Articles

What Is Laser Level Plumb Dots Mean

Modified: February 21, 2024

Discover what laser level plumb dots mean in this informative article. Gain valuable insights and expert tips on how to use this technology effectively.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Laser levels have become an essential tool for construction, surveying, and various other industries where accurate measurements and alignments are crucial. These innovative devices use advanced laser technology to project a level line or plumb dot to help professionals achieve precise and level measurements.

In this article, we will delve into the concept of laser level plumb dots and explore their significance in the process of achieving accurate measurements. Whether you are a beginner or an experienced professional, understanding the role of plumb dots in laser levels will help you make the most out of this invaluable tool.

So, let’s dive in and explore the world of laser level plumb dots and how they contribute to achieving level and accurate measurements!

Key Takeaways:

- Laser level plumb dots provide precise vertical alignment, saving time and effort in construction and installation projects. They enhance accuracy, efficiency, and versatility, revolutionizing the way professionals achieve level measurements.

- Consider surface reflectivity, lighting conditions, distance, stability, leveling, occlusion, and eye protection when using laser level plumb dots. Following best practices ensures optimal performance, accurate measurements, and professional-grade results.

Read also: 10 Best Dot Laser Level for 2024

What is a Laser Level?

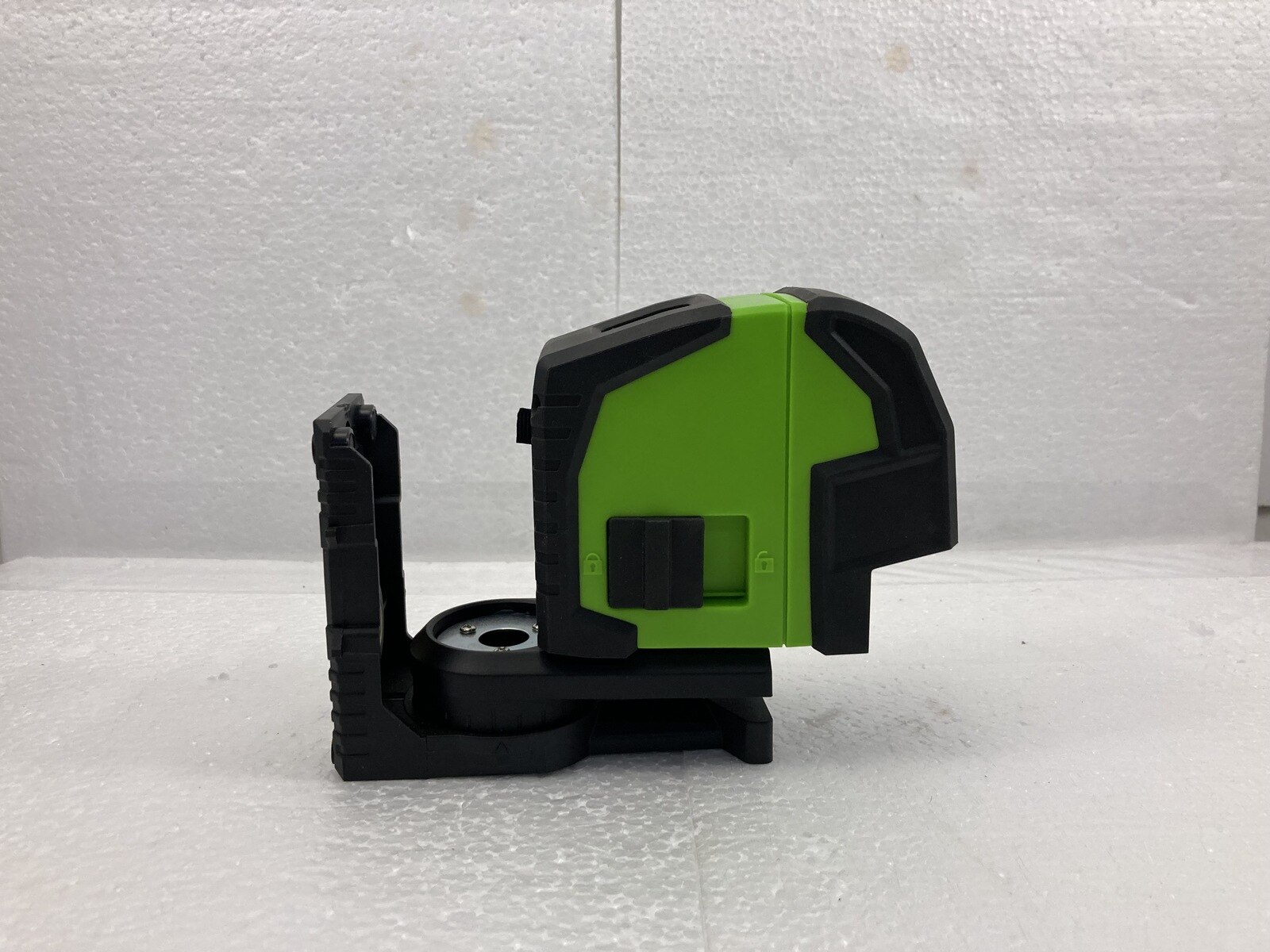

A laser level is a precision instrument used in construction, engineering, and surveying to establish a straight, level, or plumb reference line or point. It utilizes laser technology to project a highly visible beam of light onto a surface, creating a visual reference for alignment and measurement.

Laser levels come in various forms, including rotary laser levels, line laser levels, and dot laser levels. Each type has its own specific use and capabilities, but they all share the common goal of providing accurate and reliable measurements.

Rotary laser levels emit a rotating laser beam that creates a 360-degree horizontal reference plane, allowing for precise leveling of large areas. Line laser levels project a straight line onto a surface, making them ideal for tasks such as aligning tiles or installing cabinets. Dot laser levels, on the other hand, emit multiple dots of laser light to establish plumb or level points.

With their high accuracy and ease of use, laser levels have largely replaced traditional tools such as spirit levels and plumb bobs. They save time and effort, and their versatility makes them indispensable in a wide range of applications.

