can be used in various industries, including woodworking, metalworking, jewelry making, or even DIY home projects. They allow for precise shaping, smoothing, or refinishing of surfaces, making them essential tools in achieving professional and polished results.

Clamps

Clamps are essential hand tools used to hold objects securely in place during various woodworking, metalworking, or DIY projects. They provide stability and help ensure accurate and precise work by preventing materials from shifting or moving during cutting, gluing, or assembly.

There are different types of clamps available, each designed for specific applications and materials. Let’s explore some of the most common types:

C-clamps, also known as G-clamps, are versatile and widely used clamps. They have a C-shaped frame with a screw mechanism that allows for tightening the clamp around the material. C-clamps are ideal for general-purpose clamping, such as securing pieces of wood together or holding metal parts during welding or fabrication.

Bar clamps, also called F-clamps, consist of a sliding bar and a fixed jaw. The bar can be adjusted to the desired length, and the jaw is tightened using a screw mechanism. Bar clamps provide strong clamping force over a large area and are commonly used in cabinetry, woodworking, or when gluing larger pieces together.

Spring clamps, also known as pinch clamps or hand clamps, have a spring-loaded mechanism that allows for quick and easy clamping. They are lightweight and portable, making them suitable for smaller projects or holding objects temporarily in place while working. Spring clamps are commonly used for holding objects during painting, gluing, or securing fabric.

Pipe clamps utilize lengths of standard pipe and special clamp heads to create a customizable and versatile clamping system. They are commonly used for larger woodworking projects, such as assembling furniture or laminating large panels. Pipe clamps allow for high clamping pressure and have a wide opening capacity.

There are also specialized clamps, such as corner clamps, miter clamps, or band clamps, designed for specific applications like joining mitered corners or securing irregular shapes.

When working with clamps, it’s important to use the appropriate size and type of clamp for the project. Ensure that the clamps are tightened securely without causing damage to the workpiece. Additionally, be mindful of the clamping pressure to avoid excessive pressure that could deform or damage the material.

Clamps are essential tools that help in achieving accurate and professional results in a wide range of projects. Whether you’re a woodworker, metalworker, or DIY enthusiast, having a selection of clamps in your arsenal will provide stability and convenience during your work.

Read more: What Type Of Facility Makes Hand Tools

Measuring Tools

Measuring tools are crucial for ensuring accuracy and precision in various DIY, construction, or woodworking projects. These tools allow you to take precise measurements, whether it’s for determining dimensions, checking levels, or aligning surfaces. Let’s take a look at some commonly used measuring tools:

Tape Measure: A tape measure is a flexible ruler commonly made of steel or fiberglass. It features measurement markings in both metric and imperial systems, allowing you to measure distances, lengths, or heights quickly. Tape measures come in various lengths, typically ranging from a few feet to several meters, to accommodate different project needs. They are versatile, portable, and essential in almost every project.

Ruler: The ruler is a flat, rigid measuring tool typically made of wood, plastic, or metal. It features straight edges and markings in both metric and imperial measurements. Rulers are useful for measuring and drawing straight lines or checking the dimensions of smaller objects.

Square: A square is a measuring tool with a right-angled shape, usually made of metal or plastic. It is used to ensure accuracy in square or perpendicular cuts and angles. The combination square is a versatile tool that combines a 90-degree angle with a measuring ruler, allowing for precise measurements and marking.

Level: A level is used to determine whether a surface or object is perfectly horizontal (level) or vertical (plumb). It consists of a vial containing a bubble of air or liquid, which should be centered between two reference lines when the object is level. Levels come in different lengths, from small handheld levels to longer levels used for larger surfaces.

Calipers: Calipers are precision measuring devices used to measure the distance between two points, internal or external dimensions, or thickness. They come in various types, including dial calipers, digital calipers, or vernier calipers. Calipers are commonly used in metalworking, engineering, or machining applications that require high levels of accuracy.

Angle Finder: An angle finder, also known as a protractor, is used to measure and replicate angles accurately. It features a pivoting arm or a circular scale with angle markings, allowing you to measure or transfer angles with precision. Angle finders are essential in woodworking, metalworking, or any task requiring precise angle alignment or cutting.

Measuring tools are essential for any project requiring accuracy and precision. It’s important to choose high-quality measuring tools and ensure they are properly calibrated for reliable and consistent measurements. Remember to handle measuring tools with care to avoid damaging their accuracy or functionality.

Whether you’re a DIY enthusiast, woodworker, or professional tradesperson, investing in a set of reliable measuring tools will greatly enhance the quality and accuracy of your work.

Conclusion

Having a comprehensive collection of basic hand tools is essential for any DIY enthusiast or professional tradesperson. These tools empower individuals to tackle a wide range of tasks, from construction and repairs to woodworking and plumbing.

From screwdrivers and pliers to wrenches and hammers, each tool serves a specific purpose in their respective applications. Screwdrivers allow for precise insertion and removal of screws, while pliers provide a secure grip and manipulation of various materials. Wrenches ensure the proper tightening or loosening of nuts, bolts, and fasteners, while hammers provide the necessary impact for driving or striking objects. Saws enable clean and accurate cutting through different materials, and chisels allow for shaping and refining surfaces. Files help in smoothing and shaping materials, and clamps provide stability during various projects. Measuring tools ensure accuracy and precision in measurements and alignments.

It’s important to choose high-quality tools that are suitable for the task at hand. Investing in well-crafted tools ensures durability, reliability, and efficient performance. Additionally, proper maintenance and storage of hand tools will prolong their lifespan and optimize their functionality.

Remember, safety should always be a priority when using hand tools. Wear appropriate safety gear, such as gloves, safety glasses, and ear protection, when necessary. Follow proper techniques and instructions for each tool to avoid accidents or injuries.

By understanding the different types of basic hand tools and their applications, you can equip yourself with the right tools for the job and enhance your efficiency and productivity. Whether you’re a DIY hobbyist or a professional tradesperson, having a well-stocked toolbox with a variety of hand tools will allow you to tackle any task with confidence and skill.

So, gather your tools, hone your skills, and embark on your next project with the knowledge that you have the right hand tools at your disposal. With these tools in hand, you’ll be able to bring your ideas to life and achieve professional results in your DIY adventures.

Frequently Asked Questions about What Are Some Types Of Basic Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Some Types Of Basic Hand Tools”