Articles

What Is Tapered Insulation

Modified: January 19, 2024

Discover the benefits and functionality of tapered insulation with our informative articles. Learn how it improves energy efficiency and reduces heat loss for optimal building performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of tapered insulation! In the realm of construction and building design, tapered insulation plays a crucial role in ensuring the longevity and efficiency of roofing systems. This specialized type of insulation offers a practical solution to address the challenges posed by flat or low-sloped roofs.

Tapered insulation is specifically designed to promote proper drainage on these types of roofs, preventing water pooling and potential damage. By creating a gradual slope, tapered insulation redirects water towards drains, ensuring effective water management and reducing the risk of leaks and structural issues.

In this article, we will dive deeper into the world of tapered insulation, exploring its definition, purpose, benefits, types, installation process, common applications, maintenance, drawbacks, and more. Whether you’re a construction professional, a building owner, or simply curious about the topic, this article will provide you with a comprehensive understanding of tapered insulation and its importance in roofing systems.

So, let’s begin our journey into the fascinating world of tapered insulation!

Key Takeaways:

- Tapered insulation is a specialized solution for flat or low-sloped roofs, offering efficient water management, improved energy efficiency, and extended roof longevity. It is a versatile and customizable option for various construction projects.

- While tapered insulation provides numerous benefits, it requires careful consideration of installation, maintenance, and potential limitations. Working with experienced professionals is crucial for successful integration and long-term performance.

