Articles

What Is Polyiso Insulation

Modified: January 8, 2024

Discover the benefits and uses of polyiso insulation in this informative article. Learn how to properly install and maximize the efficiency of this energy-saving insulation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of polyiso insulation! In this article, we will explore the wonders and benefits of this versatile insulation material. Whether you’re a homeowner looking to improve the energy efficiency of your home or a contractor seeking the best insulation options for your projects, understanding the ins and outs of polyiso insulation is crucial.

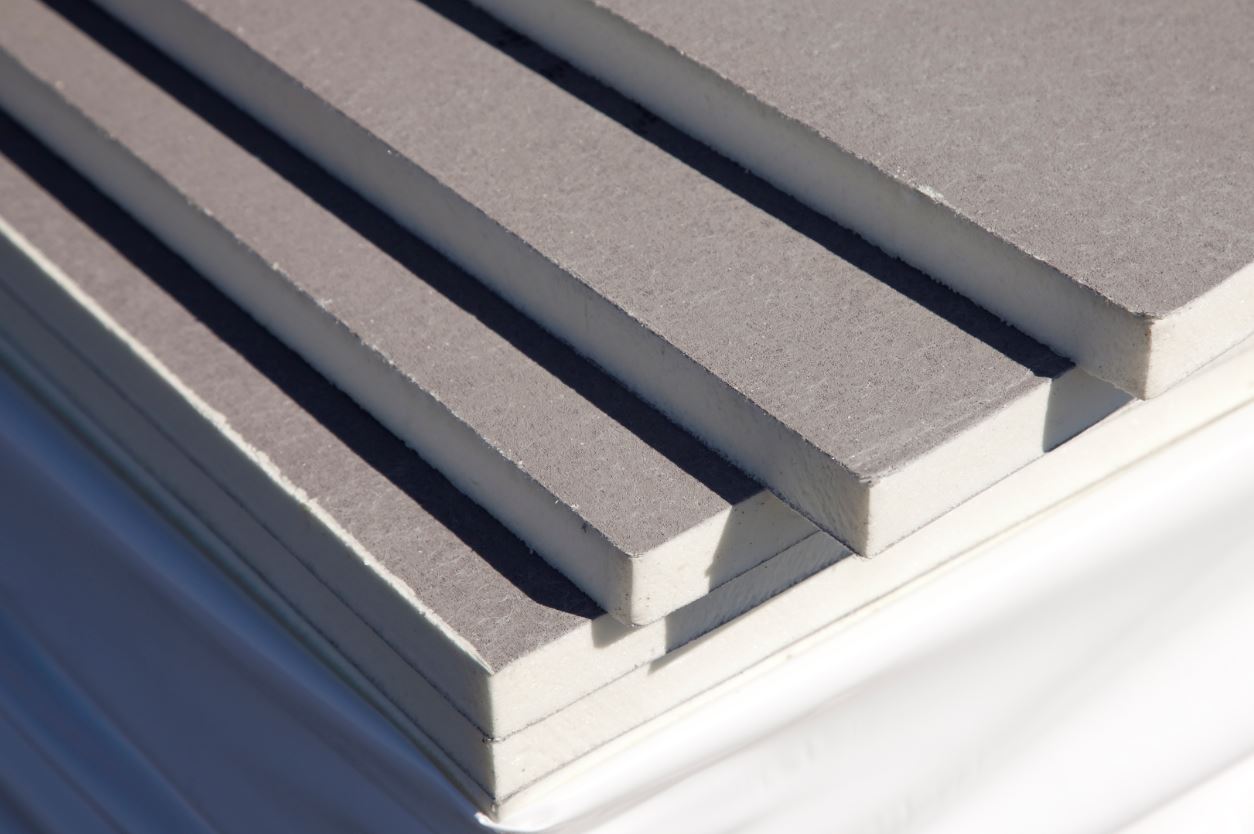

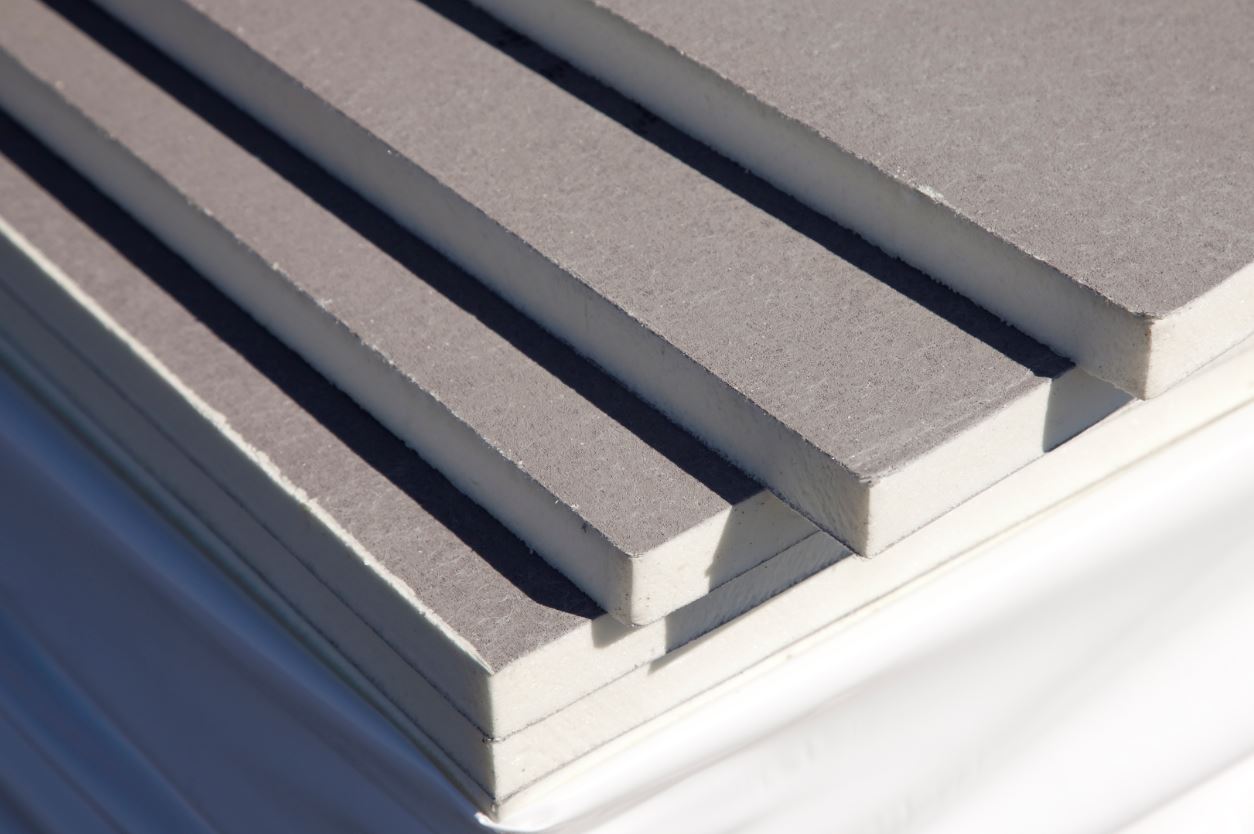

Polyiso insulation, short for polyisocyanurate insulation, is a type of rigid foam insulation widely used in residential, commercial, and industrial applications. It offers excellent thermal performance and is known for its high R-value – a measure of insulation’s resistance to heat flow. But what exactly is polyiso insulation and why is it so popular?

Polyiso insulation is composed of a closed-cell foam core sandwiched between two facers, which are typically made of coated glass fiber or foil laminates. The foam core is made by combining polyisocyanurate, a type of thermosetting plastic, with various blowing agents. These agents create the foam structure by expanding and trapping air within the cells, thus providing the insulation with its excellent thermal properties.

One of the key characteristics of polyiso insulation is its impressive R-value. The R-value of insulation measures its thermal resistance, or how well it prevents heat from passing through. Polyiso insulation boasts one of the highest R-values per inch compared to other insulation materials. This makes it an ideal choice for energy-conscious individuals and organizations looking to reduce heating and cooling costs and minimize their environmental footprint.

