Articles

What Happens When A Kegerator Freezes Up

Modified: August 27, 2024

Discover what happens when a kegerator freezes up in this informative article. Learn how to prevent and fix the issue to keep your beverages flowing smoothly.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of kegerators! If you’re a beer enthusiast or someone who loves hosting parties, then you’ve probably heard of this amazing appliance. A kegerator is essentially a refrigerator that has been specially designed to store and dispense kegs of beer. It brings the joy of having your favorite brew on tap, right in the comfort of your own home.

However, like any appliance, kegerators can sometimes encounter issues. One of the most common problems that kegerator owners face is when the kegerator freezes up. This can be a frustrating and unexpected situation, but fear not! In this article, we will explore what happens when a kegerator freezes up, why it occurs, and how to fix and prevent it from happening again.

So, grab a cold one and let’s dive into the world of frozen kegerators!

Key Takeaways:

- Understanding the causes and signs of a frozen kegerator, as well as the potential damages it can cause, is crucial for prompt and effective troubleshooting to maintain the functionality and quality of your kegerator.

- Implementing preventive measures, such as proper temperature settings, regular maintenance, and insulation, can significantly reduce the risk of a kegerator freeze-up, ensuring a continuous supply of perfectly chilled draft beer.

Read more: What Happens If A Hot Tub Freezes

What is a Kegerator?

A kegerator is a versatile and convenient appliance that allows you to have draft beer at home. It is essentially a refrigerator or a freezer that has been specially modified to store and dispense kegs of beer. With a kegerator, you can say goodbye to the hassle of buying cans or bottles of beer and enjoy the experience of pouring a perfectly chilled pint right from the tap.

Typically, a kegerator consists of a refrigeration unit, a tap tower, a CO2 tank, and a keg coupler. The refrigeration unit is designed to keep the beer at the optimal temperature, usually between 36-38 degrees Fahrenheit (2-3 degrees Celsius) for most beers. The tap tower is where the faucets are mounted, allowing for easy pouring. The CO2 tank is responsible for carbonating the beer and providing the necessary pressure to push it out of the keg. Finally, the keg coupler is the device that connects the keg to the rest of the kegerator system.

Kegerators come in various sizes, from countertop models that can hold a single keg, to larger freestanding units that can accommodate multiple kegs. Some kegerators even have additional features like temperature control, digital displays, and built-in drip trays for easy cleanup.

Having a kegerator in your home brings several advantages. Not only does it save you money in the long run by eliminating the need to purchase individual bottles or cans, but it also allows you to enjoy beer that is fresher and carbonated to your liking. Plus, it adds a touch of sophistication and convenience to your home bar or entertainment area, making it the perfect centerpiece for parties and gatherings.

Now that you have a better understanding of what a kegerator is, let’s delve into how it works and the potential issues that can arise.

How does a Kegerator work?

Understanding how a kegerator works is essential to troubleshooting and preventing issues such as freezing. Let’s take a closer look at the key components and the process of dispensing beer from a kegerator.

1. Refrigeration System: The refrigeration system is responsible for maintaining the kegerator’s temperature at the desired level. It cools the beer to a crisp, refreshing temperature, usually around 36-38 degrees Fahrenheit (2-3 degrees Celsius). This temperature range ensures that the beer stays cold without freezing.

2. CO2 System: The CO2 system provides the carbonation and pressure required to dispense the beer. The CO2 tank is connected to a regulator that controls the flow of gas into the keg. The pressure from the CO2 pushes the beer out of the keg and through the beer lines towards the tap.

3. Keg Coupler: The keg coupler is the device that connects the keg to the kegerator system. It acts as a valve, allowing the flow of beer from the keg to the faucet. Different types of kegs require specific keg couplers, so it’s important to ensure compatibility between the keg and the coupler.

4. Faucet and Tap System: The faucet and tap system are where the magic happens. When the tap handle is opened, the pressurized beer in the keg is released and flows through the beer lines into the faucet. From there, beer is poured into glasses, providing a smooth and refreshing drinking experience.