Read more: What Are Tapered Candles

Definition of Tapered Insulation

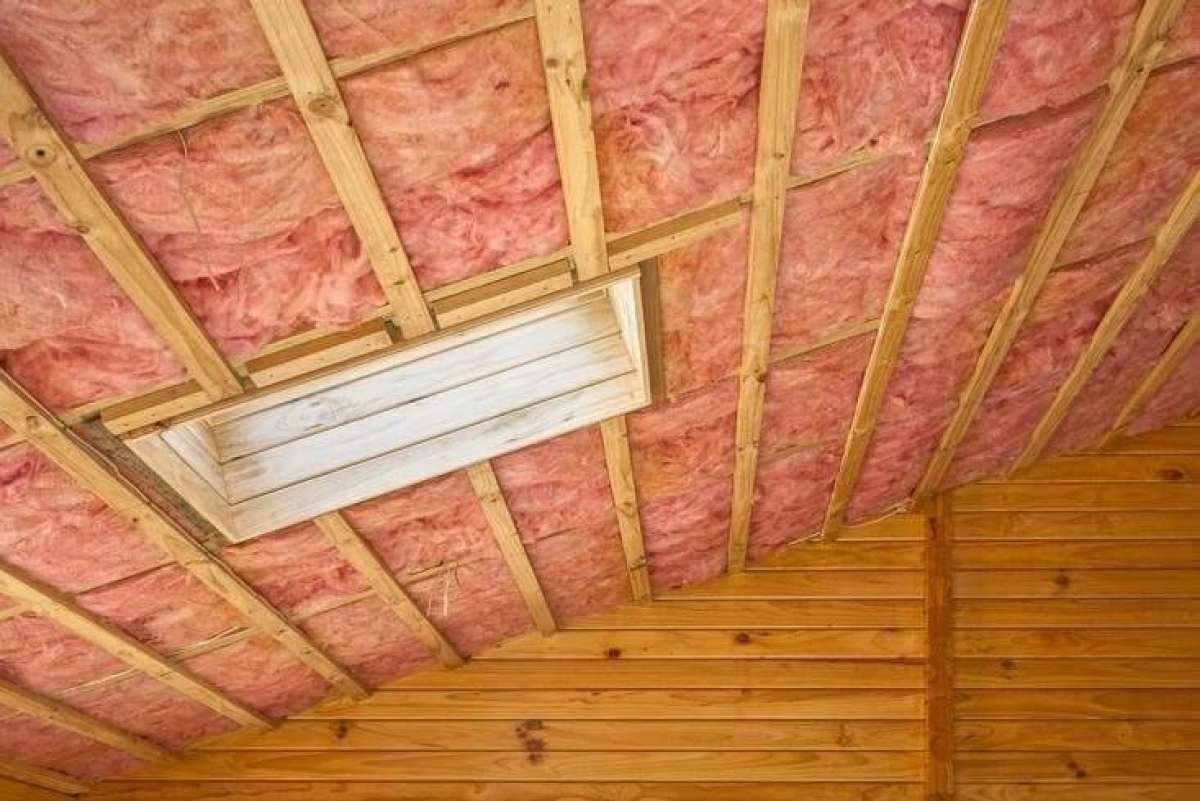

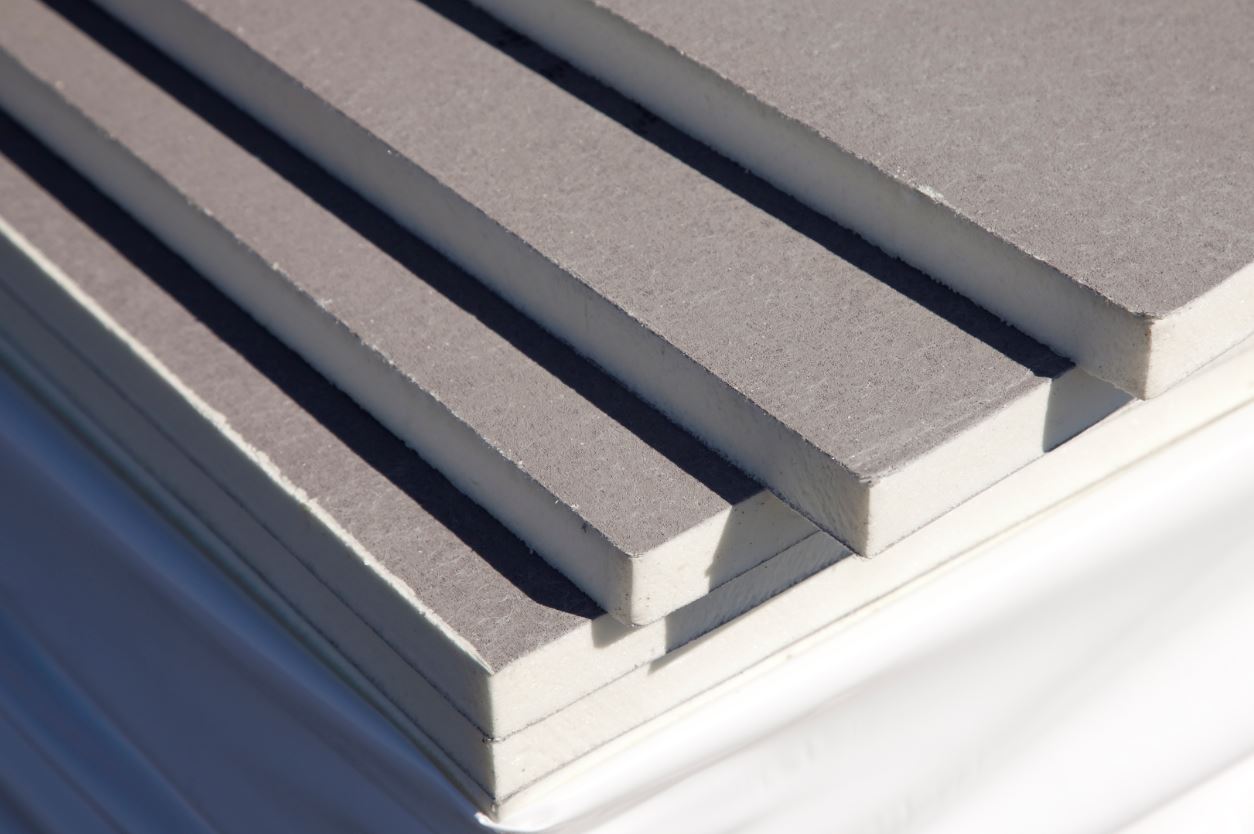

Tapered insulation is a specialized type of insulation that is designed to provide a sloped surface on flat or low-sloped roofs. It is typically made from rigid foam material, such as expanded polystyrene (EPS) or polyisocyanurate (ISO), which is known for its excellent thermal properties and durability.

The primary purpose of tapered insulation is to create a gradual slope on the roof surface, allowing for efficient drainage of rainwater. This slope is engineered to redirect water towards designated drains or scuppers, preventing pooling and ensuring proper water management.

Tapered insulation is different from traditional flat insulation in that it is custom-designed for each specific roof. The thickness of the insulation varies across the roof surface, with a higher thickness at the perimeter or low points, gradually tapering towards the drains. This strategic design ensures that water flows in the desired direction and does not accumulate in areas prone to leakage.

