Articles

What Are Some Of The Hand Tools For Saws

Modified: December 7, 2023

Find informative articles about hand tools for saws. Learn what to consider when choosing the right tools and how to maintain them for optimal performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Hand tools are essential for any woodworking enthusiast or professional. When it comes to saws, there are several hand tools that can greatly enhance their functionality and efficiency. These tools not only aid in the proper maintenance and upkeep of saws but also ensure precision and accuracy in cutting tasks.

In this article, we will explore some of the must-have hand tools for saws. From hammers to screwdrivers, chisels to saw vises, each of these tools plays a crucial role in facilitating smooth and effective sawing operations. So, let’s dive in and discover the key hand tools that every saw owner should have in their toolbox.

Key Takeaways:

- Enhance Your Sawing Experience

Equip your toolbox with essential hand tools such as a claw hammer, chisel, and coping saw blades to ensure precision, efficiency, and safety in your woodworking projects. Elevate your sawing skills and achieve exceptional results with the right tools. - Maintain Optimal Cutting Performance

Regular maintenance with specialized tools like a saw set, saw file, and saw vise is crucial for keeping saw blades sharp and properly aligned. Invest in high-quality hand tools to ensure longevity and effectiveness, and elevate the overall quality of your woodworking projects.

Read more: What Are Some Types Of Basic Hand Tools

Hand Tools for Saws

When it comes to working with saws, having the right hand tools can make a world of difference. These tools not only aid in the maintenance and sharpening of saws but also help improve precision and efficiency in cutting tasks. Let’s take a closer look at some of the essential hand tools for saws:

-

Claw Hammer

A claw hammer is a versatile tool that is indispensable in any workshop. It can be used to drive nails into wood, remove nails, or even tap and align pieces of wood together. When working with saws, a claw hammer can assist in securing workpieces or adjusting the position of the saw blade for more accurate cutting.

-

Screwdriver

A screwdriver is an essential tool for assembling and disassembling saw components. It is especially useful when adjusting or replacing saw blades or making fine adjustments to the saw mechanism. Make sure to have a variety of screwdriver sizes and types, including flathead and Phillips, to accommodate different screws used in saw construction.

-

Chisel

A chisel is a must-have tool for refining and shaping wood. When working with saws, a chisel can be used to remove excess material, adjust the fit of joints, or create intricate details in the wood. It is important to keep chisels sharp and properly maintained to ensure clean and precise cuts.

-

Read more: How To Use A Hand Saw

Mallet

A mallet is a hammer-like tool with a large head made of wood, rubber, or plastic. It is used to strike chisels or other cutting tools without damaging or causing them to chip. When using a hand saw, a mallet can be beneficial in gently tapping the saw blade to adjust its alignment or remove stuck material.

-

Saw Set

A saw set is a specialized tool used for adjusting the teeth of a saw blade. It allows you to set the teeth to the correct angle and spacing, which is crucial for efficient and clean cutting. Using a saw set regularly helps maintain the sharpness and performance of your saw blade.

-

Saw File

A saw file is used to keep the teeth of a saw blade sharp and properly shaped. It is used to remove burrs, reshape damaged teeth, and restore the cutting edge. Regular sharpening and maintenance with a saw file not only improves cutting performance but also extends the lifespan of your saw blade.

-

Coping Saw Blades

Coping saw blades are thin, narrow blades with fine teeth that are specifically designed for making intricate curved cuts and detailed work. They are typically used for cutting patterns, curves, or complex shapes in wood. Having a selection of coping saw blades with different tooth sizes and configurations allows for greater versatility in cutting tasks.