The key to the proper functioning of a kegerator lies in maintaining a balance between the temperature and the pressure. The refrigeration system keeps the beer at the ideal temperature, while the CO2 system ensures optimal carbonation and pressure for dispensing the beer. When these two factors are in harmony, you can enjoy a perfect draft beer every time.

However, in some cases, the temperature can drop too low, causing the kegerator to freeze up. We will explore the reasons behind this issue in the next section.

Why does a Kegerator freeze up?

A kegerator freeze-up occurs when the temperature inside the unit drops below the desired range, causing the beer and other components to freeze. There are several factors that can contribute to this issue:

1. Temperature Settings: Improper temperature settings are the most common cause of a kegerator freeze-up. If the temperature control is set too low or the thermostat is malfunctioning, the refrigeration system may run excessively, leading to freezing of the beer and other components.

2. Ambient Temperature: The surrounding environment can also impact the temperature inside the kegerator. If the room temperature is too cold or fluctuates significantly, it can affect the performance of the refrigeration system and result in freezing.

3. Incorrect Placement of Components: Placing the CO2 tank or other components in the wrong position within the kegerator can disrupt the airflow and cause temperature irregularities. This can contribute to freezing in certain areas of the kegerator.

4. Insufficient Air Circulation: Proper air circulation is essential for maintaining a consistent temperature. If the vents or fans inside the kegerator are obstructed or malfunctioning, it can lead to temperature imbalances and freezing in certain areas.

5. Poor Insulation: Inadequate insulation in the kegerator can allow heat transfer from the surrounding environment, causing temperature fluctuations. This can lead to freezing if the insulation cannot keep up with the cooling demands.

6. Overcarbonation: Excessive carbonation in the keg can cause the beer to freeze. When the pressure is too high, it lowers the temperature at which the beer freezes, leading to ice formation inside the kegerator.

Understanding the reasons behind a kegerator freeze-up is crucial for troubleshooting and taking preventive measures. In the next section, we will explore the signs that indicate your kegerator is frozen and the potential damages it can cause.

Signs that your Kegerator is Frozen

Dealing with a frozen kegerator can be frustrating, but fortunately, there are several warning signs that can indicate this issue. By recognizing these signs, you can take prompt action to address the problem. Here are some common signs that your kegerator is frozen:

1. Beer not Dispensing: One of the most obvious signs of a frozen kegerator is the inability to dispense beer. When the beer lines or faucets freeze, the flow of beer is obstructed, preventing you from pouring a refreshing pint.

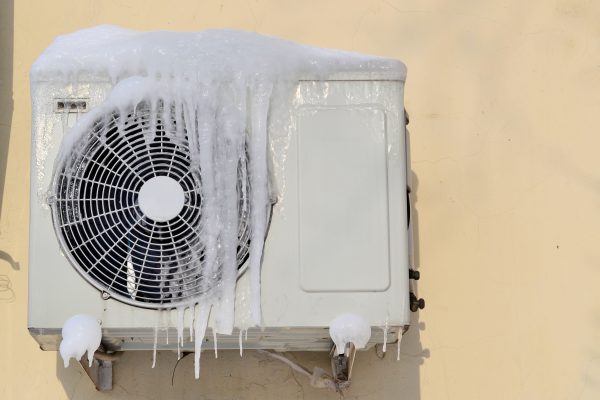

2. Frost Build-up: If you notice frost or ice forming inside the kegerator, particularly on the walls, beer lines, or coupler, it’s a clear indication that freezing has occurred. Frost build-up can impede the proper functioning of the kegerator components.

3. Temperature Fluctuations: Keep an eye on the temperature display or thermometer inside the kegerator. If you notice sudden fluctuations or a steady decrease in temperature, it may be a sign of freezing.

4. Strange Noises: Frozen components can lead to unusual noises coming from the kegerator. You may hear clicking sounds, hissing noises, or the compressor running continuously as it struggles to maintain the desired temperature.

