Articles

What Does 12/2 Electrical Wire Mean

Modified: February 22, 2024

Discover the meaning of 12 2 electrical wire and its importance in electrical installations. Read informative articles on electrical wiring and stay informed.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of electrical wires! If you are new to the field or unfamiliar with electrical terminology, you may find yourself puzzled by the various types and numbers associated with different wires. One such number you may encounter is “12 2” electrical wire. But what does it actually mean?

In this article, we will be exploring the meaning and significance of 12 2 electrical wire. We will delve into its gauge, applications, and how it differs from other wire gauges. Additionally, we will discuss safety considerations and electrical code compliance related to this type of wire.

Understanding electrical wire gauge is crucial for anyone working with electrical systems, whether you are a homeowner, a contractor, or an electrician. So, let’s begin our journey through the world of 12 2 electrical wire and unravel the mysteries behind its name.

Key Takeaways:

- 12 2 electrical wire consists of a 12-gauge wire with two conductors, commonly used in residential circuits requiring a 20-amp capacity. Understanding its characteristics empowers informed decisions for electrical projects.

- Safety and compliance with electrical codes are crucial when working with 12 2 electrical wire. Adhering to proper installation techniques and ampacity ratings minimizes the risk of electrical hazards and ensures a reliable and safe electrical system.

Read more: What Do The Letters On Electrical Wire Mean?

Understanding Electrical Wire Gauge

Before we delve into the specifics of 12 2 electrical wire, it is important to have a basic understanding of electrical wire gauge. Wire gauge refers to the thickness or diameter of the wire. The gauge of a wire determines its current-carrying capacity and the amount of electrical resistance it possesses.

Wire gauge is commonly represented by a numerical value, and the lower the number, the thicker the wire. For instance, a lower gauge like 12 is thicker than a higher gauge like 18.

The American Wire Gauge (AWG) system is the standard measurement system used to indicate wire gauge in North America. The AWG system assigns specific gauge numbers to different wire diameters, with progressively smaller numbers representing thicker wires.

It is worth noting that as the gauge number increases, the wire diameter decreases, resulting in increased electrical resistance. This resistance can lead to voltage drops and decreased electrical efficiency.

Now that we have a basic understanding of wire gauge, let’s explore what the term “12 2” means when it comes to electrical wire.

What Does 12 2 Electrical Wire Indicate?

