Articles

What Is Low E Insulation

Modified: January 8, 2024

Discover the benefits of low-E insulation in our informative articles. Lower your energy bills and increase comfort with this energy-efficient solution.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to creating energy-efficient homes and buildings, one crucial aspect to consider is insulation. Insulation plays a vital role in reducing heat transfer, thereby keeping indoor spaces comfortable and energy costs lower. Among the various types of insulation available, one that has gained significant attention is Low E insulation.

Low E insulation, also known as low emissivity insulation, is a high-performance material designed to minimize heat flow through walls, roofs, and other surfaces. It utilizes advanced technology to reflect heat radiation, preventing it from entering or escaping a building. This innovative insulation solution has revolutionized the construction industry and is becoming increasingly popular for both residential and commercial applications.

Key Takeaways:

- Low E insulation reflects radiant heat, reducing energy costs and maintaining comfortable indoor temperatures. Its versatility and durability make it a valuable investment for energy-efficient buildings.

- Low E insulation offers benefits such as UV protection, moisture prevention, and reduced reliance on HVAC systems. Its long-term energy savings outweigh the initial investment, making it a practical choice for sustainable living.

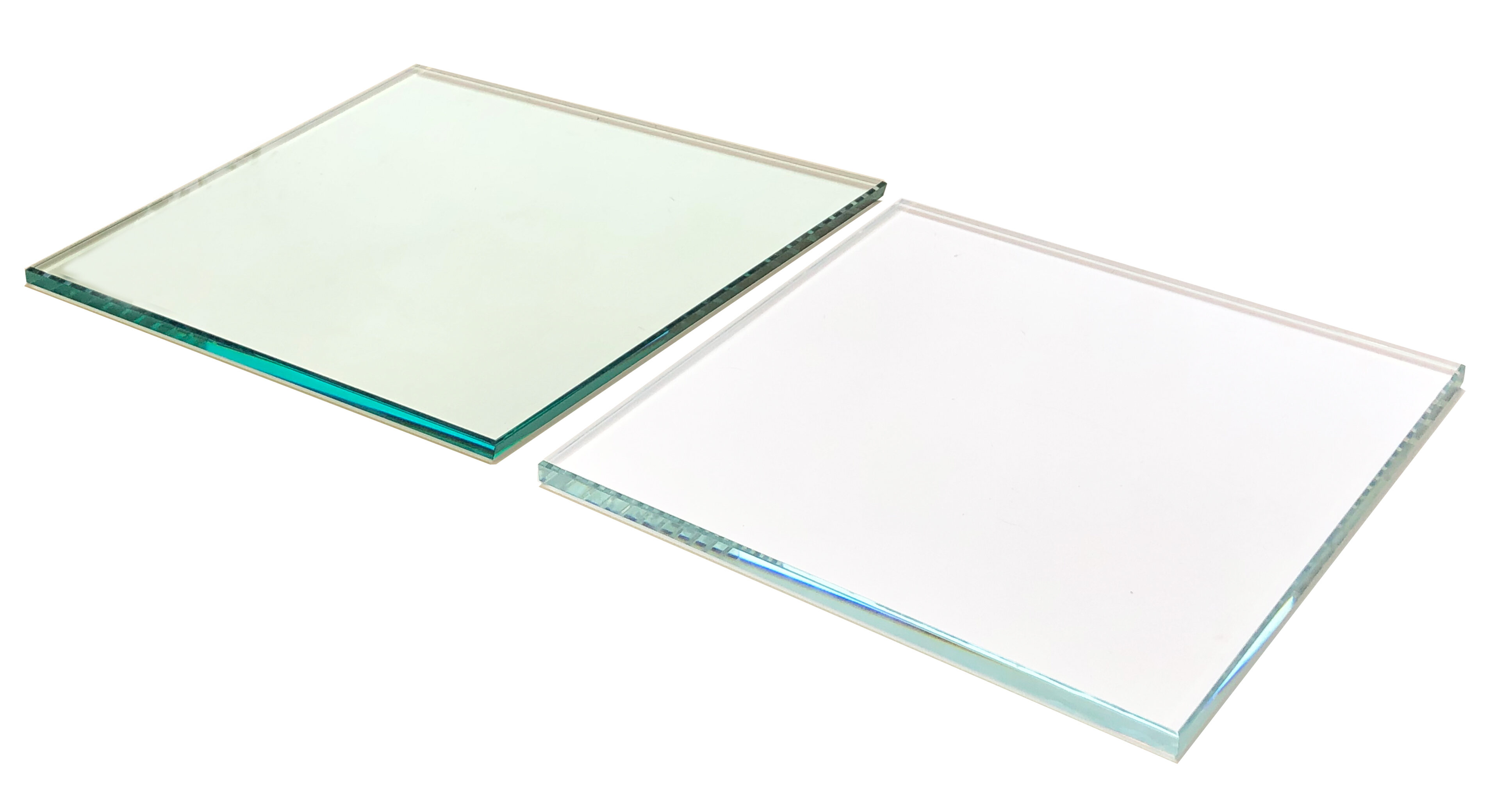

Read more: What Is Low-E Glass

Definition of Low E Insulation

Low E insulation refers to a type of insulation material that incorporates low emissivity technology to reduce the transfer of heat by thermal radiation. The term “E” in Low E stands for emissivity, which is a measure of an object’s ability to emit or absorb radiant energy. The lower the emissivity value, the better the insulation’s ability to reflect heat.

Low E insulation typically consists of a thin metallic coating, typically made of aluminum or silver, applied to one or both sides of a flexible insulating material such as foam or fiberglass. This metallic coating acts as a barrier against radiant heat, reflecting it back to its source instead of allowing it to pass through the insulation. This results in improved energy efficiency and reduced heat loss or gain.

What sets Low E insulation apart from other types of insulation is its ability to block heat transfer via radiation. Unlike traditional insulation materials, such as fiberglass or cellulose, which primarily resist heat conduction, Low E insulation offers an additional layer of protection against radiant heat.

By reducing the amount of radiant heat that can penetrate a building, Low E insulation helps maintain stable indoor temperatures, reduces reliance on heating and cooling systems, and lowers energy consumption. This not only reduces utility costs but also contributes to a more sustainable and eco-friendly living or working environment.

How Low E Insulation Works