5. Sluggish CO2 Flow: When the kegerator freezes, the CO2 gas can also be affected. If you notice a decrease in the flow of CO2 or issues with carbonation levels, it could be an indication of freezing in the system.

Remember, these signs may vary depending on the severity of the freeze-up and the specific components affected. If you observe any of these signs, it’s important to take immediate action to thaw and fix the frozen kegerator to prevent further damage.

In the next section, we will explore the potential damages caused by a frozen kegerator and how to fix the issue.

To prevent your kegerator from freezing up, regularly check and clean the condenser coils, ensure proper air circulation around the unit, and maintain the temperature at the recommended level for serving beer (usually between 36-40°F).

Read more: What Happens If Grass Seed Freezes

Potential Damages Caused by a Frozen Kegerator

A frozen kegerator can lead to various damages, both to the appliance itself and the quality of the beer. Understanding these potential damages is crucial for taking the necessary steps to resolve the issue. Here are some of the damages that can occur due to a frozen kegerator:

1. Beer Contamination: When the beer lines or components freeze, it can result in blockages or ice crystals forming within the system. This can contaminate the beer, affecting its taste and quality. It may also lead to inconsistent carbonation levels or off-flavors in the poured beer.

2. Damage to Components: The freezing and expansion of moisture inside the kegerator can damage various components such as the beer lines, faucets, coupler, and even the refrigeration system. Cracked or burst lines, damaged seals, and malfunctioning parts may occur, requiring costly repairs or replacements.

3. Reduced Efficiency: A frozen kegerator has to work harder to maintain the desired temperature. This increased strain on the system can lead to decreased energy efficiency and higher electricity consumption. In the long run, it can impact the overall performance and lifespan of the kegerator.

4. Long Thawing Time: Thawing a frozen kegerator can be a time-consuming process. Not only does it delay your ability to enjoy a cold beer on tap, but it also extends the downtime of the kegerator, impacting its functionality and convenience.

It’s important to address a frozen kegerator as soon as possible to minimize these damages. In the next section, we will discuss how to fix a frozen kegerator and get it back to optimal working condition.

How to Fix a Frozen Kegerator

Dealing with a frozen kegerator can be frustrating, but there are steps you can take to fix the issue and get your kegerator back up and running. Here are some effective methods to thaw a frozen kegerator:

1. Turn off the Kegerator: Start by unplugging the kegerator and turning off the power. This will help prevent further freezing and allow the unit to thaw naturally.

2. Open the Doors: Open the doors of the kegerator to help facilitate the thawing process. Allow warm air from the room to circulate inside and gradually raise the temperature within the unit.

3. Remove Ice Build-up: Carefully remove any visible ice build-up from the walls, beer lines, coupler, and other components of the kegerator. Use a soft cloth or towel to wipe away the ice, being cautious not to damage any parts.

4. Use a Hairdryer: If the ice is stubborn or difficult to remove, you can gently warm the affected areas with a hairdryer set to a low or medium heat setting. Keep the hairdryer at a safe distance to prevent overheating or melting plastic parts.

5. Thaw the CO2 System: If the CO2 tank or regulator is frozen, remove them from the kegerator and thaw them separately. You can place them in a warm water bath or use a hairdryer to gradually thaw the frozen components.

6. Clean and Sanitize: Once the kegerator has thawed, it’s important to clean and sanitize the components that came into contact with the ice. This will help prevent any bacteria or contamination from affecting the beer quality.

7. Restart the Kegerator: After thawing and cleaning, reconnect all the components, including the CO2 tank, regulator, and keg. Power on the kegerator and set it to the desired temperature. Monitor it closely to ensure that it functions properly and maintains a consistent temperature without freezing.

If these steps do not resolve the issue or if you are unsure about performing the repairs yourself, it’s advisable to contact a professional technician or the manufacturer for assistance in fixing the frozen kegerator.

In the next section, we will explore how to prevent your kegerator from freezing up again in the future.