Most laser levels have adjustable settings to control the visibility and intensity of the laser beam, making them suitable for both indoor and outdoor use. They are often equipped with leveling mechanisms and self-leveling features to ensure precise measurements even if the surface is not perfectly level.

Overall, laser levels have revolutionized the way construction, surveying, and other industries approach measurements and alignments. With their speed, accuracy, and ease of use, laser levels have become an essential tool for professionals seeking to achieve precise and level measurements.

What Are Plumb Dots?

A plumb dot, also known as a vertical dot, is a specific feature found in laser levels that helps establish a vertical reference point or line. While most laser levels project a straight line, plumb dots are used to create a precise vertical reference.

Plumb dots are emitted from the laser level as small, concentrated dots of light. These dots can be projected onto a surface, such as a wall or floor, allowing professionals to determine if a surface is perfectly vertical. Plumb dots are incredibly useful in tasks that require vertical alignment, such as installing cabinets, hanging shelves, or mounting fixtures.

Unlike a plumb bob, which relies on gravity to create a vertical line, plumb dots created by laser levels offer a more precise and convenient solution. By simply projecting the plumb dots onto the surface, professionals can quickly and accurately determine if it is perfectly vertical.

Plumb dots are typically emitted from the laser level alongside other laser projections, such as horizontal lines or rotating beams. This allows users to establish both horizontal and vertical reference points simultaneously, saving time and effort in aligning multiple surfaces.

It’s important to note that not all laser levels have the capability to project plumb dots. Some laser levels are designed specifically for horizontal leveling, while others can project both horizontal lines and plumb dots. Before purchasing or using a laser level, it’s crucial to ensure that it has the necessary features for your specific vertical alignment needs.

Overall, plumb dots are a valuable feature in laser levels that enhance precision and efficiency in vertical alignments. These small dots of light offer a reliable and accurate way to establish a vertical reference, making tasks like cabinet installation or shelf hanging quicker and more precise.

The Significance of Plumb Dots in Laser Levels

Plumb dots play a significant role in laser levels, elevating their usefulness and applicability in a variety of tasks. The ability to establish a precise vertical reference is crucial in many construction, carpentry, and installation projects. Here are a few key reasons why plumb dots are significant in laser levels:

Accurate Vertical Alignment: Plumb dots allow professionals to achieve precise vertical alignment in tasks such as installing doors, windows, or partitions. By projecting a perfectly vertical dot on a surface, laser levels with plumb dots ensure that vertical elements are straight and properly aligned.

