Articles

What Are The Hazards Of Hand Tools

Modified: January 8, 2024

Learn about the potential risks associated with using hand tools in this informative article. Ensure your safety by being aware of common hazards.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Hand tools are essential for completing a wide range of tasks, from simple household repairs to complex construction projects. They are a staple in various industries and are used by professionals and DIY enthusiasts alike. While hand tools offer convenience and versatility, it is important to be aware of the hazards associated with their use.

In this article, we will explore the hazards of using hand tools and provide safety tips to prevent accidents and injuries. By understanding the risks and taking appropriate precautions, you can ensure your safety while working with hand tools.

Key Takeaways:

- Safety First!

Understanding and respecting the hazards of hand tools is crucial. By prioritizing safety measures, such as using the right tool, wearing PPE, and maintaining a clean work area, you can prevent accidents and ensure a safer work environment. - Proactive Protection

From preventing cuts and strains to safeguarding against electric shock and biological hazards, taking proactive safety measures, such as using ergonomic tools, wearing eye protection, and disposing of hazardous materials properly, is essential for minimizing risks while using hand tools.

Types of Hand Tools

Hand tools come in a wide variety of shapes, sizes, and functions. Each tool is designed for a specific purpose, making it important to choose the right tool for the job at hand. Here are some common types of hand tools:

- Hammers: Used for driving nails or assembling objects by striking.

- Screwdrivers: Used for turning screws and tightening or loosening fasteners.

- Pliers: Designed for gripping, bending, and cutting wires and objects.

- Wrenches: Used to tighten or loosen nuts and bolts of various sizes.

- Chisels: Used for shaping or carving wood, stone, or metal.

- Saws: Used for cutting through different materials, such as wood or metal.

- Scissors: Used for cutting through fabric, paper, or other lightweight materials.

- Knives: Designed for cutting and slicing objects with precision.

- Files: Used for shaping, smoothing, or removing material from surfaces.

- Measuring tools: Include rulers, tape measures, and calipers to measure distances or dimensions accurately.

These are just a few examples of the many hand tools available. Each tool requires proper handling and caution to avoid accidents. Understanding the purpose and limitations of each tool is important, as misuse can lead to serious injuries.

Hazards of Using Hand Tools

While hand tools are incredibly useful, they also pose certain hazards if not used correctly. It is crucial to be aware of these hazards to prevent accidents and injuries. Here are some common hazards associated with using hand tools:

- Cuts and Abrasions: Hand tools with sharp edges, such as knives or saws, can cause cuts and abrasions if mishandled. Even seemingly blunt tools like hammers or wrenches can cause injuries if they slip or are used improperly.

- Strains and Sprains: Using hand tools that require repetitive or forceful movements can strain muscles and joints, leading to sprains or strains. Poor ergonomics, such as improper grip or posture, can also contribute to these injuries.

- Eye Injuries: When working with hand tools, debris and particles can enter your eyes, causing irritation or serious injuries. Tools that produce sparks or emit particles, such as grinders or power saws, require special eye protection.

- Electric Shock: Hand tools that are powered by electricity, such as drills or saws, can pose a risk of electric shock if not used properly. Faulty wiring, improper grounding, or using wet tools can increase the risk.

- Falling or Flying Objects: Working at heights or in elevated areas while using hand tools can result in objects falling and causing injuries. Tools that are dropped or mishandled can also become dangerous projectiles.

- Repetitive Motion Injuries: Tasks that require repetitive motion, such as using a screwdriver or gripping pliers for extended periods, can lead to repetitive motion injuries like tendonitis or carpal tunnel syndrome.

- Biological Hazards: In certain industries, hand tools can be exposed to biological hazards such as bloodborne pathogens or toxic substances. Without proper precautions, these hazards can pose health risks.

It is important to recognize these hazards and take appropriate safety measures to mitigate the risks. By following safety guidelines and using tools correctly, you can significantly reduce the likelihood of accidents and injuries.

Cuts and Abrasions

Cuts and abrasions are common hazards associated with using hand tools. Tools with sharp edges, such as knives, saws, or chisels, can cause cuts if mishandled or used improperly. Even seemingly blunt tools like hammers or wrenches can lead to abrasions if they slip while in use.

