Articles

What Is Metalworking Hand Tools

Modified: December 7, 2023

Discover the essential metal work hand tools with Articles. Learn what types of tools are used in metal work and how they are used by experts.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

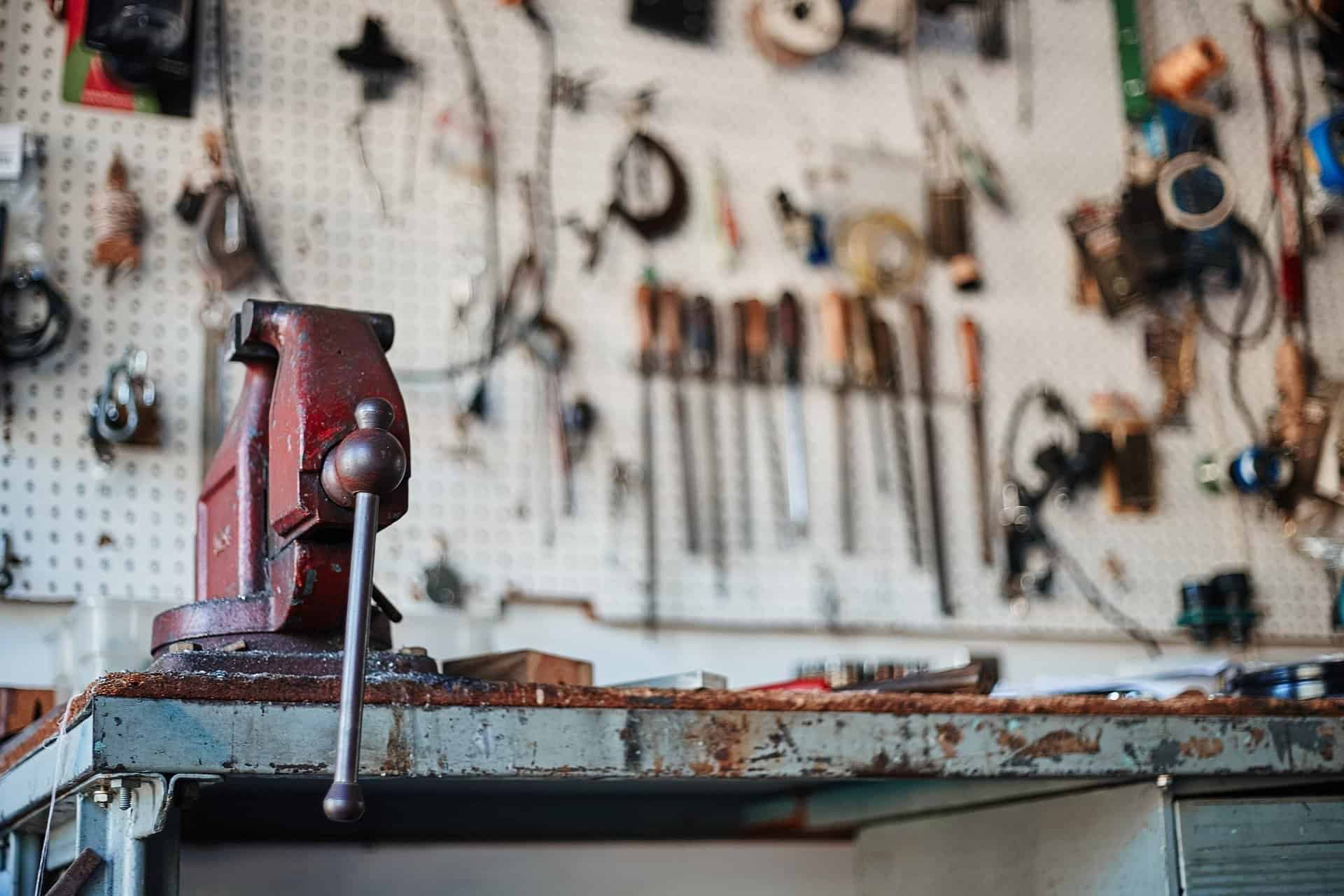

When it comes to working with metal, having the right tools is essential. Metal work hand tools are specially designed instruments that aid in cutting, shaping, and manipulating metal materials. They are a crucial component of any metalworking project, whether you are a professional welder or a DIY enthusiast.

These tools are crafted with precision and durability in mind, allowing you to create intricate designs, repair damaged parts, and build structures with ease. From hammers and screwdrivers to pliers and wrenches, each hand tool plays a unique role in the metalworking process.

In this article, we will explore the importance of metal work hand tools, discuss various types of tools used in metalworking, provide basic safety guidelines, and offer tips on their proper use and maintenance.

