Articles

What Is A Batt Of Insulation

Modified: May 6, 2024

Learn all about the different types and benefits of batt insulation with our informative articles. Start saving energy and improving your home's comfort today.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to maintaining the comfort and energy efficiency of a building, insulation plays a vital role. Insulation helps to regulate temperature and minimize heat loss or gain, making it an essential component in homes, offices, and other structures. There are various types of insulation available, each with its unique characteristics and installation methods.

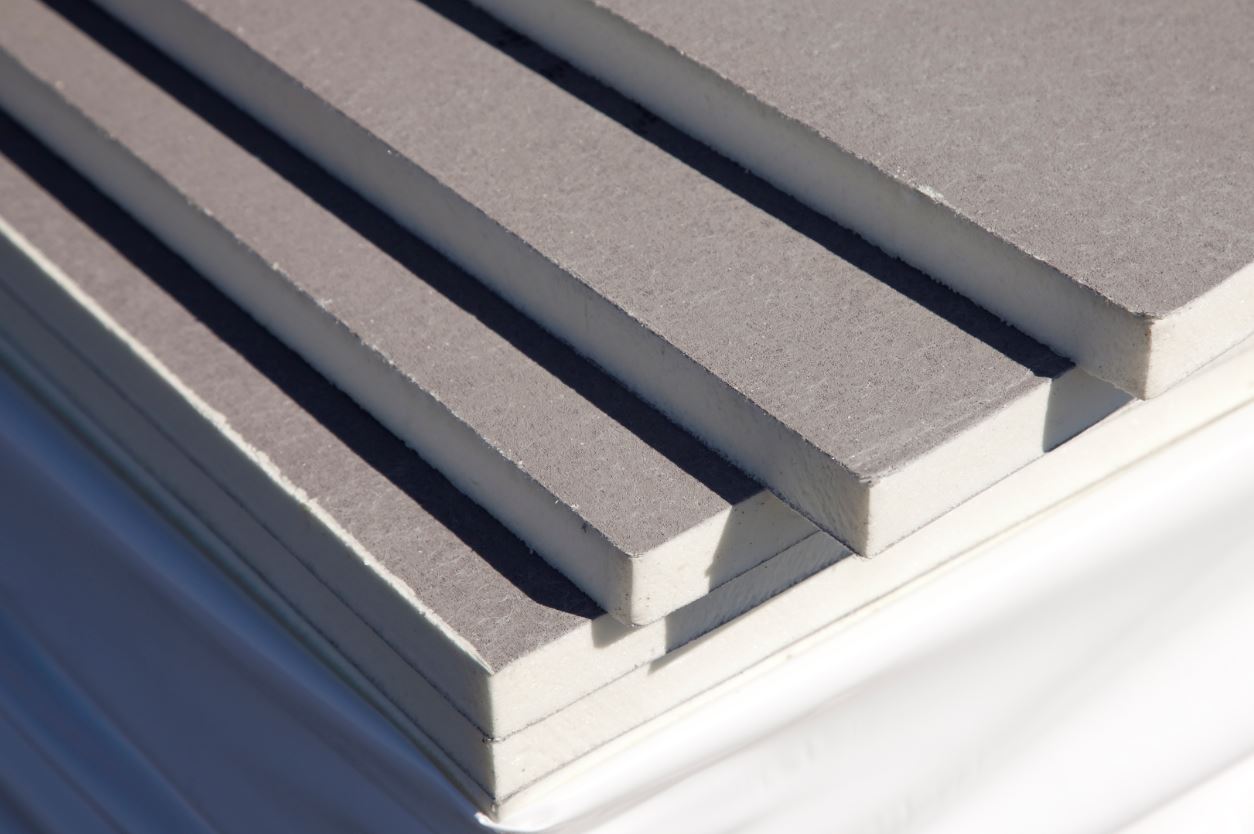

In this article, we will explore one particular type of insulation: insulation batts. Insulation batts are pre-cut, rectangular sheets made from different materials, such as fiberglass, mineral wool, or natural fibers. They are designed to fit between wall studs, floor joists, or ceiling rafters, creating a barrier that prevents the transfer of heat or cold.

