Articles

What Are Hand Tools Made Of

Modified: May 6, 2024

Learn about the materials used in hand tools in our informative article. Discover the construction and properties of various hand tools for different applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

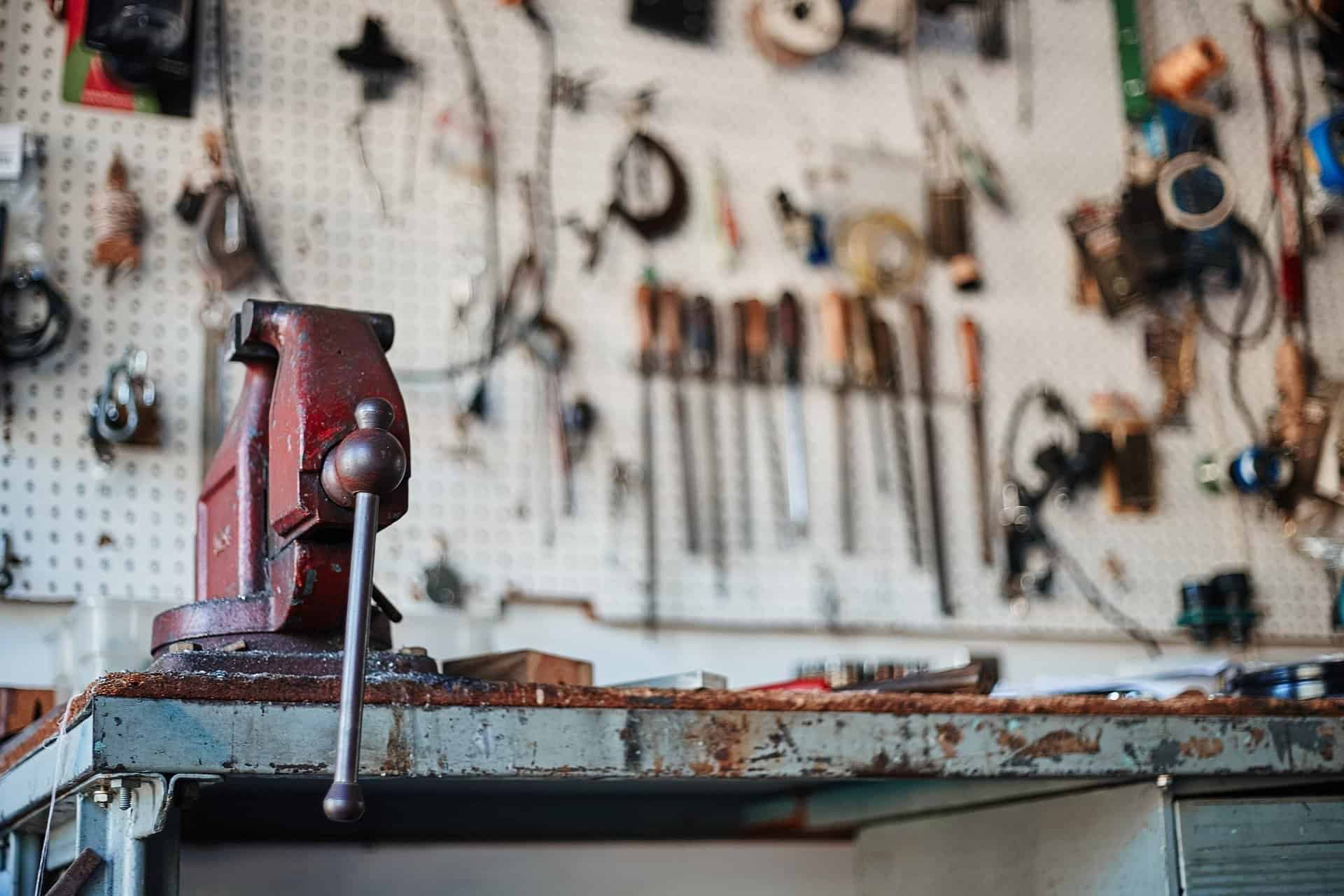

Hand tools are essential in various industries and everyday tasks. From construction to woodworking, automotive repair to gardening, hand tools play a crucial role in getting the job done efficiently and effectively.

When it comes to hand tools, the material they are made of determines their durability, strength, and overall performance. Different materials are used to manufacture hand tools, each offering unique characteristics and advantages.

