Home>Articles>What Are The Three Main Attachments For A Vertical Mixer

Articles

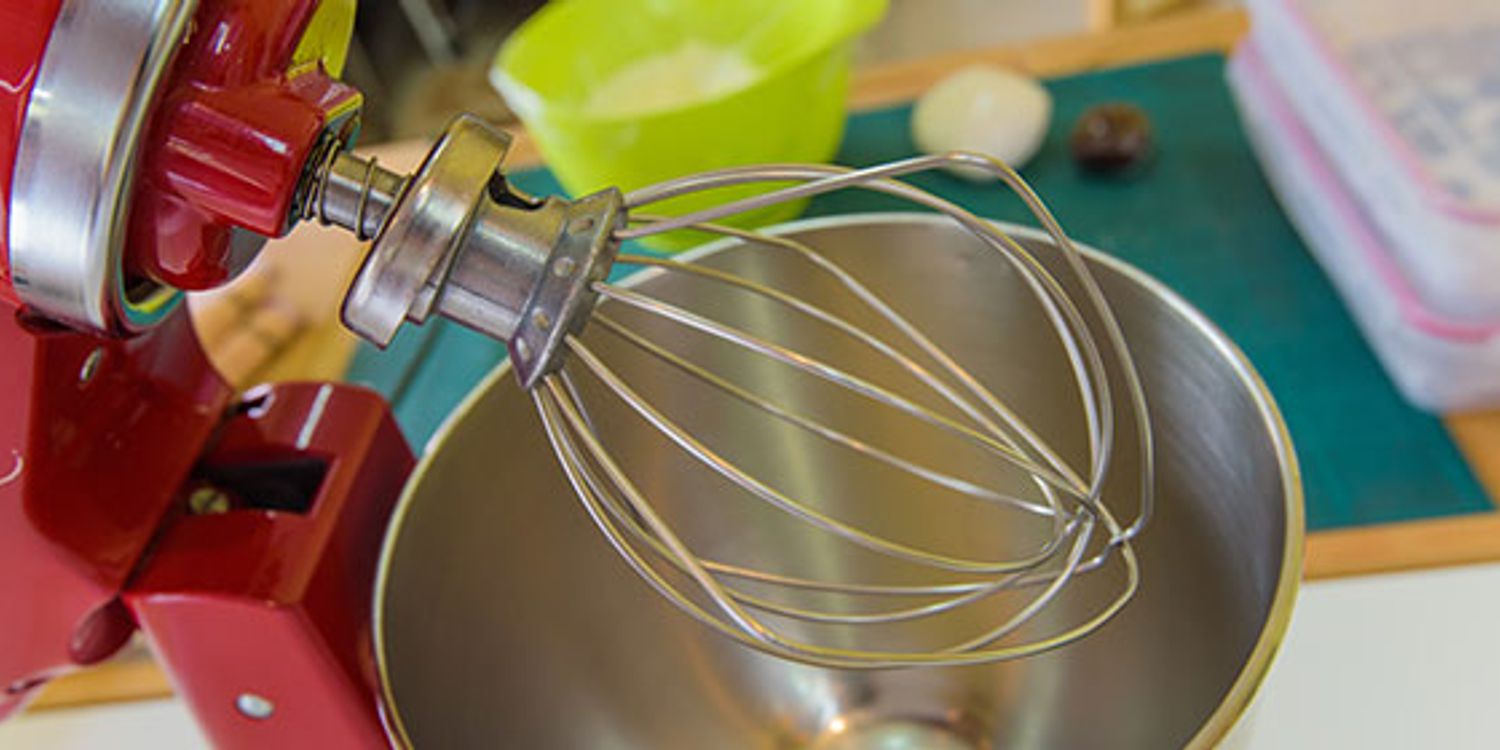

What Are The Three Main Attachments For A Vertical Mixer

Modified: January 5, 2024

Looking for articles about the three main attachments for a vertical mixer? Explore our comprehensive guide to find valuable insights and expert tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A vertical mixer is a versatile piece of equipment commonly used in various industries, including agriculture, food processing, and construction. It is specifically designed to blend and mix different materials or ingredients efficiently and thoroughly. The effectiveness of a vertical mixer greatly depends on its attachments, which play a crucial role in achieving the desired mixing results.

In this article, we will explore the three main attachments for a vertical mixer: the paddle, the ribbon, and the auger. Each attachment has its own unique features and benefits, making them suitable for different mixing applications. Understanding these attachments will help you make informed decisions when choosing the right mixer for your specific needs.

So, let’s dive in and explore these attachments in more detail!

Key Takeaways:

- The paddle attachment for vertical mixers offers versatility, efficiency, and easy maintenance. It’s a cost-effective choice for industries requiring thorough and gentle mixing of a wide range of materials, from feed to dough.

- The ribbon attachment provides gentle and precise mixing, making it ideal for fragile or heat-sensitive materials. Its versatility in handling various material types and easy maintenance make it a popular choice for industries requiring homogeneous blending.

Read more: What Are The Three Main Parts Of A Seed

Attachment 1: Paddle

One of the most commonly used attachments for a vertical mixer is the paddle. As the name suggests, this attachment consists of paddles that are strategically positioned along the mixing shaft. Paddle attachments are typically used for blending dry, granular materials or mixing wet, heavy materials.

The paddle attachment works by scooping the material from the bottom of the mixing chamber and lifting it to the top, ensuring a thorough and even distribution. The paddles are designed to effectively agitate the mixture, breaking up any clumps or lumps and promoting consistent blending.

One of the key advantages of using a paddle attachment is its versatility. It can handle a wide range of materials, including feed, fertilizer, cement, and even dough in the baking industry. The paddle attachment is especially useful in applications where gentle mixing or gentle material handling is required.