By understanding what insulation batts are, their types, advantages, installation process, and common uses, you can make an informed decision when considering insulation options for your building. Let’s dive into the details and explore the world of insulation batts.

Key Takeaways:

- Insulation batts, such as fiberglass, mineral wool, and natural fibers, offer energy efficiency, comfort, and noise reduction. Proper installation and maintenance are crucial for maximizing their performance and longevity.

- When choosing insulation batts, consider factors like R-value, material, facing, and sustainability. Consulting with professionals and adhering to local building codes ensures optimal insulation solutions for your building’s specific needs.

Read more: How To Cut Batt Insulation

Definition of a Batt of Insulation

A batt of insulation refers to a pre-cut, rectangular sheet or roll of insulation material that is designed to fit snugly between framing studs, joists, or rafters. These batts are commonly made from materials like fiberglass, mineral wool, or natural fibers, and are intended to provide thermal insulation to a building.

Insulation batts are available in various sizes, thicknesses, and R-values. The R-value is a measure of the insulation’s thermal resistance, indicating how well it can resist the transfer of heat. Higher R-values indicate greater effectiveness in retaining heat or cool air, making it crucial to select the appropriate R-value for your specific insulation needs.

The batts are typically manufactured with a paper or foil facing on one side to act as a vapor barrier and enhance moisture resistance. This facing also serves as a quick reference during installation, as it often contains the insulation product’s brand, R-value, and other essential information.

Insulation batts are versatile and can be used in various areas of a building, including walls, floors, and ceilings. They are easy to handle and install, making them a popular choice for both professionals and DIY enthusiasts.

It is important to note that not all batts of insulation are created equal. Different materials and manufacturing techniques can affect their performance, durability, and environmental impact. Understanding the specific properties and characteristics of the insulation batts you choose is crucial for achieving optimal thermal efficiency and energy savings in your building.

Types of Insulation Batts

Insulation batts come in various types, each with its unique properties and advantages. Here are some of the common types of insulation batts:

- Fiberglass Batts: Fiberglass insulation batts are perhaps the most widely used type of insulation. They are made from fine glass fibers and are available in both faced and unfaced options. Fiberglass batts are lightweight, affordable, and easy to install. They offer good thermal and sound insulation properties and are resistant to moisture, mold, and pests.

- Mineral Wool Batts: Mineral wool, also known as rock wool or stone wool, is another popular choice. These batts are made from melted basalt rock or steel slag and are known for their excellent fire resistance. Mineral wool batts provide effective thermal insulation, sound absorption, and are resistant to moisture and pests. They are available in both faced and unfaced varieties.

- Natural Fiber Batts: Natural fiber batts are made from materials such as cotton, wool, or cellulose. These batts are environmentally friendly and have excellent thermal and sound insulation properties. Natural fiber batts are often treated with fire retardants and insect repellents for added protection against fire and pests.

- Reflective Foil Batts: Reflective foil batts consist of a thin layer of foil laminated to a layer of foam or bubble wrap. These batts are primarily used for thermal insulation in areas with radiant heat transfer, such as attics and crawl spaces. Reflective foil batts reflect radiant heat and help in reducing heat gain in the summer and heat loss in the winter.

It is important to consider the specific requirements of your building and consult with a professional to determine the most suitable type of insulation batts. Factors such as climate, desired R-value, fire resistance, and budget should all be taken into account when making a decision.

Furthermore, it is worth mentioning that some insulation batts are produced with recycled materials, contributing to sustainability efforts and reducing environmental impact. Keep in mind that different regions may have specific building codes and regulations regarding insulation materials, so it is crucial to comply with local guidelines when choosing insulation batts.

