Articles

What Does SO Stand For Electrical Cord

Modified: January 6, 2024

Discover the meaning of "SO" in electrical cords with our informative articles. Explore the different types, uses, and safety tips for SO cords.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of electrical cords! They are a vital component in our everyday lives, powering our devices and allowing us to stay connected. Among the various types of electrical cords available, one that stands out is the SO cord. But what does SO stand for in the context of electrical cords?

SO stands for “Service-Entrance, Oil Resistant.” It is a specific type of power cord that is designed to withstand harsh conditions and provide a reliable power source for various applications. Whether you are a professional electrician or a homeowner looking to power your appliances, understanding the significance of SO cords is essential.

In this article, we will dive into the world of SO cords and explore their purpose, construction, features, common uses, benefits, safety considerations, and how to choose the right one for your needs. So let’s uncover the mysteries behind the abbreviation SO and unravel the secrets of this remarkable electrical cord!

Key Takeaways:

- SO cords, or Service-Entrance, Oil Resistant cords, are designed for durability, flexibility, and resistance to harsh conditions, making them ideal for industrial, construction, and outdoor applications.

- When choosing an SO cord, consider factors such as application, environment, length, amperage capacity, gauge, certifications, and budget to ensure optimal performance and safety.

Read more: What Is An Electrical Cord?

Understanding SO Cord

Before we delve into the details, let’s gain a deeper understanding of what an SO cord actually is. As mentioned earlier, SO stands for “Service-Entrance, Oil Resistant.” It is a type of power cord that is specifically designed for heavy-duty applications where durability and resistance to oil and harsh environments are essential.

SO cords are commonly used in industrial settings, construction sites, workshops, and outdoor applications where the electrical equipment is exposed to oils, chemicals, moisture, and extreme temperatures. They are engineered to withstand these challenging conditions while delivering a stable and reliable power supply.

What sets an SO cord apart from other types of electrical cords is its high flexibility, durability, and resistance to oil and water. This makes it an ideal choice for environments where cords may need to be dragged, coiled, or bent frequently. The outer jacket of an SO cord is made from a durable synthetic rubber material that provides excellent resistance to abrasion, sunlight, ozone, and chemicals.

Another distinctive characteristic of an SO cord is its high current carrying capacity. These cords are capable of handling higher electrical loads compared to standard extension cords, making them suitable for heavy-duty power tools, machinery, and equipment that require a significant amount of electricity to operate.

To ensure the safety of users, SO cords are also designed with proper insulation and grounding features. They are typically color-coded, with the jacket displaying appropriate markings to indicate the cord’s electrical specifications and compliance with safety standards.

Now that we have a basic understanding of what an SO cord is, it’s time to explore its purpose and the specific situations where it is commonly used. Stay tuned!

Purpose of SO Cord

The primary purpose of an SO cord is to provide a reliable and flexible power supply in demanding environments. Here are a few key reasons why SO cords are widely used:

- Durability: SO cords are built to withstand rugged conditions, making them ideal for use in industrial settings, construction sites, and workshops. Their robust construction and oil resistance allow them to endure constant dragging, bending, and exposure to chemicals without compromising their performance.

- Oil and Water Resistance: One of the distinctive features of an SO cord is its resistance to oil and water. This makes it an excellent choice for applications where cords are exposed to oils, lubricants, and liquids. It ensures reliable performance and minimizes the risk of electrical hazards.

- Flexibility: SO cords are designed to be highly flexible, allowing for easy handling and maneuverability even in tight spaces. Their flexibility enhances user convenience and reduces the likelihood of the cord getting tangled or snagged during use.

- High Current Carrying Capacity: SO cords are constructed with thick conductors that can handle higher electrical loads compared to standard extension cords. This makes them suitable for powering heavy-duty equipment, machinery, and power tools that require a substantial amount of electricity.