Furthermore, tapered insulation also offers the benefits of conventional insulation, including thermal insulation properties, energy efficiency, and improved indoor comfort. It helps to regulate the temperature inside the building, reducing heat loss or gain through the roof and contributing to energy cost savings.

Overall, tapered insulation serves as a key component in creating a functional, reliable, and efficient roofing system for flat or low-sloped roofs. By addressing the unique challenges posed by these types of roofs, tapered insulation helps to prolong the lifespan of the roof, minimize the risk of leaks, and optimize water drainage.

Purpose and Benefits of Tapered Insulation

The primary purpose of tapered insulation is to address the challenges posed by flat or low-sloped roofs by providing a solution for proper water drainage. By creating a gradual slope, tapered insulation ensures that water flows away from the roof surface, preventing the accumulation of water and potential damage to the roofing system.

Here are some key benefits of using tapered insulation:

- Efficient Water Management: One of the main advantages of tapered insulation is its ability to effectively manage water on flat or low-sloped roofs. By redirecting water towards drains, scuppers, or gutter systems, tapered insulation helps prevent pooling and potential leaks, reducing the risk of water damage to the roof structure.

- Improved Roof Longevity: Proper water drainage is essential for the longevity of a roofing system. By eliminating standing water, tapered insulation helps to reduce the stress on the roof structure, preventing deterioration and extending the lifespan of the roof.

- Prevention of Structural Damage: Flat or low-sloped roofs are more susceptible to water damage due to their lack of natural drainage. Tapered insulation mitigates the risk of structural damage by ensuring that water is continuously directed away from vulnerable areas such as seams, joints, and flashings.

- Enhanced Energy Efficiency: Tapered insulation serves as an additional layer of thermal insulation, contributing to energy efficiency in the building. By minimizing heat loss or gain through the roof, tapered insulation helps to regulate indoor temperatures, reduce heating or cooling costs, and improve occupant comfort.

- Customizable Design: Tapered insulation is custom-designed for each specific roof, taking into account the unique dimensions and requirements of the building. This allows for precise control over the slope and thickness distribution, ensuring optimal water drainage and minimizing material waste.

- Compatibility with Various Roofing Systems: Tapered insulation can be used in conjunction with a wide range of roofing systems, including single-ply membranes, built-up roofs, metal roofs, and more. It is adaptable to different roof configurations, making it a versatile choice for various construction projects.

By incorporating tapered insulation into the roofing system, building owners and designers can mitigate the risks associated with flat or low-sloped roofs, ensuring proper water management, improved energy efficiency, and a longer lifespan for the roof.

Types of Tapered Insulation

Tapered insulation comes in various types, each tailored to meet specific roofing requirements and design preferences. Here are some common types of tapered insulation:

- Cut-to-Fall Insulation: Cut-to-fall tapered insulation is custom-designed and fabricated to create a slope on the roof. It is made by cutting tapered pieces of insulation foam and fitting them together to form the desired slope. This type of insulation allows for precise control over the slope angle and thickness distribution, ensuring efficient water drainage.

- Composite Tapered Insulation: Composite tapered insulation consists of multiple layers, typically a base layer of flat insulation and a top layer of tapered insulation. This type of insulation offers the benefits of both flat and tapered insulation, providing thermal insulation as well as slope for water drainage. It is commonly used in roofing systems where multiple functionalities are desired.

- Factory-Tapered Insulation: Factory-tapered insulation, also known as pre-tapered insulation, is manufactured with a pre-engineered slope. It is fabricated by bonding multiple layers of tapered insulation together into large, pre-fabricated panels. This type of insulation provides a convenient and efficient solution, as it eliminates the need for on-site cutting and assembly.

- Pourable Tapered Insulation: Pourable tapered insulation, also referred to as self-leveling insulation, is an alternative option that involves pouring a liquid insulation material onto the roof surface. The liquid insulation then self-levels and sets into a tapered slope as it cures. This type of insulation is suitable for irregular roof surfaces or situations where other forms of tapered insulation may be challenging to install.

It is important to consult with a roofing professional or insulation manufacturer to determine the most suitable type of tapered insulation for a specific project. Factors such as roof design, water drainage requirements, insulation thickness, and local building codes should all be taken into consideration when selecting the appropriate type of tapered insulation.

Overall, the selection of the right type of tapered insulation is crucial in achieving an effective and efficient roofing system that ensures proper water drainage and thermal insulation.