-

Read more: What Is A Hand Tool

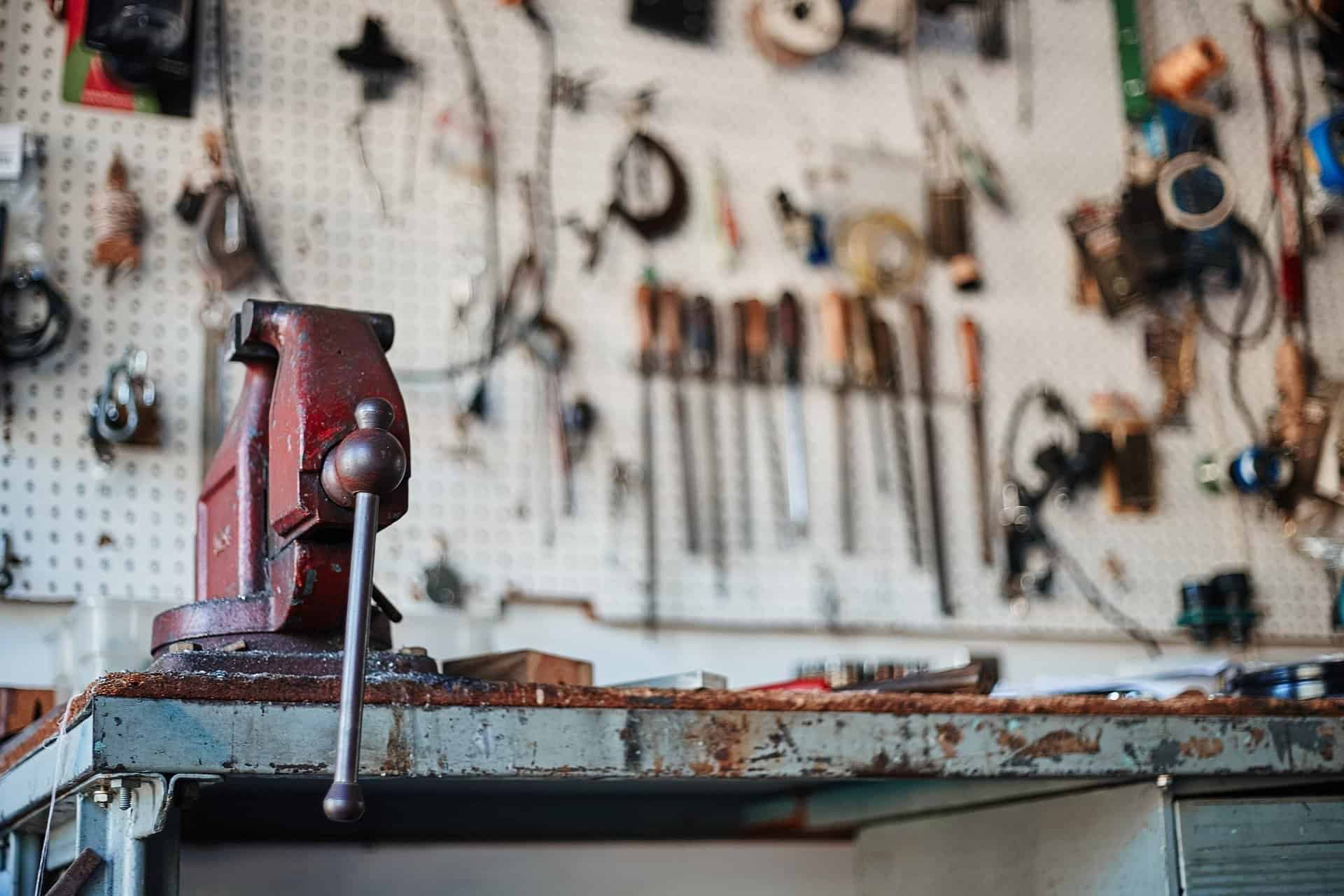

Saw Vise

A saw vise is a tool used for securely holding the saw blade while sharpening or maintaining it. It provides a stable platform and allows for precise control when filing or setting the teeth of the saw. A saw vise is an essential tool for maintaining the proper tension and alignment of the saw blade.

