Home>Articles>What Size Electrical Wire Do I Need For 220 Volts

Articles

What Size Electrical Wire Do I Need For 220 Volts

Modified: May 6, 2024

Find out the right size electrical wire needed for a 220 volt system. Read our informative articles for expert advice and recommendations.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to setting up electrical circuits, it is crucial to select the right wire size to ensure safety and optimal performance. One common scenario is determining the appropriate wire size for a 220-volt circuit. Whether you are installing a new appliance, such as an electric stove or air conditioner, or making modifications to your existing electrical system, understanding the factors that influence wire size selection is essential.

Choosing the right wire size for a 220-volt circuit is not a one-size-fits-all approach. Several factors need to be considered to determine the appropriate wire size, including voltage requirements, ampacity requirements, wire insulation type, wire length, and voltage drop. By understanding these factors and utilizing a wire gauge chart or calculation method, you can confidently select the most suitable wire size for your specific application.

In this article, we will delve into the factors that come into play when determining the wire size for a 220-volt circuit. We will explore the recommended wire gauge chart, provide a step-by-step calculation method, discuss common wire sizes used for 220V circuits, and offer tips for choosing the right wire size. By the end, you will have a comprehensive understanding of how to determine the appropriate wire size for your 220-volt electrical needs.

Key Takeaways:

- Selecting the right wire size for a 220-volt circuit involves considering voltage requirements, ampacity, insulation type, wire length, and voltage drop to ensure safety and optimal performance.

- Common wire sizes like 14 AWG, 12 AWG, 10 AWG, 8 AWG, and 6 AWG are suitable for various amperage requirements in 220V circuits, but always consult local electrical codes and consider future expansions when choosing the right wire size.

Factors to Consider

When determining the wire size for a 220-volt circuit, there are several important factors to consider. These factors will help ensure that the wire can safely carry the electrical load and meet the specific requirements of your application. Let’s take a closer look at each of these factors:

Voltage requirements

The first factor to consider is the voltage requirements of your electrical circuit. In this case, we are specifically dealing with 220 volts. It is crucial to match the wire size with the voltage requirement to ensure safe and efficient operation of your electrical devices.

Ampacity requirements

Next, you need to determine the ampacity requirements of your circuit. Ampacity refers to the maximum amount of electrical current that a wire can safely carry without overheating. It is crucial to select a wire size that can handle the expected amperage of the circuit to prevent overheating and potential fire hazards.