To prevent cuts and abrasions while using hand tools, consider the following safety measures:

- Use the right tool for the job: Ensure that the tool you are using is appropriate for the task at hand. Using the wrong tool or attempting to modify a tool can increase the risk of accidents.

- Inspect tools before use: Before starting any work, inspect your hand tools for any damage or defects. Check for any worn-out or broken parts, as they could cause accidents during use.

- Wear appropriate personal protective equipment (PPE): Use safety gloves to protect your hands from cuts and abrasions. Choose gloves made of sturdy materials that can provide adequate protection without compromising dexterity.

- Maintain a firm grip: Always maintain a firm grip on the tool while using it. Avoid holding it too tightly or loosely, as both can lead to accidents. Ensure that your hand is positioned away from the cutting edge or striking surface to prevent accidental contact.

- Keep your work area well-lit: Poor lighting can increase the chances of accidents and injuries. Make sure your work area is properly illuminated, allowing you to see the tool and the workpiece clearly.

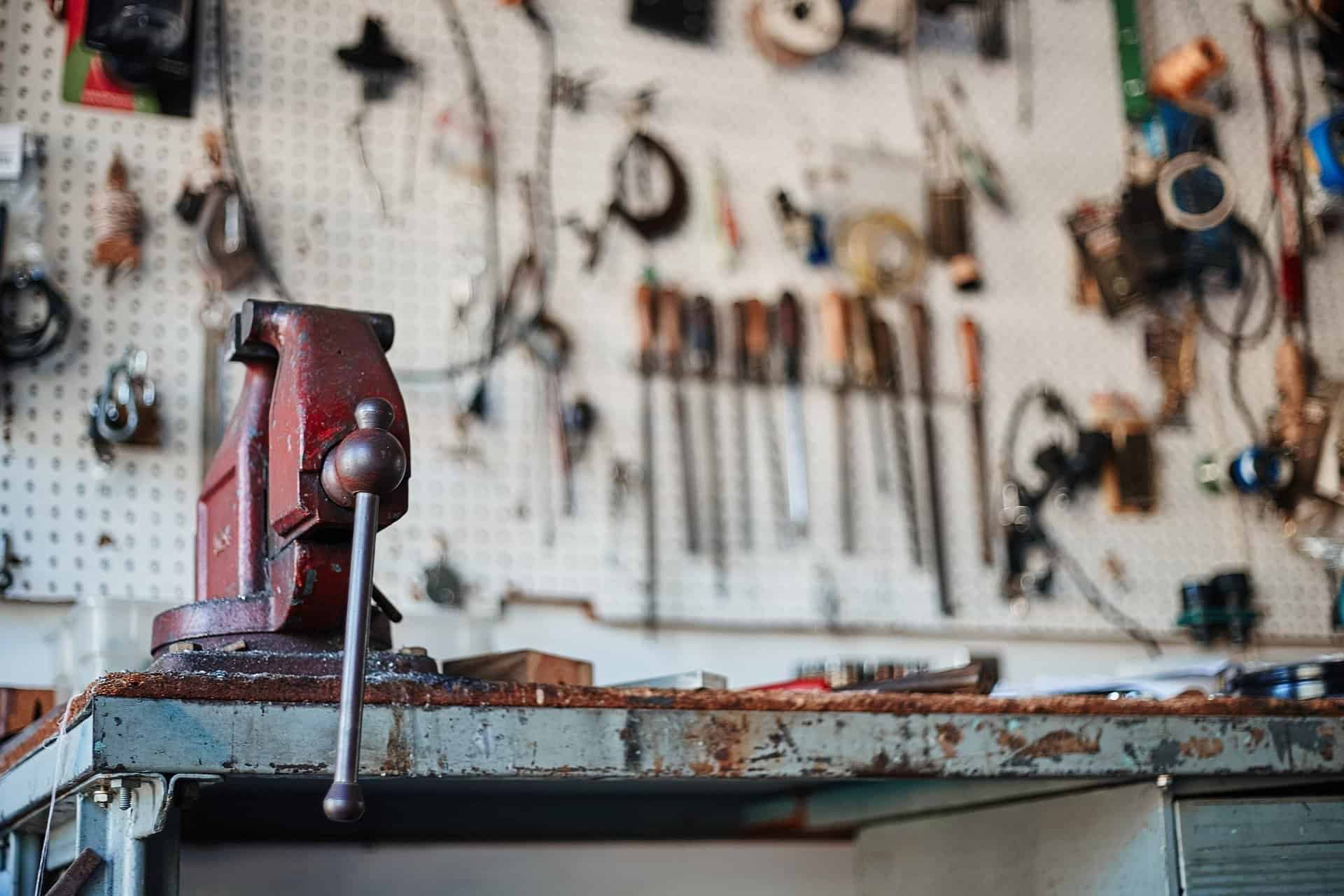

- Use clamps or vices when necessary: If possible, secure the workpiece using clamps or vices to create a stable base. This helps to prevent slippage and reduces the risk of accidents caused by unstable work surfaces.

- Store tools properly: After use, store your hand tools in a designated area that is safe and secure. Proper storage not only prevents accidents but also helps to maintain the tools in good condition and prolong their lifespan.

Remember, practicing safe habits and using appropriate precautions can minimize the risk of cuts and abrasions while working with hand tools. Stay attentive, follow safety guidelines, and always prioritize your well-being.

Strains and Sprains

Strains and sprains are common injuries that can occur when using hand tools, particularly when performing tasks that require repetitive or forceful movements. These injuries can affect the muscles, tendons, and ligaments, causing pain, inflammation, and limited mobility. Poor ergonomics, such as improper grip or posture, can also contribute to these injuries.

To prevent strains and sprains while using hand tools, consider the following safety measures:

- Use tools with ergonomic designs: Look for hand tools that are ergonomically designed to minimize strain on your muscles and joints. These tools are specifically crafted to provide better grip, reduce fatigue, and promote proper body mechanics.

- Take regular breaks: When working on tasks that require repetitive movements, take frequent breaks to rest and stretch your muscles. This helps to prevent overexertion and reduces the risk of strain or sprain injuries.

- Warm up before starting work: Just like any physical activity, warming up your muscles before using hand tools can help prevent strains and sprains. Perform simple stretches to loosen up your muscles and increase blood flow to the affected areas.