- Longevity: SO cords are built to last. Their rugged construction, combined with high-quality materials like synthetic rubber, ensures longevity and minimizes the need for frequent replacements. This makes them a cost-effective solution in the long run.

Overall, the purpose of an SO cord is to provide a durable, reliable, and flexible power supply in challenging environments where other cords would fail. Their ability to withstand oils, chemicals, moisture, and extreme temperatures make them an indispensable tool for various industries and applications.

Construction of SO Cord

An SO cord is a result of meticulous construction designed to withstand demanding environments. Let’s take a closer look at the components that make up an SO cord:

- Conductors: The conductors inside an SO cord are made of stranded copper wires to enhance flexibility and conductivity. The number of conductors varies depending on the cord’s intended use. These conductors serve as the pathway for the electric current and are insulated to prevent contact with the outer jacket.

- Insulation: Each individual conductor within an SO cord is insulated with a high-quality material such as PVC (Polyvinyl Chloride) or EPDM (Ethylene Propylene Diene Monomer). The insulation provides electrical resistance, preventing the flow of current between conductors and reducing the risk of electrical hazards.

- Jacket: The outer jacket of an SO cord is made from a durable synthetic rubber material, which gives the cord its flexibility and resistance to oil, water, chemicals, temperature, and abrasion. The jacket acts as a protective layer, shielding the conductors and insulation from external elements that could potentially damage them.

- Color Coding: To ensure safety and proper identification, SO cords are often color-coded. The colors indicate the cord’s electrical properties and compliance with safety standards. For instance, a yellow SO cord is commonly used for 120V applications, while a black cord is typically associated with 240V applications.

- Markings: Along the length of the SO cord’s jacket, you will find markings that provide important information about the cord’s specifications, including the cord type, voltage rating, and amperage capacity. These markings help users identify and choose the appropriate cord for their specific needs.

The construction of an SO cord is carefully engineered to ensure durability, flexibility, and resistance to harsh conditions. By using high-quality materials and adhering to industry standards, manufacturers create cords that can withstand frequent use, extreme temperatures, exposure to oils and chemicals, and provide a safe and reliable power supply.

Now that we understand the construction of an SO cord, let’s explore its unique features and how they contribute to its versatility and performance.

Features of SO Cord

An SO cord comes with a range of features that make it well-suited for demanding applications. Let’s explore some of the key features of an SO cord:

- Flexibility: One of the standout features of an SO cord is its high flexibility. The synthetic rubber jacket and stranded copper conductors allow the cord to bend easily without damaging the internal components. This flexibility enables convenient handling, maneuverability, and coiling of the cord, making it suitable for various settings.

- Oil Resistance: As the name suggests, an SO cord is designed to be resistant to oil. The synthetic rubber jacket provides a protective barrier that prevents oil from seeping into the cord and causing damage. This feature is crucial in environments where machinery and equipment are frequently exposed to oils and lubricants.

- Water Resistance: In addition to oil resistance, an SO cord offers excellent resistance to water. The jacket material is designed to repel moisture and prevent it from reaching the internal components. This quality is vital in outdoor applications or areas with high humidity where the cord may come into contact with water.

- Chemical Resistance: Along with oil and water, an SO cord is resistant to various chemicals, including solvents, acids, and alkaline substances. This resistance ensures that the cord can withstand exposure to a wide range of chemicals without degradation or compromise in performance.

- Abrasion Resistance: The outer jacket of an SO cord is designed to be highly resistant to abrasion. It can withstand friction, rough surfaces, and constant dragging without wearing down or exposing the internal components. This feature enhances the cord’s longevity and makes it suitable for rugged environments.

- Temperature Resistance: SO cords are formulated to have excellent temperature resistance. They can withstand extreme heat and cold without degradation or loss of flexibility. This quality makes them suitable for use in environments where temperature fluctuations are common.

