Articles

What Kind Of Electrical Cord For Fuel Pump?

Modified: January 6, 2024

Looking for information on the type of electrical cord needed for a fuel pump? Check out our articles for guidance and tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to operating a fuel pump, using the right electrical cord is crucial for ensuring efficient and safe performance. An electrical cord acts as the lifeline of a fuel pump, providing a reliable power source and connecting it to the electrical grid. However, selecting the wrong type of electrical cord or using one that does not meet the necessary requirements can lead to complications, such as decreased efficiency, potential hazards, and even equipment damage.

In this article, we will delve into the importance of using the right electrical cord for a fuel pump and discuss the various factors to consider when making your selection. We will also explore the gauge and length requirements for an electrical cord, different types of cords available, common mistakes to avoid, and proper installation and maintenance practices.

By the end of this article, you will have a comprehensive understanding of how to choose the appropriate electrical cord for your fuel pump, ensuring optimal performance and safety.

Key Takeaways:

- Selecting the right electrical cord for your fuel pump is crucial for safety, efficiency, and compliance. Consider power requirements, environmental conditions, and proper installation to ensure optimal performance and longevity.

- Avoid common mistakes such as choosing the wrong gauge, neglecting environmental conditions, or using extension cords as permanent solutions. Proper installation and regular maintenance are essential for safe and efficient fuel pump operation.

Importance of using the right electrical cord for a fuel pump

Using the right electrical cord for your fuel pump is of utmost importance to ensure smooth and efficient operation. Here are several reasons why selecting the correct cord is crucial:

1. Safety: Safety should always be a top priority when working with fuel pumps. Using an electrical cord that is not rated for the specific power requirements of the fuel pump can lead to overheating, electrical shorts, or even fires. By using the appropriate cord, you can minimize the risk of accidents and protect both yourself and your equipment.

2. Efficiency: Choosing the right electrical cord ensures that your fuel pump receives the proper power supply. Inadequate power or voltage drop due to an improper cord can result in decreased pump performance and reduced fuel flow. This can cause inefficiency and potentially lead to pump failure, disrupting operations and causing unnecessary downtime.

3. Durability: Fuel pumps are often exposed to harsh environments, including extreme temperatures, moisture, and chemicals. Using a cord specifically designed for fuel pump applications helps ensure the longevity and durability of the cord. Specialized cords are often constructed with materials that are resistant to oil, gasoline, and other harsh substances commonly found in fuel pump environments.

4. Compliance with regulations: Many industries, such as automotive, transportation, and agriculture, have specific regulations and safety standards regarding electrical equipment. Using the correct cord that meets these standards ensures compliance and helps avoid potential penalties or legal issues.

5. Compatibility: Different fuel pumps may have varying power requirements, such as voltage and amperage ratings. Selecting a cord that matches the specific power needs of your fuel pump guarantees compatibility and prevents damage to the pump or other electrical components.

Overall, using the right electrical cord for your fuel pump is essential for maintaining safety, efficiency, durability, compliance, and compatibility. Taking the time to select the appropriate cord will result in a well-functioning fuel pump system that meets your needs and operates effectively for years to come.

Factors to consider when choosing an electrical cord for a fuel pump

Choosing the right electrical cord for your fuel pump involves considering several important factors. By evaluating these factors, you can ensure that you select a cord that meets the specific needs of your fuel pump system. Here are the key factors to consider:

- Power requirements: The first and most crucial factor to consider is the power requirements of your fuel pump. Determine the voltage and amperage ratings specified by the manufacturer. Ensure that the electrical cord you choose can handle the required power without causing voltage drop or overheating.

- Gauge: The gauge of an electrical cord refers to the thickness of its conductors. A lower gauge number indicates a thicker wire, which can handle higher current loads. When selecting a cord, consider the length of the cord and the power requirements of your pump. A longer cord or a pump with higher power demands may require a lower gauge (thicker) cord to prevent voltage drop and ensure efficient power transmission.

- Length: The length of the cord plays a role in determining voltage drop. Longer cords have higher electrical resistance, which can result in a voltage drop, especially if the cord is undersized for the intended load. Measure the distance between your fuel pump and the power source to determine the appropriate cord length required.

- Environmental conditions: Consider the environmental conditions in which your fuel pump operates. If the pump is exposed to extreme temperatures, moisture, or chemicals, choose a cord that is designed to withstand these conditions. Look for cords with durable insulation and resistance to oil, gasoline, and other chemicals commonly found in fuel pump environments.

- Flexibility and durability: Depending on the layout and installation of your fuel pump system, you may require a cord that is flexible enough to navigate around obstacles or fit into tight spaces. Additionally, choose a cord that is built to last and can withstand frequent movement and bending without degradation.

