Articles

What Is Vrv System In HVAC

Modified: March 1, 2024

Learn all about VRV systems in HVAC with our informative articles. Get insights, tips, and advice on installation, maintenance, and more.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to HVAC systems, there are a variety of options available for controlling the temperature and improving indoor air quality. One such option gaining popularity in the industry is the Variable Refrigerant Volume (VRV) system.

The VRV system is a cutting-edge technology that provides flexible and efficient heating, ventilation, and air conditioning solutions. It offers precise temperature control, energy efficiency, and individual zone comfort. This article will delve into the details of the VRV system in HVAC, its functioning, benefits, drawbacks, applications, cost considerations, and maintenance.

Understanding what the VRV system is and how it works is key to appreciating its advantages. So, let’s dive into the world of VRV systems in HVAC!

Key Takeaways:

- VRV systems in HVAC offer precise temperature control, energy efficiency, and individualized comfort for residential, commercial, and industrial applications. Their advanced technology revolutionizes indoor climate management, despite initial installation costs.

- Regular maintenance and upkeep are crucial for the optimal performance and longevity of VRV systems. Proper cleaning, professional inspections, and user training ensure efficient operation, making VRV systems a reliable and sustainable HVAC choice.

Read more: What Is A Whip HVAC

Definition of VRV System in HVAC

The Variable Refrigerant Volume (VRV) system is a sophisticated and advanced technology used in HVAC systems that allows for variable refrigerant flow and precise temperature control. Also known as Variable Refrigerant Flow (VRF) systems, VRV systems are designed to provide individualized comfort for different zones or spaces within a building, allowing for customized temperature settings.

