Articles

What Are The 10 Classification Of Hand Tools?

Modified: October 19, 2024

Discover the 10 different classifications of hand tools in this informative article. From cutting tools to measuring tools, explore the essential tools every handyman should have in their arsenal.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

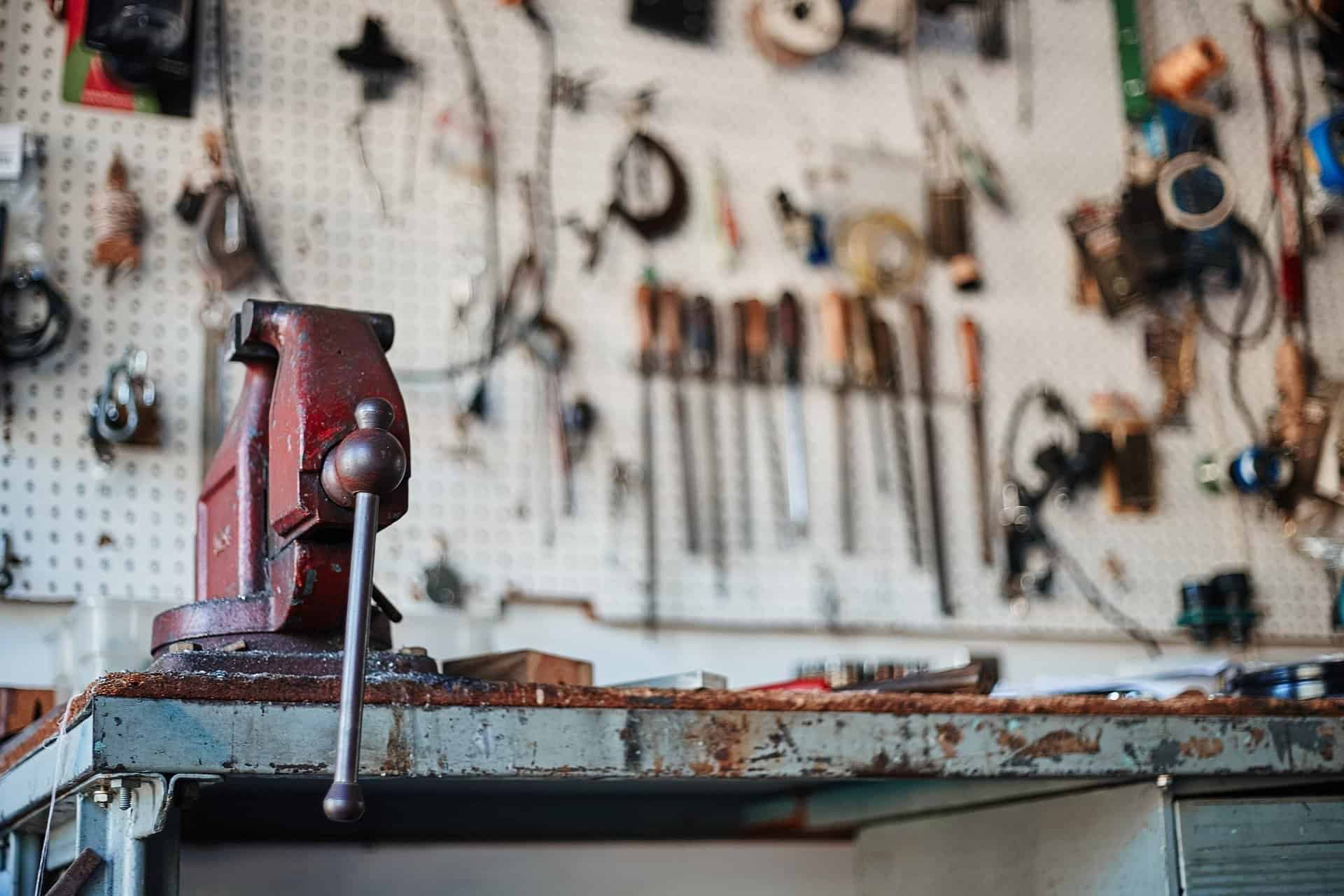

In the world of DIY projects and home repairs, having the right tools is essential. Hand tools are the backbone of any toolbox, providing the necessary leverage and precision to tackle a wide range of tasks. Whether you’re a professional tradesperson or a budding enthusiast, understanding and familiarizing yourself with the different classifications of hand tools is crucial.