Factors to Consider When Choosing Tapered Insulation

When selecting tapered insulation for a roofing project, it is important to consider several factors to ensure optimal performance and long-term durability. Here are some key factors to keep in mind:

- Roof Design: The specific design of the roof, including its shape, dimensions, and slope requirements, will influence the type and configuration of tapered insulation needed. Consider the layout of drains, scuppers, and roof edges when determining the slope and thickness distribution of the tapered insulation.

- Water Drainage Requirements: Assess the water drainage needs of the roof to determine the appropriate slope and design of the tapered insulation. Factors such as average rainfall intensity, roof length, and the number and capacity of drains should be taken into account to ensure efficient water management and prevent water pooling.

- Insulation Thickness: The required insulation thickness will depend on factors such as local building codes, climate conditions, and the desired thermal performance of the roofing system. Consider the R-value requirements and energy efficiency goals when selecting the thickness of the insulation.

- Material Type: Tapered insulation is commonly made from rigid foam materials, such as expanded polystyrene (EPS) or polyisocyanurate (ISO). Evaluate the structural properties, thermal resistance, and moisture resistance of different materials to determine the most suitable option for the specific project.

- Product Quality and Certification: Look for tapered insulation products that have been tested and certified for quality and performance. Check for industry standards and certifications, such as ASTM, ISO, or FM Global ratings, to ensure that the product meets the necessary requirements and provides reliable performance.

- Installation Considerations: Consider the complexity of the installation process and the skill level required. Depending on the chosen type of tapered insulation, there may be variations in the on-site cutting, assembly, or pouring process. Evaluate the available resources and expertise to ensure a successful and efficient installation.

- Budget and Cost: Evaluate the cost of tapered insulation materials and installation services in relation to the project budget. Consider the long-term savings that can be achieved through energy efficiency and reduced maintenance costs when making cost-related decisions.

It is always recommended to consult with roofing professionals, architects, or insulation manufacturers to ensure that the chosen tapered insulation meets the specific requirements of the project. Their expertise and guidance can help in selecting the most suitable type, thickness, and configuration of tapered insulation for optimal performance and long-lasting roofing systems.

When installing tapered insulation, make sure to properly slope the insulation to ensure proper drainage and prevent water ponding on the roof. This will help maintain the integrity of the roof and prevent water damage.

Read more: How To Make Tapered Candles

Installation Process of Tapered Insulation

The installation process of tapered insulation involves several steps to ensure proper placement, alignment, and adherence to the roof substrate. Here is a general outline of the installation process:

- Prepare the Roof Surface: Start by ensuring that the roof surface is clean, free of debris, and in good condition. Repair any damaged or deteriorated areas before proceeding with the installation.

- Layout and Design: Based on the roof design and water drainage requirements, create a detailed layout and design plan for the tapered insulation. This includes determining the desired slope, thickness distribution, and locations of drains, scuppers, and roof edges.

- Cut or Fabricate the Insulation: If the chosen tapered insulation requires on-site cutting or fabrication, carefully cut or shape the insulation panels according to the design plan. Ensure precise measurements and smooth edges for proper fit and alignment.

- Install the Base Layer: Begin by installing the base layer of flat insulation on the roof surface. Use adhesive or mechanical fasteners to secure the insulation to the roof substrate, following the manufacturer’s instructions. Ensure proper alignment and avoid gaps or overlaps in the insulation panels.

- Place and Secure Tapered Insulation: Install the tapered insulation panels on top of the base layer, following the design plan. Ensure that the panels are aligned correctly to create the desired slope. Adhere the tapered insulation to the base layer using adhesive or mechanical fasteners. Confirm that the transition areas between different insulation thicknesses are smooth and seamless.

- Seal and Insulate Joints: Pay attention to the joints and seams between the insulation panels. Use sealant or insulation adhesive to secure and seal the joints, preventing air leakage and maintaining thermal performance. Follow manufacturer recommendations to ensure proper application and adhesion.

- Install Roofing Material: Once the tapered insulation is in place, proceed with the installation of the selected roofing material, such as single-ply membranes, built-up roofing, or metal roofing. Follow the manufacturer’s guidelines for proper installation techniques and ensure compatibility with the tapered insulation system.

- Quality Assurance: Regularly inspect the installation to verify proper alignment, adhesion, and overall quality. Address any issues or defects promptly to ensure a reliable and effective tapered insulation system.