- Maintain good posture: Maintain a neutral posture while using hand tools. Avoid awkward bending, twisting, or reaching positions that can strain your muscles and joints. Use your body’s core strength to perform tasks rather than relying solely on your arms and hands.

- Use tools with proper grip: Ensure that the handles of your hand tools are in good condition and provide a secure grip. Tools with slippery or worn-out handles increase the risk of accidental slips, which can lead to strains or sprains.

- Use mechanical assistance when needed: For tasks that require lifting or applying significant force, consider using mechanical assistance, such as a pulley system or a lever. This helps to minimize strain on your muscles and reduces the risk of overexertion injuries.

- Stay physically fit: Regular exercise and strength training can help improve your overall fitness level, making you less susceptible to strains and sprains while using hand tools. Focus on exercises that target the muscles and joints used during manual tasks.

By adopting these safety measures and incorporating good ergonomic practices into your work routine, you can significantly reduce the risk of strains and sprains while working with hand tools. Prioritize your well-being and take the necessary steps to protect yourself from these types of injuries.

Read more: What Is A Hand Tool

Eye Injuries

Eye injuries are a significant hazard when using hand tools. The eyes are extremely delicate and susceptible to damage from flying debris, particles, or even sparks generated during certain tasks. It is crucial to take necessary precautions to protect your eyes while working with hand tools.

To prevent eye injuries while using hand tools, consider the following safety measures:

- Wear appropriate eye protection: Always wear safety goggles or glasses specifically designed to protect your eyes from debris, flying particles, and sparks. Ensure that the eye protection you choose meets the necessary safety standards and provides adequate coverage.

- Use face shields when needed: For tasks that involve significant debris or sparks, consider using a face shield in addition to safety goggles or glasses. Face shields provide additional protection to your entire face, including your eyes, from potential hazards.

- Keep a clean work area: Maintain a clean and clutter-free work area to minimize the risk of debris entering your eyes. Clear away any objects or materials that could potentially cause injury if they become dislodged or scattered during use.

- Choose the right tool for the job: Use tools specifically designed for the task at hand. Tools with inadequate safety features or those known to produce significant debris should be used with extra caution and appropriate eye protection.

- Inspect your tools and work area: Before starting any work, inspect your hand tools and work area for any potential hazards. Check for loose or damaged parts that could cause debris to fly, and make sure your work area is free from any loose materials that might pose a risk.

