Articles

What Size Wire For Dryer

Modified: January 19, 2024

Find the right wire size for your dryer with our informative articles. Learn about the best wire gauge and get tips for a safe and efficient installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Choosing the right size wire for your dryer is crucial for ensuring safe and efficient operation. The wire size directly affects the electrical current capacity and voltage drop, which are crucial considerations when selecting the appropriate wire gauge for your dryer. By understanding the voltage and amperage requirements of your dryer, as well as the factors that influence wire gauge selection, you can make an informed decision and install the correct wire size.

In this article, we will delve into the details of what size wire you should use for your dryer. We will provide you with the necessary information to understand how the voltage and amperage requirements of your dryer impact wire gauge selection. We will also discuss the factors to consider when determining the appropriate wire size and provide guidance on installing the correct wire size for your dryer.

So let’s dive in and explore the world of wiring for dryers!

Key Takeaways:

- Selecting the right wire size for your dryer involves considering voltage, amperage, distance, and insulation. Following electrical codes and guidelines is crucial for safe and compliant installation.

- Proper installation of the correct wire size for your dryer requires turning off power, secure connections, grounding, and testing. When in doubt, consult a licensed electrician for a safe and reliable installation.

Read more: What Size Wire for a Ceiling Fan

Understanding Voltage and Amperage Requirements

Before delving into the process of determining the wire gauge for your dryer, it’s important to understand the concepts of voltage and amperage requirements.

Voltage refers to the electrical potential difference between two points in an electric circuit. In the case of your dryer, the voltage requirement is typically 240 volts. This means that the electrical current flowing through the dryer operates at 240 volts, ensuring efficient performance of the appliance.

Amperage, on the other hand, refers to the amount of electrical current flowing through a circuit. The amperage requirement of your dryer can vary depending on its specific model and manufacturer, but it is typically within the range of 30 to 50 amps. It’s important to note that using a wire with inadequate amperage capacity can result in overheating, potentially leading to electrical hazards.

To ensure proper electrical safety and functionality, the wire you choose for your dryer should meet both the voltage and amperage requirements of the appliance.

In addition to voltage and amperage, it’s also important to consider the distance between the dryer and the electrical panel. The length of the wire can impact the voltage drop, which refers to the decrease in voltage as the current flows through the wire. A greater distance between the dryer and the electrical panel can result in a higher voltage drop. Therefore, the choice of wire gauge should also take into account the distance to minimize voltage drop and optimize energy efficiency.

Now that you have a basic understanding of voltage and amperage requirements, let’s move on to determining the appropriate wire gauge for your dryer.