These features collectively make an SO cord a reliable and versatile option for various applications. Whether it’s powering heavy-duty equipment in an industrial setting or providing a dependable power supply in outdoor environments, an SO cord’s flexibility, oil resistance, water resistance, chemical resistance, abrasion resistance, and temperature resistance ensure optimal performance and longevity.

Now that we have explored the features of an SO cord, let’s see some of the common uses for this versatile power cord.

Read more: What Does Electrical Cord E315020 Fit

Common Uses of SO Cord

An SO cord finds utility in a wide range of applications due to its durability and resistance to harsh conditions. Here are some of the common uses of an SO cord:

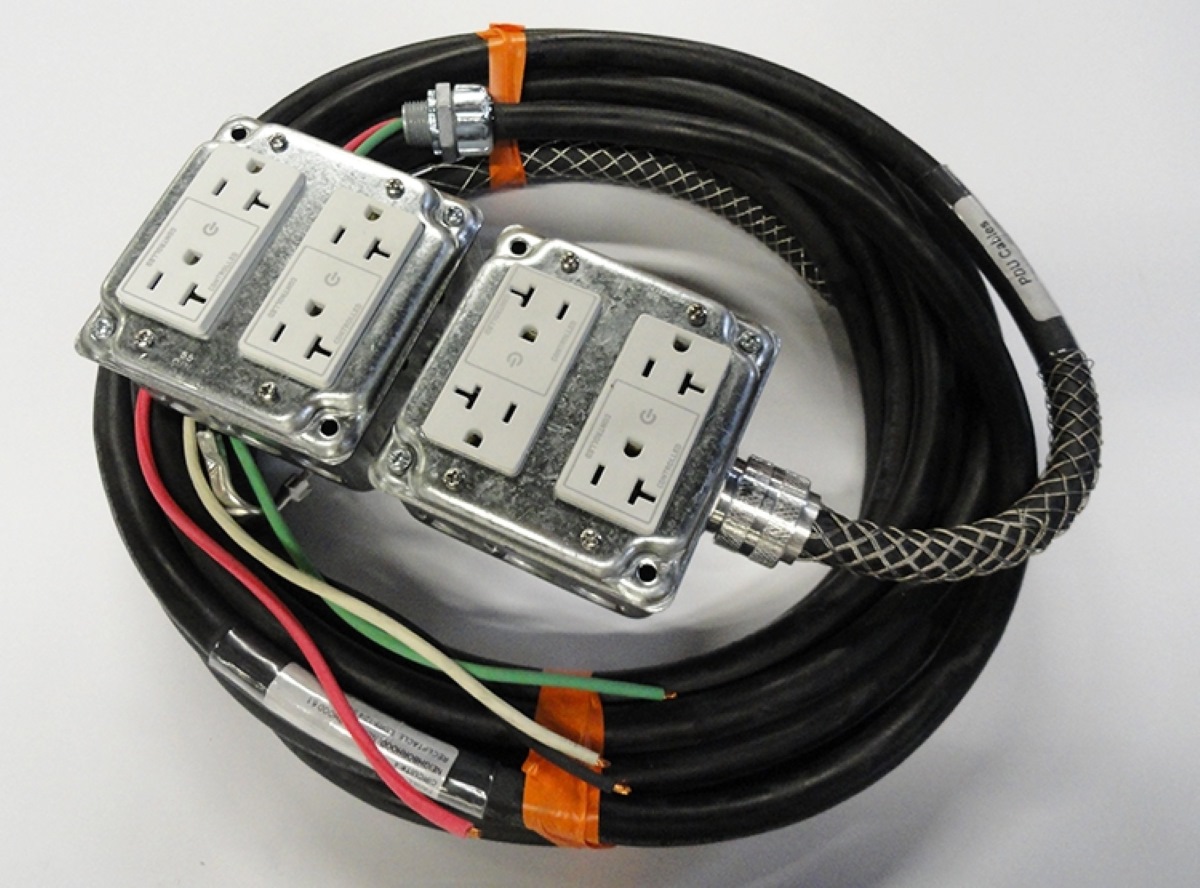

- Construction Sites: Construction sites often require reliable power sources for various tools and equipment. SO cords are commonly used to power heavy-duty tools such as drills, saws, and compressors, providing a safe and flexible power supply in rugged environments.