-

Saw Dust Blower

A saw dust blower is a handy tool that helps clear away dust and debris from the cutting area. It ensures better visibility and prevents dust from interfering with the sawing process. Using a saw dust blower can significantly improve cutting accuracy and reduce the risk of accidents or injuries caused by obscured vision.

-

Saw Bench

A saw bench, also known as a workbench, is a sturdy table-like surface used for supporting wood during sawing operations. It provides a stable and safe work area, allowing for precise and controlled cutting. A well-designed saw bench with adjustable height and clamping mechanisms can greatly enhance the efficiency and comfort of sawing tasks.

Having these hand tools for saws in your toolbox will not only ensure the proper maintenance and care of your saw but also enhance your woodworking experience. Each tool serves a specific purpose, allowing for precise, efficient, and accurate cutting operations. So, make sure to equip yourself with these essential hand tools and take your sawing skills to the next level.

Claw Hammer

A claw hammer is a versatile hand tool that is a staple in any toolbox. It consists of a handle and a head with a flat striking surface on one end and a curved claw on the other. The flat surface is used for driving nails into wood, while the claw is used for removing nails or aligning wood pieces.

When it comes to working with saws, a claw hammer can be incredibly useful. It can be used to secure workpieces, ensuring they stay in place while you make precise cuts with your saw. By tapping the sides of the workpiece with the hammer, you can adjust its position and alignment, ensuring accurate and straight cuts.

In addition, a claw hammer can also be used to adjust the position of the saw blade itself. Sometimes, the saw blade may come loose or shift during cutting, leading to less accurate cuts. By gently tapping the blade with the claw end of the hammer, you can reposition it and ensure it remains securely in place.

Furthermore, if you encounter any nails or screws that are obstructing your cutting path, the claw end of the hammer can come to the rescue. Simply use the curved claw to grip and pull out the fasteners, clearing the way for smooth and uninterrupted cutting.

When using a claw hammer with saws, it is important to exercise caution. Ensure that the workpiece is securely held down to avoid any accidents or injury. Also, make sure to use controlled and precise strikes when adjusting the saw blade to avoid damaging the blade or the surrounding material.

Overall, a claw hammer is an essential hand tool for any woodworking project, including sawing tasks. Its versatility and practicality make it a valuable asset in your toolbox, allowing you to secure workpieces, adjust blade position, and remove obstructions. So, make sure to have a high-quality claw hammer in your collection to enhance your sawing experience.

Read more: What Are Insulated Hand Tools?

Screwdriver

A screwdriver is a fundamental hand tool that is indispensable for any woodworking or DIY project. It is designed to tighten or loosen screws by applying torque to their heads. When it comes to working with saws, having a reliable set of screwdrivers is crucial for various tasks, including blade replacement, maintenance, and adjustments.

When working with saws, you may need to remove or replace the saw blade for different purposes, such as changing to a different blade type or replacing a dull blade. To accomplish this, you’ll require a suitable screwdriver to remove the screws that secure the blade in place. Depending on the manufacturer and model of your saw, you may encounter different screw types, such as Phillips or flathead screws. Therefore, having a diverse set of screwdrivers is essential to accommodate different screw designs and sizes.

In addition to blade replacement, a screwdriver is also handy for making fine adjustments to the saw mechanism. Often, saws have various adjustment points, such as blade height, angle, or tension. To achieve optimal performance and precise cuts, you may need to adjust these settings periodically. A screwdriver allows you to access and manipulate the screws or knobs that control these adjustments, ensuring that your saw operates at its best.

When using a screwdriver with saws, it’s important to match the size and type of the screwdriver tip to the screw head to avoid stripping or damaging the screws. Applying excessive force or using the wrong screwdriver can lead to irreversible damage, compromising the functionality of your saw.

It’s also worth mentioning that investing in screwdrivers with ergonomic handles can make a significant difference in your comfort and grip. This is particularly important when dealing with tight or hard-to-reach screw locations. A comfortable grip reduces hand fatigue and allows for better control, resulting in more precise adjustments and safer work practices.