Hand tools are often categorized based on their specific function or the type of work they are designed for. From the trusty hammer to the versatile screwdriver, each tool has its own unique purpose and application. By having a good understanding of these classifications, you can optimize your tool selection for any project and ensure the best results.

In this article, we will explore the top 10 classifications of hand tools and delve into their functionalities, variations, and common uses. Whether you’re a seasoned DIYer or just starting out, this guide will serve as a valuable resource to expand your knowledge and improve your tool arsenal.

Key Takeaways:

- Understanding the classifications of hand tools, from hammers to clamps, empowers DIY enthusiasts and professionals to select the right tool for any project, ensuring precision and efficiency.

- Investing in high-quality hand tools, maintaining them properly, and using them with the appropriate techniques and safety precautions are essential for achieving professional-quality results in DIY projects and beyond.

Read more: What Are The 10 Hand Tools

Hammer

The hammer is perhaps the most iconic and widely recognized hand tool. It consists of a sturdy handle and a heavy head, typically made of metal, that is used for striking or pounding. Hammers come in various shapes and sizes, each tailored to a specific purpose.

One of the most common types of hammers is the claw hammer, which features a curved claw on one side of the head. This design allows for the removal of nails from materials. It is an essential tool for carpentry and construction projects. The flat, smooth side of the hammer head is used for driving nails into surfaces, creating a secure bond.

There are also ball-peen hammers, which have a round peen opposite the flat striking surface. This type of hammer is commonly used in metalworking, shaping and striking metal objects, and riveting. The peen can also be used for rounding off edges or making small dents.

The sledgehammer is a much larger and heavier version of the hammer. It is primarily used for heavy-duty tasks like demolition, breaking through walls, or driving stakes into the ground. The long handle provides increased leverage, allowing for more forceful strikes.

Additionally, there are specialty hammers, such as the mallet. A mallet has a non-metal head, usually made of rubber or wood, and is used to strike delicate materials or woodworking chisels to avoid damaging them. It is commonly used in woodworking, upholstery, and other crafts.

When choosing a hammer, consider the weight, handle length, and head material. Lighter hammers are suitable for smaller tasks, while heavier hammers are needed for more demanding applications. The handle should provide a comfortable grip and absorb shock to prevent strain on your hand and arm muscles. Materials like steel, fiberglass, or wood are commonly used for handles.

Overall, the hammer is a versatile tool that can be found in almost every toolbox. It is essential for various tasks, from driving nails to breaking objects apart. Having a few different types of hammers ensures you are prepared for any job that comes your way.

Screwdriver

The screwdriver is a fundamental hand tool used for tightening or loosening screws. It consists of a handle and a shaft with a shaped tip that fits into the corresponding slotted or cross-slotted head of a screw. Screwdrivers come in various sizes and types to accommodate different screw heads.

One of the most common types of screwdrivers is the flathead, also known as a slotted screwdriver. It has a flat, straight-edged tip that fits into a simple, single-slot screw head. Flathead screwdrivers are widely used in household applications, electronics, and many other industries.

The other prevalent type is the Phillips screwdriver. It features a four-star cross-shaped tip, which is designed to fit into Phillips head screws. Phillips screws have a small indentation in the center, enabling the screwdriver to hold onto the screw more securely and apply greater torque. The Phillips screwdriver is commonly found in construction, automotive, and appliance assembly.

There are also specialized screwdrivers, such as the Torx screwdriver. Torx screws have a star-shaped pattern with six rounded points, and Torx screwdrivers are designed to fit these specific screws. They are often used in electronic devices, automotive systems, and machinery.

Additionally, there are square-drive screwdrivers, also known as Robertson screwdrivers. They have a square-shaped tip that fits into square-headed screws. Square-drive screws offer high torque transfer and are commonly used in woodworking and construction.

When selecting a screwdriver, it is important to match the size and type of the screw head. Using the wrong size or type of screwdriver can cause damage to both the screw and the tool. It’s worthwhile to invest in a set of screwdrivers that includes a variety of sizes and types to cover all your needs.