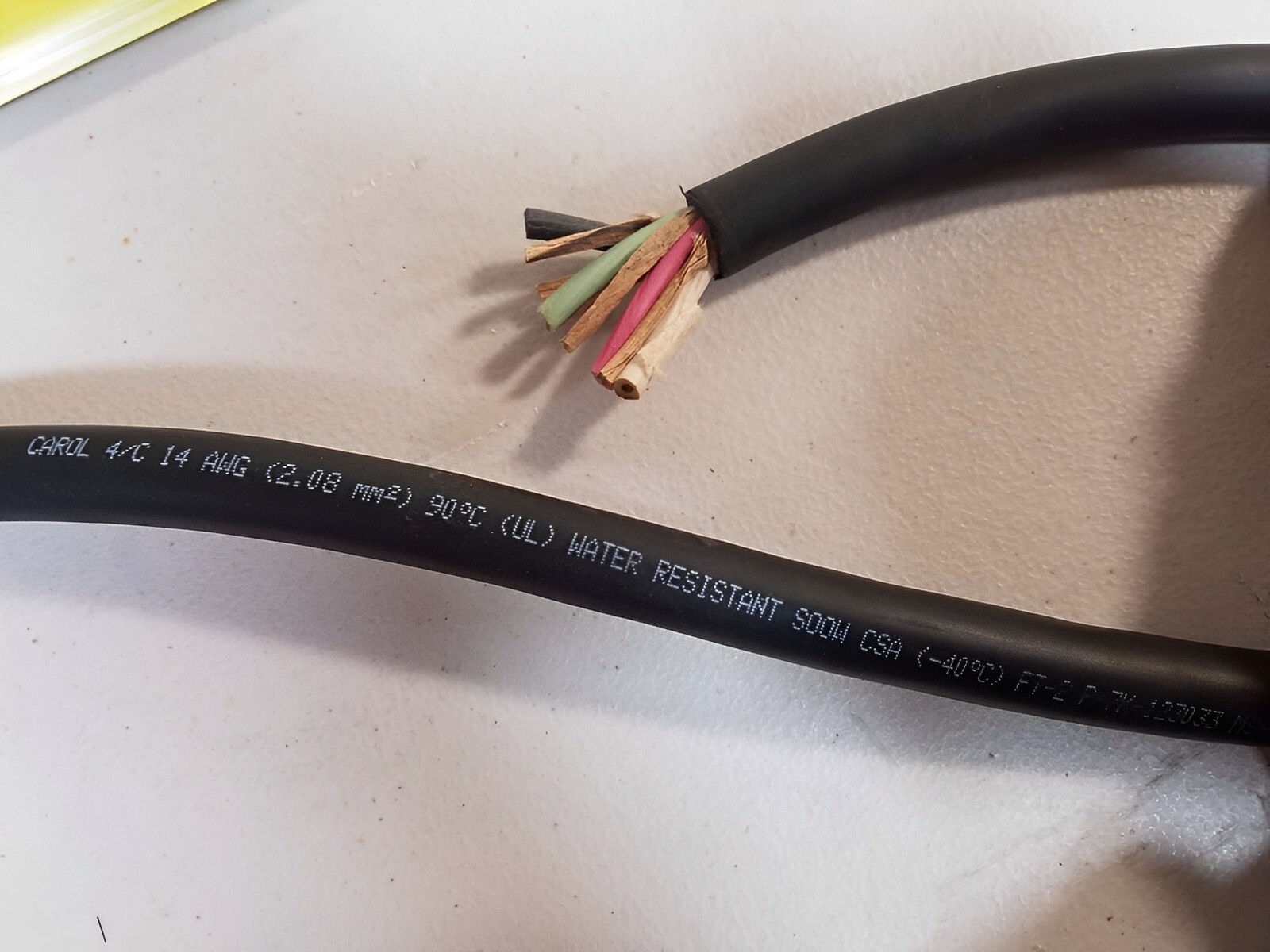

The term “12 2” electrical wire indicates specific characteristics about the wire. In this case, “12” refers to the wire gauge, while “2” indicates the number of conductors within the wire.

Starting with the gauge, a 12-gauge wire is relatively thick and has a diameter of approximately 0.0808 inches (2.05mm). It is capable of carrying a larger amount of electrical current compared to thinner wires with higher gauge numbers. The 12-gauge wire is commonly used in residential applications where a 20-amp circuit is required.