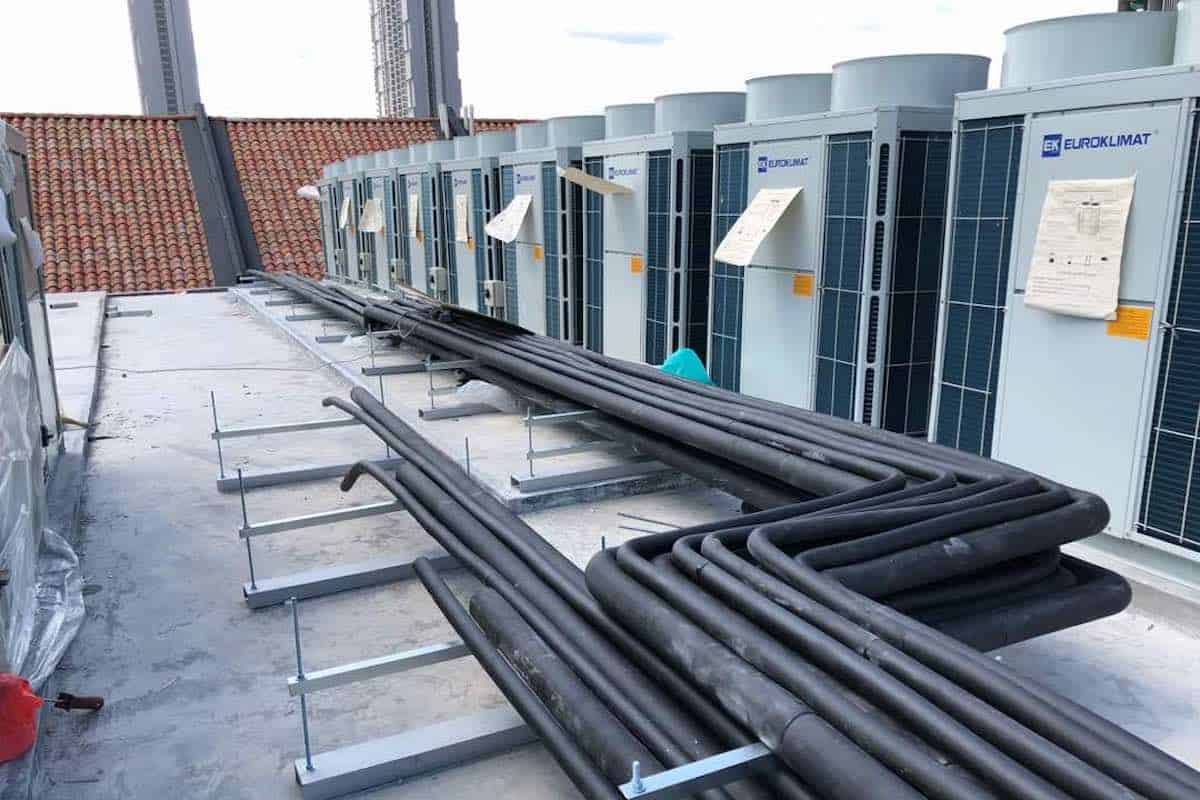

The VRV system operates by utilizing a single outdoor unit that connects to multiple indoor units. The outdoor unit contains a variable-speed compressor and refrigerant control valves that adjust the refrigerant flow based on the load requirements of each indoor unit. This flexible refrigerant flow allows for simultaneous heating and cooling in different zones of the building.

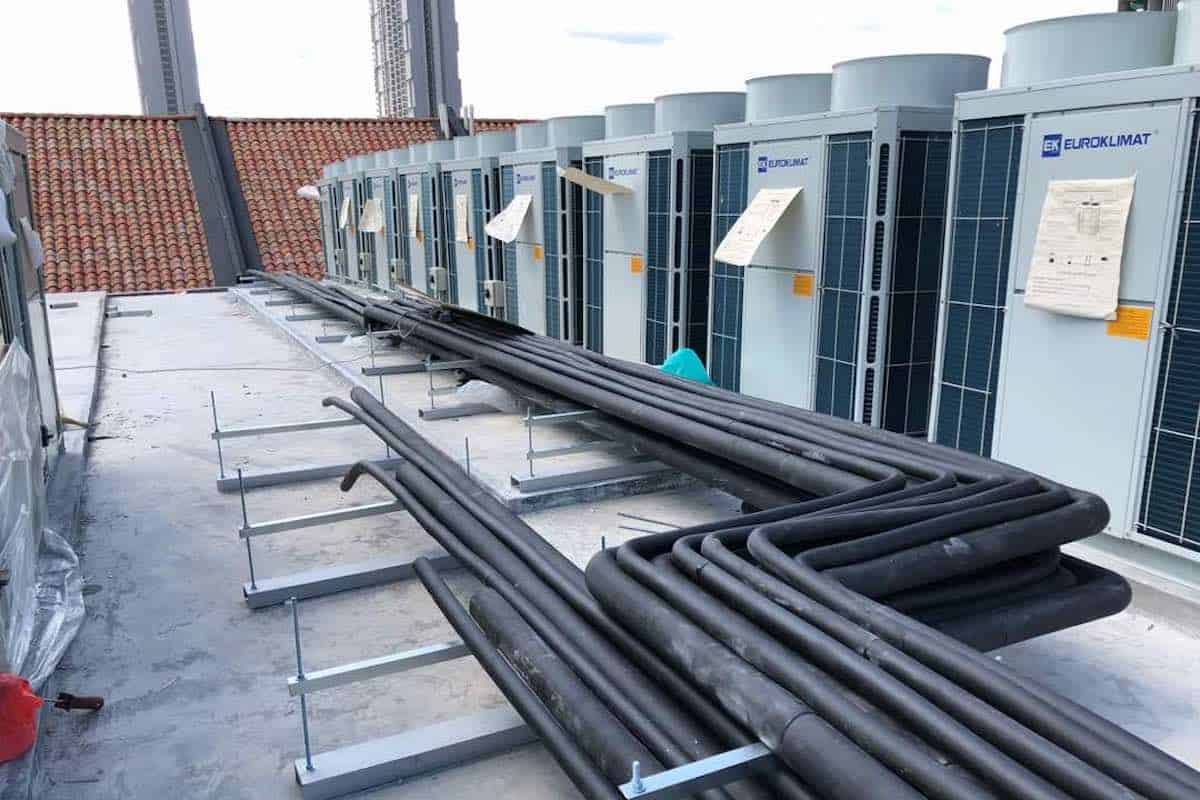

The indoor units of a VRV system come in various forms, including ceiling-mounted cassettes, wall-mounted units, ducted units, and floor-standing units. Each indoor unit is equipped with its own thermostat, allowing occupants to independently control the temperature in their respective zones.

What sets the VRV system apart from traditional HVAC systems is its ability to modulate the refrigerant volume based on the varying heating or cooling demands of different zones. This results in energy savings and increased efficiency, as the system only delivers the necessary amount of refrigerant to each indoor unit, avoiding unnecessary energy consumption.