In this article, we will dive into the world of hand tools and explore the materials commonly used in their construction. By understanding the materials, you will be able to make informed decisions when selecting the right hand tool for your needs.

So, let’s explore the fascinating materials that make up hand tools and discover what makes them so valuable.

Key Takeaways:

- Steel, including alloy steel, carbon steel, and stainless steel, is a popular choice for hand tools due to its exceptional strength, durability, and resistance to wear and tear, making it ideal for heavy-duty applications.

- Wood hand tools offer a unique blend of natural feel, shock absorption, and customization possibilities, making them a popular choice among woodworking enthusiasts for precision and versatility.

Read more: What Are Old Hand Tools Made Out Of

Steel

When it comes to hand tools, steel is one of the most commonly used materials. Steel is an alloy of iron and carbon, making it incredibly strong and durable.

One of the main advantages of steel hand tools is their resistance to wear and tear. Their hardness and toughness make them ideal for heavy-duty tasks. Steel tools are less likely to bend or break under pressure, ensuring longevity and reliability.

There are different types of steel used in the manufacturing of hand tools:

- Alloy Steel: Alloy steel is made by adding various elements such as chromium, nickel, and molybdenum to improve the strength, hardness, and resistance to corrosion. This type of steel is commonly used in high-quality hand tools, providing exceptional performance and durability.

- Carbon Steel: Carbon steel contains a higher carbon content, which enhances hardness and overall strength. It is popularly used in many hand tools due to its affordability and effectiveness in various applications.

- Stainless Steel: Stainless steel is a corrosion-resistant type of steel. It contains chromium, which forms a protective layer on the surface, preventing rust and corrosion. Stainless steel hand tools are highly durable and ideal for tasks that involve exposure to moisture or chemicals.

Steel hand tools offer excellent performance and reliability, making them a go-to choice for many professionals and enthusiasts. They provide the necessary strength to handle demanding tasks and can withstand prolonged use without compromising their functionality.

Alloy Steel

Alloy steel is a type of steel that is created by blending various elements with iron. The addition of these alloying elements enhances the strength, hardness, and overall performance of the steel, making it an excellent choice for hand tools.

The most common alloying elements used in alloy steel include chromium, nickel, molybdenum, and vanadium. Each element contributes unique properties to the steel, resulting in exceptional performance characteristics.

One of the primary advantages of alloy steel in hand tools is its superior strength and durability. The alloying elements increase the hardness of the steel, making it highly resistant to wear and tear. This not only extends the lifespan of the hand tool but also ensures its functionality and reliability even under demanding conditions.

Additionally, alloy steel also offers improved resistance to corrosion. Chromium, in particular, forms a protective layer on the surface of the steel, preventing rust and corrosion. This makes alloy steel hand tools suitable for use in environments with high humidity or exposure to chemicals.

Furthermore, alloy steel exhibits excellent heat resistance, making it ideal for applications that involve high temperatures. This characteristic allows the hand tools to maintain their strength and integrity even in extreme heat conditions.

Another advantage of alloy steel is its versatility. It can be shaped and forged into various intricate designs, allowing for the creation of hand tools with specialized features and functionalities. The ability to customize alloy steel hand tools makes them highly desirable for specific tasks.

Overall, alloy steel hand tools offer a combination of strength, durability, corrosion resistance, and versatility. These qualities make them an excellent choice for professionals and enthusiasts who require reliable and high-performance tools to tackle a wide range of tasks.

Carbon Steel

Carbon steel is a widely used material in the manufacturing of hand tools. It is composed predominantly of iron and carbon, with a carbon content typically ranging from 0.05% to 1.5%.

One of the primary advantages of carbon steel hand tools is their affordability. Compared to other materials like stainless steel or alloy steel, carbon steel hand tools are often more cost-effective, making them accessible to a wide range of users.

Carbon steel hand tools are known for their exceptional strength and durability. The carbon content enhances the hardness of the steel, making it capable of withstanding heavy-duty tasks without bending or breaking. This property is especially valuable for applications that involve hammering or impacting.

In addition to its strength, carbon steel also offers excellent sharpness and edge retention. This makes carbon steel hand tools well-suited for precision tasks such as cutting, shaping, or carving. The ability to maintain a sharp edge for an extended period minimizes the need for frequent sharpening, improving efficiency and productivity.