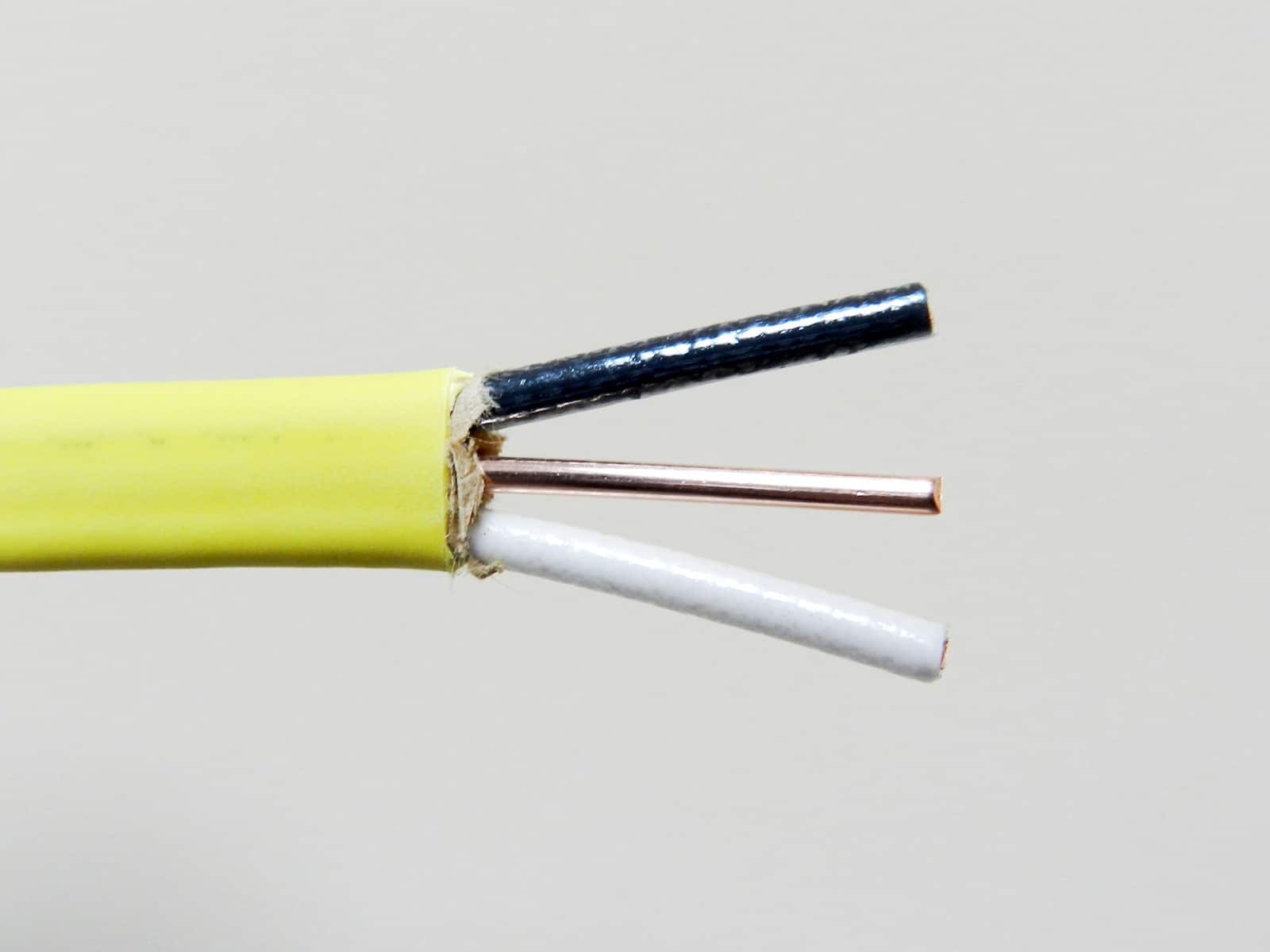

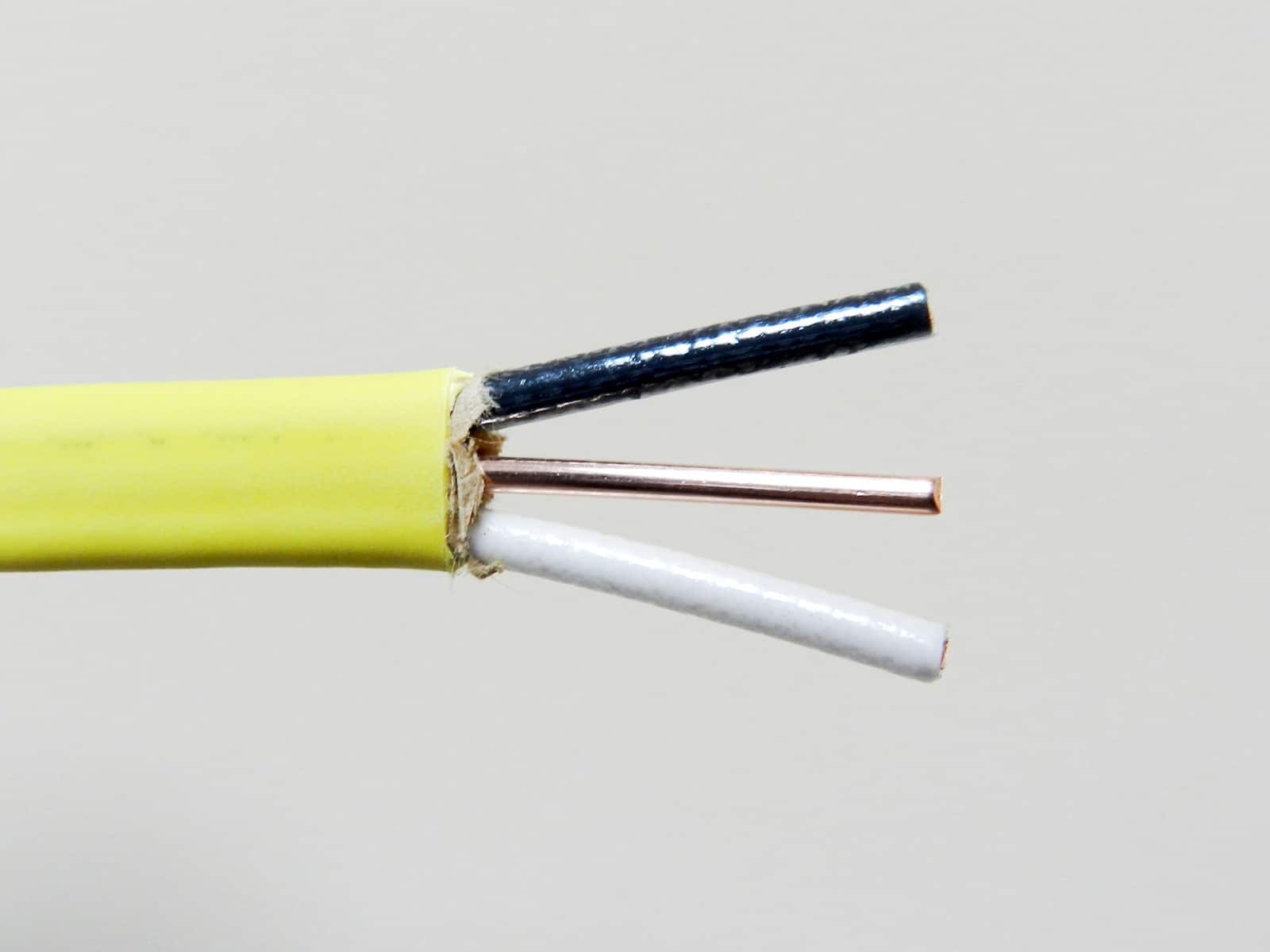

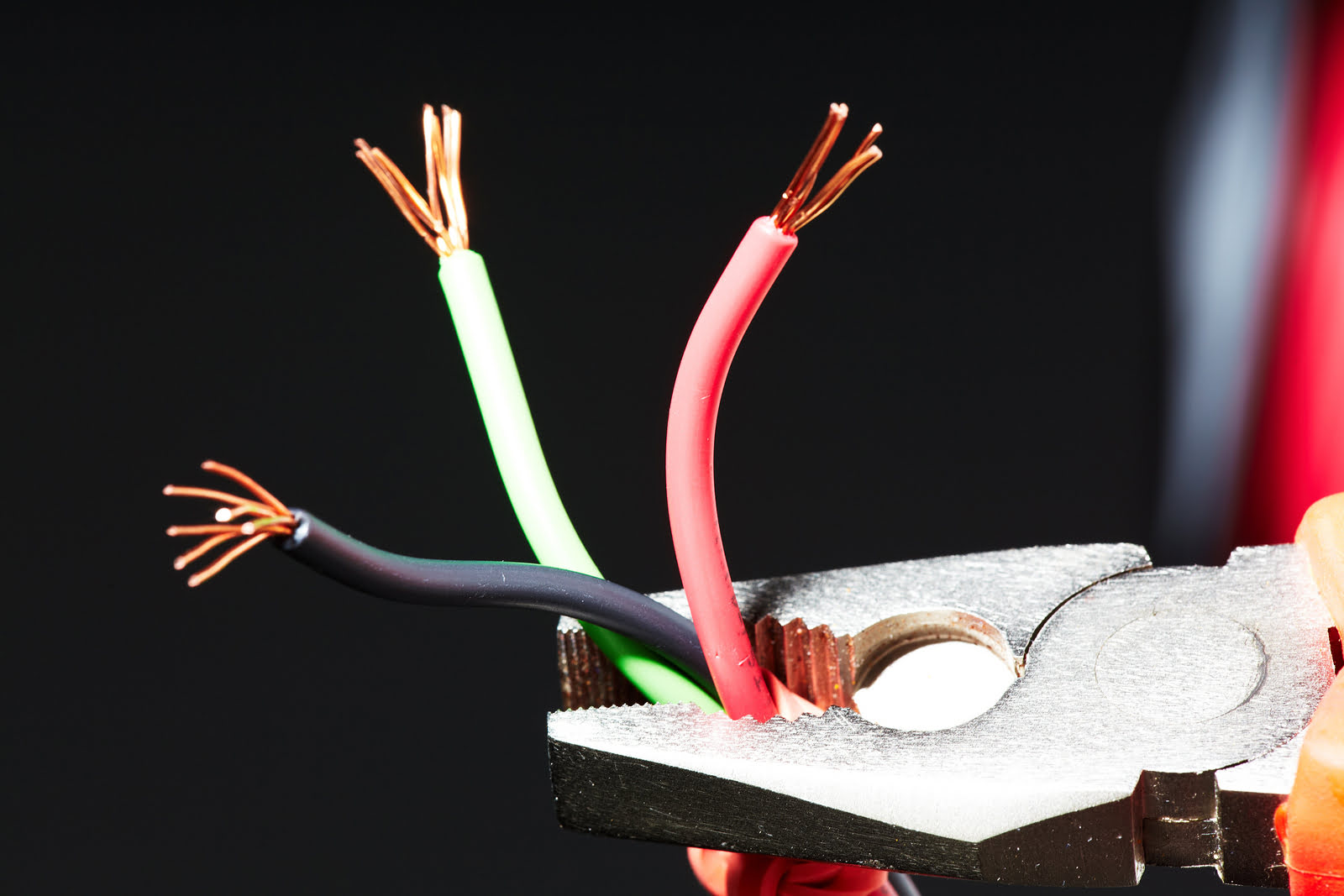

The “2” in 12 2 electrical wire signifies that it consists of two conductors within the same cable. These conductors are typically color-coded, with one being black and the other being white. The black wire is designated for the hot or live electrical connection, while the white wire is used as the neutral conductor.

In addition to the two main conductors, 12 2 electrical wire often includes a bare copper or green wire, which serves as the grounding conductor. This is crucial for safety reasons, as it provides a path for electrical current to flow in the event of a fault, ensuring that the electrical system remains grounded and protects against electric shock.

To summarize, the “12 2” designation of electrical wire signifies a 12-gauge wire with two conductors (a black hot wire, a white neutral wire) and possibly a bare copper or green wire for grounding.