Furthermore, the VRV system offers a heat recovery capability. This means that while one indoor unit may require cooling, another indoor unit in a different zone may require heating. The system can transfer excess heat from the cooling zone to the heating zone, eliminating the need for additional energy consumption.

Overall, the VRV system provides precise temperature control, individual comfort settings, and energy-efficient operation, making it a popular choice for both commercial and residential applications.

How VRV Systems Work

The VRV system operates using a combination of advanced refrigerant flow control technology and individual zone control. Here’s a breakdown of how VRV systems work:

- Outdoor Unit: The VRV system starts with a single outdoor unit that houses the compressor and controls the refrigerant flow. The outdoor unit is responsible for taking in the outside air, modifying its temperature using the compressor, and supplying it to the indoor units.

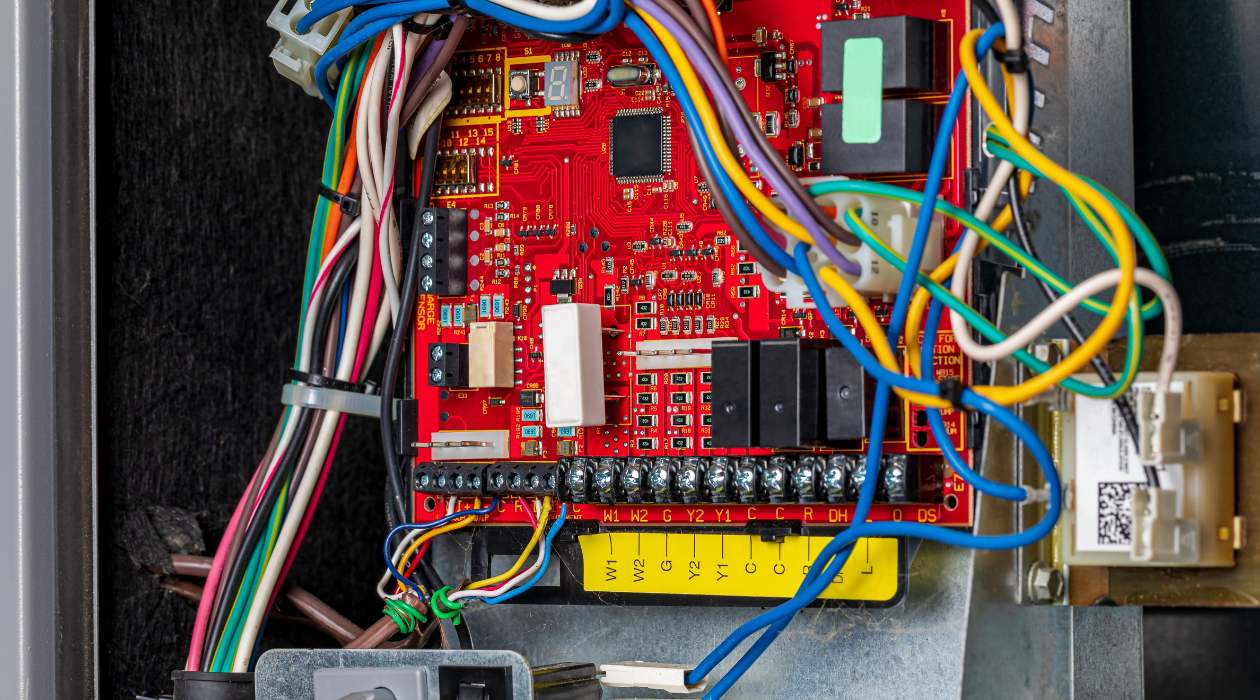

- Refrigerant Flow Control: The VRV system utilizes advanced refrigerant flow control to optimize energy efficiency. It adjusts the refrigerant flow based on the heating or cooling demands of each zone. The variable-speed compressor allows for different capacities of refrigerant flow, ensuring precise temperature control.

- Multiple Indoor Units: The VRV system connects to multiple indoor units installed in different zones or rooms within the building. These indoor units can be in the form of ceiling cassettes, wall-mounted units, ducted units, or floor-standing units. Each indoor unit has its own fan and heat exchanger.