Determining Wire Gauge for Dryer

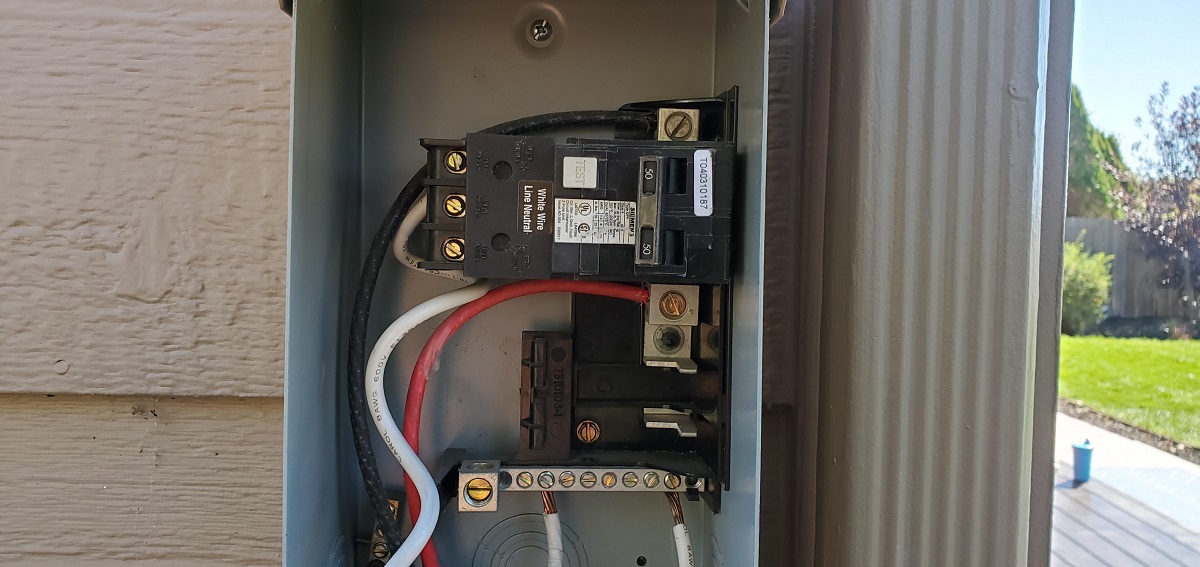

When it comes to determining the wire gauge for your dryer, there are several factors to consider. These factors include the amperage rating of your dryer, the distance between the dryer and the electrical panel, and the specific wire gauge recommendations provided by electrical codes and guidelines.

First and foremost, you need to determine the amperage rating of your dryer. This information can usually be found on the appliance’s label or in the owner’s manual. Once you have the amperage rating, you can use it as a reference point for selecting the appropriate wire gauge.

The amperage rating will help you determine the minimum wire gauge required to safely handle the electrical current of your dryer. For example, if your dryer has an amperage rating of 30 amps, you would need to choose a wire gauge that can handle at least 30 amps without overheating.

The distance between the dryer and the electrical panel also plays a role in determining the wire gauge. As mentioned earlier, a longer distance can result in a higher voltage drop. To compensate for this, it is recommended to use a thicker wire gauge to minimize the voltage drop and ensure the proper functioning of your dryer.

Additionally, it is important to consult the electrical codes and guidelines in your area. These regulations provide specific recommendations and requirements for wire gauge selection based on the amperage rating and distance. Following these guidelines will help ensure electrical safety and code compliance.

There are numerous resources available online and in electrical code books that provide charts and tables for wire gauge selection based on amperage rating and distance. These resources can serve as useful references in determining the appropriate wire gauge for your dryer.

It is worth mentioning that if you are unsure about the wire gauge selection or if you have any doubts about your electrical knowledge, it is always best to consult a licensed electrician. They have the expertise and experience to guide you in selecting the right wire gauge and ensuring a safe electrical installation for your dryer.

Now that you understand the factors involved in determining the wire gauge for your dryer, let’s move on to the practical aspects of installing the correct wire size.