Wire insulation type

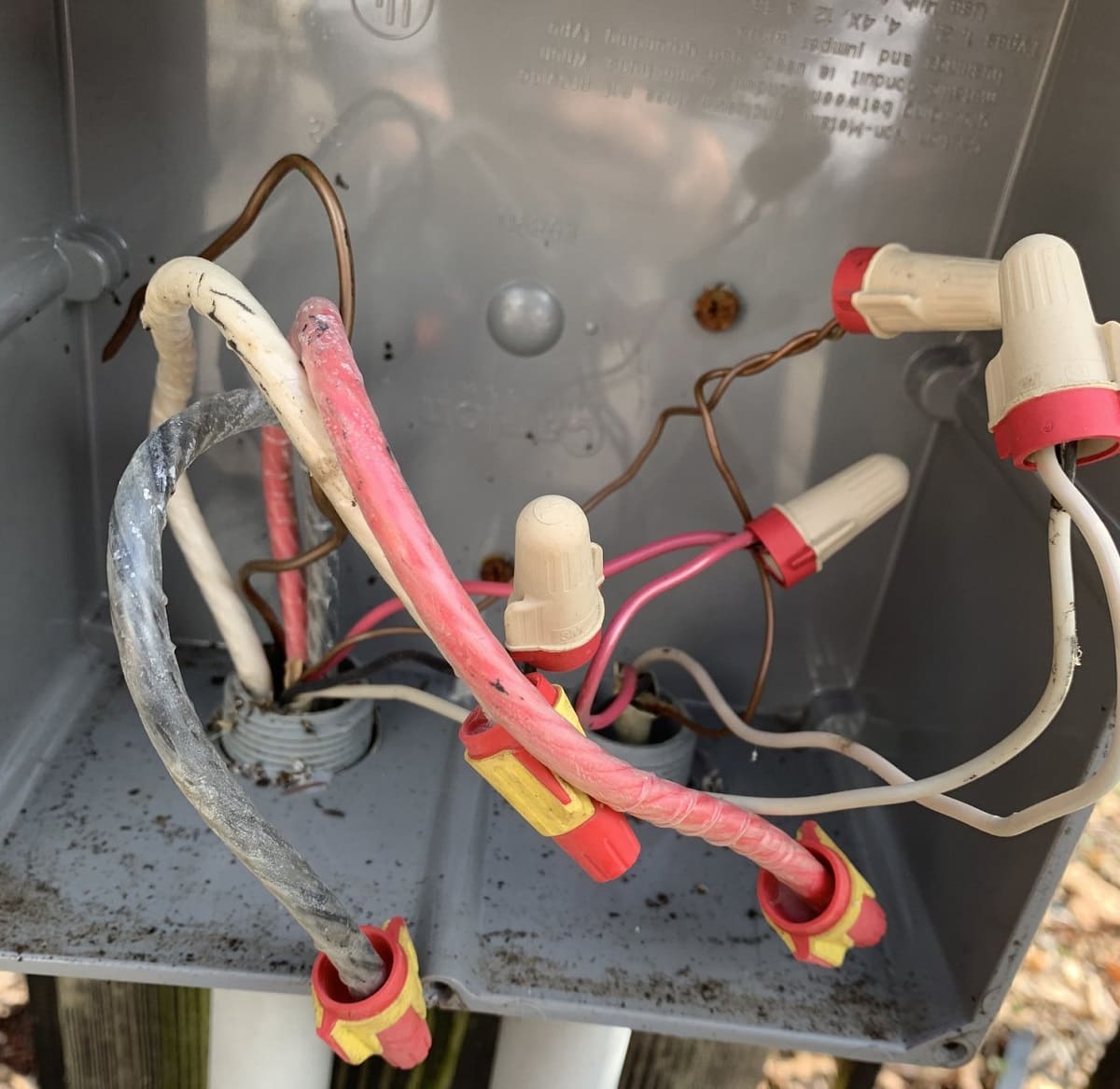

The insulation type of the wire plays an important role in selecting the right wire size. Different applications may require different types of insulation, such as PVC (Polyvinyl Chloride), THHN (Thermoplastic High Heat-Resistant Nylon), or XHHW (Cross-Linked Polyethylene High-Heat Water-Resistant). Each insulation type has its own temperature and moisture resistance properties, which should be considered based on the specific environment and electrical needs of your installation.

Read more: How To Wire A 220 Volt Electric Motor

Wire length

The length of the wire between the power source and the device being powered is another significant factor. As the wire length increases, the resistance of the wire also increases. This resistance can lead to a voltage drop, affecting the performance of the connected devices. It is essential to take into account the distance the wire will need to travel and the associated voltage drop when selecting the wire size.

Voltage drop

Voltage drop is the reduction in voltage that occurs as electrical current flows through a wire. Excessive voltage drop can lead to poor device performance, inefficient operation, and premature failure of electrical components. It is important to consider the acceptable voltage drop for your application and select a wire size that can minimize voltage loss over the specified distance.

By carefully considering these factors, you can ensure that the wire size for your 220-volt circuit meets the specific requirements of your electrical application. Taking the time to properly evaluate these factors will help ensure the safety, efficiency, and longevity of your electrical system.

Wire Gauge Chart

When determining the appropriate wire size for a 220-volt circuit, referring to a wire gauge chart can be incredibly helpful. A wire gauge chart provides a reference for selecting the right wire size based on the amperage requirements of your circuit. Below is a sample wire gauge chart that shows the recommended wire gauge for different amperage levels at 220 volts:

| Amperage | Wire Gauge (AWG) |

|---|---|

| 15A | 14 AWG |

| 20A | 12 AWG |

| 30A | 10 AWG |

| 40A | 8 AWG |

| 50A | 6 AWG |

| 60A | 4 AWG |

| 70A | 2 AWG |

| 80A | 1/0 AWG |

| 90A | 2/0 AWG |

| 100A | 3/0 AWG |

This is just a sample chart, and wire gauge recommendations may vary depending on the specific application and local electrical codes. It is always advisable to consult with a licensed electrician or refer to the National Electrical Code (NEC) for precise wire size requirements.