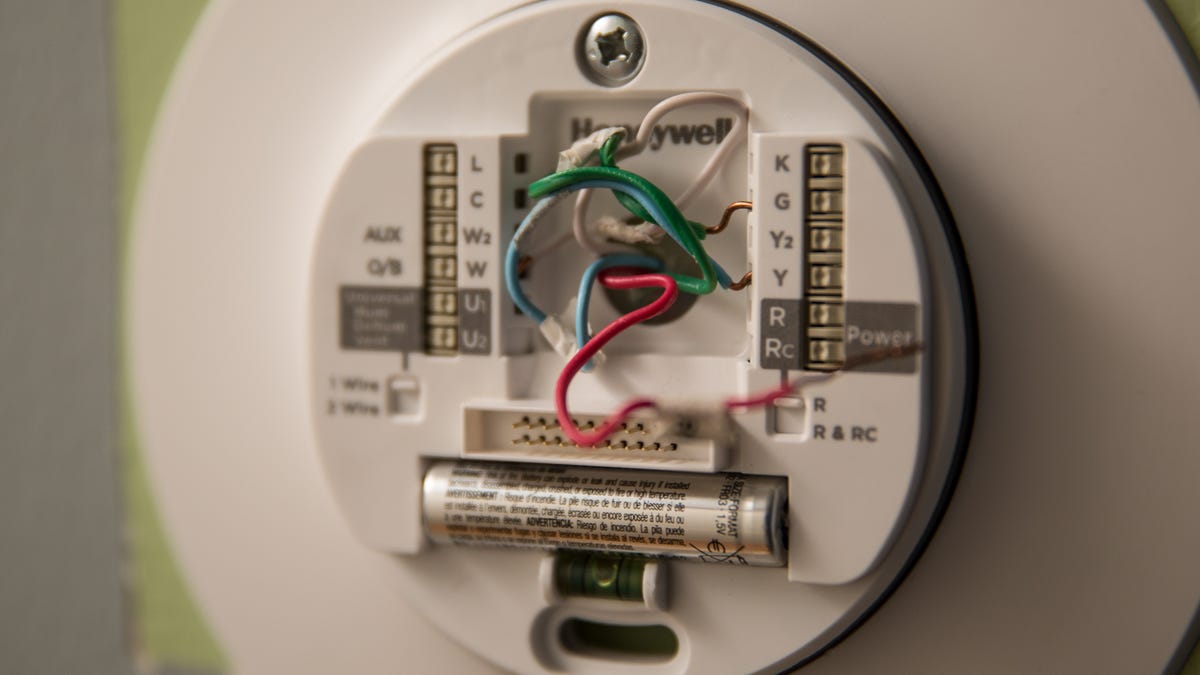

- Zone Control: One of the key features of the VRV system is its ability to provide individual zone control. Each indoor unit is equipped with its own thermostat, allowing occupants to set their desired temperature independently. This ensures personalized comfort and energy savings as individual zones are only conditioned when needed.

- Heat Recovery: The VRV system offers a heat recovery capability, allowing for simultaneous heating and cooling within different zones. When one zone requires cooling and another requires heating, the system can transfer excess heat from the cooling zone to the heating zone. This heat recovery process eliminates the need for separate heating and cooling systems, resulting in energy efficiency.

- Control System: The VRV system is controlled through a centralized control system. This control system allows for easy management of individual zone settings, monitoring energy consumption, and scheduling operations. Some VRV systems even offer remote control options, enabling users to adjust temperature settings through mobile apps or web interfaces.

By utilizing variable refrigerant flow, individual zone control, and heat recovery capabilities, VRV systems provide precise temperature control, energy efficiency, and customized comfort.

Benefits of VRV Systems in HVAC

The VRV system offers numerous advantages over traditional HVAC systems. Here are some key benefits of incorporating VRV systems in HVAC:

- Precision Temperature Control: VRV systems provide precise temperature control in individual zones or areas within a building. Each indoor unit is equipped with its own thermostat, allowing occupants to set and maintain their preferred temperature. This level of control enhances comfort and satisfaction.

- Energy Efficiency: One of the most notable benefits of VRV systems is their energy efficiency. By employing advanced refrigerant flow control and heat recovery technology, the system optimizes energy usage. The variable-speed compressor adjusts the refrigerant flow based on the specific heating or cooling needs of each zone. This ensures that only the necessary amount of energy is consumed, resulting in reduced energy bills and environmental impact.

- Flexibility in Zoning: VRV systems provide flexibility in zoning. Each indoor unit can be independently controlled, allowing for different temperature settings in various zones or rooms. This flexibility is particularly advantageous in commercial buildings where different areas may have distinct cooling or heating requirements.