So, whether you are a beginner or an experienced metalworker, read on to discover the world of metal work hand tools and how they can elevate your craftsmanship to new heights.

Key Takeaways:

- Metal work hand tools are essential for precision, efficiency, and safety in metalworking, enabling craftsmen to achieve professional-quality results and tackle a wide range of projects with confidence.

- Proper use and maintenance of metal work hand tools are crucial for longevity and optimal performance, ensuring reliable results and unlocking endless possibilities for creativity and craftsmanship.

Read more: What Is A Hand Tool

Importance of Metal Work Hand Tools

Metal work hand tools are indispensable for anyone involved in metalworking, regardless of their skill level. Here are some key reasons why these tools are of utmost importance:

- Precision: Metal work hand tools are designed to provide precise control and accuracy, allowing you to create intricately detailed metal pieces. Whether you need to make clean cuts, shape edges, or manipulate metal surfaces, these tools enable you to achieve the desired results with precision.

- Efficiency: The right hand tools can significantly improve your workflow and productivity. With their ergonomic designs and optimal features, they make your metalworking tasks more efficient by reducing fatigue and saving time. By using appropriate tools, you can accomplish tasks quickly and effectively, boosting your overall productivity.

- Versatility: Metal work hand tools come in various shapes and sizes, each designed for specific purposes. This versatility allows you to work on a range of projects, from small-scale repairs to large-scale constructions. Having a comprehensive set of tools ensures that you are prepared for any metalworking challenge that comes your way.

- Safety: Using the appropriate hand tools greatly enhances safety during metalworking. These tools are specifically engineered to minimize the risk of accidents and injuries. They provide a secure grip, reduce slippage, and protect your hands from sharp edges and hot surfaces. Adhering to proper safety precautions and using the right tools can prevent accidents and keep you safe in the workshop.

- Quality: The quality of your work depends largely on the tools you use. Metal work hand tools, when crafted with high-quality materials and precision engineering, ensure that your finished products are of superior quality. From precise measurements to clean finishes, these tools contribute to the overall aesthetic and functionality of your metalwork.

Overall, metal work hand tools are essential for achieving professional-level results in metalworking. They offer precision, efficiency, versatility, safety, and quality, enabling you to tackle a wide range of projects and produce exceptional work.

Types of Metal Work Hand Tools

In the world of metalworking, there are various types of hand tools that serve specific purposes. Let’s explore some of the most common ones:

- Hammers: Hammers are versatile tools used for shaping and bending metal, as well as driving nails and removing dents. They come in different sizes and shapes, such as ball peen hammers, claw hammers, and rubber mallets, each suitable for different tasks.

- Screwdrivers: Screwdrivers are essential hand tools for manipulating screws and bolts. They come in various sizes and types, including flathead and Phillips-head screwdrivers. Having a set of screwdrivers with different tips ensures that you can handle different screw types and sizes.

- Pliers: Pliers are used for gripping, bending, and cutting metal. They come in different variations, including needle-nose pliers, slip-joint pliers, and locking pliers. Pliers are indispensable for manipulating wires, pulling nails, and holding small objects securely.

- Wrenches: Wrenches are used to tighten or loosen nuts, bolts, and other fasteners. They come in different types, such as open-end wrenches, box-end wrenches, and adjustable wrenches. Having a variety of wrenches in your toolbox ensures that you can handle different sizes of fasteners.

- Files: Files are abrasive hand tools used for shaping and smoothing metals. They come in different shapes, including flat, round, and half-round, allowing you to work on different surfaces and contours. Files are ideal for removing burrs, refining edges, and achieving a smooth finish on metal surfaces.

- Chisels: Chisels are used for cutting and shaping metal by hand. They have sharp beveled edges and come in various sizes and types, such as bench chisels and cold chisels. Chisels are commonly used for carving intricate designs, cutting grooves, and removing excess material from metal surfaces.

- Punches: Punches are metal rods with pointed ends used for marking, indenting, and aligning holes in metal. They are available in different sizes and shapes, such as center punches, prick punches, and pin punches. Punches are essential for creating accurate markings and starting holes for drilling.

These are just a few examples of the many types of metal work hand tools available. Each tool serves a specific purpose in metalworking and is essential for achieving precise and professional results. Having a well-rounded collection of hand tools ensures that you are prepared for any metalworking project that comes your way.

When working with metal hand tools, always wear appropriate safety gear such as gloves and eye protection to prevent injury from sharp edges and flying debris.

Basic Hand Tool Safety Guidelines

Working with metal work hand tools requires caution and adherence to proper safety practices. Here are some basic hand tool safety guidelines to follow:

- Wear appropriate personal protective equipment (PPE): Always wear the necessary PPE, such as safety glasses, gloves, and ear protection, to protect yourself from potential hazards. Metalworking can generate sparks, flying debris, and loud noises, so it’s important to safeguard your eyes, hands, and ears.