Advantages of Using Insulation Batts

Insulation batts offer several benefits when it comes to enhancing the thermal efficiency and comfort of a building. Here are some of the advantages of using insulation batts:

- Energy Efficiency: Insulation batts provide excellent thermal insulation, reducing the transfer of heat between the inside and outside of a building. This helps to minimize heat loss during the winter and heat gain during the summer, resulting in lower energy consumption and reduced utility bills.

- Comfort: By preventing outside temperature fluctuations from affecting indoor spaces, insulation batts help create a more comfortable living or working environment. They keep interiors cooler in hot weather and warmer in cold weather, reducing the need for excessive heating or cooling systems.

- Noise Reduction: Insulation batts also serve as effective sound barriers, reducing the transmission of noise between rooms or from outside sources. This can be particularly beneficial in areas near busy roads, airports, or noisy environments where a quieter indoor atmosphere is desired.

- Moisture Control: Many insulation batts are designed with built-in moisture resistance properties, preventing the buildup of condensation and the growth of mold or mildew. This helps to maintain a healthy indoor environment and protect the structural integrity of the building.

- Easy Installation: Insulation batts are lightweight and relatively easy to handle and install, making them suitable for both professional contractors and DIY enthusiasts. They can be easily cut to fit between framing studs, joists, or rafters, allowing for a seamless and efficient installation process.

- Affordability: Compared to some other insulation options, insulation batts are generally more affordable. They offer a cost-effective solution for improving energy efficiency and thermal performance in buildings, without requiring a significant upfront investment.

Overall, insulation batts provide a practical and efficient way to enhance insulation in various areas of a building, improving energy efficiency, comfort, and environmental conditions. They offer a versatile and affordable solution for both new construction projects and retrofitting existing structures.

However, it is important to select the appropriate insulation batt type and ensure proper installation to fully maximize the benefits and performance of the insulation. Consider consulting with insulation professionals or referring to local building codes for guidance on insulation requirements specific to your region.

Installation Process for Insulation Batts

The installation process for insulation batts is relatively straightforward, making it suitable for both professionals and inexperienced homeowners. Here is a general overview of the steps involved:

- Prepare the area: Before installing insulation batts, make sure the area is clean, dry, and free from any debris or obstructions. Ensure that any air leaks or gaps are sealed to maximize the effectiveness of the insulation.

- Measure and cut: Measure the space between the framing studs, joists, or rafters. Using a utility knife or insulation cutting tool, cut the insulation batts to the appropriate size. Be careful not to compress the insulation too much, as it can reduce its performance.

- Attach facing (if applicable): If the insulation batts have a paper or foil facing, ensure that the facing side is facing the interior space. This will act as a vapor barrier and improve moisture resistance. Staple or use insulation fasteners to secure the facing to the framing members.

- Fit the batts: Place the insulation batts into the cavity, ensuring a snug fit between the framing members. Gently press the batts into place, making sure there are no gaps or voids. Avoid compressing the insulation too much, as it can reduce its thermal efficiency.

- Seal the seams: To achieve a more airtight and effective insulation barrier, seal the seams between insulation batts using insulation tape or caulk. This will help prevent air leakage and improve the overall thermal performance.

- Repeat the process: Continue installing insulation batts, working your way across the area until the entire space is covered. Take care to cut and fit the batts around any obstacles like electrical outlets, pipes, or ductwork. Use a serrated knife or insulation cutting tool to make precise cuts.

- Double-check and inspect: Once the insulation batts are installed, inspect the area to ensure there are no gaps, compression, or damage to the insulation. Take note of any areas that may need reinforcement or additional insulation.

It’s important to follow manufacturer instructions and any local building codes or regulations during the installation process. If you are uncertain or uncomfortable with installing insulation batts yourself, it’s recommended to consult with a professional insulation contractor who can ensure a proper and effective insulation installation.

Remember, the accuracy and quality of the installation will directly impact the energy efficiency and thermal performance of the insulation. Investing time and effort into a well-executed installation will yield long-term benefits for your building’s comfort and energy savings.