Some screwdrivers come with a ratcheting mechanism, allowing for faster and more efficient screwdriving. Additionally, there are electric screwdrivers that operate with battery power, providing even more convenience and speed for repetitive or challenging projects.

The screwdriver is an essential tool for any DIY enthusiast or professional. It is used in various applications, from assembling furniture to repairing electronics. Having a reliable set of screwdrivers in your toolbox ensures that you can tackle any screw-related task with ease.

Wrench

A wrench is a versatile hand tool used for gripping and turning objects such as nuts, bolts, and pipes. It consists of a handle and a fixed or adjustable jaw that applies pressure on the object to secure a firm grip. Wrenches are commonly used in plumbing, automotive repairs, and mechanical engineering.

One of the most commonly used wrenches is the adjustable wrench, also known as a crescent wrench. It has a movable jaw that can be adjusted to fit different sizes of fasteners. The adjustable wrench is versatile and can tackle various tasks when a specific size of wrench is not readily available.

There are also combination wrenches, which have a closed-end wrench on one side and an open-end wrench on the other. The closed-end is a ring-shaped jaw that fits over nuts or bolts, providing a secure grip. The open-end has a U-shaped jaw that allows for quick tightening or loosening of fasteners in tight spaces.

Another type of wrench is the socket wrench, which uses interchangeable socket attachments. The socket wrench is commonly used in automotive repairs and machinery maintenance. It provides excellent leverage and allows for easy tightening or loosening of fasteners.

For plumbing tasks involving pipes, a pipe wrench is essential. It has serrated jaws that provide a strong grip on round objects, such as pipes. Pipe wrenches are specifically designed to minimize damage to the pipe while providing sufficient leverage to turn and secure the pipe fittings.

Additionally, there are specialty wrenches such as the torque wrench, which is used to apply specific torque measurements. Torque wrenches are commonly used in automotive and mechanical applications where precise torque settings are critical. They help prevent overtightening or undertightening of fasteners, ensuring proper assembly and avoiding damage.

When selecting a wrench, consider the size and type of fasteners or objects you will be working with. Ensure that the wrench fits securely and provides enough leverage for the task at hand. It’s also important to choose a wrench made of high-quality materials to ensure durability and longevity.

Wrenches are indispensable tools in various industries and projects. Having a well-rounded set of wrenches in your toolbox allows you to tackle a wide range of tasks with confidence and ease.

Pliers

Pliers are handy hand tools designed for gripping, bending, and cutting various materials. They consist of two pivoting arms joined at a fulcrum, with one end acting as the handle and the other end equipped with jaws or blades for performing specific tasks. Pliers are commonly used in electrical work, plumbing, and general repairs.

One of the most commonly used types of pliers is the combination pliers, also known as lineman’s pliers. These pliers have a flat, serrated gripping area near the joint, allowing for a firm grip on objects. They also have a section near the tip that can be used for cutting wires. Combination pliers are versatile and can be used for a wide range of tasks.

Another common type is the needle-nose pliers, characterized by their long, pointed jaws that taper to a fine tip. These pliers are ideal for reaching into tight spaces, manipulating small objects, and bending wires with precision. They are commonly used in electronics, jewelry making, and other intricate tasks.

For gripping and turning pipes or other cylindrical objects, pipe wrench pliers, also known as tongue and groove pliers or Channellock® pliers, are widely used. These pliers have adjustable jaws that offer a firm grip and can accommodate various pipe sizes. Pipe wrench pliers are commonly used in plumbing and mechanical applications where a strong, adjustable grip is required.

For cutting wires and cables, diagonal cutting pliers, often referred to as wire cutters or diagonal pliers, are the go-to tool. These pliers have angled cutting blades that can easily cut through wires and other materials. They are commonly used in electrical work, cable installations, and general DIY projects.

Some pliers incorporate additional features. For example, locking pliers, often called Vise-Grip® pliers, have a locking mechanism that allows them to stay clamped securely on an object without continuous pressure from the user. This feature is particularly useful when working with stubborn or hard-to-grip materials.

When choosing pliers, consider the specific tasks you will be performing and the materials you will be working with. Look for pliers made of high-quality materials to ensure durability and a comfortable grip. It’s also important to choose the right size and type of pliers for the job to ensure optimum performance and safety.