Application and Common Uses of 12 2 Electrical Wire

Now that we understand the gauge and composition of 12 2 electrical wire, let’s explore its applications and common uses. Due to its specific characteristics and capabilities, this type of wire is commonly employed in various electrical installations.

One of the primary applications of 12 2 electrical wire is in residential electrical wiring. It is often used to supply power to outlets, switches, and lighting fixtures. This wire gauge is suitable for circuits that require a higher current capacity, such as kitchen appliances, air conditioning units, and power tools.

When it comes to residential electrical wiring, 12 2 electrical wire is commonly utilized in circuits that carry a maximum load of 20 amps. This can include general lighting circuits, bedroom circuits, and living room circuits.

In addition to residential applications, 12 2 electrical wire is also utilized in some commercial and industrial settings. It can be employed for various lighting and power applications, depending on the specific requirements of the establishment.

It is important to note that the use of 12 2 electrical wire should align with local electrical codes and regulations. These codes may specify the allowed uses and installation requirements for different wire gauges.

Overall, the versatility and capacity of 12 2 electrical wire make it suitable for a wide range of residential, commercial, and industrial applications, wherever a 20-amp circuit is required.

The “12 2” electrical wire refers to a type of electrical cable that consists of 12-gauge wire and includes 2 insulated conductors, typically used for general household wiring. Always consult local building codes and a qualified electrician when working with electrical wiring.