When installing a batt of insulation, make sure to wear protective clothing, gloves, and a mask to avoid irritation from the fibers. Also, ensure that the batt fits snugly in the space to maximize its effectiveness.

Read more: How Many Batts Are In A Bag Of Insulation

Factors to Consider When Choosing Insulation Batts

Choosing the right insulation batts for your specific needs requires careful consideration of several key factors. Here are some important factors to keep in mind:

- R-Value: The R-value of insulation batts determines their thermal resistance. Higher R-values indicate greater insulating effectiveness. Consider the climate of your region and the desired level of insulation when selecting the R-value for your insulation batts.

- Material: Insulation batts are made from various materials, such as fiberglass, mineral wool, or natural fibers. Consider the pros and cons of each material, including factors like fire resistance, moisture resistance, sound absorption, and environmental impact, before making a decision.

- Facing: Some insulation batts come with a facing, typically made of paper or foil, which acts as a vapor barrier. The facing helps to improve moisture resistance and provides a quick reference for product information. Determine if a facing is necessary for your application and choose the appropriate type.

- Size and Thickness: Insulation batts are available in different sizes and thicknesses to fit various framing stud, joist, or rafter spacings. Measure the space carefully and choose insulation batts that will fit snugly without compressing or leaving gaps.

- Fire Resistance: Consider the fire resistance properties of the insulation batts, especially in areas where fire hazards are a concern. Some insulation materials, such as mineral wool, offer excellent fire resistance properties, providing an added layer of safety.

- Sustainability: If environmental sustainability is important to you, consider insulation batts made from recycled or renewable materials. Look for products with certifications like GREENGUARD or Energy Star that indicate their commitment to sustainability and eco-friendliness.

- Installation Ease: Assess your comfort level with DIY installation and choose insulation batts that are easy to handle and install. Some materials, like fiberglass batts, are known for their ease of installation, while others may require professional expertise.

- Budget: Consider your budgetary constraints when selecting insulation batts. Compare prices and evaluate the long-term cost savings in energy consumption when choosing insulation batts with higher initial costs but better energy efficiency.

- Local Building Codes: Ensure that the insulation batts you choose comply with local building codes and regulations. Different regions may have specific requirements regarding insulation materials and R-values, so consult with building authorities or professionals to ensure compliance.

By considering these factors, you can make an informed decision when choosing insulation batts that best suit your specific needs, ensuring optimal thermal performance, energy efficiency, and overall comfort in your building.

Remember that professional advice from insulation contractors or experts can provide invaluable guidance in selecting and installing insulation batts suitable for your building. Their expertise will help you navigate the complexities of insulation choices and ensure optimal results.

Common Uses of Insulation Batts

Insulation batts are versatile and can be used in various areas of a building, providing effective thermal insulation and energy efficiency. Here are some common uses of insulation batts:

- Walls: Insulation batts are commonly used in exterior walls to prevent heat loss or gain through the building envelope. They fit snugly between the wall studs, creating a thermal barrier and improving energy efficiency.

- Floors: Insulation batts can be used in floor cavities to minimize heat transfer between different levels of a building. They help keep lower floors warmer in the winter and cooler in the summer, increasing comfort and reducing energy demands.

- Roofs and Attics: Insulation batts are often installed in the attic or on the underside of the roof to provide thermal insulation. They help prevent heat from entering the living spaces during hot summer months and reduce heat loss during winter, improving energy efficiency and temperature regulation.

- Ceilings and Crawl Spaces: Insulation batts can be used in ceilings and crawl spaces to enhance insulation and reduce heat flow between different areas of a building. They contribute to maintaining consistent indoor temperatures and improving energy efficiency.

- Soundproofing: Insulation batts are effective in reducing the transmission of sound between rooms or from outside sources. They can be used in interior walls or between floors and ceilings to create a quieter and more peaceful environment.