- Inspect tools before use: Before using any hand tool, inspect it for any signs of damage, such as cracks, chips, or loose handles. Using damaged tools can lead to accidents and injuries, so it’s crucial to ensure that your tools are in good condition.

- Use the right tool for the job: Each hand tool is designed for specific tasks. Ensure that you are using the appropriate tool for the job at hand. Using the wrong tool can lead to poor results and increase the risk of accidents.

- Maintain a clean and organized work area: Keep your work area clean and free from clutter. Remove any obstacles or debris that could cause accidents or interfere with your work. Proper organization allows you to easily locate and access your tools, reducing the risk of mishaps.

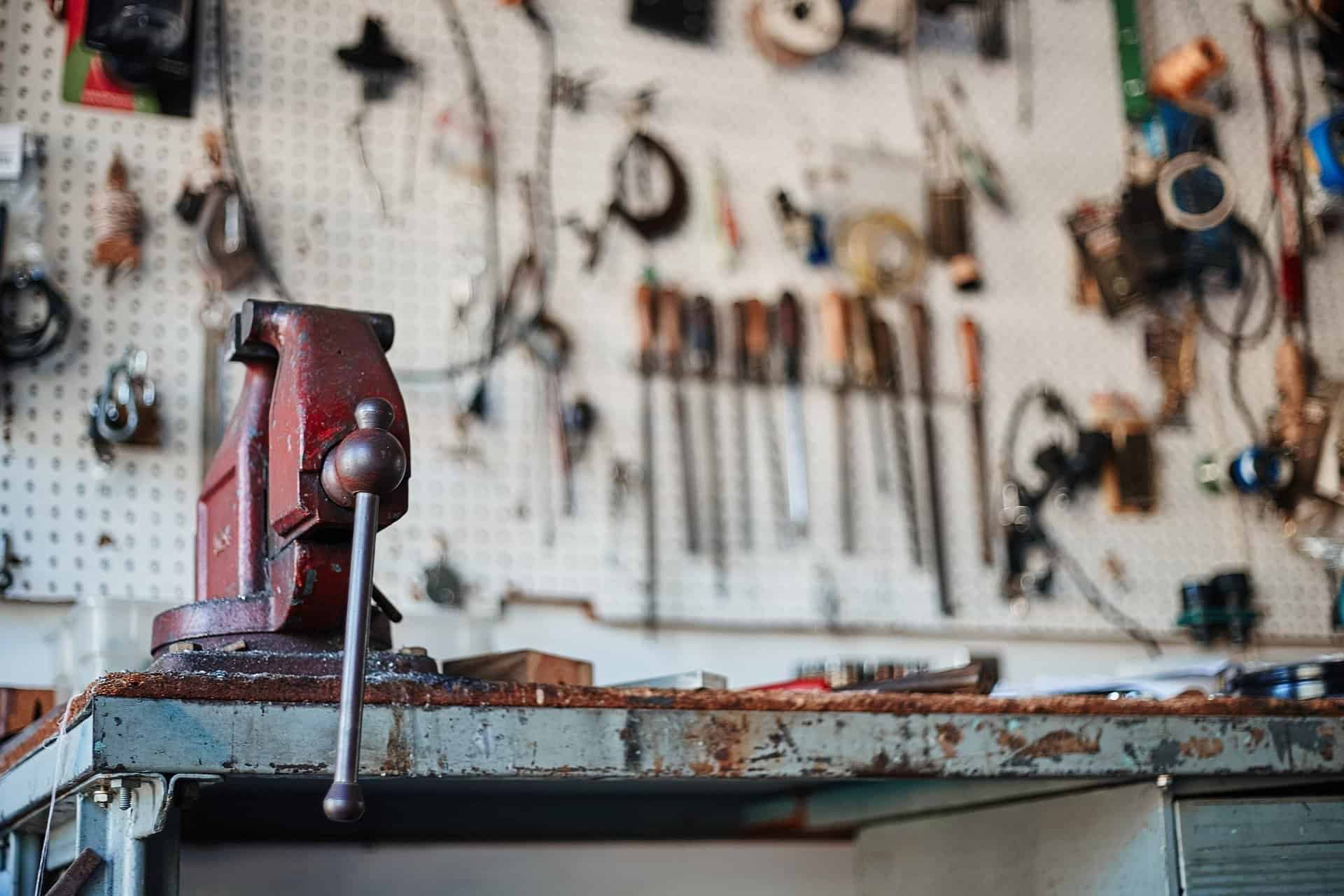

- Secure your workpiece: Before beginning any metalworking task, securely fasten your workpiece in a vise or clamp. This prevents movement or slipping, ensuring stability and reducing the risk of injuries caused by unexpected shifts.