Pliers are essential tools for any DIY enthusiast or professional tradesperson. Their versatility and ability to grip, bend, and cut make them indispensable in a wide range of applications. With a selection of different pliers in your toolbox, you will be well-equipped to handle various tasks with ease.

Read more: What To Look For In Hand Tools

Chisel

A chisel is a cutting tool with a shaped blade that is designed for carving, shaping, and cutting hard materials such as wood, stone, or metal. It consists of a handle and a sharp, beveled blade that can be struck with a mallet or hammer to remove material or create intricate details. Chisels are commonly used in woodworking, masonry, and metalworking.

There are several types of chisels, each designed for specific purposes. One of the most common types is the bench chisel, which is used for general woodworking tasks. Bench chisels have a flat, straight-edged blade that tapers to a sharp cutting edge. They are used for cutting, paring, and shaping wood by hand.

Another common type is the mortise chisel, which has a thicker, stronger blade designed for cutting mortises, or rectangular holes, in wood. Mortise chisels often have a narrower, longer blade with squared sides, allowing for precise and clean cuts when creating joinery.

For carving intricate designs and shaping wood, carving chisels are used. Carving chisels have various specialized shapes and sizes, such as gouges, v-parting tools, and skew chisels. These chisels allow for more precise and detailed work in sculpting wood.

In addition to woodworking, chisels are also used in masonry and metalworking. Masonry chisels have a wider, wedge-shaped blade designed for cutting and shaping bricks, stones, and concrete. They are used in tasks such as cutting grooves, removing mortar, or shaping stones for construction or restoration projects.

For metalworking, cold chisels are commonly used. They have a wider, thicker blade that is designed to cut through metal when struck with a hammer. Cold chisels are used in tasks such as cutting or shaping metal sheeting, chipping away welds, or removing rusted bolts.

When using chisels, it is important to ensure proper technique and safety precautions. Always wear protective eyewear and gloves to prevent injury from flying debris. Keep the chisel sharp to maintain optimum cutting performance and avoid using excessive force, as this can lead to damage or accidents. Additionally, take care when striking the chisel with a mallet or hammer to ensure accuracy and prevent injury.

Chisels are essential tools for artisans and craftsmen in various disciplines. Their versatility and ability to shape and cut hard materials make them invaluable in creating intricate designs or executing precise cuts. Invest in a good set of chisels and learn proper techniques to unlock the full potential of this powerful tool.

When classifying hand tools, consider their function and purpose. Categories may include cutting tools, gripping tools, striking tools, measuring tools, fastening tools, and more.

Saw

The saw is a versatile cutting tool used for making straight or curved cuts in various materials, such as wood, metal, or plastic. It consists of a blade with sharp teeth that is attached to a handle or frame, allowing for controlled cutting motions. Saws are essential tools in woodworking, construction, and metalworking.

There are several types of saws, each designed for specific tasks and materials. One of the most common types is the handsaw. Handsaws have a long, straight blade with teeth along one side. They are used for cutting wood by hand and are suitable for making both crosscuts and rip cuts. Handsaws come in various sizes and tooth configurations to suit different needs.

For more precise and intricate cuts, coping saws are commonly used. Coping saws have a thin, narrow blade stretched across a U-shaped frame. They are primarily used for cutting curves or making intricate designs in wood, plastic, or light metal.

In carpentry and construction, power saws are widely used to make fast and efficient cuts. Circular saws are versatile power saws with a circular blade that spins rapidly to cut through various materials. They can be handheld or mounted on a table or miter saw stand for more controlled cuts. Circular saws are commonly used for making straight cuts in wood, plywood, and other building materials.

Another commonly used power saw is the jigsaw. Jigsaws have a narrow, reciprocating blade that moves up and down rapidly. This movement allows for curved or intricate cuts in materials such as wood, metal, or plastic. Jigsaws are often used in woodworking, DIY projects, and artistic endeavors.

When working with metal, hacksaws are the go-to tool. Hacksaws have a fine-toothed blade that is tensioned in a frame. They are used for cutting through metal pipes, bars, or sheets. Hacksaws can be operated by hand or mounted in a hacksaw frame for better control and stability.