To summarize, a set of reliable screwdrivers is a must-have tool for working with saws. Whether it’s for blade replacement, maintenance, or adjustments, a screwdriver provides the necessary torque to manipulate screws effectively. Remember to use the appropriate screwdriver size and type, exercise caution to avoid stripping or damaging screws, and prioritize ergonomic handles for improved comfort and control.

Chisel

A chisel is a versatile hand tool that is essential for woodworking projects, including tasks related to saws. It consists of a long, sharp blade with a beveled edge and a handle for grip and control. Chisels are primarily used for shaping, carving, and removing material from wood, making them invaluable when it comes to refining and adjusting saw cuts.

When working with saws, a chisel can be used for a variety of purposes. One common application is to remove excess material left by the saw blade. Even with the most precise cuts, there may be slight irregularities or protrusions that need to be smoothed out. A chisel allows you to carefully pare away any unwanted wood and achieve a clean and flush surface.

In addition, chisels can be useful for adjusting the fit of joints in woodworking projects involving saw cuts. For instance, if you have two pieces of wood that need to fit together seamlessly, but there is a slight gap or unevenness, a chisel allows you to carefully remove wood from one or both pieces until the desired fit is achieved. This ensures a tight and sturdy joint, enhancing the overall quality and strength of the project.

Furthermore, chisels can be employed to create intricate details or decorative elements in wood. Whether you’re working on a furniture piece or a smaller craft project, a chisel can be used to carve out designs, patterns, or chamfers, adding visual interest and personalization to your work.

When using a chisel, it’s important to employ proper technique and take safety precautions. Always ensure the wood is firmly secured in a vise or clamp to prevent slipping or accidental injury. Maintain a controlled grip on the chisel and apply pressure only when necessary, avoiding excessive force that could lead to chisel slippage or damage to the wood. Additionally, keep the chisel blade sharp and properly maintained for optimal performance and safety.

Overall, a chisel is an indispensable hand tool for working with saws. Its versatility allows for precise shaping, adjusting, and detailing of saw cuts. By adding a chisel to your toolkit, you open up a world of possibilities for fine-tuning your woodworking projects and achieving professional-level results.

Mallet

A mallet is a specialized hammer-like hand tool that is commonly used in woodworking and carpentry. Unlike a regular hammer, a mallet typically has a larger, rounded head made of wood, rubber, or plastic. It is designed to deliver controlled blows without causing damage or leaving marks on the workpiece. When it comes to working with saws, a mallet can be a valuable tool for various tasks.

One of the primary uses of a mallet in conjunction with saws is for gentle tapping or adjustment of the saw blade. Over time, the saw blade may become misaligned or stuck due to sawdust accumulation or other factors. By using a mallet to lightly tap the side of the blade, you can adjust its position and ensure smooth cutting. The soft impact of the mallet helps avoid damaging the blade or the surrounding material while providing enough force to dislodge any obstacles.

In addition to blade adjustment, a mallet can also be used to strike chisels when working on woodworking projects involving saw cuts. Chisels are commonly used to shape, mark, or remove wood, and a mallet provides the necessary force to safely drive the chisel into the material. The weight and shape of the mallet head, combined with the controlled force applied, ensure precision and control in chiseling tasks.

Furthermore, a mallet can assist in assembly or disassembly tasks when working with saws. For example, when fitting parts together or joining two pieces of wood, a mallet can be used to gently tap them into place without risking damage from a metal hammer. The soft impact of the mallet head ensures that the force is distributed evenly, minimizing the likelihood of splintering or denting the wood.

When using a mallet with saws, it’s important to choose the right type and weight for the task at hand. Different materials and sizes of mallet heads will produce varying levels of impact. Some tasks may require a lightweight mallet for delicate adjustments, while others may call for a heavier mallet for more substantial force. Consider using a mallet with a comfortable and ergonomic handle to improve grip and reduce hand fatigue during prolonged use.