Differences between 12 2 and Other Wire Gauges

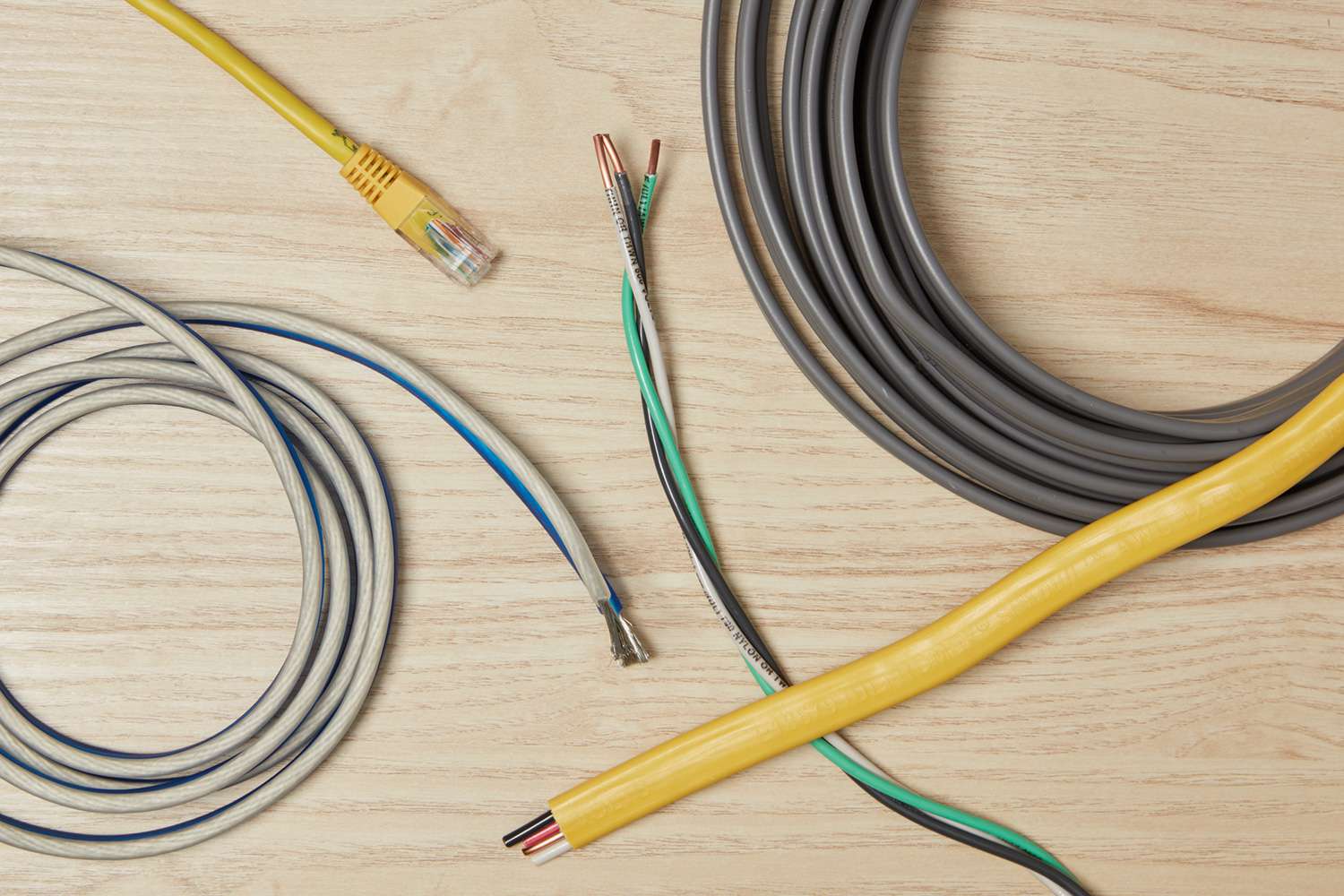

While 12 2 electrical wire is commonly used for specific applications, there are significant differences between this wire gauge and others. Understanding these differences can help you make informed decisions when selecting the appropriate wire gauge for your electrical projects. Let’s explore some key distinctions:

1. Wire Thickness: The primary difference lies in the wire thickness. As we mentioned earlier, a lower gauge number like 12 indicates a thicker wire diameter compared to higher gauge numbers. Thicker wires generally have higher current-carrying capacity.