- Quiet Operation: VRV systems operate quietly, enhancing the overall comfort and tranquility of the space. The outdoor unit, which contains the compressor, is designed to minimize noise. Additionally, the indoor units are equipped with noise-absorbing materials, ensuring a peaceful environment.

- Space-Saving Design: VRV systems have a compact and space-saving design. The use of a single outdoor unit for multiple indoor units reduces the need for bulky equipment, freeing up valuable space in both residential and commercial settings.

- Improved HVAC Control and Integration: VRV systems can be integrated with other HVAC control systems, allowing for centralized management and control. This integration simplifies operations, enables energy monitoring, and facilitates automation for enhanced efficiency.

- Reduced Maintenance Needs: VRV systems generally require less maintenance compared to traditional HVAC systems. The use of advanced technology and durable components results in fewer breakdowns and repairs, reducing long-term maintenance costs.

- Long Lifespan: VRV systems are built to last, with an average lifespan of 15 to 20 years. This longevity ensures a reliable and cost-effective HVAC solution for both residential and commercial applications.

Overall, the benefits of VRV systems in HVAC include precise temperature control, energy efficiency, flexible zoning, quiet operation, space-saving design, improved HVAC control, reduced maintenance needs, and a long lifespan. These advantages make VRV systems an increasingly popular choice for those seeking optimal comfort and sustainability in their indoor environments.

Drawbacks of VRV Systems in HVAC

While VRV systems offer many benefits, it’s important to consider their drawbacks as well. Here are some of the potential limitations of VRV systems in HVAC:

- Initial Installation Cost: VRV systems tend to have higher upfront costs compared to traditional HVAC systems. The complexity of the technology, the need for multiple indoor units, and the advanced refrigerant flow control contribute to the higher installation expenses. However, it’s important to consider the long-term energy savings and operational efficiency that can offset these initial costs.

- System Complexity: VRV systems are more complex compared to traditional HVAC systems. Their intricate design and advanced features require professional expertise for installation and maintenance. This can result in higher service costs and the need for specialized technicians.

- Refrigerant Leak Risk: Since VRV systems rely heavily on refrigerant flow, there is a possibility of refrigerant leaks. These leaks can affect the system’s performance, energy efficiency, and environmental impact. Regular maintenance and proper installation can help mitigate this risk.

- Limitations in Extreme Climates: VRV systems may struggle to maintain optimal performance in extreme climates. In extremely hot or cold environments, the system may experience limitations in reaching the desired temperature levels in all zones. Special considerations and additional equipment may be required to overcome these challenges.

- Reliance on Electricity: VRV systems rely on electricity to power the compressor and other components. This means that if there is a power outage, the system will not be able to operate, resulting in a temporary loss of heating or cooling. An alternative power backup or generator may be needed to ensure continuous operation during power disruptions.

- Compatibility and Integration: Integrating VRV systems with existing HVAC systems or building automation systems might pose compatibility challenges. Proper planning and coordination with experienced professionals are essential to ensure seamless integration and optimal performance.

- Limited Availability of Qualified Technicians: Due to the relatively new technology and complexity of VRV systems, finding qualified technicians for installation, maintenance, and repair can be a challenge in some areas. It’s important to work with certified professionals who have experience with VRV systems to ensure reliable service and support.

While these drawbacks should be considered, it’s important to note that with proper planning, installation, and maintenance, many of these limitations can be effectively managed. The benefits of VRV systems often outweigh the drawbacks, making them a viable option for efficient and customized HVAC solutions.

A VRF (Variable Refrigerant Flow) system in HVAC is a type of heating and cooling system that uses refrigerant as the cooling and heating medium. It allows for individual control of the temperature in different zones, making it energy efficient and flexible for various building types.

Read more: What Is A VFD In HVAC

Applications and Uses of VRV Systems in HVAC

VRV systems in HVAC have a wide range of applications and are suitable for various residential, commercial, and industrial settings. Here are some common applications and uses of VRV systems:

- Residential Buildings: VRV systems are increasingly popular in residential buildings, including single-family homes, apartments, and condominiums. They provide individualized comfort control for different rooms or zones, allowing residents to set their preferred temperature settings and optimize energy usage.