Time and Effort Savings: With plumb dots, professionals no longer need to rely on traditional methods like plumb bobs or measuring tools to establish vertical lines. Plumb dots offer a quicker and more convenient solution, saving both time and effort in the alignment process.

Increased Efficiency: By having both horizontal lines and plumb dots in a laser level, professionals can simultaneously align both vertical and horizontal elements. This eliminates the need for multiple tools or adjustments, streamlining the entire alignment process and increasing overall efficiency.

Improved Precision: Plumb dots provide a high level of precision in establishing vertical reference points. The concentrated and focused nature of the dots ensures an accurate representation of a true vertical line. This precision is essential in tasks that require straight and perfectly aligned vertical elements.

Enhanced Versatility: Laser levels with plumb dots offer greater versatility in various applications. Whether it’s hanging artwork, aligning shelves, or mounting light fixtures, the ability to establish vertical lines with plumb dots expands the range of tasks that can be accomplished with a laser level.

Consistent Measurements: Plumb dots help ensure consistent measurements across different surfaces or locations. By referring to the plumb dots, professionals can ensure that various vertical elements in a project maintain a consistent alignment and measurement.

In summary, the significance of plumb dots in laser levels cannot be overstated. Their ability to provide precise vertical alignment, save time and effort, increase efficiency, improve precision, enhance versatility, and maintain consistent measurements makes them an invaluable feature in laser levels. Whether you’re a professional in the construction industry or a DIY enthusiast, a laser level with plumb dots can greatly enhance the accuracy and efficiency of your projects.

When using a laser level with plumb dots, ensure that the dots are perfectly aligned with the vertical reference point to achieve accurate and precise vertical measurements.

How Plumb Dots Help in Achieving Level and Accurate Measurements

Plumb dots, a feature found in laser levels, play a crucial role in achieving level and accurate measurements in various construction, carpentry, and installation projects. Here are some ways in which plumb dots aid in achieving precise and level measurements:

Vertical Alignment: Plumb dots provide a visual indicator of a perfectly vertical line. By projecting a dot onto a surface, professionals can easily determine if it is aligned vertically. This is particularly useful when aligning elements such as cabinets, shelves, or partitions, ensuring that they are plumb and straight.

Elimination of Guesswork: Plumb dots remove the need for manual measurement and estimation when aligning vertical elements. Instead of relying on traditional methods like plumb bobs or measuring tools, professionals can simply project a plumb dot and align the element according to its position relative to the dot. This eliminates the guesswork and ensures accuracy in vertical alignments.

Quick and Convenient Setup: Plumb dots make the setup process faster and more efficient. Unlike traditional methods, which may require multiple steps and adjustments, laser levels with plumb dots can be set up quickly and easily. With the press of a button, the dot is projected, providing an instant reference for vertical alignment.

Increased Precision: Plumb dots offer a high level of precision when establishing vertical references. The laser technology employed in laser levels ensures that the dot is accurately projected onto the surface, minimizing any potential errors that may occur with manual measurement. This precision contributes to achieving level and accurate measurements.

Consistency Across Multiple Locations: Plumb dots enable professionals to maintain consistency in measurements across different surfaces or locations. By referencing the plumb dot, they can ensure that multiple vertical elements in a project are aligned consistently. This is especially important in large-scale projects where uniformity is key.

Accessibility in Various Environments: Laser levels with plumb dots are versatile and can be used in a wide range of environments. Whether indoors or outdoors, plumb dots remain visible and effective in establishing vertical lines. This accessibility allows professionals to achieve level and accurate measurements regardless of the working conditions.

Overall, plumb dots are invaluable in achieving level and accurate measurements. Their ability to provide a clear vertical reference, eliminate guesswork, streamline setup, increase precision, ensure consistency, and adapt to different environments makes them an essential feature in laser levels. Incorporating plumb dots into your workflow will help you achieve professional-grade results and save time and effort in your projects.