However, one consideration with carbon steel hand tools is its susceptibility to corrosion. Without proper care and maintenance, carbon steel can rust, affecting its performance and longevity. It is important to clean and dry carbon steel hand tools after use and apply a protective coating to prevent oxidation.

Despite its susceptibility to corrosion, many users appreciate the patina that develops on carbon steel hand tools over time. This natural aging process not only adds character to the tools but also provides increased rust resistance. Many enthusiasts and craftsmen actively embrace and maintain the patina on their carbon steel hand tools.

Overall, carbon steel hand tools offer a balance of affordability, strength, sharpness, and edge retention. With proper care, they can provide reliable and effective performance for a wide range of applications, making them a popular choice among professionals and hobbyists alike.

Stainless Steel

Stainless steel is a popular material used in the manufacturing of hand tools due to its exceptional corrosion resistance and durability. It is an alloy of iron, chromium, and other elements, with a minimum chromium content of 10.5% by mass.

One of the key advantages of stainless steel hand tools is their resistance to rust and corrosion. The chromium present in stainless steel forms a thin, transparent oxide layer on the surface, known as a passive film. This film acts as a protective barrier, preventing the steel from coming into contact with oxygen and moisture, which can lead to rusting.

Stainless steel hand tools are highly versatile and suited for various applications. They are commonly used in industries such as automotive, plumbing, and food preparation, where exposure to moisture, chemicals, and harsh environments is common.

Another advantage of stainless steel hand tools is their strength and durability. They are resistant to impact, bending, and wear, providing long-lasting performance. The ability of stainless steel to withstand high levels of stress without deforming makes it suitable for heavy-duty applications.

In addition to its corrosion resistance and strength, stainless steel hand tools are also valued for their hygienic properties. The smooth, non-porous surface of stainless steel makes it easy to clean and maintain, reducing the risk of bacterial growth. This feature is particularly important in industries such as healthcare and food service, where cleanliness is essential.

Furthermore, stainless steel hand tools offer an aesthetic appeal with their sleek and polished appearance. This makes them highly sought after by professionals and enthusiasts who value both functionality and visual appeal.

While stainless steel hand tools offer many advantages, it’s important to note that they can be more expensive compared to other materials like carbon steel. However, the long-term benefits of their corrosion resistance, durability, and hygienic properties often outweigh the initial investment.

Overall, stainless steel hand tools are a reliable and popular choice for professionals and individuals who require strong, corrosion-resistant tools that can withstand demanding environments. Their combination of durability, versatility, and aesthetics make them an excellent option for a wide range of applications.

Cast Iron

Cast iron is a durable and robust material that has been used for centuries in the construction of hand tools. It is formed by melting iron and adding a small amount of carbon, which gives it its distinctive properties.

One of the main advantages of cast iron hand tools is their exceptional strength and durability. Cast iron is known for its high compressive strength, making it resistant to breaking or cracking under pressure. This makes cast iron tools well-suited for heavy-duty applications that require substantial force.

Another advantage of cast iron is its excellent heat retention and even heat distribution. Cast iron tools can withstand high temperatures without warping or deforming, making them ideal for applications that involve heat, such as cooking or blacksmithing.

Additionally, cast iron hand tools have superior wear resistance and can endure rough usage. They are less likely to wear down or become damaged with regular use, ensuring longevity and reliability.

Cast iron hand tools also have the advantage of being less expensive compared to some other materials. This makes them a cost-effective choice for individuals and professionals who require durable tools without breaking the bank.

However, it is important to note that cast iron hand tools are susceptible to rust and corrosion if not properly maintained. Regular cleaning, drying, and applying a protective coating are necessary to prevent oxidation and ensure their longevity.

Despite the need for maintenance, many people appreciate the unique aesthetic appeal of cast iron hand tools. The dark and rugged appearance adds a touch of nostalgia and charm, making cast iron tools a favorite among collectors and enthusiasts.

Overall, cast iron hand tools offer exceptional strength, durability, and heat resistance. Their robustness and longevity make them a reliable choice for heavy-duty applications, while their affordable price makes them accessible to a wide range of users.

When choosing hand tools, look for those made of high-quality materials such as steel, aluminum, or titanium for durability and longevity. Avoid tools made of low-quality materials that may break or wear out quickly.

Aluminum

Aluminum is a lightweight and versatile material commonly used in the manufacturing of hand tools. It is highly favored for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity.