For more specialized tasks, there are also saws like the reciprocating saw, band saw, and miter saw. Reciprocating saws have a straight blade that moves back and forth rapidly, making them useful for demolition or rough cutting tasks. Band saws feature a continuous loop of teethed blade, perfect for cutting curves or intricate shapes in wood, metal, or plastic. Miter saws are designed for making precise angled cuts, commonly used in woodworking and trim work.

When using saws, it is important to follow safety precautions, such as wearing safety goggles, gloves, and using clamps to secure the material being cut. Additionally, it’s crucial to select the appropriate saw for the material and task at hand to ensure efficient and accurate cuts.

Saws are essential tools in various industries and projects. By having a selection of different saws in your toolbox, you can handle a wide range of cutting tasks with precision and ease.

File

A file is a hand tool used for shaping, smoothing, and removing material from surfaces. It consists of a handle and a hardened steel blade with a series of parallel ridges or teeth along its surface. Files are invaluable tools in metalworking, woodworking, and general DIY projects, allowing for precise and controlled material removal.

Files come in various shapes, sizes, and cuts to suit different tasks. One of the most commonly used files is the flat file. It has a rectangular cross-section and is used for leveling surfaces, smoothing edges, or removing material from flat surfaces. Flat files are often employed in woodworking and metalworking to achieve smooth and even finishes.

A half-round file has a curved cross-section, resembling the shape of a half circle. It is used for shaping concave surfaces and removing material from curved or rounded objects. Half-round files are commonly used in metalworking and woodworking to create rounded or curved edges on projects.

A round file has a cylindrical shape and is used for enlarging holes, shaping round objects, or filing inner curved surfaces. It is commonly used in metalworking for tasks such as deburring holes or enlarging existing bores.

A triangular file has a triangular cross-section, with three flat sides meeting at a point. It is primarily used for filing corners, grooves, or channels. Triangular files are commonly used in metalworking and woodworking for precise filing of angles and narrow spaces.

In addition to these basic shapes, there are also needle files. Needle files are small, thin files with various shapes, such as flat, round, or square. They are used for intricate and detailed work, such as refining jewelry, working on models, or filing small parts.

When using a file, it’s important to choose the right size, shape, and cut. The cut refers to the density and size of the teeth on the file. Coarser cuts are suitable for rapid material removal, while finer cuts are used for smoothing and finishing. It’s also important to use a file with consistent and even pressure to ensure a uniform surface.

Files should be cleaned and maintained regularly to keep the teeth sharp and prevent clogging. Brushing the file with a wire brush and periodically applying a lubricant, such as a file card or chalk, can help extend its life and maintain its effectiveness.

Files are versatile tools that offer precision and control in shaping and smoothing surfaces. Including a variety of files in your toolbox ensures that you are equipped to tackle a range of projects in different materials with ease and precision.

Punch

A punch is a hand tool used for creating small holes or marks in various materials, such as metal, wood, or leather. It consists of a hardened metal rod with a pointed or flat end and a handle for gripping and striking. Punches are essential tools in metalworking, jewelry making, leather crafting, and other precision work.

One of the most commonly used types of punches is the center punch. Center punches have a pointed tip and are used to create small indentations or starter holes in a material. These marks help guide a drill bit or other tools, ensuring accuracy and precision when drilling or shaping.

Another common type is the pin punch. Pin punches have a flat, pointed end and are used for driving out pins, such as those found in machinery or hinges. Pin punches are commonly used in automotive repairs, electronics, and other applications where the removal of pins is necessary.

A transfer punch is useful for accurately transferring hole positions from one material to another. It has a tapered tip that allows it to fit inside an existing hole and create an indentation in another material. Transfer punches are commonly used in metalworking or woodworking to ensure proper alignment when drilling or inserting fasteners.

For leatherworking and upholstery, a drive punch is often used. Drive punches consist of a hollow tube with a sharp cutting edge. When struck with a hammer, they create clean, round holes in leather or fabric. Drive punches come in various sizes to accommodate different hole diameters.

In metalworking, a drift punch is commonly used for aligning or enlarging holes. Drift punches have a tapered, flat end that allows them to be driven through a hole to adjust its size or alignment. This type of punch is frequently used in automotive or machinery repairs.

When using punches, it’s essential to wear protective eyewear and use a sturdy surface or punch block to prevent injury or damage. Selecting the appropriate size and type of punch for the task at hand ensures accuracy and prevents damage to the material being worked on. Regularly inspect the punch for any signs of wear or damage and replace it if necessary.

