Home> How To Kegerator

How To Kegerator: Ultimate Guide for the Best Home Brewing Experience

Uncover the secrets of How To Kegerator in our comprehensive guide. Boost your home brewing skills to a new level – fix, maintain, and enjoy!

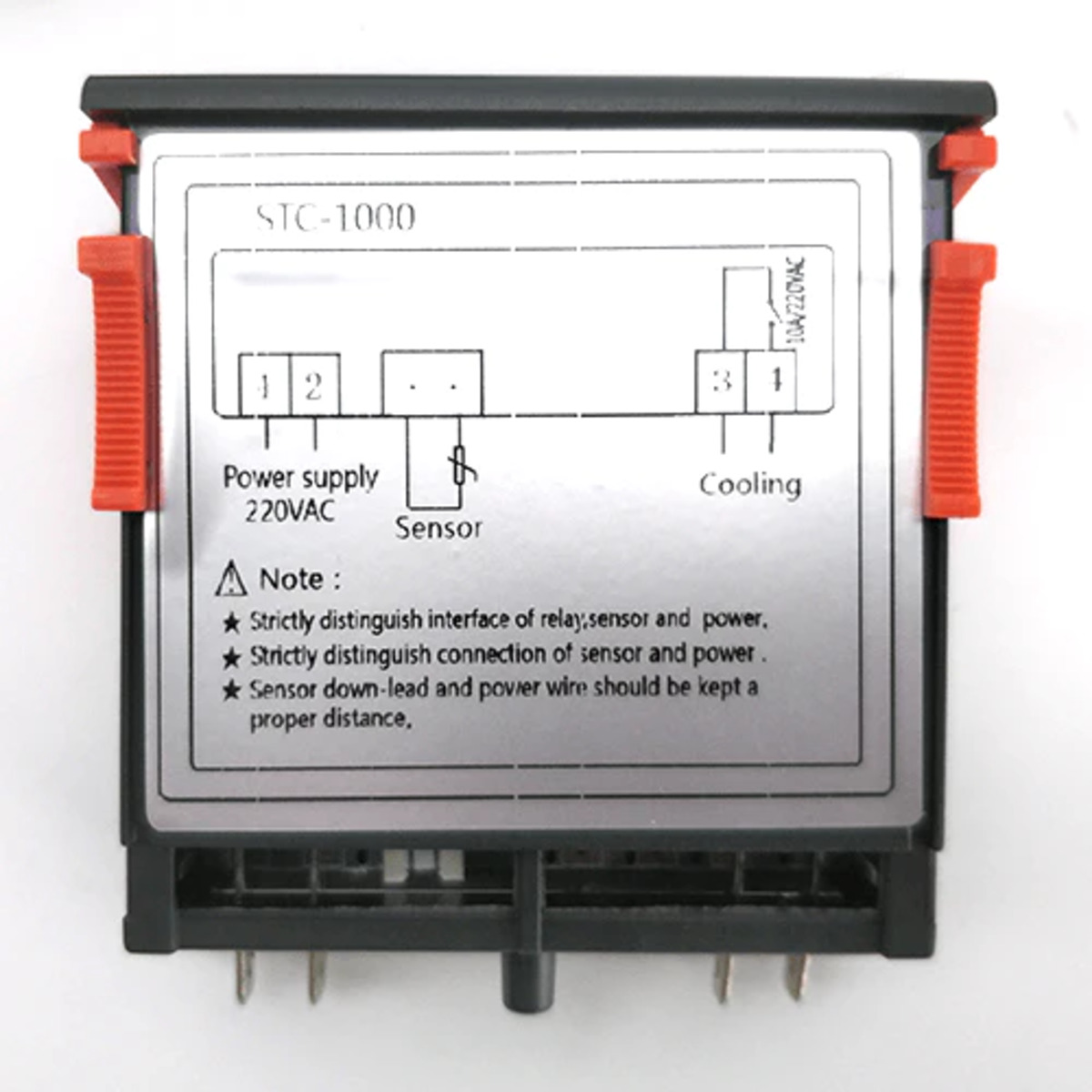

What Is The Best Sensor Placement For A STC 1000 Kegerator

By: Henry Campbell • 100 Best Kitchen Furniture To Make Your Cooking Hassle-Free

How To Create Your Very Own Guinness Kegerator

By: Daniel Carter • 100 Best Kitchen Furniture To Make Your Cooking Hassle-Free

How To Install A Mercury Thermostat In A Kegerator

By: William Harrison • 100 Best Kitchen Furniture To Make Your Cooking Hassle-Free

What Size Co2 Tank For A Kegerator Nostalgia

By: James Anderson • 100 Best Kitchen Furniture To Make Your Cooking Hassle-Free

How To Install A Fan Inside A Kegerator

By: William Harrison • 100 Best Kitchen Furniture To Make Your Cooking Hassle-Free

How To Fill A Growler Using Your Kegerator

By: William Harrison • 100 Best Kitchen Furniture To Make Your Cooking Hassle-Free