- Commercial Buildings: VRV systems are well-suited for commercial applications, including office buildings, hotels, restaurants, retail stores, and educational institutions. These systems offer flexibility in zoning and temperature control, allowing different areas within a building to have their own climate settings based on occupancy and usage requirements.

- Hospitals and Healthcare Facilities: VRV systems are ideal for healthcare facilities due to their precision temperature control and individual zone capabilities. These systems ensure comfortable and healthy environments for patients, staff, and visitors, while also providing energy-efficient solutions for medical facilities.

- Data Centers: Data centers require precise temperature and humidity control to ensure optimal equipment performance and prevent damage. VRV systems are capable of delivering precise cooling to different areas within a data center, offering efficient and reliable environmental control.

- Hotels and Hospitality: VRV systems provide customized comfort for hotel rooms, lobbies, and other public areas. Individual temperature control in each room ensures guest satisfaction, while the energy efficiency of VRV systems contributes to cost savings for hotel owners.

- Retail and Commercial Spaces: VRV systems are a great choice for retail stores, shopping centers, and commercial spaces. These systems allow for different comfort settings in individual shops or units, helping create a pleasant shopping experience for customers.

- Industrial Facilities: VRV systems can be used in specific areas or zones within industrial facilities to provide cooling or heating requirements for equipment or processes. These systems offer precise control and energy efficiency, making them suitable for diverse industrial applications.

- Multi-Zone Buildings: Buildings with different occupancy patterns, such as multi-tenant residential or mixed-use buildings, can benefit from VRV systems. These systems allow for independent temperature control in each unit or zone, accommodating varying preferences and schedules.

The versatile nature of VRV systems makes them adaptable to different environments and requirements. They offer tailored comfort, energy efficiency, and precise temperature control, making them an appealing choice for a wide range of applications in the HVAC industry.

Cost Considerations for VRV Systems

When considering the installation of a VRV system, it is important to take into account various cost factors. While VRV systems offer numerous benefits, they typically involve higher upfront costs compared to traditional HVAC systems. Here are some key cost considerations for VRV systems:

- Equipment Cost: The cost of VRV systems can vary depending on factors such as the size of the building, the number of indoor units, and the overall system capacity. VRV systems require an outdoor unit, multiple indoor units, refrigerant piping, and control devices. The cost of these components can vary, so it is essential to obtain accurate quotes from reputable HVAC contractors.

- Installation Expenses: The installation cost of a VRV system can be higher compared to traditional HVAC systems due to the complexity of the technology and the need for specialized expertise. Proper installation is critical to ensure optimal performance and efficiency. It is recommended to work with certified HVAC professionals who have experience with VRV systems to ensure proper installation and avoid any costly mistakes.

- Operating Costs: While VRV systems offer energy savings and increased efficiency, it is important to consider the ongoing operating costs. VRV systems rely on electricity to power the compressor and the indoor units. It may be beneficial to analyze the energy consumption and compare it with projected energy savings to determine the long-term operating costs of the system.

- Maintenance and Repairs: VRV systems generally require less maintenance compared to traditional HVAC systems. However, regular maintenance is still necessary to ensure optimal performance and avoid potential breakdowns. It is recommended to inquire about maintenance contracts or service agreements to budget for the periodic maintenance and potential repairs of the VRV system.

- Return on Investment: When evaluating the cost of a VRV system, it’s essential to consider the potential return on investment (ROI). The energy efficiency and customization capabilities of VRV systems can result in long-term energy savings and improved comfort, potentially offsetting the higher upfront costs over time. Calculating the ROI will help determine the financial viability of investing in a VRV system.

- Financial Incentives: It is worth researching whether any financial incentives, rebates, or grants are available for installing energy-efficient systems like VRV. Many regions offer incentives to encourage the adoption of sustainable and energy-efficient HVAC systems. These incentives can help offset the initial costs and improve the overall cost-effectiveness of the VRV system.

It is important to have a thorough understanding of the cost considerations associated with VRV systems before making a decision. Consulting with HVAC professionals and obtaining multiple quotes will help ensure that all cost factors are properly assessed, and the installation is within the budget while considering the long-term benefits and potential energy savings of the VRV system.

Maintenance and Upkeep of VRV Systems

Proper maintenance and regular upkeep are crucial for the optimal performance and longevity of VRV systems. Here are some important considerations for the maintenance and upkeep of VRV systems:

- Professional Inspections: It is recommended to have regular professional inspections of the VRV system. HVAC technicians with experience in VRV systems should conduct thorough inspections to check for any potential issues, leaks, or malfunctions. Regular inspections help identify and address problems early on, preventing further damage and ensuring efficient operation.