- Maintain a safe distance: When using tools that produce sparks or debris, maintain a safe distance from your face. Consider your positioning and make sure you are not directly in line with the potential hazard.

- Dispose of debris safely: When working with materials that create debris, such as cutting wood or grinding metal, make sure to dispose of the debris properly. Collect and safely discard the debris in designated containers or disposal methods to prevent accidental eye injuries.

Remember, even a small particle or flying object can cause significant damage to your eyes. Prioritize your eye safety by wearing appropriate eye protection and following these safety measures while using hand tools. By doing so, you can minimize the risk of eye injuries and maintain good ocular health.

Always wear appropriate personal protective equipment, such as gloves and safety glasses, when using hand tools to protect yourself from potential hazards.

Electric Shock

Electric shock is a serious hazard that can occur when using hand tools powered by electricity. It is important to prioritize electrical safety to prevent life-threatening injuries. Hand tools such as drills, saws, or any other tool that requires electrical power can pose a risk if not used correctly.

To prevent electric shock while using hand tools, consider the following safety measures:

- Inspect your tools and cords: Before using any electrical hand tool, inspect it for any damage or frayed cords. Avoid using tools with damaged cords, as they can increase the risk of electric shock.

- Ensure proper grounding: Plug your tools into grounded outlets that are designed to handle the electrical load. Avoid using extension cords or adapters that do not provide proper grounding.

- Use ground fault circuit interrupters (GFCIs): GFCIs are electrical devices that provide protection against electric shocks. Use tools with built-in GFCIs or plug your tools into GFCI-protected outlets to prevent electric shock.

- Avoid wet conditions: Do not use hand tools with electrical components in wet or damp conditions. Water can conduct electricity, significantly increasing the risk of electric shock.

- Disconnect power before making adjustments: When making adjustments or changing tool accessories, always disconnect the power source. This ensures that accidental activation does not lead to unexpected electric shock.

- Do not overload circuits: Avoid overloading electrical circuits by plugging in too many tools or appliances. Overloading can cause electrical fires or damage to the tools and increase the risk of electric shock hazards.

- Use insulated tools: When working on or near electrical components, use insulated tools. Insulated tools have handles or shafts that prevent electrical conductivity, reducing the risk of electric shock.

- Store and handle tools properly: Store electrical hand tools in a dry, secure location, away from moisture or extreme temperatures. Carry and handle the tools by the insulated grip or the designated areas to prevent accidental contact with the electrical components.

Electrical safety is crucial when using hand tools powered by electricity. By following these safety measures, being aware of potential electrical hazards, and prioritizing your safety, you can significantly reduce the risk of electric shock and ensure a safe working environment.

Falling or Flying Objects

Working with hand tools can involve tasks that may lead to objects falling or flying, posing a risk of injury. Whether you are working at heights or even at ground level, it is important to take precautions to prevent objects from causing harm.

To prevent injuries from falling or flying objects while using hand tools, consider the following safety measures:

- Wear appropriate personal protective equipment (PPE): Use a hard hat to protect your head from falling objects. Depending on the task, consider using safety goggles or face shields to shield your face from flying debris.

- Secure objects when working at heights: When working at elevated areas, make sure to secure all tools and materials. Use lanyards, tool belts, or other appropriate methods to prevent objects from accidentally falling and endangering others.

- Avoid overloading work surfaces: Do not exceed the recommended weight limits of work surfaces or platforms. Overloading can cause them to collapse, leading to objects falling and potential injuries.

- Clear the work area: Keep your work area clean and organized. Remove any unnecessary objects or debris that could potentially fall or be a tripping hazard. Maintaining a clutter-free workspace lowers the risk of accidents.

- Ensure proper storage: Store tools and materials in designated areas when not in use. Avoid leaving objects unsecured on ledges or hanging over edges where they can accidentally fall and cause harm.

- Use caution when passing tools to others: When handing tools to co-workers or receiving tools from others, exercise caution. Ensure a secure handoff to prevent accidental dropping and potential injuries from the objects falling.

- Supervise overhead work closely: If work is being done overhead or above ground level, make sure there is appropriate supervision to manage the risk of falling objects. Use barricades or warning signs to alert others to potential hazards.