- Industrial Settings: Industries such as manufacturing, mining, and oil and gas rely on robust power cords to ensure uninterrupted operations. SO cords are preferred for their ability to withstand oil, chemicals, moisture, and high temperatures, making them suitable for powering machinery and equipment in these demanding environments.

- Workshops and Garages: DIY enthusiasts, mechanics, and hobbyists often use SO cords in their workshops and garages. They provide a reliable power supply for various power tools, welders, and other equipment, while their flexibility and durability make them easy to manage and coil.

- Outdoor Events: Outdoor events such as concerts, festivals, and fairs require power to accommodate lighting, sound systems, and other electrical equipment. SO cords are an ideal choice in these situations due to their ability to withstand exposure to the elements, including rain and sunlight.

- Marine Applications: The resistance of SO cords to moisture, oils, and chemicals makes them suitable for use in marine environments. They are commonly employed on boats, yachts, and docks to power lighting, navigation systems, and other electrical components.

- Generator Connections: When using generators to provide temporary power, it is crucial to have a reliable and durable connection between the generator and the equipment being powered. SO cords are often used in generator setups to deliver stable and safe power transfer.

These are just a few examples of the many applications where an SO cord is a preferred choice. The versatility, durability, and resistance to harsh conditions make it an essential tool in various industries, construction sites, workshops, outdoor events, and marine applications.

Now that we understand the common uses of an SO cord, let’s move on to the benefits of using this versatile power cord.

SO stands for “Service Order” in the context of electrical cords. It is a document that outlines the details of the work to be performed, including the type and length of cord needed.

Benefits of Using SO Cord

Using an SO cord for your electrical power needs offers several benefits that make it a reliable and advantageous choice. Here are some key benefits of using an SO cord:

- Durability: SO cords are built to withstand tough environments and heavy use. Their robust construction and resistance to oil, water, chemicals, abrasion, and temperature fluctuations ensure a long lifespan, reducing the need for frequent replacements.

- Flexibility: The high flexibility of an SO cord allows for easy handling and coiling. It can be maneuvered through tight spaces and around obstacles, making it convenient to use in various settings.

- Reliable Power Supply: An SO cord is designed to deliver a stable and dependable power supply. It can handle higher electrical loads, providing ample power for heavy-duty equipment, machinery, and tools without compromising performance.

- Safety: SO cords are manufactured to meet strict safety standards and regulations. They are designed with proper insulation, grounding features, and color-coded jackets for easy identification and compliance. This helps minimize the risk of electrical hazards and ensures user safety.

- Versatility: From construction sites to workshops to outdoor events, an SO cord can adapt to various applications. Its resistance to oils, water, chemicals, and extreme temperatures allows it to function reliably in a wide range of environments.

- Cost-Effective: While the initial cost of an SO cord may be higher than that of regular extension cords, their durability and longevity make them a cost-effective investment in the long run. You won’t have to frequently replace worn-out cords, saving you money over time.

- Peace of Mind: By using an SO cord, you can have peace of mind knowing that you have a reliable and durable power source. Whether you are working on a construction site or powering equipment in your garage, you can focus on your tasks without worrying about power interruptions or cord failures.

These benefits of using an SO cord highlight its value and practicality in various applications. Whether you are a professional contractor, a DIY enthusiast, or an event organizer, an SO cord can provide the reliability, flexibility, and safety you need to power your electrical equipment.

Now, to further understand the benefits of an SO cord, let’s compare it with other types of electrical cords.