2. Current Capacity: Wire gauge directly affects the amount of electrical current the wire can safely carry. Thicker wires like 12 2 can handle higher currents compared to thinner wires with higher gauge numbers. It is important to select the appropriate wire gauge based on the electrical load requirements.

3. Voltage Drop: Thicker wires have lower electrical resistance, resulting in less voltage drop along the length of the wire. This is particularly important for long wire runs, as excessive voltage drop can impact the performance of electrical devices and equipment.

4. Cost: Thicker wires generally cost more due to the increased amount of metal used in their construction. This cost consideration may play a role in selecting the appropriate wire gauge for a specific project.

5. Flexibility: Thicker wires tend to be less flexible than thinner wires. This can affect their ease of installation and suitability for certain applications where flexibility is essential.

It’s important to note that each wire gauge has its own unique purpose and application. While 12 2 electrical wire is commonly used for residential circuits, smaller gauge wires may be used for low-voltage applications, while larger gauge wires may be used for heavy-duty industrial applications.

Always consult electrical codes and guidelines specific to your region to ensure compliance when selecting the appropriate wire gauge for your project.

Read more: What Is 4 Wire Electrical Wire

Safety Considerations and Electrical Code Compliance

When working with electrical wire, including 12 2 electrical wire, safety should always be a top priority. It is crucial to adhere to electrical codes and regulations to ensure proper installation and minimize the risk of electrical accidents or fires. Here are some important safety considerations and electrical code compliance guidelines:

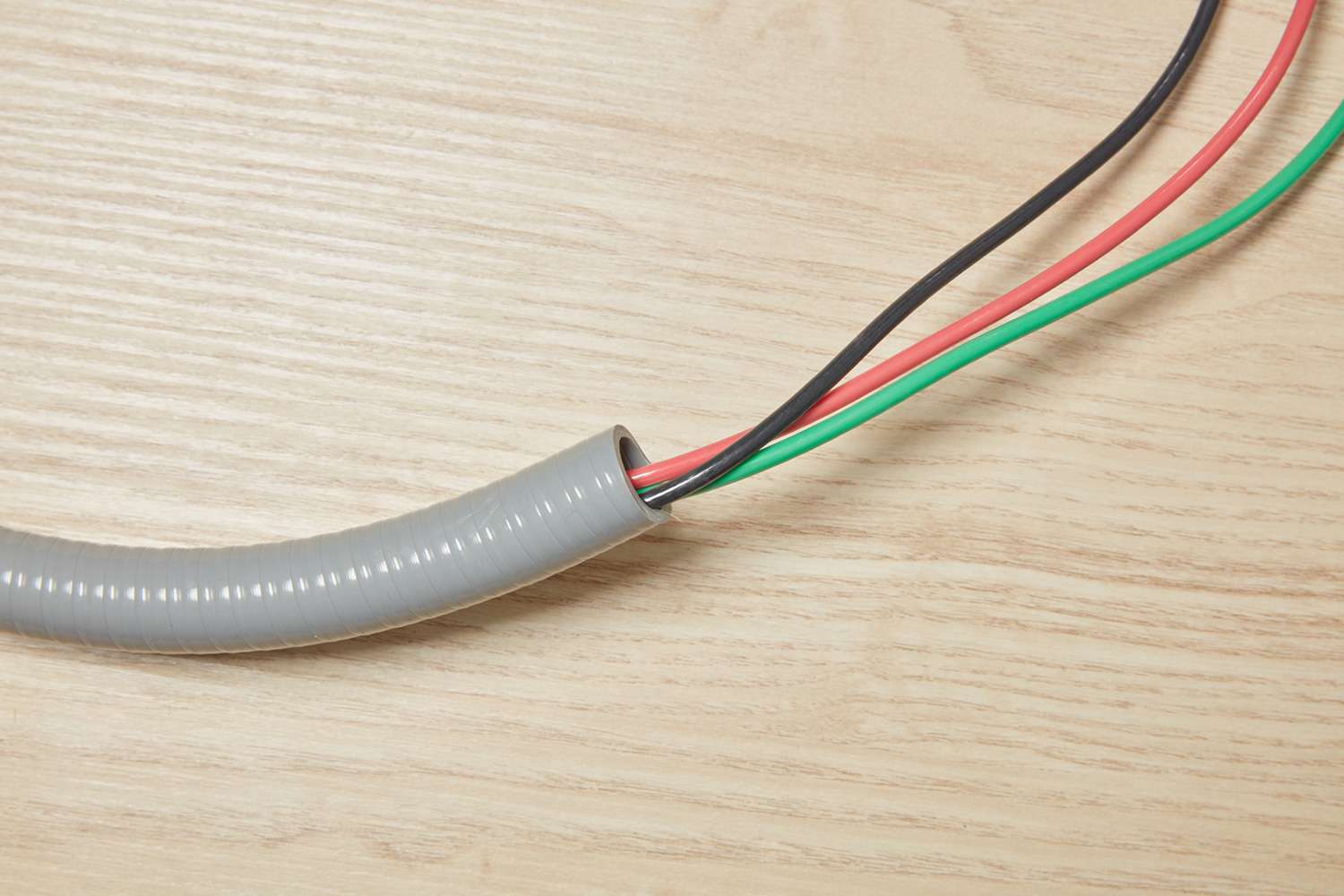

1. Proper Installation: Follow manufacturer instructions and best practices for installing 12 2 electrical wire. This includes correctly stripping the insulation, securely connecting wires, and using appropriate connectors, junction boxes, and conduits.

2. Grounding Requirements: Ensure that the grounding conductor, typically a bare copper or green wire, is properly installed and connected to grounding points, such as metal junction boxes or grounding rods. This helps protect against electrical shocks and ensures safe operation.

3. Ampacity Ratings: Be mindful of the ampacity ratings, or the maximum current-carrying capacity, of 12 2 electrical wire. This will help prevent overloading the wire, which can cause overheating and potential fire hazards.

4. Proper Insulation: Inspect the wire’s insulation for any damage or wear. Damaged insulation can lead to short circuits or electrical shocks. Replace any defective wires before proceeding with installation.

5. Spacing and Routing: Follow electrical code guidelines regarding wire spacing and routing. Keep wires away from potential sources of damage, such as sharp edges or areas prone to moisture or excessive heat.

6. Qualified Professionals: For complex or extensive electrical projects, it is advisable to consult and hire licensed electricians who are knowledgeable about local electrical codes. They can ensure compliance and provide expert guidance to maintain safety.

Remember, electrical work should never be taken lightly, and compliance with electrical codes and regulations is essential. By adhering to safety guidelines and electrical code requirements, you can minimize the risk of electrical hazards and ensure the well-being of occupants and the longevity of the electrical system.

Conclusion

In conclusion, 12 2 electrical wire plays a crucial role in residential, commercial, and industrial electrical installations. Understanding its meaning and characteristics is essential for anyone working with electrical systems.

We have explored that “12 2” refers to a 12-gauge wire with two conductors, typically a black hot wire, a white neutral wire, and a bare copper or green grounding wire. This wire gauge is commonly used in residential circuits that require a 20-amp capacity.

By having a basic understanding of electrical wire gauge, we can make informed decisions when selecting the appropriate wire for specific applications. Thicker wires like 12 2 can handle higher current capacities and have lower voltage drops, making them suitable for heavy-duty electrical demands.

However, it is crucial to ensure safety and comply with electrical codes and regulations throughout the installation process. Adhering to proper installation techniques, grounding requirements, and ampacity ratings helps minimize the risk of electrical accidents and ensures a reliable and safe electrical system.

Whether you are a homeowner, contractor, or electrician, having a comprehensive understanding of 12 2 electrical wire empowers you to make informed choices and carry out electrical projects with confidence.

Remember, when in doubt, consult with electrical professionals to ensure compliance and safety. With the right knowledge and precautions, you can confidently work with 12 2 electrical wire and create efficient, reliable, and safe electrical systems.

Frequently Asked Questions about What Does 12/2 Electrical Wire Mean

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does 12/2 Electrical Wire Mean”