- Keep a firm grip: When using hand tools, maintain a firm and secure grip. Avoid using excessive force or applying pressure at awkward angles, as this can result in loss of control or strain on your hands and wrists.

- Avoid distractions: Focus solely on the task at hand when working with hand tools. Avoid distractions, such as talking on the phone or engaging in unrelated activities, as they can lead to accidents and mistakes.

- Store tools properly: After each use, clean your hand tools and store them in a designated place. This protects them from damage and prevents accidental contact with sharp edges or moving parts.

- Seek proper training: If you are new to metalworking or unfamiliar with certain hand tools, seek proper training and guidance before using them. Understanding how to use tools correctly reduces the risk of accidents and ensures optimal results.

By following these basic hand tool safety guidelines, you can protect yourself from potential hazards and work confidently in your metalworking projects. Remember, safety should always be the top priority when using hand tools.

Proper Use and Maintenance of Metal Work Hand Tools

Using metal work hand tools correctly and maintaining them properly ensures their longevity and optimal performance. Here are some tips for the proper use and maintenance of these essential tools:

- Read the manufacturer’s instructions: Before using a new hand tool, familiarize yourself with the manufacturer’s instructions and recommended usage guidelines. Understanding the tool’s features, limitations, and proper use will help you work safely and effectively.

- Use tools with the correct technique: Each hand tool has a specific technique for optimal use. Learn the proper technique for each tool to avoid strain and maximize efficiency. For example, when using a hammer, strike with a controlled force and use the correct gripping technique.

- Regularly clean your hand tools: After each use, clean your hand tools to remove dust, debris, and any residue. Wipe them down with a clean cloth or use a brush to remove stubborn dirt. Regular cleaning prevents buildup and keeps the tools in good working condition.

- Protect tools from moisture and corrosion: Metal hand tools are susceptible to rust and corrosion. To prevent this, store them in a dry area away from moisture. Consider applying a thin coat of oil on metal surfaces to provide additional protection against corrosion.

- Inspect tools for wear and damage: Regularly inspect your hand tools for signs of wear, such as loose handles, worn-out edges, or damaged parts. Replace or repair any damaged tools promptly to ensure safe and efficient use.

- Sharpen cutting tools when necessary: Cutting tools, such as chisels and punches, may become dull over time. Sharpen them as needed using appropriate sharpening tools or seek professional sharpening services. Sharp cutting tools perform better and reduce the risk of accidents.

- Properly store your tools: Store your hand tools in a dry and organized manner. Consider using toolboxes, racks, or designated storage compartments to protect them from damage and make them easily accessible.

- Protect against accidental contact: When not in use, cover sharp edges or points of hand tools with protective caps or sheaths. This prevents accidental contact and reduces the risk of injuries when retrieving or storing the tools.

- Replace worn-out or damaged tools: Over time, even the highest quality hand tools may wear out or become damaged beyond repair. Replace these tools with new ones to maintain the quality and safety of your work.

By using your metal work hand tools correctly and maintaining them properly, you can extend their lifespan, ensure reliable performance, and achieve outstanding results in your metalworking projects.

Read more: What Are Hand Tools Made Of

Conclusion

Metal work hand tools are an integral part of any metalworking process, providing precision, efficiency, and versatility to craftsmen of all skill levels. These tools allow you to shape, manipulate, and refine metal materials with accuracy and control, resulting in professional-quality work.

From hammers and screwdrivers to pliers and wrenches, each hand tool serves a unique purpose in the metalworking realm. They enable you to achieve precise cuts, smooth finishes, and secure fastenings, ultimately enhancing the overall quality of your metal creations.

However, it’s important to prioritize safety when working with these tools. Adhering to basic safety guidelines, such as wearing appropriate protective equipment and properly maintaining your tools, helps prevent accidents and ensures a secure working environment.

By using metal work hand tools correctly and maintaining them properly, you can extend their lifespan and optimize their performance. Regular cleaning, inspection for damage, and sharpening when necessary are key practices to keep your tools in top shape.

Whether you are a professional metalworker or a DIY enthusiast, having a comprehensive set of metal work hand tools is essential. It allows you to tackle a wide range of metalworking projects and unlocks endless possibilities for creativity and craftsmanship.

In conclusion, embrace the world of metal work hand tools and explore the incredible potential they offer in your metalworking endeavors. With the right tools and knowledge, you can unleash your creativity, achieve outstanding results, and take your metalworking skills to new heights.

Frequently Asked Questions about What Is Metalworking Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Metalworking Hand Tools”