Overall, a mallet is a versatile tool that complements the use of saws in woodworking projects. Whether it’s for adjusting the saw blade, striking chisels, or assembling/disassembling components, the controlled impact of a mallet ensures precise and safe work practices. Incorporating a mallet into your toolkit will enhance your sawing capabilities and contribute to the overall quality of your woodworking projects.

Saw Set

A saw set is a specialized hand tool that is essential for maintaining the optimal performance of hand saws. It is designed to adjust the teeth of a saw blade, ensuring proper alignment and spacing for effective cutting. When it comes to working with saws, a saw set is a valuable tool that can significantly improve the efficiency and longevity of your saw blades.

One of the primary functions of a saw set is to set the teeth of a saw blade to a consistent angle and depth. This ensures that each tooth engages with the material being cut in a uniform manner, resulting in smoother and cleaner cuts. By adjusting the set of the teeth, you can control the cutting action and reduce the chances of the saw blade binding or getting stuck in the wood.

Another important aspect of a saw set is its ability to maintain the spacing between the teeth. Over time, the teeth of a saw blade may become overcrowded or clogged with sawdust and debris. Using a saw set, you can restore the proper spacing between the teeth, allowing for efficient chip removal and preventing excessive heat build-up during cutting. This helps to prolong the life of your saw blade and maintain its cutting performance.

When using a saw set, it’s important to understand the specific requirements of your saw blade. Different saws have varying tooth sizes, shapes, and configurations, and each may require a specific set adjustment. It’s crucial to follow the manufacturer’s guidelines and recommendations for your particular saw to ensure accurate and effective tooth setting.

Using a saw set is a relatively straightforward process. The tool typically consists of a series of notches or jaws that correspond to the tooth spacing of your saw blade. By placing the individual teeth in the appropriate notch and applying pressure, you can accurately bend the teeth to the desired position. Some saw sets also include depth adjustment mechanisms, allowing for precise control over the amount of tooth projection.

Regularly using a saw set to maintain the teeth of your saw blade is essential for optimal cutting performance. It helps to reduce the effort required for cutting, minimizes the risk of binding or buckling, and ensures cleaner and smoother cuts. By investing in and using a saw set, you can extend the lifespan of your saw blades and enhance the overall quality of your woodworking projects.

Read more: What Are The Newest Hand Tools

Saw File

A saw file is a specialized hand tool that is crucial for maintaining the sharpness and performance of saw blades. It is designed to shape and sharpen the teeth of a saw, ensuring clean and efficient cuts. When it comes to working with saws, having a high-quality saw file is essential for proper blade maintenance and longevity.

The teeth of a saw blade can become dull or damaged over time due to regular use. This can result in less effective cutting, increased effort required, and rougher finishes. Using a saw file allows you to restore the sharpness and precision of the teeth, ensuring smooth cutting and optimal performance.

A saw file typically consists of a hardened steel bar with a series of parallel grooves or ridges, known as the file’s “teeth.” These teeth are the cutting surfaces that remove metal from the saw teeth when filing. Saw files are available in different sizes and cuts, each suitable for specific types of saws and tooth configurations.

When filing a saw blade, it’s important to follow the proper technique and consider the specific requirements of your saw. Begin by securing the saw blade in a vice or clamp, ensuring it is stable and firmly held. Position the saw file at the appropriate angle, matching the existing tooth angle, and apply even and controlled pressure as you file in a consistent and smooth motion. Remember to file each tooth evenly, ensuring the same amount of material is removed from each one.

In addition to sharpening dull teeth, a saw file can also be used to reshape damaged or misshapen teeth. If a tooth is chipped or missing, the saw file can help create a new, properly shaped tooth by removing material from adjacent teeth. This enables you to salvage and restore the functionality of your saw blade, minimizing the need for expensive replacements.