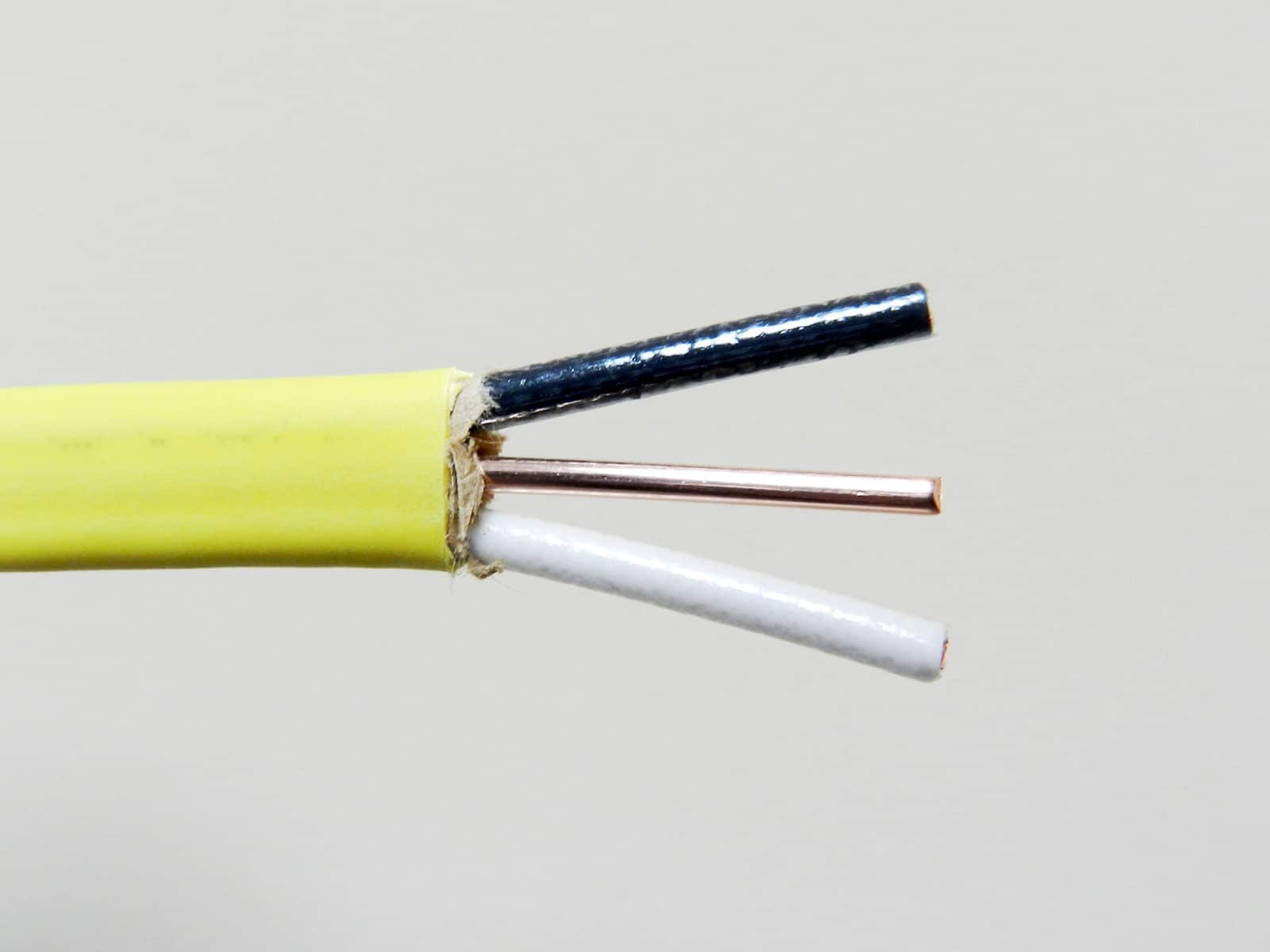

When determining the size of wire for a dryer, it’s important to consider the electrical requirements of the appliance. Typically, a 30-amp circuit requires 10-gauge wire, while a 40-amp circuit requires 8-gauge wire. Always consult the manufacturer’s specifications and local building codes for the correct wire size.

Factors to Consider

When installing the correct wire size for your dryer, there are several factors you should consider to ensure safe and efficient operation. These factors include the wire insulation type, wire material, and the location of the dryer.