So, what are the advantages of polyiso insulation over other types? Let’s explore some of its notable benefits.

Key Takeaways:

- Polyiso insulation is a top choice for energy-conscious individuals and organizations due to its high R-value, durability, and environmental friendliness. It offers exceptional thermal performance and long-term energy savings.

- From roofing to refrigeration, polyiso insulation’s versatility and impressive thermal properties make it an ideal choice for a wide range of applications. Its lightweight nature and ease of installation further contribute to its appeal.

Read more: Where To Buy Polyiso Insulation

Definition of Polyiso Insulation

Polyiso insulation, short for polyisocyanurate insulation, is a type of rigid foam insulation that is widely used in the construction industry. It is known for its excellent thermal performance and high R-value – a measure of insulation’s resistance to heat flow. Polyiso insulation is designed to minimize heat transfer and maintain comfortable indoor temperatures in both residential and commercial buildings.

The term “polyisocyanurate” refers to the chemical composition of this insulation material. It is formed by combining polymeric isocyanates with polyols, which results in a closed-cell foam structure. The closed-cell structure creates air pockets within the foam, which helps to slow down the transfer of heat through conduction, convection, and radiation.

What sets polyiso insulation apart from other types of insulation is its superior R-value. R-value is a measure of an insulation material’s thermal resistance. The higher the R-value, the better the insulation’s ability to resist heat flow. Polyiso insulation has one of the highest R-values per inch compared to other commonly used insulation materials.

Polyiso insulation is available in various forms, including rigid panels and sheets. These panels and sheets are typically used in walls, roofs, and floors to provide thermal insulation. The insulation material comes in different thicknesses to meet the specific thermal requirements of a building.

In addition to its thermal properties, polyiso insulation also offers other advantages. It is lightweight and easy to handle, making installation quick and efficient. The material is durable, resistant to moisture and mold, and has good sound absorption properties, enhancing the overall comfort and quality of a building’s interior.

Furthermore, polyiso insulation is environmentally friendly. It is often manufactured with recycled content and can be recycled at the end of its lifespan. This makes it a sustainable choice for those looking to minimize their environmental impact.

In summary, polyiso insulation is a highly efficient insulation material that provides excellent thermal performance and energy savings. Its superior R-value, durability, ease of installation, and environmental benefits make it a popular choice for insulating residential and commercial buildings.

Composition of Polyiso Insulation

Polyiso insulation is composed of several layers that work together to provide optimal thermal performance and insulation properties. The composition of polyiso insulation typically consists of a foam core and two facers.

The foam core of polyiso insulation is made from polyisocyanurate, a thermosetting plastic. Polyisocyanurate is created by combining polymeric isocyanates with polyols, which undergo a chemical reaction to form a closed-cell foam structure. This foam structure is what gives polyiso insulation its excellent insulation properties and high R-value.

The foam core is sandwiched between two facers, which are the outer layers of the insulation panel. These facers can be made of coated glass fiber or foil laminates. The facers serve as protective barriers, providing strength, durability, and resistance to water, moisture, and other environmental factors.

The coated glass fiber facers are made by reinforcing a layer of glass fiber with a polymer coating. This coating enhances the facers’ resistance to moisture and improves their overall durability. The glass fiber facers also contribute to the insulation’s structural integrity.

The foil laminates facers, on the other hand, consist of a thin layer of aluminum foil adhered to a backing material. The foil layer acts as a radiant barrier, reflecting heat radiation away from the insulation. This helps to further enhance the insulation’s thermal performance.

The combination of the foam core and the facers creates a rigid insulation panel that is lightweight and easy to handle. The facers provide a protective layer to the foam core, preventing moisture absorption and adding strength to the insulation.

It is important to note that the composition of polyiso insulation can vary slightly depending on the manufacturer and specific product line. Some polyiso insulation products may have additional layers or coatings to enhance their fire resistance or improve their adhesion to other building materials.

In summary, polyiso insulation is composed of a foam core made from polyisocyanurate, sandwiched between two facers – coated glass fiber or foil laminates. This composition provides polyiso insulation with excellent thermal performance, durability, and resistance to moisture, making it a popular choice for various insulation applications.