- Building Extensions: Insulation batts are commonly used during building extensions or renovations to ensure consistent insulation throughout the entire structure. They are installed in new walls, floors, and ceilings to maintain energy efficiency and thermal comfort levels.

- Commercial Buildings: Insulation batts find extensive use in commercial buildings, including offices, retail spaces, and warehouses. They contribute to energy efficiency, occupant comfort, and sound insulation in these high-occupancy environments.

- Residential Homes: Insulation batts are widely used in residential homes to improve energy efficiency and comfort. Whether it’s a new construction project or a retrofitting endeavor, insulation batts play a crucial role in maintaining a comfortable living environment and reducing energy consumption.

Insulation batts are adaptable and can be used in various applications. Their ease of installation and affordability make them a popular choice for both residential and commercial buildings, enabling effective thermal insulation and energy conservation.

It’s important to select the appropriate insulation batts based on the specific requirements of each area within the building. Consulting with insulation professionals can help determine the optimal insulation solutions for different spaces and ensure optimal results in terms of thermal efficiency and occupant comfort.

Potential Issues with Insulation Batts

While insulation batts offer numerous benefits, it’s important to be aware of potential issues that may arise. Understanding these challenges will help you make informed decisions and address them effectively. Here are some potential issues associated with insulation batts:

- Improper Installation: Improper installation of insulation batts can significantly reduce their effectiveness. Gaps, compressions, or poorly sealed seams can allow air leakage and compromise the thermal barrier. It is crucial to follow manufacturer guidelines and seek professional help or guidance if needed to ensure proper installation.

- Moisture Issues: Inadequate moisture management can lead to issues like condensation and mold growth. While some insulation batts have moisture-resistant properties, it is essential to address any existing moisture issues and, if necessary, consult with professionals to choose the appropriate insulation material for areas prone to moisture.

- Inadequate Insulation: Insufficient insulation, including underestimating the required R-value or using insulation batts of inappropriate thickness, can result in reduced insulation performance. This can lead to poor energy efficiency, lower comfort levels, and increased heating or cooling costs.

- Settling and Compression: Over time, insulation batts may settle or compress, reducing their insulating properties. This can be a result of improper installation or the natural settling of materials. Regular inspection and maintenance can help identify and address any issues related to settling or compression.

- Fire Hazards: Some insulation materials, particularly those made from natural fibers, may be more susceptible to fire. It is crucial to choose insulation batts with appropriate fire resistance properties and ensure compliance with local fire safety regulations to mitigate potential fire hazards.

- Pest Intrusion: Insulation batts made from certain materials may be more susceptible to pest infestations. Proper sealing and addressing any existing pest issues in the building are essential to prevent pests from nesting or damaging the insulation material.

- Health and Safety: Handling insulation batts, particularly fiberglass, can cause skin irritations or respiratory discomfort if proper precautions are not taken. It is important to wear protective clothing, masks, and goggles when handling insulation materials to minimize any potential health risks.

Understanding and proactively addressing these potential issues can help maximize the benefits and longevity of your insulation batts. Regular inspection, maintenance, and professional guidance are recommended to ensure the insulation remains effective and provides the desired thermal comfort and energy efficiency.

When choosing insulation batts, consider their specific properties, such as fire resistance, moisture resistance, and pest resistance, and select materials suitable for the intended application. Consulting with insulation professionals can provide valuable insights and guidance in making the right choices to avoid potential issues and maximize the performance of your insulation batts.

How to Properly Maintain Insulation Batts

Proper maintenance of insulation batts is crucial for ensuring their long-term effectiveness and preserving the energy efficiency of your building. Here are some key steps to properly maintain insulation batts:

- Regular Inspection: Schedule regular inspections to check the condition of your insulation batts. Look for signs of damage, settling, or compression, as well as any gaps or areas in need of resealing. Regular inspections allow you to detect and address issues early on.

- Address Moisture Issues: Moisture can compromise the performance of insulation batts and lead to mold or mildew growth. Address any moisture issues promptly, such as leaks or high humidity levels. Ensure proper ventilation and consider using moisture-resistant insulation materials in areas prone to moisture.