- Compliance and certifications: Ensure that the electrical cord you choose complies with relevant safety standards and regulations. Look for cords that are UL-listed or meet other industry-specific certifications to ensure their safety and reliability.

By carefully considering these factors, you can choose an electrical cord that is appropriate for your fuel pump system. Taking the time to evaluate these factors will help ensure optimal performance, safety, and longevity of your fuel pump and electrical equipment.

Gauge and length requirements for an electrical cord

The gauge and length of an electrical cord are two vital factors to consider when selecting a cord for your fuel pump. These factors determine the cord’s ability to handle the required power and prevent voltage drop. Let’s explore the gauge and length requirements in more detail:

Gauge:

The gauge of an electrical cord refers to the thickness of its conductive wires. It is represented by a numerical value, where a smaller number indicates a thicker wire. The gauge plays a crucial role in determining the cord’s ability to handle the current load without voltage drop or overheating.

For fuel pump applications, it is essential to select a cord with an appropriate gauge to match the power requirements of the pump. A lower gauge (thicker) cord is capable of carrying higher current loads and is less prone to voltage drop. On the other hand, a higher gauge (thinner) cord may result in inefficient power transmission and increased resistance along the cord.

The specific gauge required for your fuel pump depends on several factors, including the power rating and the distance between the pump and the power source. As a general rule, larger fuel pumps with higher power requirements will necessitate a lower gauge (thicker) cord to minimize voltage drop. Consult the manufacturer’s specifications to determine the recommended gauge for your fuel pump.

Length:

The length of the electrical cord is another crucial consideration when choosing a cord for your fuel pump. Longer cords result in higher electrical resistance, which can lead to voltage drop and decreased power output. It is important to select an appropriate cord length to ensure efficient and reliable power transmission.

When measuring the cord length, consider the distance between the fuel pump and the power source. Avoid using excessively long cords, as they can increase the chances of voltage drop and potential power issues. If a longer cord is necessary, choose a lower gauge (thicker) cord to compensate for the increased resistance.

Remember that it is always better to choose a shorter cord that matches the intended distance rather than relying on extension cords. Using extension cords can further contribute to voltage drop and potential hazards. Whenever possible, position the fuel pump within a reasonable distance from the power source to minimize cord length.

By considering the appropriate gauge and length for your electrical cord, you can ensure effective power transmission and prevent voltage drop, ultimately maximizing the performance and reliability of your fuel pump system.

When selecting an electrical cord for a fuel pump, be sure to choose a cord that is rated for the appropriate voltage and current for the pump. It’s important to use a cord that is designed for outdoor or wet conditions to ensure safety and reliability.

Understanding different types of electrical cords for fuel pumps

When choosing an electrical cord for your fuel pump, it is important to understand the different types available. Each type has its own characteristics and features that make it suitable for specific applications. Here is an overview of the common types of electrical cords for fuel pumps:

1. Heavy-duty cords: Heavy-duty cords are designed to handle high power loads and are constructed with durable materials that can withstand harsh environments. These cords often have a lower gauge (thicker wires) to minimize voltage drop and ensure efficient power transmission. Heavy-duty cords are ideal for commercial and industrial fuel pump setups that require reliable, long-lasting performance.

2. Oil-resistant cords: Fuel pumps are often exposed to oil, gasoline, and other chemicals. Using an oil-resistant cord can prevent the degradation of the cord due to prolonged exposure to these substances. Oil-resistant cords are usually constructed with specialized materials that are more resistant to chemical corrosion, ensuring the longevity of the cord in fuel pump environments.

3. Portable cords: Portable cords are designed for ease of use and flexibility. They are typically lightweight and more pliable, making them ideal for temporary or mobile fuel pump setups. Portable cords often have a higher gauge (thinner wires) to maintain flexibility while still providing sufficient power transmission.

4. Water-resistant cords: If your fuel pump is located in an area prone to moisture or damp conditions, it is essential to choose a water-resistant cord. These cords are designed to withstand exposure to water and moisture, reducing the risk of electrical short circuits and ensuring safe operation. Water-resistant cords may have additional protective features such as specialized insulation or sealing to prevent water ingress.

5. Twist-lock cords: Twist-lock cords have connectors that require a twisting motion to securely attach and detach them from the power source. These cords provide a more reliable and secure connection compared to standard plug-in cords. Twist-lock cords are commonly used in industrial or commercial settings where a strong and stable connection is necessary for uninterrupted power supply.

When selecting an electrical cord for your fuel pump, consider the specific needs of your setup, such as power requirements, environmental conditions, and flexibility. Choose a cord that is suitable for the intended application to ensure optimal performance, safety, and durability of your fuel pump system.