Punches are versatile tools that offer precision and control when working with various materials. Their ability to create precise holes or marks makes them invaluable in many industries and projects. Including a set of punches in your toolbox allows you to tackle a wide range of tasks with accuracy and efficiency.

Read more: What Are The Hazards Of Hand Tools

Clamp

A clamp is a versatile hand tool used for securing objects or materials together to provide stability, support, or pressure during various tasks. Clamps consist of two jaws, operated by a screw, lever, or other mechanism, that can be adjusted to grip objects of different sizes. Clamps are essential tools in woodworking, metalworking, welding, and a range of other applications.

One of the most common types of clamps is the C-clamp, also known as a G-clamp. It has a C-shaped frame with a threaded screw that adjusts the distance between the two jaws. C-clamps are widely used in woodworking and metalworking to hold pieces together during assembly, gluing, or welding processes.

Bar clamps, also known as F-clamps, consist of a long bar with two jaws at the end. The bar can be slid in and out to adjust the clamping capacity. Bar clamps are versatile and suitable for a wide range of applications, from woodworking to metal fabrication. They offer a strong, secure hold and are often used for larger projects or when a greater clamping force is required.

Spring clamps are another commonly used type of clamp. They have a spring-loaded mechanism that provides quick and easy clamping without the need for manual adjustment. Spring clamps are often used in woodworking, crafting, and DIY projects to hold materials together temporarily or for light-duty applications.

In woodworking, there are specialized clamps such as the pipe clamp and parallel clamp. Pipe clamps use pipes of various lengths together with their jaw mechanism to create clamping pressure over a larger area. Parallel clamps have jaws that are parallel when closed, allowing for even pressure distribution along the entire length of the clamp.

For welding applications, welding clamps are used to hold workpieces securely in place during the welding process. They are designed to withstand high temperatures and provide stability. Welding clamps come in various shapes and sizes, specialized for different welding techniques and materials.

When choosing a clamp, consider the size and type of the objects or materials you will be working with, as well as the amount of clamping force required. Ensure that the clamp is made of durable materials to withstand the pressure exerted during clamping without deforming or breaking. Look for features such as padded jaws or non-marring surfaces to prevent damage to the workpiece.

Clamps are indispensable tools in many industries and projects, providing stability, support, and precise pressure during various tasks. By having a selection of different clamps in your toolbox, you can ensure that you are well-equipped to handle a wide range of projects with ease and confidence.

Conclusion

Hand tools are the backbone of any toolbox and are essential for a wide range of projects, from simple repairs to complex DIY endeavors. Understanding the different classifications of hand tools allows you to optimize your tool selection and ensure that you have the right tool for the job at hand.

From the reliable hammer and versatile screwdriver to the essential wrench and handy pliers, each hand tool serves a specific purpose, enabling you to tackle various tasks with precision and efficiency. Whether you’re a professional tradesperson or a DIY enthusiast, having a well-rounded collection of hand tools ensures that you’re equipped to handle any project that comes your way.

The chisel allows for intricate shaping and carving, while the file provides the means for smoothing and refining surfaces. The punch creates precise holes or marks, and the saw offers the capability to make accurate cuts in diverse materials. Last but not least, the clamp provides stability, support, and pressure during tasks, ensuring accurate and secure positioning.

By understanding the functions, variations, and common uses of these hand tools, you can not only maximize their efficiency but also ensure their longevity. It’s important to select high-quality tools, maintain them properly, and use them with the appropriate techniques and safety precautions to achieve the best results.

Whether you’re a professional craftsman, a hobbyist, or a homeowner looking to tackle some DIY projects, investing in a comprehensive set of hand tools is crucial. By having the right tools at your disposal, you can save time, overcome challenges, and achieve professional-quality results.

So, stock your toolbox with a hammer, screwdriver, wrench, pliers, chisel, saw, file, punch, clamp, and other essential hand tools. With a thorough understanding of their classifications and applications, you’ll be well-prepared to take on any project and unleash your creativity and ingenuity.

Frequently Asked Questions about What Are The 10 Classification Of Hand Tools?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The 10 Classification Of Hand Tools?”