Regular maintenance with a saw file not only keeps your saw blade sharp but also prolongs its lifespan. By regularly filing the teeth, you can remove any accumulated pitch or resin, preventing clogging and maintaining optimal cutting performance. The frequency of filing depends on the frequency of use and the type of work you are doing, so it’s important to assess and file your saw blade as needed.

Overall, a saw file is an indispensable tool for maintaining the sharpness and effectiveness of saw blades. It allows you to restore the cutting edge of the teeth, reshape damaged teeth, and remove pitch or debris that can affect cutting performance. By investing in a quality saw file and incorporating regular filing into your blade maintenance routine, you can ensure clean, precise cuts and prolong the life of your saw blades.

Coping Saw Blades

Coping saw blades are thin, narrow blades with fine teeth that are specifically designed for use with coping saws. They are an essential hand tool for woodworking projects that involve intricate curved cuts and detailed work. When it comes to working with saws, having a selection of quality coping saw blades is crucial for achieving precise and intricate cuts.

One of the primary advantages of coping saw blades is their flexibility. The thin, narrow design allows for easy maneuverability around tight curves and intricate patterns. This makes coping saw blades the go-to choice when you need to cut complex shapes, curves, or internal cutouts in wood.

When using coping saw blades, it’s important to choose the appropriate blade for the task at hand. Coping saw blades come in different tooth sizes and configurations, including regular tooth, skip tooth, and spiral tooth. Each type of blade offers specific cutting characteristics and is suitable for different materials and cutting techniques.

Regular tooth blades have teeth evenly spaced along the blade, providing a smooth cutting action. They are versatile and suitable for a wide range of materials, from softwoods to hardwoods. Skip tooth blades, on the other hand, have larger gaps between the teeth, allowing for efficient chip clearance. They are ideal for faster cutting and are commonly used for rougher cuts in softer materials.

Spiral tooth blades have teeth arranged in a spiral pattern along the blade. This unique tooth design provides excellent cutting performance and is particularly effective for cutting intricate or irregular shapes. Spiral tooth blades are often preferred for detailed work, such as crafting ornate designs or cutting intricate joints.

When replacing a coping saw blade, it’s important to follow the manufacturer’s instructions to ensure proper installation. Generally, coping saw blades are attached to the coping saw frame by clamping or tensioning mechanisms. Ensure the blade is securely held in place, allowing for controlled movement and minimizing blade flex during cutting.

Using coping saw blades requires patience, skill, and a steady hand. The narrow width of the blade allows for precise cutting, but it also means that the blades are delicate and can break if too much lateral force is applied. Exercise caution and take your time when maneuvering the saw through intricate cuts or tight curves.

In summary, coping saw blades are a vital tool for achieving intricate curved cuts and detailed work. Their flexibility and narrow design allow for precise and accurate cutting around tight curves and complex patterns. By having a selection of coping saw blades with different tooth sizes and configurations, you can tackle a variety of woodworking projects with confidence and precision.

Saw Vise

A saw vise is a specialized tool designed to securely hold a saw blade during maintenance and sharpening. It provides a stable platform, allowing you to work on the saw blade with ease and precision. When it comes to working with saws, a saw vise is an essential tool for proper blade maintenance and achieving accurate cuts.

One of the primary functions of a saw vise is to securely grip the saw blade, preventing any movement or slippage while you work on it. This stability is crucial when sharpening or filing the teeth of the saw blade, as it ensures consistent contact and control over the cutting edges. A firm grip also helps maintain the proper tension of the saw blade, reducing the risk of damage or warping.

Using a saw vise simplifies the process of sharpening and maintaining the teeth of the saw blade. It allows you to position the blade at a comfortable working height and angle, ensuring better visibility and control during filing or tooth setting. With the saw securely clamped in the vise, you can focus on achieving accurate tooth geometry and maintaining uniformity across the entire length of the blade.