It is important to note that the specific steps and techniques involved in the installation process may vary depending on the chosen type of tapered insulation and roofing system. It is recommended to consult the manufacturer’s guidelines and instructions for the specific product being used, as well as engage the expertise of roofing professionals to ensure a successful and code-compliant installation.

Common Applications of Tapered Insulation

Tapered insulation finds widespread application in various construction projects that feature flat or low-sloped roofs. Here are some common applications where tapered insulation is utilized:

- Commercial Buildings: Tapered insulation is frequently used in commercial buildings, such as office complexes, shopping centers, and warehouses. These structures often have large roof areas with minimal slope, making proper water drainage crucial. Tapered insulation helps prevent water pooling and potential leaks in these high-traffic buildings.

- Industrial Facilities: Industrial facilities, including manufacturing plants, distribution centers, and processing plants, often have expansive roofs with complex configurations. Tapered insulation offers a practical solution to ensure efficient water management in these challenging environments.

- Hospitals and Healthcare Facilities: Tapered insulation plays a vital role in healthcare settings, where the integrity of the roofing system is critical to maintain the safety and well-being of patients. Proper water drainage helps prevent the spread of waterborne contaminants and contributes to a sterile environment.

- Schools and Educational Institutions: Educational buildings, such as schools, colleges, and universities, require reliable roofing systems that can withstand heavy foot traffic and adverse weather conditions. Tapered insulation assists in preventing water damage, ensuring a safe and conducive learning environment for students and staff.

- Residential Buildings: While residential buildings often have steeper roof slopes, there are instances with flatter areas or low-sloped sections. Tapered insulation is employed in these areas to ensure proper water drainage and protect the overall integrity of the roofing system.

- Government and Municipal Buildings: Government offices, municipal buildings, and public facilities can benefit from the reliable performance of tapered insulation. These structures often have large roof areas and diverse roof configurations, requiring a tailored approach to water management.

- Leisure and Hospitality: Hotels, resorts, sports complexes, and recreational facilities rely on effective roofing systems to provide a comfortable and enjoyable experience for guests. Tapered insulation helps prevent water-related issues that could disrupt activities and compromise guest satisfaction.

- Green Roofs: Tapered insulation is also utilized in green roof systems, where vegetation is installed on the roof surface. Green roofs require careful consideration of water drainage to maintain the health and longevity of plantings, making tapered insulation an essential component.

These are just a few examples of the many applications of tapered insulation in various industries and sectors. The versatility and effectiveness of tapered insulation make it an integral part of ensuring the longevity, efficiency, and overall performance of flat or low-sloped roofing systems.

Maintenance and Care of Tapered Insulation

Maintaining and caring for tapered insulation is essential to ensure its long-term performance and the integrity of the roofing system. Here are some key maintenance tasks and care considerations:

- Regular Inspections: Conduct periodic inspections of the tapered insulation to identify any signs of damage, wear, or deterioration. Inspect for cracks, punctures, or gaps in the insulation panels, as well as areas where the slope might have been compromised. Address any issues promptly to prevent further damage.

- Clean the Roof Surface: Keep the roof surface clean and free from debris that can impede water drainage. Remove leaves, dirt, and other obstructions that can accumulate on the roof and prevent proper water flow. Regular cleaning helps maintain the efficiency of the tapered insulation system.

- Ensure Proper Drainage: Monitor the drains, scuppers, and gutter systems to ensure they are clear of debris and functioning correctly. This will ensure that water is effectively directed away from the roof and prevent water pooling or overflow, which can put stress on the tapered insulation and lead to leaks or damage.

- Address Water Issues Promptly: If any signs of water infiltration or leakage are detected, take immediate action to identify and rectify the source of the problem. Investigate for any damaged or compromised areas in the roofing system, including the tapered insulation. Repair or replace any faulty components to prevent further water damage.

- Protect the Roof Surface: Avoid excessive foot traffic, equipment storage, or other activities that could potentially damage the roof surface and the tapered insulation. Install walkways or protective pads in areas where frequent access is required to minimize the risk of punctures or tears in the insulation.

- Seal Joints and Seams: Inspect and maintain the seals and joints between the tapered insulation panels, as well as at transitions between different roofing materials or roof penetrations. Ensure that sealants and adhesives are intact and not deteriorated, as they play a vital role in preventing water infiltration.