Read more: What Is An Electrical Cord?

Common mistakes to avoid when selecting an electrical cord for a fuel pump

Choosing the right electrical cord for your fuel pump is essential for safety, efficiency, and optimal performance. However, there are several common mistakes that people often make when selecting an electrical cord. Here are some mistakes to avoid:

1. Choosing the wrong gauge: One of the most common mistakes is selecting an electrical cord with the wrong gauge. Using an undersized cord with a higher gauge than necessary can result in voltage drop, decreased power output, and potential equipment damage. Conversely, using an oversized cord with a lower gauge than required can be unnecessary and more expensive.

2. Ignoring environmental conditions: It is crucial to consider the environmental conditions in which your fuel pump operates. If the pump is exposed to extreme temperatures, moisture, or chemicals, choosing an electrical cord without proper insulation or resistance to these elements can lead to cord deterioration, electrical shorts, or even fire hazards. Ensure the cord you choose is suitable for the specific environmental conditions.

3. Neglecting certification and compliance: Failing to choose an electrical cord that meets relevant safety standards and certifications can lead to potential hazards and legal issues. Look for cords that are UL-listed or have other industry-specific certifications to ensure their safety and compliance with regulations.

4. Using extension cords as a permanent solution: While extension cords may seem like a convenient solution for extending the reach of your electrical cord, they should not be used as a permanent fix. Extension cords are often not designed to handle high power loads or prolonged use. They can cause voltage drop, overheating, and unsafe electrical connections. Instead, choose a cord of an appropriate length for your fuel pump installation.

5. Not considering future needs: It is important to anticipate any potential changes or expansions in your fuel pump system. While your current fuel pump may have specific power requirements, future upgrades or additions may require a higher power capacity. Selecting an electrical cord that can accommodate potential future needs can save you time and money in the long run.

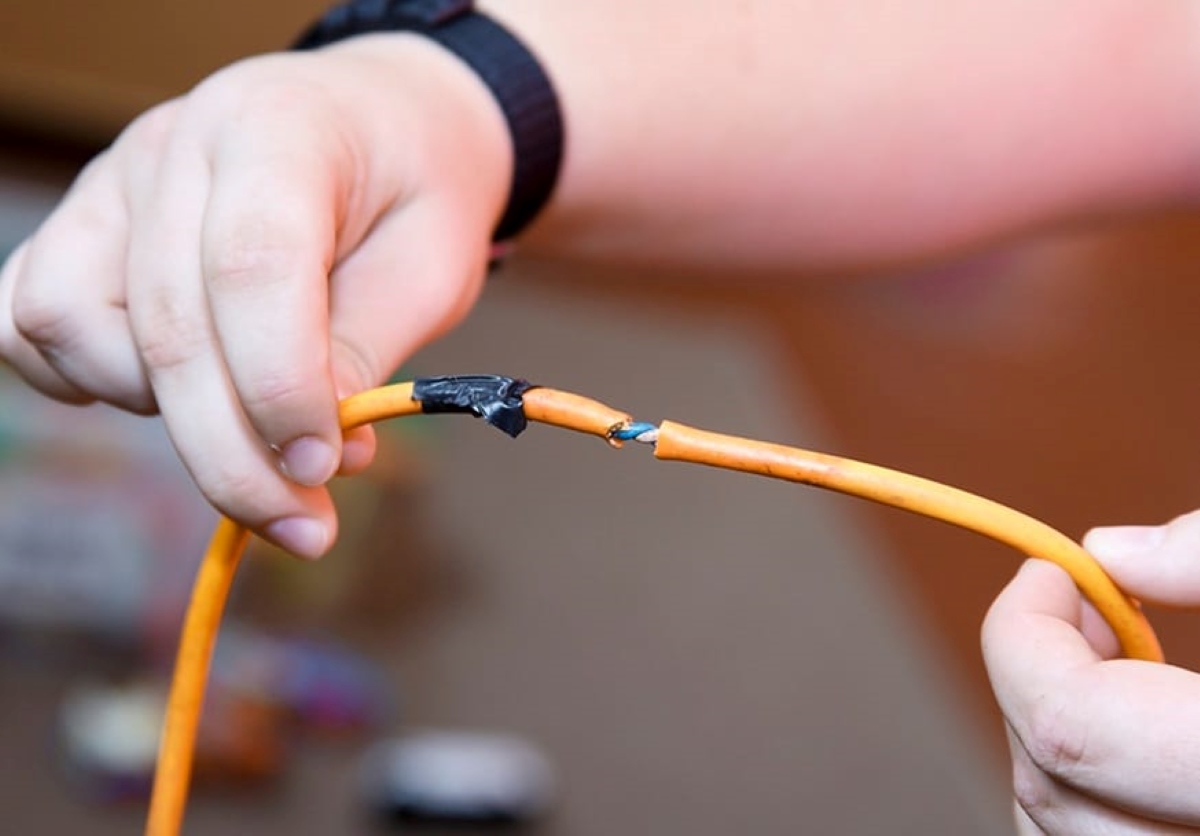

6. Overlooking cord maintenance and inspections: Once you have selected the appropriate electrical cord, it is essential to regularly inspect and maintain it. Over time, cords can become damaged or worn, compromising their safety and performance. Regularly check for any signs of wear, fraying, or damage and replace the cord if necessary.