Low E insulation works by utilizing the principles of thermal radiation and reflection. The thin metallic coating on the insulation’s surface acts as a reflective barrier that helps to block radiant heat transfer.

Thermal radiation occurs when heat energy is emitted in the form of electromagnetic waves. When the sun or any other heat source radiates energy towards a building, Low E insulation reflects a significant portion of that energy back, preventing it from entering the structure and keeping the interior cool.

Similarly, when heat is generated inside a building, Low E insulation reflects the radiant heat back into the building, helping to maintain a comfortable temperature and reduce the need for excessive heating or cooling.

This technology is particularly effective in reducing heat gain during hot summer months and minimizing heat loss during colder seasons. By reducing the reliance on HVAC systems, Low E insulation contributes to energy conservation and cost savings.

It is worth noting that while Low E insulation is highly efficient in blocking radiant heat transfer, it does not provide significant insulation against conductive heat transfer. For optimal insulation performance, it is often used in combination with other types of insulation, such as foam or fiberglass, to create a comprehensive insulating envelope.

In summary, Low E insulation works by reflecting thermal radiation, thereby reducing heat transfer in and out of a building. Its ability to reflect and block radiant heat makes it an excellent choice for enhancing energy efficiency and maintaining comfortable indoor environments.

Benefits of Low E Insulation

Low E insulation offers a wide range of benefits, making it an ideal choice for enhancing energy efficiency and improving comfort in residential and commercial buildings. Here are some of the key advantages of using Low E insulation:

- Energy Efficiency: Low E insulation significantly reduces heat transfer through thermal radiation, resulting in reduced reliance on heating and cooling systems. This leads to lower energy consumption and decreased utility bills.

- Improved Comfort: By reflecting radiant heat, Low E insulation helps maintain consistent indoor temperatures, preventing hotspots and cold drafts. This results in more comfortable living and working environments.

- Increased Sustainability: The energy-saving properties of Low E insulation contribute to a reduced carbon footprint. By using less energy for temperature control, buildings with Low E insulation can help mitigate greenhouse gas emissions.

- No Condensation: The reflective surface of Low E insulation helps to prevent condensation buildup on walls and windows, reducing the risk of mold and mildew growth and improving indoor air quality.

- UV Protection: Low E insulation also offers UV protection, preventing harmful ultraviolet rays from penetrating through windows and causing fading or damage to furniture, flooring, and other interior elements.

- Durable and Long-Lasting: Low E insulation is designed to be durable and resistant to wear and tear. It does not degrade over time, ensuring long-lasting performance and minimal maintenance requirements.