- Sealing Gaps and Air Leaks: Regularly inspect and seal any gaps, cracks, or air leaks in the building envelope. These gaps can allow air to pass through, reducing the effectiveness of insulation batts. Use weatherstripping, caulk, or insulation tape to seal gaps around windows, doors, and other potential sources of air leakage.

- Remediate Pest Intrusion: Address any pest issues promptly to prevent pests from nesting or damaging the insulation batts. Take necessary measures to seal entry points and consult with professionals if needed to safely and effectively deal with pests while preserving the insulation.

- Replace Damaged Insulation: If you observe any significant damage or deterioration in the insulation batts, consider replacing the affected areas. Damaged insulation will not provide optimal thermal performance and can lead to energy inefficiency. Consult with insulation professionals to ensure proper replacement.

- Provide Adequate Ventilation: Proper ventilation is essential for maintaining a healthy indoor environment and preventing moisture-related issues. Ensure that attics, crawl spaces, and other enclosed areas with insulation batts are adequately ventilated to allow moisture to escape and prevent the buildup of excessive heat.

- Consult with Insulation Professionals: If you are unsure about the maintenance of your insulation batts or need assistance in addressing specific issues, consult with insulation professionals. They can provide guidance, conduct inspections, and perform any necessary repairs or replacements to ensure optimized insulation performance.

Regular maintenance and proactive measures to address issues will prolong the lifespan of your insulation batts and ensure their continued energy-saving benefits. Taking a proactive approach to insulation maintenance can help you maximize energy efficiency and thermal performance while maintaining a comfortable indoor environment.

Remember to consult local building codes and regulations when performing maintenance activities related to insulation. These codes may provide specific guidance on insulation maintenance requirements and best practices for your region.

Read more: How Much Batt Insulation Do I Need

Conclusion

Insulation batts are a versatile and effective solution for improving the thermal insulation and energy efficiency of buildings. Whether used in walls, floors, roofs, or other areas, insulation batts play a crucial role in maintaining comfortable indoor environments and reducing energy consumption.

In this article, we have explored the definition of insulation batts, the different types available, and their advantages. We have discussed the installation process, factors to consider when choosing insulation batts, common uses, potential issues, and proper maintenance techniques.

Insulation batts offer benefits such as energy efficiency, improved comfort, noise reduction, and moisture control. They are relatively easy to install and come in various sizes, thicknesses, and R-values to suit different applications and climate requirements.

However, it is important to be aware of potential issues with insulation batts, such as improper installation, moisture problems, inadequate insulation, and fire hazards. Regular inspections, addressing moisture issues promptly, and sealing gaps and air leaks are essential for maintaining the effectiveness of insulation batts.

By properly maintaining insulation batts and addressing any issues that may arise, you can maximize their performance and enjoy the benefits of improved energy efficiency, comfort, and reduced utility costs.

When choosing insulation batts, consider factors such as R-value, material, facing, size, fire resistance, sustainability, and budget. It is also advisable to consult with insulation professionals to ensure the selection of the most suitable insulation batts for your specific needs.

Remember, insulation batts are a long-term investment in the energy efficiency and comfort of your building. With proper installation, regular maintenance, and professional guidance when needed, insulation batts can provide significant energy savings and create a more sustainable and comfortable living or working environment.

Take the time to assess your insulation needs and explore the options available. By choosing and maintaining insulation batts effectively, you can enhance the insulation performance of your building and enjoy the benefits for years to come.

If you found our guide on batt insulation helpful, you won't want to miss our next feature! Get ready for an eye-opening look at fiberglass insulation options set to redefine home comfort and energy efficiency in the coming year. This upcoming article is packed with insights to help you choose the best insulation solution for your needs. Whether you're renovating an old space or building anew, understanding these options is key to a cozy, cost-effective home.

Frequently Asked Questions about What Is A Batt Of Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Batt Of Insulation”