Furthermore, the paddle attachment is highly efficient, as it enables the material to move in multiple directions during the mixing process. This multidirectional movement ensures that every particle of the material is thoroughly mixed, resulting in a homogenous mixture.

Paddle attachments also offer quick and easy maintenance. The design of the attachment allows for easy cleaning and inspection, reducing downtime and increasing productivity. Additionally, paddle attachments are generally more affordable compared to other mixing attachments, making them a cost-effective choice for many industries.

In summary, the paddle attachment is a versatile and efficient option for vertical mixers. Its ability to handle a wide range of materials and provide thorough blending makes it a popular choice in various industries. Whether you’re mixing feed, fertilizer, or even dough, the paddle attachment can help you achieve consistent and high-quality results.

Attachment 2: Ribbon

The ribbon attachment is another commonly used attachment for a vertical mixer. It consists of a helical ribbon-shaped blade that runs along the mixing shaft. The ribbon attachment is designed to efficiently mix dry, powdery materials as well as viscous or sticky materials.

One of the key advantages of the ribbon attachment is its ability to create a gentle and efficient mixing action. The helical blade moves the material in a spiral motion, ensuring that every particle is being consistently mixed. This gentle mixing action is especially beneficial for fragile or heat-sensitive materials that require careful handling.

The ribbon attachment is particularly effective in applications where homogeneous blending is essential. It excels in mixing ingredients for pharmaceuticals, chemicals, and food products, where precise and even distribution of particles is crucial for the final product’s quality and consistency.

Another advantage of the ribbon attachment is its versatility in handling various types of materials. The design of the ribbon blade allows it to handle both dry materials and materials with a high moisture content. This makes it a valuable attachment for industries like cosmetics, ceramics, and plastics, where a wide range of materials need thorough blending.

Additionally, the ribbon attachment offers easy maintenance and cleaning. The design of the attachment allows for quick access to the mixing chamber, making it convenient to clean and inspect. This reduces downtime and ensures that the mixer remains in optimal operating condition.

In summary, the ribbon attachment is a versatile and efficient option for vertical mixers. Its gentle mixing action, ability to handle various materials, and ease of maintenance make it a popular choice in industries that require precise and homogeneous blending. Whether you’re mixing pharmaceutical ingredients, cosmetics, or powdery chemicals, the ribbon attachment can help you achieve consistent and high-quality results.

When using a vertical mixer, the three main attachments to consider are the paddle attachment for mixing heavy batters and doughs, the whisk attachment for whipping cream and egg whites, and the dough hook for kneading bread dough.

Attachment 3: Auger

The auger attachment is a powerful and versatile tool for vertical mixers. It consists of a spiral-shaped screw blade that runs along the mixing shaft, resembling a large drill bit. The auger attachment is specifically designed for handling heavy, viscous, or sticky materials with ease.

One of the key advantages of the auger attachment is its ability to effectively move and mix dense materials. The spiral design of the blade creates a strong pushing and lifting action, allowing it to handle materials with high viscosity or a tendency to clump together. This makes it suitable for mixing components such as wet concrete, thick pastes, and heavy dough.

The auger attachment is especially beneficial in applications where thorough mixing and kneading are required. It excels in industries like construction, where it can efficiently mix cement, mortar, and other building materials. The strong pushing and lifting action of the auger attachment ensures that every particle of the material is evenly distributed, resulting in a consistent and stable mixture.

Furthermore, the auger attachment offers excellent control over the mixing process. Its slow and steady rotation speed allows for precise mixing and prevents over-mixing or excessive agitation. This is particularly important in industries such as food processing, where delicate ingredients or fragile structures need to be preserved during the mixing process.

In addition to its mixing capabilities, the auger attachment also facilitates easy material handling. Its design helps in effectively transporting the mixed material to the desired location, whether it’s a storage container, a packaging machine, or a different part of the production process. This makes the auger attachment an efficient tool for enhancing workflow and productivity.

In summary, the auger attachment is a powerful and versatile option for vertical mixers. Its ability to handle heavy and viscous materials, precise mixing control, and efficient material handling capabilities make it a valuable tool in industries that require thorough blending and controlled agitation. Whether you’re mixing construction materials or heavy dough, the auger attachment can help you achieve consistent and high-quality results.

Conclusion

Vertical mixers are essential equipment for various industries, providing efficient and thorough mixing capabilities. The attachments used in these mixers play a vital role in achieving the desired mixing results. In this article, we explored the three main attachments for a vertical mixer: the paddle, the ribbon, and the auger.

The paddle attachment offers versatility and efficiency, making it suitable for a wide range of materials. Its ability to handle both dry and wet materials, along with its thorough mixing action, makes it a popular choice in many industries.

The ribbon attachment excels in creating a gentle and precise mixing action, making it ideal for fragile or heat-sensitive materials. Its ability to achieve homogeneous blending is crucial in industries that require consistent and high-quality end products.

The auger attachment is a powerful tool for handling heavy and viscous materials. Its strong pushing and lifting action, combined with its precise mixing control, makes it a valuable attachment for industries such as construction and food processing.

Understanding the characteristics and benefits of these attachments will help you choose the right attachment for your specific mixing needs. Whether you’re blending feed, pharmaceutical ingredients, or constructing materials, selecting the appropriate attachment will ensure efficient and reliable mixing results.

In conclusion, the paddle, ribbon, and auger attachments offer unique features and advantages, catering to different materials and mixing requirements. By utilizing these attachments effectively, you can achieve optimal blending results and enhance productivity in your industry.

Frequently Asked Questions about What Are The Three Main Attachments For A Vertical Mixer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The Three Main Attachments For A Vertical Mixer”