Comparison with Other Types of Electrical Cords

When it comes to choosing the right electrical cord for your specific needs, it’s essential to understand the differences between different types of cords. Let’s compare an SO cord with other commonly used electrical cords to see how they stack up in terms of features and applications:

- SO Cord vs. SJ Cord: The SJ cord, commonly known as the Junior Service cord, is another type of flexible power cord. While both cords offer flexibility, the key difference lies in their construction and resistance. Unlike an SO cord, which is oil-resistant, an SJ cord does not offer the same level of resistance to oils and chemicals. Therefore, an SO cord is more suitable for environments where exposure to oils and chemicals is likely.

- SO Cord vs. SJOOW Cord: The SJOOW cord is designed for outdoor and heavy-duty applications, just like the SO cord. However, the SJOOW cord is characterized by its resistance to oil, water, and sunlight (indoor and outdoor use), while the SO cord is primarily built for oil resistance (indoor use). So, if your application requires protection against sunlight in addition to oil and water resistance, the SJOOW cord may be the better choice.

- SO Cord vs. Extension Cord: An extension cord is a versatile cord used to extend the reach of a power source. While extension cords come in various types and lengths, they are typically less durable and less resistant to harsh environments compared to an SO cord. An SO cord is specifically designed for heavy-duty applications, making it a more suitable option for powering machinery, equipment, and tools in industrial or construction settings.

- SO Cord vs. Welding Cord: Welding cords are specifically designed for welding applications and carry higher currents. They have an even higher current-carrying capacity than an SO cord, making them suitable for the intense demands of welding. However, welding cords are not typically oil-resistant or as flexible as an SO cord, making the SO cord more versatile for general power applications.

It’s important to assess the specific requirements of your application when choosing between different types of cords. Consider factors such as the environment, exposure to oils or chemicals, flexibility needs, and the level of resistance required. By understanding the unique features and applications of each cord, you can make an informed decision and select the most suitable option for your needs.

Now that we have compared the SO cord with other types of electrical cords, let’s move on to discussing some safety considerations when working with SO cords.

Safety Considerations with SO Cord

While an SO cord is designed to be durable and safe, it is important to follow proper safety guidelines when working with electrical cords to prevent accidents and ensure user safety. Here are some key safety considerations to keep in mind when using an SO cord:

- Inspect the Cord: Before each use, inspect the cord for any signs of damage, such as cuts, cracks, or exposed wires. If you find any damage, do not use the cord and replace it immediately. Regular inspections help identify potential hazards and prevent accidents.

- Proper Storage: When not in use, store the SO cord in a safe and dry location away from heat sources, sharp objects, and chemicals. Avoid tightly coiling the cord, as this can cause stress and potential damage to the internal components.

- Avoid Overloading: Ensure that the electrical load does not exceed the amperage capacity of the SO cord. Overloading can cause overheating, leading to potential fire hazards. Refer to the manufacturer’s specifications to determine the maximum load the cord can safely handle.

- Unplug Correctly: When disconnecting the cord, always grasp the plug firmly and pull it straight out of the outlet. Do not yank or pull on the cord itself, as this can damage the cord or the outlet. Proper unplugging reduces the risk of damaging the cord and minimizes the possibility of electrical shocks.

- Avoid Wet Conditions: Although an SO cord is water-resistant, it is still important to avoid using it in wet conditions or when your hands are wet. Moisture can increase the risk of electrical shock. If you need to use the cord outdoors, ensure that it is protected from rain or other sources of water.