By avoiding these common mistakes, you can ensure that you choose the right electrical cord for your fuel pump system. Taking the time to consider the necessary factors and making informed decisions will result in a safe and efficient fuel pump setup that meets your requirements.

Proper installation and maintenance of an electrical cord for a fuel pump

Installing and maintaining an electrical cord for your fuel pump correctly is crucial for optimal performance, safety, and longevity. Follow these guidelines to ensure a proper installation and effective maintenance routine:

1. Proper installation:

- Ensure that the power source is turned off before starting the installation process.

- Select the appropriate gauge and length of the electrical cord based on the power requirements and distance between the fuel pump and the power source.

- Inspect the cord for any signs of damage or wear before installation. If any issues are found, replace the cord to avoid potential hazards.

- Route the cord away from any sharp edges, heat sources, or moving parts to prevent damage or wear over time. Secure the cord in place using appropriate cable management tools such as cable ties or clamps.

- If necessary, use conduit or suitable protective covers to shield the cord from exposure to moisture, chemicals, or extreme temperatures.

- Make sure the cord connectors are securely attached to the fuel pump and the power source. If using twist-lock connectors, ensure they are properly twisted and locked into place.

- Double-check all connections and confirm that there are no loose or exposed wires.

- Once the installation is complete, carefully test the fuel pump to ensure proper operation and monitor for any abnormal behavior.

2. Regular maintenance:

- Regularly inspect the electrical cord for any signs of wear, fraying, or damage. If any issues are identified during inspections, replace the cord immediately to prevent potential hazards.

- Keep the cord clean and free from debris or contaminants that could compromise the integrity of the insulation. Wipe down the cord using a clean, dry cloth as needed.

- Avoid overloading the cord with excessive power demands. Ensure that the electrical cord is rated to handle the specific power requirements of the fuel pump.

- Periodically check the cord connections to ensure they are secure and free from corrosion or loose contacts. Tighten or clean the connectors if necessary.

- If the fuel pump or cord is exposed to extreme weather conditions, inspect them more frequently and consider using weatherproofing solutions or covers to protect them.

- Train personnel on proper handling and care of the electrical cord to minimize the risk of accidental damage.

- Consider implementing a maintenance schedule that includes regular inspections, cleaning, and replacement intervals based on the manufacturer’s recommendations and industry best practices.

By following these installation and maintenance practices, you can ensure that your fuel pump’s electrical cord operates reliably, minimizes the risk of accidents, and prolongs the overall lifespan of the equipment.

Conclusion

Choosing the right electrical cord for your fuel pump is a critical decision that directly impacts the safety, efficiency, and overall performance of your pump system. By considering factors such as power requirements, gauge, length, and environmental conditions, you can ensure that you select the most suitable cord for your specific needs.

Using the wrong electrical cord can lead to voltage drop, overheating, decreased pump performance, and potential hazards. By avoiding common mistakes such as choosing the wrong gauge, neglecting environmental conditions, or using extension cords as a permanent solution, you can prevent these issues and maintain a safe and efficient fuel pump operation.

Proper installation of the electrical cord is equally important. Ensure that the cord is properly routed, secured, and insulated to protect it from damage and exposure to harsh elements. Regular maintenance, including inspections for wear or damage, cleaning, and ensuring secure connections, is essential for the long-term reliability and safety of the cord and the fuel pump system as a whole.

Remember to consult the manufacturer’s specifications and industry guidelines when selecting and installing the electrical cord. Always prioritize safety and compliance with regulations to avoid potential legal issues and ensure the smooth operation of your fuel pump.

By taking the time to understand the importance of using the right electrical cord, considering the necessary factors, and following proper installation and maintenance practices, you can optimize the performance, extend the lifespan, and safeguard the reliability of your fuel pump system.

Investing in the proper electrical cord is an investment in the long-term success of your fuel pump, providing you with a reliable and efficient fueling solution for your needs.

Frequently Asked Questions about What Kind Of Electrical Cord For Fuel Pump?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Electrical Cord For Fuel Pump?”