One of the primary advantages of aluminum hand tools is their lightness. Aluminum is significantly lighter than steel, making tools made from this material easy to handle and reducing fatigue during prolonged use. This makes aluminum hand tools ideal for applications that require repetitive movements or overhead work.

In addition to its lightweight nature, aluminum hand tools possess great strength. The alloying elements added to aluminum, such as copper and magnesium, enhance its mechanical properties, allowing for tools that are both strong and durable.

Another key benefit of aluminum is its resistance to corrosion. When exposed to the atmosphere, aluminum forms a thin and protective oxide layer that prevents further oxidation. This makes aluminum hand tools suitable for outdoor or high-moisture environments where rust and corrosion are common concerns.

Aluminum hand tools also offer excellent thermal conductivity. They can quickly dissipate heat, which is advantageous for applications that involve heat transfer, such as plumbing or HVAC work. Additionally, this property minimizes the risk of the tool becoming uncomfortably hot during use.

Furthermore, aluminum hand tools are non-magnetic, making them suitable for tasks where magnetic interference could be problematic, such as electronics or certain laboratory settings.

Despite its many advantages, it is important to note that aluminum hand tools may not be suitable for heavy-duty applications that require extreme strength or impact resistance. However, they excel in tasks that require precision, agility, and resistance to corrosion.

Overall, aluminum hand tools offer a compelling combination of lightweight design, strength, corrosion resistance, and thermal conductivity. Their versatility and ease of use make them a popular choice among professionals and hobbyists alike.

Titanium

Titanium is a lightweight and highly durable material commonly used in the manufacturing of high-quality hand tools. It is renowned for its exceptional strength, corrosion resistance, and biocompatibility.

One of the main advantages of titanium hand tools is their remarkable strength-to-weight ratio. Despite being incredibly lightweight, titanium is exceptionally strong and can withstand heavy-duty applications. This makes titanium hand tools ideal for tasks that require strength and durability without adding excessive weight.

Titanium hand tools also offer excellent corrosion resistance. Titanium naturally forms a protective oxide layer on its surface when exposed to oxygen, protecting the metal from rust and corrosion. This corrosion resistance makes titanium hand tools suitable for use in moist or corrosive environments, such as marine applications.

Another advantage of titanium is its biocompatibility. Titanium is non-toxic and hypoallergenic, making it ideal for medical and dental applications. It is often used for surgical instruments and implants due to its ability to integrate with the human body without causing adverse reactions.

In addition to its strength and corrosion resistance, titanium hand tools are highly resistant to extreme temperatures. They can withstand high heat and resist thermal expansion, making them reliable in applications that involve heat exposure.

However, it’s important to note that titanium hand tools can be more expensive compared to other materials like steel or aluminum. The cost of production and the specialized nature of titanium contribute to its higher price point. However, the long-term benefits of its strength, corrosion resistance, and biocompatibility often outweigh the initial investment.

Overall, titanium hand tools offer exceptional strength, corrosion resistance, and biocompatibility. Their lightweight design, coupled with their durability, makes them favored by professionals in various industries—including aerospace, automotive, and medical—for their reliability, versatility, and outstanding performance.

Wood

Wood has been used for centuries as a natural and renewable material for hand tools. It offers a unique blend of warmth, aesthetic appeal, and functionality that makes it a popular choice among craftsmen and artisans.

One of the main advantages of wood hand tools is their natural feel and comfortable grip. Wood has a warm and tactile quality that makes it pleasant to hold and work with. This natural grip is especially beneficial for hand tools that require precision and control, such as chisels or hand planes.

Wood hand tools also exhibit excellent shock absorption properties. The fibrous nature of wood helps to dissipate vibrations, reducing the strain on the user’s hand and minimizing fatigue during use. This makes them well-suited for tasks that involve repetitive movements or prolonged use.

Additionally, wood hand tools are less likely to damage or mar the workpiece compared to metal tools. The softer nature of wood reduces the risk of leaving marks or scratches on the material being worked on, making them ideal for delicate woodworking projects.

Wood hand tools are also appreciated for their versatility and ease of customization. Wood can be shaped and carved into various intricate designs, allowing craftsmen to create tools tailored to their specific needs and preferences. This customization aspect makes wood hand tools highly valued by woodworking enthusiasts.