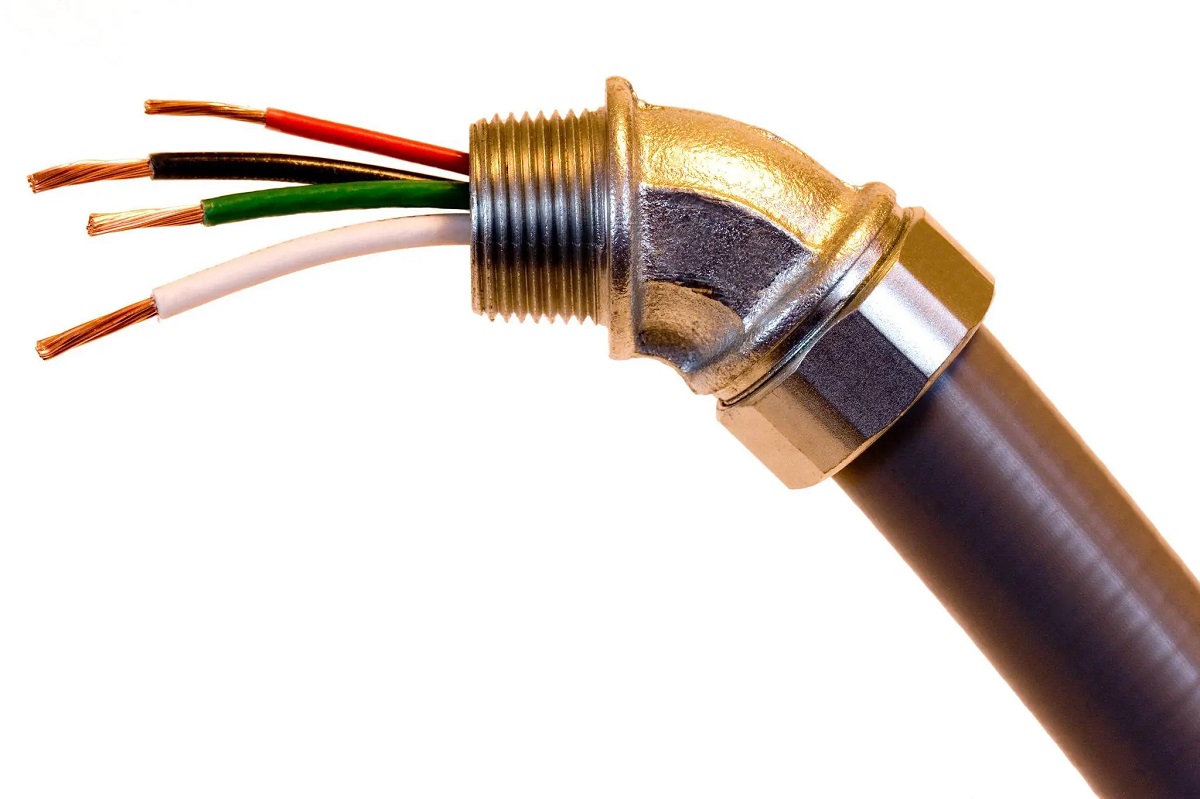

The first factor to consider is the wire insulation type. Dryers require the use of a specific type of wire insulation, typically labeled as “THHN/THWN” or “XHHW.” These insulations are rated for the high temperatures and heavy loads associated with dryer operation. It is important to choose wires with the appropriate insulation rating to ensure they can withstand the heat generated by the dryer without melting or becoming damaged.

Another important factor is the wire material. Copper is the most commonly used material for wiring due to its excellent conductivity and resistance to corrosion. Copper wires are suitable for most residential dryer installations. However, in some cases, aluminum wiring may be used. If you have aluminum wiring, it is crucial to consult with a qualified electrician to ensure that the appropriate wire gauge is used and proper connections are made to prevent any compatibility issues.

The location of the dryer is another factor to consider. If the dryer is located in a damp or wet environment, such as a laundry room or basement, it is important to choose wires with moisture resistance. Wires with moisture-resistant insulation, such as “UF” (Underground Feeder) or “W” (Weather-Resistant) rating, can help prevent damage and ensure safe operation in these conditions.

It is also worth mentioning that the wire size should be chosen to accommodate any foreseeable future modifications or upgrades. If you plan to install a more powerful dryer in the future, it is wise to select a wire gauge that can handle the higher amperage to avoid the need for rewiring later on.

Lastly, it is crucial to adhere to local electrical codes and regulations when selecting and installing the wire for your dryer. These codes provide specific guidelines and requirements to ensure electrical safety and compliance. Consulting with a licensed electrician or researching your local electrical codes can help ensure that you are meeting all the necessary regulations.

By considering these factors – wire insulation type, wire material, location, and future needs – you can make an informed decision when selecting the wire size for your dryer, ensuring safe and efficient operation for years to come.