Preventing your Kegerator from Freezing Up Again

Dealing with a frozen kegerator can be a hassle, but there are measures you can take to prevent it from happening again in the future. Here are some tips to keep your kegerator running smoothly and avoid freeze-ups:

1. Set the Correct Temperature: Ensure that your kegerator is set to the appropriate temperature range for storing beer, typically between 36-38 degrees Fahrenheit (2-3 degrees Celsius). Avoid setting the temperature too low, as it increases the risk of freezing.

2. Monitor Room Temperature: Be mindful of the ambient temperature where the kegerator is located. Avoid placing it in extremely cold areas or near sources of heat, such as radiators or direct sunlight. Keep the room temperature relatively stable to prevent temperature fluctuations inside the kegerator.

3. Check Temperature Control and Thermostat: Regularly inspect the temperature control and thermostat of the kegerator to ensure they are functioning properly. If you notice any issues or inconsistencies, consider contacting a professional for repairs or adjustments.

4. Maintain Proper Air Circulation: Ensure that there is adequate air circulation inside the kegerator. Avoid overstocking the unit or blocking the vents to allow for proper airflow. This helps maintain a consistent temperature and reduces the risk of freezing.

5. Insulate the Kegerator: If you live in an area with extreme temperature fluctuations, consider insulating your kegerator. Use insulation tape or foam to seal gaps and minimize heat transfer from the surrounding environment. This helps the kegerator to maintain a more stable temperature and reduces the risk of freezing.

6. Regularly Clean and Inspect: Regularly clean and inspect all components of the kegerator, including the beer lines, coupler, and faucet, to ensure they are free from debris and ice build-up. This helps maintain the proper functioning of the kegerator and reduces the risk of freeze-ups.

7. Store CO2 Tanks Properly: Ensure that the CO2 tank is securely fastened and positioned in an upright position within the kegerator. This allows for better airflow and helps prevent freezing within the CO2 system.

By following these preventive measures, you can minimize the chances of your kegerator freezing up again and ensure a smooth and enjoyable beer-tapping experience.

To conclude, a frozen kegerator can be a temporary setback, but with proper handling and preventative steps, you can avoid this issue and continue to enjoy the convenience of having your favorite beer on tap whenever you desire. Cheers!

Conclusion

Having a kegerator in your home allows you to elevate your beer-drinking experience by providing fresh, draft beer at your fingertips. However, it’s important to be aware of the possibility of a frozen kegerator and how to address and prevent this issue.

In this article, we explored what a kegerator is and how it works, diving into the causes of a kegerator freeze-up. We discussed the signs that indicate your kegerator is frozen, such as the inability to dispense beer, frost build-up, temperature fluctuations, and sluggish CO2 flow.

Furthermore, we highlighted the potential damages that a frozen kegerator can cause, including beer contamination, damage to components, reduced efficiency, and long thawing times. It’s crucial to address these damages promptly to maintain the functionality and longevity of your kegerator.

To fix a frozen kegerator, we provided practical steps to thaw the unit properly, including turning off the kegerator, opening the doors, removing ice build-up, using a hairdryer if necessary, and cleaning and sanitizing the components. Seeking professional help is advisable if needed.

Lastly, we discussed preventive measures to avoid future freeze-ups, such as setting the correct temperature, monitoring room temperature, checking temperature control and thermostat, maintaining proper air circulation, insulation, regular cleaning and inspection, and storing CO2 tanks properly.

By following these preventive guidelines, you can keep your kegerator running smoothly, prevent freeze-ups, and continue enjoying the satisfaction of pouring a perfectly chilled pint of beer from your own tap.

Now that you’re equipped with the knowledge and tools to handle a frozen kegerator, you can confidently troubleshoot and prevent this issue, ensuring that your kegerator delivers crisp, refreshing beer consistently. Cheers to endless pints of good times with a properly functioning kegerator!

Frequently Asked Questions about What Happens When A Kegerator Freezes Up

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Happens When A Kegerator Freezes Up”