Using a wire gauge chart as a reference can give you a starting point for selecting the appropriate wire size based on the amperage rating of your circuit. However, it is important to note that other factors, such as wire length and voltage drop, should also be taken into consideration when making your final wire size determination.

By utilizing a wire gauge chart and considering other relevant factors, you can ensure that you are choosing the correct wire size to meet the electrical demands of your 220-volt circuit.

Calculation Method

If you prefer a more precise approach for determining the wire size for your 220-volt circuit, you can use a calculation method. This method takes into account factors such as the amperage, distance, and voltage drop, providing a more customized wire size recommendation. Here is a step-by-step guide to help you calculate the wire size:

- Determine the amperage: Start by identifying the amperage rating of the circuit. This information can typically be found on the device or in the user manual. For example, if you have a circuit rated at 30 amps, note down this value.

- Calculate the voltage drop: Determine the maximum allowable voltage drop for your circuit. This value is typically specified in percentage or volts. For example, if the maximum allowable voltage drop is 3%, multiply the voltage (220 volts) by 3% (0.03) to get the maximum allowable voltage drop (6.6 volts).

- Estimate the wire length: Measure the distance that the wire needs to span from the power source to the device. As a rule of thumb, add an additional 10% to account for any overhead or unforeseen factors. For instance, if the measured distance is 50 feet, add 10% (5 feet) to get a total estimated wire length of 55 feet.

- Use a voltage drop calculator: Use an online voltage drop calculator or consult an electrician to calculate the voltage drop based on the estimated wire length and amperage. This will provide you with an accurate voltage drop value for your specific installation.

- Refer to a wire size table: Using the calculated voltage drop value, refer to a wire size table or chart that provides wire sizes based on ampacity and voltage drop. Select the appropriate wire size that meets or exceeds the calculated voltage drop and ampacity requirements.

- Consider other factors: While the calculated wire size based on the voltage drop is a good starting point, it is crucial to consider other factors, such as wire insulation type and local electrical codes, to ensure compliance and safety. Consult with a licensed electrician if you have any doubts or questions.

By following this step-by-step calculation method, you can determine the most suitable wire size for your specific 220-volt circuit. This customized approach takes into account the amperage, voltage drop, and wire length, ensuring optimal performance and safety for your electrical installation.

Common Wire Sizes for 220V Circuits

When it comes to 220-volt circuits, there are several commonly used wire sizes that are suitable for various applications. These wire sizes are chosen based on factors such as amperage, voltage drop considerations, and specific installation requirements. Here is an overview of some of the common wire sizes used for 220V circuits and their applications:

14 AWG

14 AWG wire is commonly used for circuits with amperage ratings up to 15 amps. It is typically used for smaller appliances such as lighting fixtures and low-power devices. This wire size is sufficient for applications with lower power demands and shorter wire runs.

12 AWG

12 AWG wire is suitable for circuits with amperage ratings up to 20 amps. It is frequently used for general household circuits such as lighting circuits, outlets, and smaller appliances. This wire size offers a balance between affordability and capacity for moderate amperage requirements.

10 AWG

10 AWG wire is commonly used for circuits with amperage ratings up to 30 amps. It is often chosen for larger appliances such as electric dryers, air conditioners, and water heaters. This wire size can handle higher amperage loads and longer wire runs without excessive voltage drop.

Read more: What Size Humidifier Do I Need

8 AWG

8 AWG wire is suitable for circuits with amperage ratings up to 40 amps. It is frequently used for more demanding applications such as electric stoves, hot tubs, and larger air conditioners. This wire size provides a higher ampacity and reduced voltage drop for heavier loads.

6 AWG

6 AWG wire is commonly used for circuits with amperage ratings up to 50 amps. It is often chosen for applications such as subpanels, welders, and electric vehicle chargers. This wire size can handle heavier loads and longer wire runs, making it suitable for larger electrical installations.

4 AWG and larger

For circuits with amperage ratings beyond 50 amps, wire sizes like 4 AWG, 2 AWG, 1/0 AWG, or larger may be necessary. These larger wire sizes are typically used for high-demand applications such as commercial or industrial equipment, large HVAC systems, and power distribution.