- Regular Roof Maintenance: In addition to the tapered insulation, follow recommended maintenance practices for the entire roofing system, including the roofing material, flashings, and other components. This comprehensive approach will help in preserving the overall performance and longevity of the roof.

It is advisable to consult with a professional roofing contractor or insulation manufacturer for specific maintenance guidelines and recommendations based on the type of tapered insulation used in the roofing system. Following a proactive maintenance plan will help ensure that the tapered insulation functions optimally and continues to provide efficient water management for the life of the roof.

Potential Drawbacks and Limitations of Tapered Insulation

While tapered insulation offers numerous benefits for flat or low-sloped roofing systems, it is essential to be aware of its potential drawbacks and limitations. Here are some factors to consider:

- Additional Cost: Tapered insulation can add to the overall cost of a roofing project compared to traditional flat insulation. The custom design, on-site cutting, or pre-fabrication required for tapered insulation can result in higher material and labor expenses.

- Complex Installation: Installing tapered insulation requires specialized knowledge and skills to ensure proper alignment, slope, and adhesion. It may necessitate professional expertise or specialized equipment for precise installation, especially for intricate roof designs.

- Sensitivity to Poor Installation: The effectiveness of tapered insulation heavily relies on its proper installation. Any mistakes or lapses in installation, such as inconsistent slope or improper sealing, can compromise its ability to manage water effectively and result in potential leaks or water damage.

- Limitations on Roof Design: Tapered insulation may impose limitations on the design and layout of flat or low-sloped roofs. It requires careful planning and consideration of drains, scuppers, and roof edges to ensure effective water drainage. Complex roof configurations may present challenges in achieving the desired slope and thickness distribution.

- Dependence on Drainage Systems: The performance of tapered insulation is closely tied to the functionality of drainage systems, such as drains and gutters. Inadequate maintenance or failure of these systems can impact the overall effectiveness of tapered insulation in managing water and preventing water-related issues.

- Reduced Usable Roof Space: The installation of tapered insulation can result in a loss of usable roof space due to the creation of slopes. This reduction in available space may impact the installation of equipment, storage, or future expansions on the roof surface.

- Potential for Ponding in Uneven Areas: While tapered insulation aims to prevent water pooling, areas with irregularities or depressions on the roof surface may still be prone to ponding. It is crucial to address these areas during the design and installation process to minimize the risk of water accumulation.

It is important to carefully evaluate the specific project requirements, budget constraints, and roof design considerations when incorporating tapered insulation. Working closely with experienced professionals can help in mitigating these drawbacks and ensuring the successful integration of tapered insulation into the roofing system.

Read more: What Is Insulation

Conclusion

Tapered insulation is an essential component in the world of construction and building design, especially for flat or low-sloped roofs. It provides a practical solution to address the challenges posed by these types of roofs by promoting proper water drainage and preventing water pooling and potential damage. Throughout this article, we have explored the definition, purpose, benefits, types, installation process, common applications, maintenance, and limitations of tapered insulation.

Tapered insulation offers numerous benefits, including efficient water management, improved roof longevity, prevention of structural damage, enhanced energy efficiency, customizable design, and compatibility with various roofing systems. It is a versatile solution that finds applications in commercial buildings, industrial facilities, hospitals, schools, residential buildings, government structures, and more.

When choosing tapered insulation, it is important to consider factors such as roof design, water drainage requirements, insulation thickness, material type, product quality, installation considerations, and budget constraints. These factors will help in selecting the appropriate type, thickness, and configuration of tapered insulation for optimal performance and long-term durability.

Maintaining and caring for tapered insulation involves regular inspections, cleaning the roof surface, ensuring proper drainage, addressing water issues promptly, protecting the roof surface, sealing joints and seams, and following recommended maintenance practices for the entire roofing system.

However, it is crucial to be aware of the potential drawbacks and limitations of tapered insulation, such as additional cost, complex installation, sensitivity to poor installation, limitations on roof design, dependence on drainage systems, reduced usable roof space, and potential for ponding in uneven areas.

In conclusion, tapered insulation plays a vital role in creating functional, reliable, and efficient roofing systems for flat or low-sloped roofs. It ensures proper water management, improves energy efficiency, and prolongs the lifespan of the roof. By considering the specific project requirements and working with experienced professionals, tapered insulation can be seamlessly integrated to deliver long-lasting and trustworthy roofing solutions.

Frequently Asked Questions about What Is Tapered Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Tapered Insulation”