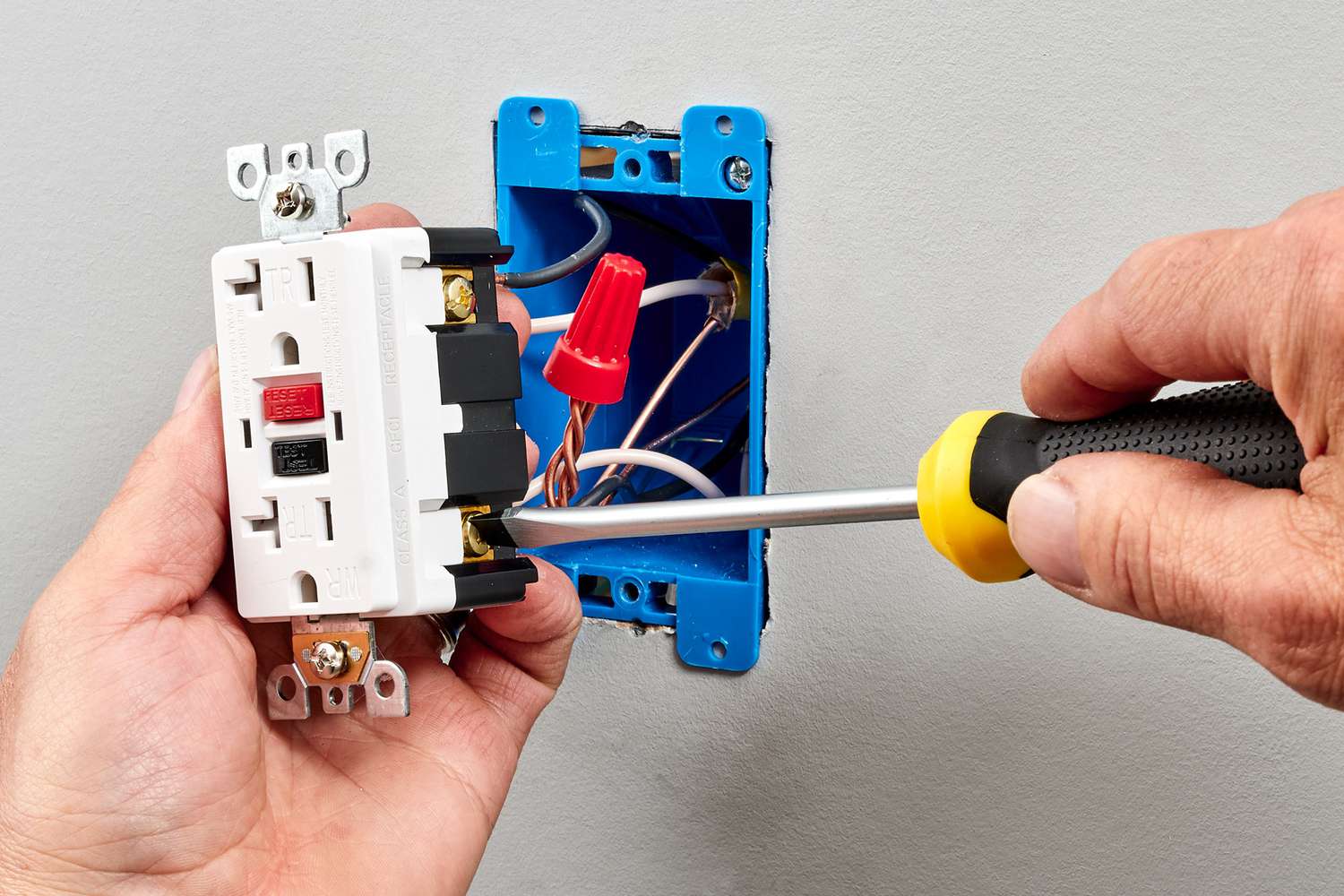

- Use GFCI Outlets: When using an SO cord in areas where water is present, it is crucial to plug it into a Ground Fault Circuit Interrupter (GFCI) outlet. GFCI outlets are designed to detect electrical imbalances caused by ground faults and quickly cut off the power, minimizing the risk of electrical shocks.

- Follow Proper Extension Cord Usage: If you need to extend the length of the SO cord using an extension cord, ensure that the extension cord is of the appropriate length, gauge, and rating for the intended load. Using improper extension cords can lead to overheating and electrical hazards.