However, it’s important to note that wood hand tools require regular maintenance to ensure their longevity. Wood can be susceptible to damage from moisture, changes in humidity, and wood-boring insects. Proper cleaning, drying, and applying protective finishes are necessary to prevent warping, cracking, and degradation over time.

Overall, wood hand tools offer a harmonious blend of beauty, functionality, and craftsmanship. The natural feel, shock absorption, and customization possibilities make them a popular choice among woodworkers and individuals who appreciate the timeless appeal of traditional hand tools.

Read more: Who Made Craftsman Hand Tools

Plastic

Plastic is a versatile and lightweight material commonly used in the manufacturing of hand tools. It offers a range of benefits that make it a popular choice for various applications.

One of the primary advantages of plastic hand tools is their lightweight design. Plastic is significantly lighter than materials like steel or cast iron, making tools made from this material easy to handle and reducing fatigue during use. This makes plastic hand tools ideal for tasks that require extended periods of use or overhead work.

Plastic hand tools also offer excellent durability and resistance to impact. They are less prone to wear and tear and can withstand rough use without breaking or cracking. Additionally, plastic hand tools are often designed with ergonomic handles, ensuring comfortable grip and reduced strain on the user’s hand.

Another advantage of plastic is its resistance to corrosion and rust. Unlike metals that can oxidize over time, plastic hand tools are not susceptible to these issues, making them suitable for use in outdoor environments or humid conditions.

Plastic hand tools are also valued for their electrical insulation properties. Because plastic is a non-conductive material, it minimizes the risk of electrical shock when working on electrical systems or live wires. This makes plastic hand tools an important choice for electricians and individuals working with electricity.

Additionally, the use of plastic in hand tools allows for a wide range of colors and designs. Manufacturers can produce tools in vibrant colors, improving visibility and making them easier to locate in a busy workshop or toolbox.

However, it’s important to note that plastic hand tools may not be as durable as those made from materials like steel or aluminum. They may be more prone to wear and can be less effective for heavy-duty applications that require significant force or impact resistance.

Overall, plastic hand tools offer a lightweight, durable, and corrosion-resistant option for various applications. Their affordability, versatility, and electrical insulation properties make them suitable for both professional and DIY use.

Conclusion

Hand tools are essential for a wide range of tasks, and the materials they are made of play a crucial role in their performance and durability. Understanding the different materials used in hand tool construction allows for informed decision-making when choosing the right tool for the job.

Steel, including alloy steel, carbon steel, and stainless steel, is a popular choice for its strength, durability, and resistance to wear and tear. These materials excel in heavy-duty applications and provide reliable and long-lasting performance.

Cast iron hand tools offer exceptional strength and durability, along with excellent heat retention and wear resistance. They are well-suited for heavy-duty tasks where impact resistance is paramount.

Aluminum hand tools are valued for their lightweight design, making them easy to handle and reducing user fatigue. They also offer corrosion resistance and thermal conductivity, making them suitable for a range of applications.

Titanium hand tools provide a combination of strength, corrosion resistance, and biocompatibility. Their lightweight design, exceptional durability, and resistance to extreme temperatures make them highly desirable in various industries.

Wood hand tools, with their natural feel, comfortable grip, and shock absorption properties, offer a unique experience for woodworking enthusiasts. They provide precision and versatility while minimizing the risk of damage to delicate workpieces.

Plastic hand tools provide a lightweight and durable option for a broad range of applications. They offer corrosion resistance, electrical insulation properties, and an array of colors and designs to suit individual preferences.

In conclusion, the choice of material for hand tools is essential in determining their performance, durability, and suitability for specific tasks. Whether it’s the strength of steel, the aesthetics of wood, or the versatility of plastic, understanding the characteristics of each material allows for the selection of hand tools that best meet the needs of the user.

It’s important to consider factors such as the nature of the task, the environment in which the tool will be used, and the desired level of durability when choosing a hand tool material. By selecting the right material, users can enhance their productivity, efficiency, and overall satisfaction when working with hand tools.

If you've enjoyed learning about the materials used in crafting hand tools, you might be intrigued by our latest guides on related topics. For those passionate about crafting and creating, dive into our guide on the best woodworking projects. Garden enthusiasts will also love our creative compilation of garden fence ideas. Both articles offer fresh, practical insights to enhance your space and skills.

Frequently Asked Questions about What Are Hand Tools Made Of

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Hand Tools Made Of”