Saw vises come in various designs and styles, including bench-mounted and clamp-on options. Bench-mounted saw vises are permanently attached to a workbench or dedicated work surface, providing a stable and dedicated area for saw maintenance. Clamp-on saw vises, on the other hand, can be easily attached and detached from different work surfaces, providing more flexibility in terms of portability and working locations.

When using a saw vise, it’s important to ensure that the blade is properly positioned and tightened. The vise should securely grip the blade without applying excessive pressure that could damage the blade or cause it to bow. Take your time to set up the vise correctly and double-check the stability and alignment of the blade before proceeding with any maintenance tasks.

In addition to blade sharpening, a saw vise can also be useful for other saw-related tasks, such as blade replacement, tensioning, or cleaning. It provides a safe and controlled environment for handling the saw, minimizing the risk of accidental injury or damage to the workpiece.

To conclude, a saw vise is an essential tool for maintaining and sharpening saw blades. It provides stability, control, and convenience when working on the teeth of the saw, ensuring accurate sharpening and proper blade maintenance. By investing in a quality saw vise, you can enhance the overall performance and longevity of your saw blades, resulting in cleaner and more precise cuts.

Saw Dust Blower

A saw dust blower is a handy tool that helps to clear away dust and debris from the cutting area when working with saws. It plays a crucial role in enhancing visibility, maintaining clean work conditions, and improving cutting accuracy. When it comes to working with saws, a saw dust blower is a valuable accessory that can make a significant difference in your woodworking projects.

When cutting materials with a saw, the accumulation of sawdust and debris can quickly obscure your view of the cutting line and the workpiece. This can make it challenging to maintain accurate cuts and may result in errors or inconsistencies. A saw dust blower solves this problem by directing a stream of air to blow away the dust and debris, keeping the cutting area clear and your line of sight unobstructed.

By clearing away the sawdust, a saw dust blower improves visibility, allowing you to follow the cutting line more accurately. This is particularly important when performing intricate or detailed cuts that require precision. With a clear view of the workpiece and cutting line, you can achieve cleaner and more precise cuts, resulting in improved overall craftsmanship.

Another benefit of using a saw dust blower is the maintenance of clean work conditions. Sawdust can accumulate quickly and clutter your workbench or workspace, making it harder to move and handle materials effectively. By using a saw dust blower to remove the dust as you work, you can maintain a clean and organized work environment, minimizing the chances of tripping, slipping, or damaging your workpiece due to debris.

Saw dust blowers are available in various formats, including handheld blowers, attachment accessories, or even integrated features in certain saw models. Handheld blowers typically consist of a portable device that you can direct towards the cutting area for effective dust removal. Attachment accessories can be added to your existing tools or saws, providing a convenient and adjustable solution for clearing away the sawdust. Some advanced saw models come equipped with built-in dust blowers that automatically clear the dust as you cut, eliminating the need for separate tools.

When using a saw dust blower, be mindful of safety precautions. Ensure that the blower is positioned and directed away from your body and others nearby to avoid blowing debris into sensitive areas. Also, be aware of your surroundings and take precautions to prevent dust from being blown into the eyes or face.

In summary, a saw dust blower is a valuable tool that improves visibility, maintains clean work conditions, and enhances cutting accuracy when working with saws. By incorporating a saw dust blower into your workflow, you can enjoy improved precision, reduced cleanup efforts, and a safer and more pleasant woodworking experience.

Read more: What Are The 10 Hand Tools

Saw Bench

A saw bench, also known as a workbench, is an essential piece of equipment for woodworking projects, especially those involving saws. It provides a stable and elevated surface for supporting the workpiece during cutting operations. When it comes to working with saws, a saw bench is a valuable tool that enhances safety, accuracy, and overall efficiency.

One of the key advantages of a saw bench is its stability. The sturdy construction of a saw bench ensures that the workpiece remains secure and immovable during cutting. This stability is essential in achieving accurate and precise cuts, as it prevents the workpiece from shifting or vibrating while you’re using a saw. It also reduces the risk of accidents or injuries caused by the workpiece moving unexpectedly during cutting operations.