- Cleaning of Filters and Coils: Regular cleaning of filters and coils is essential to maintain the efficiency and airflow of the system. Clogged filters and dirty coils can restrict airflow, reduce energy efficiency, and affect indoor air quality. Cleaning or replacing filters on a regular basis helps ensure proper air filtration and prevents the accumulation of dust and debris on the indoor units.

- Lubrication and Fan Maintenance: The fans and motors in the VRV system should be regularly checked and lubricated as per manufacturer’s recommendations. Proper lubrication reduces friction and extends the life of the components. Cleaning and inspecting the fan blades and ensuring that they are balanced is also important for smooth operation and efficiency.

- Refrigerant Levels and Leaks: Monitoring and maintaining appropriate refrigerant levels in the system is crucial for its performance. Low refrigerant levels can lead to reduced cooling or heating capacity. Regular inspections should be conducted to check for refrigerant leaks, as refrigerant leaks can impact the efficiency and effectiveness of the system. Any leaks should be promptly addressed and repaired by qualified technicians.

- Control System Calibration: The centralized control system of the VRV system should be regularly calibrated to ensure accurate temperature control and proper functioning of the system. Thermostats and sensors should be checked and calibrated as needed to maintain consistent comfort levels throughout the building.

- Condenser Cleaning: The outdoor unit’s condenser coils should be cleaned regularly to remove dirt, debris, and vegetation. A dirty condenser can inhibit heat transfer and reduce the efficiency of the system. A thorough cleaning of the condenser coils helps maintain optimal system performance and energy efficiency.

- Documentation and Record-Keeping: It is important to keep detailed records of maintenance activities, inspections, and repairs of the VRV system. This documentation helps track the system’s performance, identify recurring issues, and ensure proper maintenance schedules are followed.

- Training for Users: Providing training to the building occupants or users on the proper operation and use of the VRV system is essential. Educating users on temperature control settings, maintenance requirements, and efficient use of the system can help optimize its performance and prevent any misuse or unnecessary stress on the equipment.

Regular maintenance, proper cleaning, and timely repairs are vital to the longevity and efficient operation of VRV systems. Following manufacturer’s guidelines and working with experienced HVAC professionals ensures that the VRV system is well-maintained, providing comfort and energy efficiency for years to come.

Conclusion

VRV systems in HVAC have revolutionized the way we control temperature and ensure comfort in various settings. These systems offer precise temperature control, energy efficiency, individual zone comfort, and customized solutions for residential, commercial, and industrial applications.

Throughout this article, we explored the definition and functioning of VRV systems, highlighting their benefits and drawbacks. VRV systems provide precise temperature control with their variable refrigerant flow capabilities, allowing for tailored comfort in different zones or rooms. The heat recovery feature further enhances their efficiency by transferring excess heat from cooling zones to heating zones.

One notable advantage of VRV systems is their energy efficiency. Despite the higher initial costs, VRV systems can result in significant long-term energy savings, reducing both utility bills and environmental impact. Furthermore, VRV systems offer flexibility in zoning, quiet operation, space-saving design, and improved HVAC control.

However, there are also some considerations to keep in mind. VRV systems may have higher installation costs, require specialized expertise for installation and maintenance, and may struggle to operate optimally in extreme climates. Additionally, refrigerant leaks and dependencies on electricity are factors to be aware of when considering a VRV system.

VRV systems have a wide range of applications, from residential buildings and commercial spaces to hospitals, data centers, and industrial facilities. Their versatility and individualized control make them ideal for various settings, providing comfort and energy efficiency to occupants.

Regular maintenance and upkeep are crucial to ensure the optimal performance and longevity of VRV systems. Cleaning filters and coils, conducting professional inspections, and monitoring refrigerant levels are important maintenance activities. Proper documentation, training, and calibration of the control system are also essential for the efficient operation of the system.

In conclusion, VRV systems in HVAC offer advanced technology and benefits that outweigh their drawbacks. These systems provide precise temperature control, energy efficiency, and individual zone comfort, making them a reliable and sustainable choice for optimizing indoor environments.

Frequently Asked Questions about What Is Vrv System In HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Vrv System In HVAC”