- Maintain focus and attentiveness: Stay focused on the task at hand and be mindful of your surroundings. Distractions can lead to accidents, including objects slipping from your grasp and causing injuries to yourself or others nearby.

By following these safety measures and remaining vigilant, you can significantly reduce the risk of injuries from falling or flying objects. Take the necessary precautions to create a safe working environment and protect yourself and those around you.

Repetitive Motion Injuries

Repetitive motion injuries can occur when using hand tools that require repetitive movements over an extended period. These injuries, such as tendonitis or carpal tunnel syndrome, can cause pain, discomfort, and reduced functionality in the affected areas.

To prevent repetitive motion injuries while using hand tools, consider the following safety measures:

- Take regular breaks: Schedule regular breaks to rest and stretch your muscles. This allows your body to recover from repetitive movements and reduces the risk of overuse injuries.

- Vary your grip and hand positions: Avoid using the same grip or hand position for an extended period. Alternate between different grips and positions to distribute the stress on different muscles and reduce strain on specific areas.

- Use tools with ergonomic designs: Choose hand tools that are specifically designed with ergonomics in mind. These tools help to reduce the strain on your muscles and joints, allowing for more comfortable and efficient work.

- Stretch before and after work: Perform simple stretching exercises before and after using hand tools to warm up and cool down your muscles. Focus on stretching the muscles and tendons involved in the repetitive motion tasks.

- Practice proper posture: Maintain good posture throughout your work. Sit or stand in a neutral position, supporting your back and shoulders properly. Avoid slouching or hunching over, as this can contribute to muscle imbalances and strain.

- Use padded and anti-vibration handles: When possible, choose hand tools with padded or anti-vibration handles. These features cushion the impact and vibrations, reducing the stress on your joints and decreasing the risk of repetitive motion injuries.

- Exercise and strengthen your muscles: Regular exercise and strength training can help improve the endurance and strength of the muscles used during manual tasks. Focus on exercises that target the wrists, hands, and forearms.

- Listen to your body: Pay attention to any discomfort, pain, or fatigue in your muscles or joints. If you experience any symptoms of repetitive motion injuries, seek medical attention and make necessary modifications to your work routine.

Preventing repetitive motion injuries requires a proactive approach. By incorporating these safety measures into your work routine, you can reduce the risk of overuse injuries and ensure a healthier and more comfortable experience when using hand tools.

Read more: What To Look For In Hand Tools

Biological Hazards

In certain industries or situations, hand tools can be exposed to biological hazards, including bloodborne pathogens, toxic substances, or hazardous materials. It is crucial to take appropriate precautions to protect yourself from potential health risks associated with these hazards.

To prevent biological hazards while using hand tools, consider the following safety measures:

- Wear personal protective equipment (PPE): Use appropriate PPE, such as gloves, masks, or coveralls, when working with hand tools that may be exposed to biological hazards. Ensure that your PPE is suitable for the specific task and provides adequate protection.

- Handle contaminated tools with care: If you are working with tools that may be contaminated with blood, bodily fluids, or other hazardous substances, handle them with caution. Use designated containers for disposal and follow proper procedures for decontamination.

- Follow proper hygiene practices: Maintain good personal hygiene by washing your hands thoroughly before and after using hand tools. Use soap and water, or alcohol-based hand sanitizers when clean water is not readily available.

- Dispose of hazardous materials properly: When working with hand tools that come into contact with hazardous materials, ensure proper disposal. Follow industry regulations and guidelines for disposing of materials safely and responsibly.

- Receive proper training: If you work in an industry that exposes you to biological hazards, make sure you receive appropriate training on handling and using tools safely. Stay informed about best practices, safety protocols, and emergency procedures.

- Follow safety data sheets (SDS): When working with chemicals or other hazardous materials, refer to safety data sheets for information on handling, storage, and disposal. Follow the guidelines provided to minimize the risk of exposure and potential health hazards.

- Regularly clean and sanitize tools: Clean and sanitize your hand tools regularly, especially when working in environments where biological hazards are present. This helps to eliminate or reduce potential contamination and ensures safe use.

- Report any concerns or incidents: If you encounter any potential biological hazards or incidents, promptly report them to your supervisor or safety personnel. This allows for appropriate investigation, risk assessment, and implementation of corrective measures.