By following these safety considerations, you can ensure the safe and proper use of an SO cord. Prioritizing safety not only protects you and those around you but also extends the lifespan of the cord, ensuring its reliability for future use.

Now that we have discussed safety considerations, let’s move on to understanding how to choose the right SO cord for your specific needs.

How to Choose the Right SO Cord

Choosing the right SO cord for your specific needs requires consideration of various factors. Here are some important factors to keep in mind when selecting an SO cord:

- Application and Environment: Determine the specific application and environment where the SO cord will be used. Consider factors such as whether it will be used indoors or outdoors, exposed to oils or chemicals, or subjected to extreme temperatures. This will help determine the level of oil resistance, water resistance, and temperature resistance required.

- Length: Measure the distance between the power source and the equipment to be powered. Choose an SO cord that is long enough to reach the desired location while avoiding excessive cord length, which can increase the risk of tangling or voltage drop.

- Amperage Capacity: Consider the electrical load requirements of the equipment to be powered. Select an SO cord with an amperage rating that exceeds the load requirements to ensure safe and reliable power delivery. Refer to the manufacturer’s specifications for the amperage capacity of the SO cords you are considering.

- Gauge: The gauge of an SO cord determines its current-carrying capacity. Thicker gauges have a higher current capacity. Consider the power requirements of your equipment and select an appropriate gauge size to ensure adequate power supply. Larger appliances and heavy-duty equipment may require a thicker-gauged cord.

- Certifications and Standards: Look for SO cords that are certified and meet industry standards for safety and performance. Check for labels or markings on the cord indicating compliance with relevant specifications such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association).

- Manufacturer Reputation: Choose reputable brands or manufacturers known for producing high-quality power cords. Research customer reviews, ratings, and recommendations to ensure you are purchasing a reliable and durable SO cord.

- Budget: Consider your budget when selecting an SO cord. While it’s important to prioritize quality and safety, there are options available at different price points. Evaluate your needs and preferences to find a balance between cost and quality.

By considering these factors, you can make an informed decision and choose the right SO cord that meets your specific requirements. If you are unsure about which cord to select, consult with a knowledgeable professional or seek guidance from the manufacturer or supplier.

Now that we have discussed choosing the right SO cord, let’s wrap up our article.

Conclusion

SO cords, or Service-Entrance, Oil Resistant cords, are a remarkable and versatile solution for powering electrical equipment in demanding environments. Designed with durability, flexibility, and resistance in mind, these cords offer several benefits that make them an excellent choice for a wide range of applications.

Whether you’re working on a construction site, in an industrial setting, or in your own workshop, an SO cord provides a reliable and safe power supply. Its construction, including durable insulation and an oil-resistant jacket, ensures longevity and performance even in harsh conditions.

From their resistance to oil, water, chemicals, and abrasion to their ability to handle high electrical loads, SO cords offer a unique set of features that set them apart from other types of electrical cords. Their flexibility and excellent temperature resistance further contribute to their versatility.

When using an SO cord, it is crucial to prioritize safety. Regularly inspect the cord for damage, store it properly, avoid overloading, and follow proper unplugging procedures. Adhering to safety guidelines ensures a safe working environment and extends the lifespan of the cord.

When choosing an SO cord, consider factors such as the application, environment, length, amperage capacity, gauge, certifications, and budget. Evaluating these factors will help you select an SO cord that meets your specific needs, ensuring optimal performance and safety.

With their durability, versatility, and reliability, SO cords have become an indispensable tool in various industries, construction sites, workshops, and outdoor settings. By understanding their purpose, construction, features, common uses, benefits, safety considerations, and how to choose the right one, you can make informed decisions and harness the power of these exceptional electrical cords.

So, next time you require a power cord that can withstand challenging conditions, look no further than an SO cord. Its ability to deliver reliable power while enduring harsh environments makes it an indispensable companion for all your electrical power needs.

Frequently Asked Questions about What Does SO Stand For Electrical Cord

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does SO Stand For Electrical Cord”