Another benefit of a saw bench is its adjustable height feature. Many saw benches allow you to customize the height of the work surface, ensuring a comfortable and ergonomic working position. This is particularly important when using hand saws or powered saws for extended periods. Having the workpiece at the correct height can prevent strain or fatigue and promote better control and accuracy in your cuts.

Saw benches often come equipped with clamping mechanisms or features that allow you to secure the workpiece in place. These clamps can hold the material firmly, allowing you to focus on the cutting without worrying about the workpiece sliding or moving. This enhances safety and ensures consistent cutting, especially when dealing with harder or denser materials.

In addition to stability and clamping capabilities, a saw bench may have built-in features that further improve cutting accuracy. For example, some saw benches have integrated measuring guides or fences that can be adjusted to set precise cutting dimensions. These features help ensure consistent and repeatable cuts, particularly when making multiple identical pieces or working on projects with specific sizing requirements.

Saw benches come in various designs, including portable and stationary models. Portable saw benches are lightweight and easy to transport, making them ideal for on-site or mobile woodworking tasks. Stationary saw benches are typically larger and more robust, providing a dedicated and permanent work surface in a workshop setting.

When using a saw bench, it’s important to maintain a clutter-free and organized work area to prevent accidents. Keep the bench surface clean from debris and ensure that there is adequate workspace around the saw. This will minimize the risk of tripping or interference during cutting.

Overall, a saw bench is an invaluable tool for working with saws and woodworking projects. Its stability, adjustable height, and clamping capabilities ensure safe and accurate cutting. By incorporating a saw bench into your woodworking setup, you can enhance your cutting precision, improve workflow efficiency, and enjoy a safer and more ergonomic work environment.

To prevent rust and corrosion on hand tools for saws, always clean and dry them after use, and store them in a dry place. Consider using a rust-preventative spray or coating for added protection.

Conclusion

Working with saws requires the right tools to ensure precision, efficiency, and safety. In this article, we have explored ten essential hand tools that greatly enhance the functionality and maintenance of saws. From the versatile claw hammer to the precision of coping saw blades, each tool plays a vital role in achieving accurate and clean cutting results.

The claw hammer, screwdriver, chisel, and mallet are tools that assist in securing workpieces, adjusting blade positions, and removing obstructions. They provide stability and precision, allowing for controlled and accurate cutting. The saw set and file are specialized tools for maintaining the teeth of the saw blade, ensuring optimal cutting performance and extending the blade’s lifespan.

For intricate and detailed cuts, coping saw blades are invaluable. Their narrow and flexible design allows for precise maneuverability around curves and intricate patterns. A saw vise provides stability and control when working on blade maintenance, ensuring proper tension and enabling accurate filing and sharpening.

In addition to the tools directly related to the saw blade itself, a saw dust blower is essential for maintaining a clear cutting area, improving visibility, and enhancing accuracy. Lastly, a saw bench provides stability, adjustable working heights, and clamping capabilities, ensuring safety, comfort, and consistent cutting performance.

By equipping your toolbox with these ten hand tools, you can enhance your sawing experience and elevate your woodworking projects to new levels of craftsmanship. Regular maintenance and proper use of these tools will help ensure the longevity and effectiveness of your saws.

Remember to prioritize safety when working with any hand tools, using protective equipment and following proper techniques. Always refer to manufacturer guidelines and instructions for the specific tools and saws you are using.

Whether you are a novice woodworker or an experienced professional, having the right hand tools for saws is essential. These tools not only facilitate precise cutting but also contribute to the overall quality, efficiency, and safety of your woodworking projects. So, invest in high-quality tools, maintain them properly, and enjoy the satisfaction of achieving exceptional results with your saws.

Frequently Asked Questions about What Are Some Of The Hand Tools For Saws

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Some Of The Hand Tools For Saws”