These benefits make Low E insulation a valuable investment for both new construction projects and retrofitting existing buildings. By improving energy efficiency, comfort, and sustainability, Low E insulation helps create healthier and more environmentally friendly living and working spaces.

Common Applications of Low E Insulation

Low E insulation is versatile and can be used in various applications to enhance energy efficiency and thermal comfort in buildings. Here are some of the common applications of Low E insulation:

- Exterior Walls: Low E insulation can be installed in exterior walls to reduce heat gain in the summer and heat loss in the winter. It helps maintain a consistent indoor temperature and reduces the load on HVAC systems.

- Roofing: Roofing is one of the major areas where heat gain and loss occur. By incorporating Low E insulation in the roofing system, it reflects radiant heat, preventing it from entering the building and ensuring better insulation performance.

- Attics and Loft Spaces: Insulating attics and loft spaces with Low E insulation helps to maintain a comfortable temperature within the living areas below. It prevents excessive heat buildup in summer and minimizes heat loss during colder months.

- Windows and Doors: Low E insulation can be applied as a coating on windows and glass doors. This helps to block heat transfer through windows, reducing heat gain in the summer and heat loss in the winter, while still allowing natural light to enter the spaces.

- Basements and Crawl Spaces: Insulating basements and crawl spaces with Low E insulation helps control temperature and moisture, preventing heat loss or gain from the ground. It also helps prevent drafts and moisture-related issues such as mold and mildew growth.

- Pipe and Duct Insulation: Low E insulation can also be used to insulate pipes and ductwork, preventing heat loss or gain during the transportation of hot or cold air or fluids. This improves the efficiency of heating and cooling systems.

These are just a few examples of the common applications of Low E insulation. Its versatility and effectiveness make it a valuable choice for enhancing energy efficiency and thermal performance in a wide range of residential, commercial, and industrial buildings.

Low E insulation, or low emissivity insulation, is designed to reduce heat transfer through windows and walls. It has a thin metallic coating that reflects heat back into the building, making it more energy efficient. Consider using low E insulation to improve the thermal performance of your home or building.

Read more: How Much Is Insulation At Lowes

Cost Considerations for Low E Insulation

When evaluating the cost of Low E insulation for your project, it is important to consider various factors that can influence the overall investment. While Low E insulation may have a higher upfront cost compared to traditional insulation materials, it offers long-term benefits that can outweigh the initial expenses. Here are some cost considerations to keep in mind:

- Material Cost: The cost of Low E insulation materials can vary depending on the thickness, size, and quality of the product. It is essential to compare prices from different suppliers and manufacturers to find the most cost-effective option without compromising on performance.

- Installation Expenses: The cost of installation is an important aspect to consider. If you plan to hire a professional installer, you should factor in their labor charges. However, if you have the necessary skills and experience, you might be able to save money by installing the insulation yourself.

- Energy Savings: While Low E insulation may have a higher upfront cost, it can deliver significant energy savings in the long run. By reducing heat transfer and minimizing reliance on heating and cooling systems, Low E insulation can lead to lower utility bills and potentially offset the initial investment over time.

- Durability and Lifespan: Consider the durability and lifespan of Low E insulation when assessing the cost. High-quality Low E insulation materials are designed to be long-lasting, requiring minimal maintenance and replacement. Investing in a durable product can provide cost savings in the long term.

- Return on Investment (ROI): It is essential to evaluate the ROI of Low E insulation based on energy savings and reduced maintenance costs. Consider the estimated payback period and calculate how long it would take to recoup the initial investment through energy savings.

It is also worth noting that the cost of Low E insulation may vary depending on the size and complexity of the project. Larger buildings or those with unique architectural designs may require more materials, resulting in higher costs. Consulting with insulation experts and obtaining multiple quotes can help you understand the specific cost considerations for your project.

Overall, while Low E insulation may have an initial cost, its long-term benefits in terms of energy savings, comfort, and durability make it a worthwhile investment for enhancing the thermal performance of your building.

Installation Process for Low E Insulation

The installation process for Low E insulation may vary depending on the specific application and the type of insulation material used. However, here is a general overview of the installation process:

- Preparation: Before starting the installation, ensure that the area to be insulated is clean and free of any debris or obstacles. If necessary, remove any existing insulation or damaged materials.

- Measure and Cut: Measure the dimensions of the space where the Low E insulation will be installed. Use these measurements to cut the insulation material to the appropriate size. Take care to ensure precise and accurate cuts.

- Secure the Insulation: Carefully position the Low E insulation in the desired location, making sure it covers the entire surface area. Use adhesive or mechanical fasteners, depending on the specific requirements of the insulation material, to secure it in place, ensuring a tight and secure fit.