R-Value of Polyiso Insulation

The R-value of an insulation material is a measure of its thermal resistance. It indicates how well the insulation material can resist the flow of heat through it. The higher the R-value, the better the insulation’s ability to prevent heat transfer. Polyiso insulation is known for its high R-value, making it an excellent choice for energy-efficient building insulation.

The R-value of polyiso insulation is determined by various factors, including the thickness of the insulation, the density of the foam core, and the type of facers used. Generally, polyiso insulation offers one of the highest R-values per inch compared to other commonly used insulation materials.

On average, polyiso insulation has an R-value ranging from 5.6 to 8.0 per inch, depending on the specific product and manufacturer. This high R-value means that polyiso insulation provides superior thermal insulation and efficiency, helping to reduce heat loss or gain in buildings.

It is important to note that the R-value of polyiso insulation can vary based on the temperature and climate conditions. The R-value is usually tested under laboratory conditions, assuming steady-state conditions. However, in real-world applications, factors such as moisture, wind, and temperature fluctuations can affect the actual thermal performance of the insulation.

Polyiso insulation’s impressive R-value is attributed to its closed-cell foam structure and the thermal resistance of the facers. The closed-cell foam traps air within its cells, creating an insulation barrier that helps slow down heat transfer through conduction and convection. The facers, whether coated glass fiber or foil laminates, contribute to the overall thermal resistance of the insulation and help to minimize heat radiation.

Another advantageous aspect of polyiso insulation is its ability to maintain its R-value over time. Unlike some other insulation materials that may degrade or lose effectiveness over time, polyiso insulation is known for its long-term performance stability. This means that the R-value of polyiso insulation remains relatively unchanged over the life of the building, providing consistent energy efficiency benefits.

In summary, polyiso insulation offers a high R-value, making it an excellent choice for maximizing thermal performance in buildings. With its superior thermal resistance, polyiso insulation helps to reduce energy consumption, lower heating and cooling costs, and create a more comfortable indoor environment.

Advantages of Polyiso Insulation

Polyiso insulation offers numerous advantages that make it a popular choice for both residential and commercial insulation applications. Let’s explore some of the key benefits of polyiso insulation:

- High Thermal Performance: Polyiso insulation has one of the highest R-values per inch among insulation materials. Its excellent thermal performance helps to minimize heat transfer and maintain comfortable indoor temperatures year-round.

- Energy Efficiency: With its high R-value, polyiso insulation helps to reduce heating and cooling costs by effectively insulating buildings. This energy efficiency can lead to significant savings over time.

- Environmentally Friendly: Polyiso insulation is often manufactured using recycled content, making it a sustainable choice. Additionally, it can be recycled at the end of its lifespan, reducing waste and promoting environmental stewardship.

- Moisture Resistance: The facers of polyiso insulation, whether coated glass fiber or foil laminates, provide a protective layer that helps resist moisture intrusion. This moisture resistance contributes to the durability and longevity of the insulation.

- Lightweight and Easy to Install: Polyiso insulation panels are lightweight, making them easy to handle and install. This can help save time and labor costs during the installation process.

- Durability: Polyiso insulation is known for its durability and long-term performance. It can withstand various weather conditions, such as temperature fluctuations and high winds, without compromising its thermal efficiency.

- Sound Absorption: In addition to thermal insulation, polyiso insulation also offers sound absorption properties. It can help reduce noise transmission, creating a more comfortable and quieter indoor environment.

- Fire Resistance: Many polyiso insulation products are manufactured with fire-resistant additives, making them resistant to flames and limiting fire spread. This can help enhance the safety of buildings and comply with fire codes and regulations.

The combination of these advantages makes polyiso insulation an attractive choice for a wide range of applications. Whether used in residential homes, commercial buildings, or industrial facilities, polyiso insulation offers energy efficiency, durability, and environmental benefits that contribute to overall comfort and savings.

When installing polyiso insulation, make sure to properly seal all joints and edges to prevent air leakage and maximize its effectiveness as a thermal barrier.