It is important to note that these are general guidelines, and specific applications and local electrical codes may vary. Consulting with a licensed electrician or referring to the National Electrical Code (NEC) is recommended for precise wire size requirements.

By considering the amperage requirements of your circuit, the wire length, and other factors such as voltage drop, you can select the appropriate wire size from the common options listed above. Always prioritize safety and compliance when choosing the wire size for your 220-volt circuits.

Choosing the Right Wire Size

When it comes to selecting the appropriate wire size for a 220-volt circuit, there are several tips and considerations to keep in mind. These factors will help ensure the safety, efficiency, and performance of your electrical installation. Here are some tips to guide you in choosing the right wire size:

Read more: What Size Gutters Do I Need

1. Determine the amperage requirements:

Identify the amperage rating of your circuit by referring to the device or appliance specifications. This will help determine the minimum wire size needed to safely carry the electrical load.

2. Consider the wire length:

Take into account the distance between the power source and the device being powered. Longer wire lengths can lead to voltage drop, so you may need to choose a larger wire size to compensate for the distance.

3. Consult local electrical codes:

Check your local electrical codes and regulations to ensure compliance. These codes may specify minimum wire size requirements based on the application and environment.

4. Calculate the voltage drop:

Using an online voltage drop calculator or consulting an electrician, calculate the voltage drop based on the wire length and amperage. Keep in mind the acceptable voltage drop for your specific application. Select a wire size that minimizes voltage drop and provides optimal performance.

Read more: What Size Mixer Do I Need

5. Consider future expansion:

If you anticipate adding additional devices or increasing the electrical load in the future, it is wise to choose a slightly larger wire size to accommodate these future expansions. This will save you from having to replace the wire in the future.

6. Factor in wire insulation type:

Consider the type of wire insulation needed for your specific application. Different insulation types offer varying degrees of temperature and moisture resistance. Choose a wire with insulation suitable for the environment in which it will be installed.

7. Seek professional advice:

If you are unsure about the wire size selection or the specific requirements of your installation, it is always advisable to consult with a licensed electrician. They can provide expert guidance and ensure that you select the appropriate wire size for your 220-volt circuit.

By following these tips and considering the various factors, you can make an informed decision when selecting the right wire size for your 220-volt circuit. Remember, safety should always be the top priority, so it is crucial to adhere to electrical codes and consult professionals when needed.

Conclusion

Choosing the right wire size for a 220-volt circuit is critical to ensure the safety, efficiency, and optimal performance of your electrical installation. By considering factors such as voltage requirements, ampacity, wire insulation type, wire length, and voltage drop, you can make an informed decision when selecting the appropriate wire size.

Wire gauge charts provide a helpful reference for wire size selection based on amperage ratings at 220 volts. These charts serve as a starting point, but it is important to consider other factors such as wire length and voltage drop to ensure accurate sizing. Additionally, using a calculation method can provide a more precise wire size recommendation tailored to your specific installation.

Common wire sizes for 220-volt circuits, such as 14 AWG, 12 AWG, 10 AWG, 8 AWG, and 6 AWG, are commonly used for various applications, depending on the amperage requirements. However, it is crucial to consult local electrical codes to ensure compliance and safety.

When choosing the right wire size, it is essential to consider factors such as the amperage requirements, wire length, voltage drop, future expansions, wire insulation type, and professional advice. By following these tips and considerations, you can make an informed decision and ensure a successful electrical installation.

Remember, electrical work should always be performed by a qualified professional. If you have any doubts or concerns regarding wire size selection or the installation process, consult with a licensed electrician to ensure the job is done correctly and safely.

By understanding the importance of wire size selection and considering the various factors involved, you can confidently choose the right wire size for your 220-volt circuit. This will result in a safe, efficient, and reliable electrical setup for your specific needs.

Excited to tackle more DIY electrical projects? Our next guide walks you through how to safely and efficiently run overhead electrical wiring to your garage. Mastering this skill opens up new possibilities for power distribution in your home without compromising safety or aesthetics. Don't miss out on these practical tips that ensure your garage has the power it needs for tools, lighting, and more.

Frequently Asked Questions about What Size Electrical Wire Do I Need For 220 Volts

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Size Electrical Wire Do I Need For 220 Volts”