Read more: What Is Laser Level

Factors to Consider When Using Laser Level Plumb Dots

When using laser level plumb dots for vertical alignment, there are several important factors to consider to ensure accurate and reliable measurements. Here are some key considerations when using laser level plumb dots:

Surface Reflectivity: The reflectivity of the surface onto which the plumb dot is projected can affect its visibility. Highly reflective surfaces, such as mirrors or polished metals, may cause the dot to appear faint or distorted. It is important to consider the surface reflectivity and make any necessary adjustments to ensure clear visibility of the plumb dot.

Lighting Conditions: Lighting conditions can impact the visibility of plumb dots. In bright or outdoor environments, the laser dot may appear less visible. Conversely, in low-light conditions, the dot may be more difficult to see. Adjusting the laser level’s brightness settings or using additional lighting can help improve visibility in different lighting conditions.

Distance: The distance between the laser level and the surface being measured can affect the accuracy and visibility of the plumb dot. It is important to consider the recommended working distance specified by the manufacturer and position the laser level accordingly to ensure optimal performance.

Stability and Mounting: Securely mounting or stabilizing the laser level is crucial for accurate measurements. Any movement or instability can cause the plumb dot to shift, leading to inaccurate results. Use a tripod or mounting accessories recommended by the manufacturer to ensure the laser level remains stable during use.

Leveling and Calibration: Properly leveling and calibrating the laser level is essential for accurate plumb dot projections. Utilize the built-in leveling mechanisms and follow the manufacturer’s instructions for calibration to ensure precise vertical alignment. Regularly check and recalibrate the laser level as necessary to maintain accurate measurements over time.

Occlusion: Ensure that there are no obstructions blocking the path of the plumb dot. Objects such as furniture, equipment, or walls can disrupt the projection and prevent accurate alignment. Clearing the workspace and ensuring a clear line of sight for the plumb dot will help achieve accurate measurements.

Proper Eye Protection: Laser beams can be harmful to the eyes, so it is crucial to wear appropriate eye protection when using a laser level. Follow the safety guidelines provided by the manufacturer and use safety glasses or goggles to protect your eyes from any potential laser beam exposure.

Manufacturer’s Instructions: Always refer to the manufacturer’s instructions and guidelines specific to your laser level model. Each laser level may have its own unique features and operating instructions. Familiarize yourself with the recommended usage guidelines and safety precautions provided by the manufacturer to ensure proper and accurate use of the plumb dots.

By considering these factors and following best practices, you can maximize the accuracy and reliability of laser level plumb dots during vertical alignments. Taking the time to properly set up and adjust the laser level will result in more precise measurements, saving you time and ensuring professional-grade results.

Conclusion

Laser level plumb dots are a valuable feature that enhances the functionality and accuracy of laser levels in achieving level and accurate measurements. With the ability to establish a vertical reference with precision and convenience, plumb dots have become an essential tool for professionals in various industries, including construction, carpentry, and installation.

By projecting a visible dot onto a surface, plumb dots eliminate the need for manual measurement and estimation when aligning vertical elements. They provide a quick and reliable indication of whether a surface is perfectly vertical, saving time and effort in the alignment process. Plumb dots also offer improved precision, ensuring that measurements are accurate and consistent across different surfaces.

When using laser level plumb dots, it is important to consider factors such as surface reflectivity, lighting conditions, distance, stability, leveling, occlusion, eye protection, and following the manufacturer’s instructions. By taking these factors into account and adopting best practices, professionals can optimize the performance of plumb dots and achieve accurate vertical alignments in their projects.

Overall, laser level plumb dots have revolutionized the way professionals approach vertical alignments, providing enhanced precision, efficiency, and convenience. Whether you are a construction professional, a carpenter, or a DIY enthusiast, incorporating a laser level with plumb dots into your toolset will greatly improve the quality and accuracy of your measurements.

As technology continues to advance, it is likely that laser levels will become even more sophisticated, offering additional features and capabilities. But one thing is clear: laser level plumb dots will remain a fundamental element in achieving level and accurate measurements, enabling professionals to work with precision and confidence.

Frequently Asked Questions about What Is Laser Level Plumb Dots Mean

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Laser Level Plumb Dots Mean”