- Seal Gaps and Joints: Pay attention to sealing any gaps or joints in the insulation. This can be done using appropriate sealant or tape to ensure that there are no areas where heat or air can penetrate through.

- Windows and Doors: If applying Low E insulation to windows or glass doors, follow the manufacturer’s instructions for installation. This may involve applying a special adhesive film or coating to the glass surface. Ensure proper alignment and smooth out any air bubbles or wrinkles.

- Finishing Touches: Once the insulation is securely in place, check for any areas that may need additional insulation or sealing. Trim any excess material if necessary. Double-check that all seams are properly sealed to maximize the insulation’s effectiveness.

It is worth noting that the installation process may require different techniques and considerations depending on the specific application and building requirements. It is recommended to consult with insulation professionals or follow the manufacturer’s guidelines to ensure proper and effective installation.

Additionally, if you are unsure about the installation process or if the project involves complex or large-scale insulation, it is advisable to seek the assistance of experienced insulation contractors who have the expertise and equipment to handle the job.

By following proper installation procedures, you can ensure that Low E insulation provides optimal thermal performance and energy efficiency for your building.

Maintenance and Care of Low E Insulation

Maintaining and caring for Low E insulation is essential to ensure its long-lasting performance and energy efficiency. Here are some important tips for maintaining and caring for Low E insulation:

- Inspect Regularly: Regularly inspect the Low E insulation for any signs of damage, such as tears, punctures, or gaps. Pay special attention to areas with potential for moisture buildup, such as basements or crawl spaces.

- Address Moisture Issues: Moisture can compromise the effectiveness of Low E insulation. If you notice any signs of moisture, such as condensation or leaks, identify and address the source of the moisture promptly. Repair any plumbing leaks or improve ventilation to prevent moisture-related damage.

- Keep it Clean: Keep the Low E insulation surface clean by gently dusting or wiping off any dirt or debris. This helps maintain its reflective surface and prevents any substances from compromising its performance. Avoid using abrasive cleaners or harsh chemicals that can damage the insulation material.

- Seal Cracks and Gaps: Regularly inspect the insulation for any cracks, gaps, or joints that may have developed over time. These areas can allow air infiltration and reduce the effectiveness of the insulation. Seal these gaps using appropriate sealant or tape to ensure a tight and continuous barrier.

- Protect from Physical Damage: Take precautions to protect the Low E insulation from physical damage. Avoid placing heavy objects on the insulation surface and be mindful of activities that may cause impact or abrasion. Proper care can help maintain the integrity and performance of the insulation material.

- Consult Professionals: If you notice any significant issues or concerns with the Low E insulation, it is advisable to consult insulation professionals. They can provide expert advice, inspect the insulation, and offer solutions to address any problems effectively.

Regular maintenance and care of the Low E insulation can extend its lifespan and ensure optimal thermal performance. By taking proactive measures to protect and maintain the insulation, you can continue to reap the energy-saving benefits and enjoy a comfortable indoor environment.

Conclusion

Low E insulation is a highly effective and innovative solution for improving energy efficiency and thermal comfort in buildings. Through its ability to reflect radiant heat, Low E insulation reduces heat transfer, resulting in lower energy consumption and a more comfortable living or working environment.

By incorporating Low E insulation in various applications, such as walls, roofs, windows, and doors, buildings can experience significant energy savings, reduced utility bills, and improved sustainability. The insulation’s durability and long lifespan make it a worthwhile investment that can provide long-term benefits.

While Low E insulation may have a higher upfront cost compared to traditional insulation materials, its exceptional performance and energy-saving potential make it a practical choice. The initial investment can be offset over time through reduced energy costs and improved thermal performance.

Proper installation, regular maintenance, and care are crucial in maximizing the effectiveness of Low E insulation. Monitoring for any damage, addressing moisture issues, keeping the insulation clean, and sealing gaps are important steps to ensure peak performance and longevity.

When considering insulation options for your home or building, Low E insulation stands out as an excellent choice. Its ability to block and reflect radiant heat, coupled with its energy-saving and comfort-enhancing properties, make it an investment that pays off in the long run.

In conclusion, Low E insulation offers numerous benefits, including energy efficiency, improved comfort, reduced carbon footprint, and long-lasting performance. By choosing this innovative insulation solution, you can create a more sustainable, cost-effective, and comfortable living or working space.

Frequently Asked Questions about What Is Low E Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Low E Insulation”