Read more: What Is Insulation

Applications of Polyiso Insulation

Polyiso insulation is a versatile insulation material that find its application in a wide range of residential, commercial, and industrial settings. Let’s explore some of the common applications of polyiso insulation:

- Roofing: Polyiso insulation is commonly used in roofing systems to provide thermal insulation and improve energy efficiency. It is installed on top of the roof deck and under the roofing material or membrane to help reduce heat transfer and prevent condensation.

- Walls: Polyiso insulation is used in both interior and exterior walls to enhance thermal performance and reduce energy consumption. It is installed between wall studs or as continuous insulation to create a barrier against heat transfer and improve overall comfort.

- Floors: Polyiso insulation can be placed under concrete slabs or between floor joists to provide insulation and reduce heat loss from the floor. This is particularly beneficial in areas with cold climates or where heated floors are desired.

- Attics and Ceilings: Insulating attics and ceilings with polyiso insulation helps to prevent heat gain in the summer and heat loss in the winter. This results in a more comfortable indoor environment and reduced energy usage for heating and cooling.

- HVAC Ductwork: Polyiso insulation is often used to insulate HVAC ductwork to minimize energy loss and improve system efficiency. Insulating ducts helps to maintain the desired temperature of conditioned air as it travels through the building.

- Refrigeration Systems: Polyiso insulation is commonly employed in the insulation of refrigeration systems, including cold storage spaces, walk-in coolers, and refrigerated trucks. Its high R-value and moisture resistance make it an ideal choice for maintaining temperature control and preventing condensation in these environments.

- Industrial Applications: Polyiso insulation is also utilized in various industrial applications, such as thermal insulation for tanks, pipelines, boilers, and equipment. Its ability to withstand high temperatures and its thermal efficiency make it suitable for insulating industrial processes.

These are just a few examples of the many applications of polyiso insulation. Its versatility and excellent thermal performance make it a preferred choice in the construction industry. Whether in residential, commercial, or industrial projects, polyiso insulation provides energy efficiency, thermal comfort, and cost savings.

Installation Process of Polyiso Insulation

The installation process of polyiso insulation may vary depending on the specific application and the building’s requirements. Here is a general overview of the installation process:

- Preparation: Before installing polyiso insulation, it is important to ensure that the area is clean, dry, and free from any debris or obstructions. This may involve removing existing insulation, repairing any damaged surfaces, and ensuring proper ventilation.

- Measurements: Accurate measurements should be taken to determine the required dimensions and thickness of the polyiso insulation panels. These measurements will help in cutting the insulation to the appropriate size for installation.

- Cutting the Insulation: Using a sharp knife or insulation cutting tool, the polyiso insulation panels can be cut to the desired dimensions. It is important to follow the manufacturer’s guidelines and make precise cuts to ensure a proper fit.

- Placement: The cut polyiso insulation panels are then placed in the desired location, such as walls, roof, or floor, ensuring they fit snugly and cover the entire area to be insulated. The panels may be secured using adhesive, mechanical fasteners, or a combination of both.

- Sealing: To ensure maximum insulation effectiveness, all joints, edges, and penetrations should be sealed properly to prevent air leakage and moisture intrusion. This can be done using compatible sealing tapes or sealants recommended by the insulation manufacturer.

- Finishing: Once the polyiso insulation panels are properly installed and sealed, the final step is to finish the area as required. This may involve adding a vapor barrier, installing drywall or other finishing materials, and applying the appropriate finishes or coatings.

It is important to note that the installation of polyiso insulation should be done in accordance with local building codes and regulations. Hiring a professional insulation contractor is highly recommended for complex installations or for those with limited experience in insulation installation.

Additionally, it is crucial to follow the manufacturer’s recommendations and guidelines specific to the polyiso insulation product being used. This will ensure proper installation techniques and maximize the insulation’s thermal performance.

Regular inspection of the installed polyiso insulation is also recommended to ensure it remains intact and in good condition. Any damage, such as tears, gaps, or water infiltration, should be addressed promptly to maintain the insulation’s effectiveness.