Protecting yourself from biological hazards is essential for your safety and well-being. By implementing these safety measures and adhering to proper protocols, you can minimize the risk of exposure and maintain a healthy work environment while using hand tools.

Safety Tips for Using Hand Tools

Using hand tools safely is paramount to prevent accidents and injuries. By following these safety tips, you can ensure a safer work environment and decrease the risk of incidents while using hand tools:

- Read and follow instructions: Familiarize yourself with the manufacturer’s instructions and guidelines for each hand tool you use. Follow the recommended practices and safety precautions outlined in the user manual.

- Wear appropriate personal protective equipment (PPE): Use the necessary PPE, such as safety goggles, gloves, ear protection, or face shields, depending on the specific tool and task. PPE provides an extra layer of protection against potential hazards.

- Inspect tools before use: Before using any hand tool, inspect it for any signs of damage, wear, or defects. Look for loose parts, cracked handles, or any other issues that could compromise its safety or functionality.

- Use tools for their intended purpose: Always use hand tools for their intended purpose and within their specified limits. Using a tool incorrectly or exceeding its capabilities can lead to accidents and damage to the tool itself.

- Use the correct tool for the job: Choose the right tool for the task at hand. Using the wrong tool can result in inefficient work and increase the risk of accidents and injuries.

- Maintain a clean and organized work area: Keep your work area clean and free from clutter. Remove any obstacles or debris that may pose a tripping hazard or interfere with your work. An organized workspace promotes efficiency and safety.

- Use a secure grip: Maintain a firm and secure grip on the tool while using it. Avoid holding the tool too loosely or tightly, as both can lead to loss of control and accidents. Ensure proper hand placement to prevent slippage.

- Keep tools sharp and in good condition: Ensure that cutting tools, such as knives or saws, are properly sharpened and maintained. Dull or damaged tools can lead to inefficient work and increase the risk of accidents.

- Avoid distractions: Stay focused on the task at hand and avoid distractions while using hand tools. Distractions can lead to accidents and compromise your safety and the quality of your work.

- Keep bystanders at a safe distance: Ensure that bystanders, especially children or pets, are kept at a safe distance from your work area. This minimizes the risk of injury to others and prevents distractions while you work.

- Never leave tools unattended: Always keep an eye on your tools and never leave them unattended, especially when they are in use or within reach of others. Unattended tools can be accidentally bumped or misused, resulting in accidents.

- Properly store and maintain tools: After use, clean and store your hand tools properly in designated spaces. This ensures they are not damaged, misplaced, or accessible to unauthorized individuals.

By incorporating these safety tips into your work routine, you can significantly decrease the risk of accidents or injuries while using hand tools. Remember, prioritizing safety is essential to ensure a successful and incident-free experience when working with hand tools.

Conclusion

Hand tools are invaluable assets for various tasks and projects, whether in professional settings or as part of DIY projects at home. However, it is crucial to understand and respect the hazards associated with using hand tools, as accidents and injuries can occur if proper safety precautions are not taken.

In this article, we explored the hazards commonly associated with using hand tools, including cuts and abrasions, strains and sprains, eye injuries, electric shock, falling or flying objects, repetitive motion injuries, and biological hazards. Each hazard poses its own risks, but by following safety tips and guidelines, you can protect yourself and minimize the chances of accidents.

It is important to always prioritize safety while using hand tools. Wear appropriate personal protective equipment (PPE), inspect tools before use, and choose the right tool for the job. Practice proper body mechanics, maintain a clean and organized work area, and be attentive to potential hazards.

Remember to regularly take breaks, vary your hand positions, and use tools with ergonomic designs to prevent strains and sprains. Protect your eyes with safety goggles or face shields and take precautions to avoid electric shock when using electric-powered tools. Secure tools when working at heights and be mindful of falling or flying objects.

When it comes to biological hazards, use proper PPE and follow proper hygiene practices. Dispose of hazardous materials safely, and report any concerns or incidents promptly. By following these safety measures, you can reduce the risk of accidents and create a safer work environment.

In conclusion, with proper knowledge, caution, and adherence to safety practices, you can minimize the hazards associated with using hand tools and ensure your own well-being while accomplishing your tasks effectively. Stay safe, take care, and enjoy the benefits of using hand tools for all your projects.

Frequently Asked Questions about What Are The Hazards Of Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The Hazards Of Hand Tools”