By following these installation procedures and guidelines, polyiso insulation can provide optimal thermal insulation, energy savings, and a comfortable living or working environment.

Maintenance of Polyiso Insulation

Polyiso insulation is known for its durability and long-term performance. However, regular maintenance is still necessary to ensure its effectiveness and prolong its lifespan. Here are some maintenance practices for polyiso insulation:

- Inspect for Damage: Periodically inspect the polyiso insulation for any signs of damage, such as tears, punctures, or compression. Address any issues promptly to prevent further damage and maintain the insulation’s thermal efficiency.

- Monitor Moisture Levels: Keep an eye on moisture levels in the building, as excessive moisture can affect the performance of polyiso insulation. Address any moisture-related issues, such as leaks or condensation, to prevent damage to the insulation and potential mold growth.

- Ensure Proper Ventilation: Proper ventilation is crucial to prevent the accumulation of moisture and maintain the effectiveness of the insulation. Ensure that attics, crawl spaces, and other areas with polyiso insulation have adequate ventilation to allow for proper airflow.

- Seal Gaps and Cracks: Regularly check for any gaps, cracks, or air leaks in the insulation or its surrounding areas. These can compromise the insulation’s thermal performance. Seal any gaps or cracks using compatible sealants or insulation tapes.

- Protect from Mechanical Damage: Take precautions to protect the polyiso insulation from mechanical damage, such as impacts or crushing. Avoid placing heavy objects on top of the insulation or allowing excessive foot traffic in areas where the insulation is installed.

- Remove Debris: Keep the area around the polyiso insulation clean and free from debris. Remove any accumulated dirt, leaves, or other materials that may hinder the performance of the insulation or create a breeding ground for pests.

- Regular HVAC Maintenance: If polyiso insulation is used in HVAC ductwork, proper maintenance of the HVAC system is essential. Regularly clean and service the system to prevent dust buildup, which can affect the airflow and efficiency of the insulation.

- Monitor the Insulation’s Performance: Keep track of the energy usage and indoor comfort in the building. If there are noticeable changes or issues with insulation performance, consider consulting a professional to assess and address any concerns.

It is important to note that maintenance practices may vary depending on the specific installation and environmental conditions. Consulting the manufacturer’s guidelines and recommendations for maintenance is highly recommended to ensure proper care of the polyiso insulation.

By following these maintenance practices, you can help extend the lifespan and maintain the thermal performance of polyiso insulation, ultimately maximizing its energy efficiency benefits and ensuring a comfortable indoor environment.

Conclusion

Polyiso insulation is a remarkable insulation material that offers exceptional thermal performance, energy efficiency, and durability. With its high R-value, polyiso insulation effectively reduces heat transfer, minimizing energy consumption and providing cost savings in residential, commercial, and industrial applications.

The composition of polyiso insulation, consisting of a foam core and protective facers, ensures its long-term effectiveness and resistance to moisture, mold, and other environmental factors. It is a lightweight and easy-to-install insulation option that contributes to the overall comfort and energy efficiency of a building.

Polyiso insulation finds its application in various areas, including roofing, walls, floors, attics, HVAC systems, and refrigeration. Its versatile nature and impressive thermal properties make it an ideal choice for a range of insulation needs.

Maintenance of polyiso insulation is crucial to ensuring its optimal performance and longevity. Regular inspections, monitoring moisture levels, sealing gaps, and protecting it from mechanical damage are essential maintenance practices that can help preserve the insulation’s effectiveness and energy-saving capabilities.

In conclusion, polyiso insulation is a valuable asset for improving energy efficiency, reducing heating and cooling costs, and creating a comfortable indoor environment. Its high R-value, durability, and environmental benefits make it a popular choice among builders, contractors, and homeowners who prioritize energy efficiency and sustainability.

When considering insulation options for your next project or home improvement endeavor, polyiso insulation is certainly worth considering due to its excellent thermal properties, ease of installation, and long-term performance. With polyiso insulation, you can enjoy the benefits of a well-insulated space that provides superior comfort and energy savings for years to come.

Frequently Asked Questions about What Is Polyiso Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Polyiso Insulation”