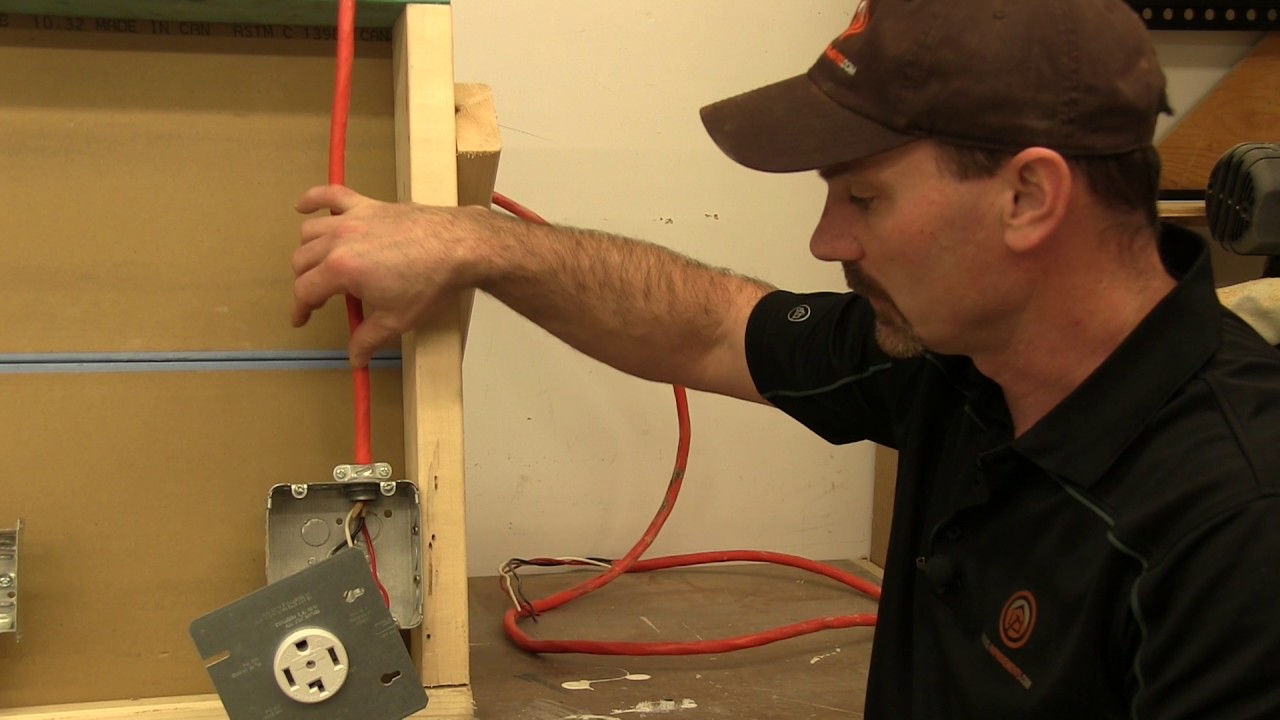

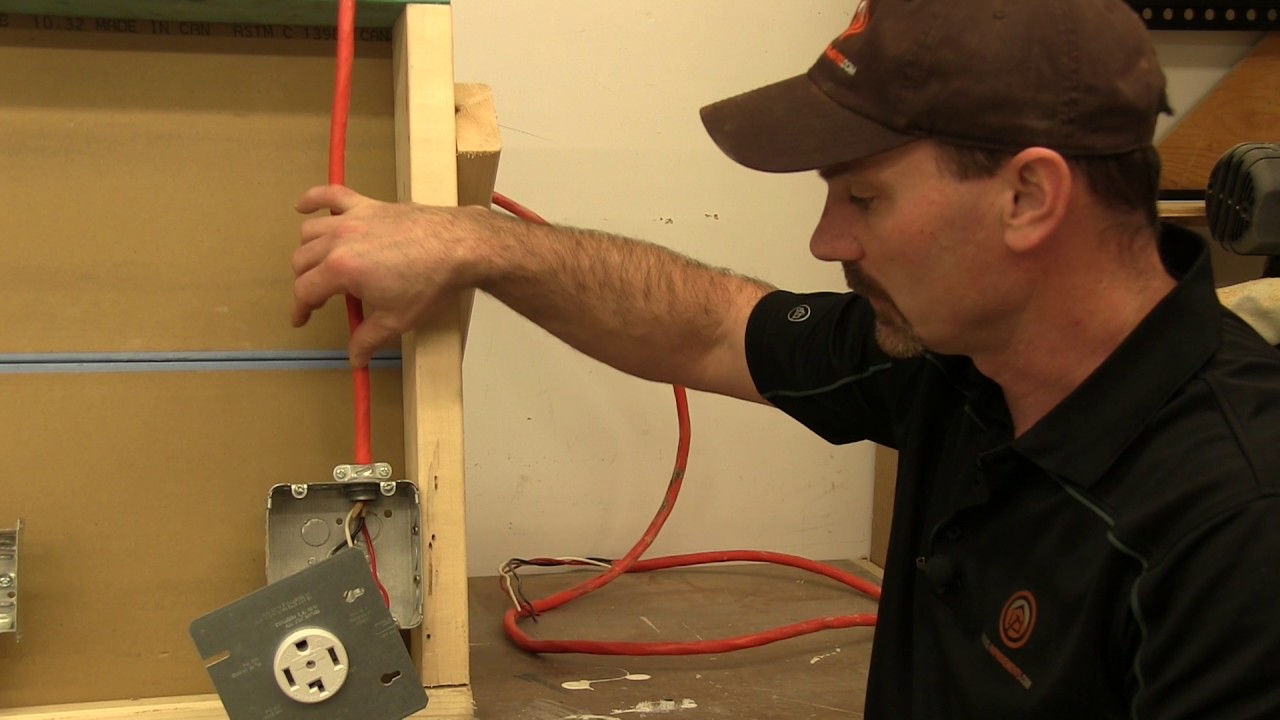

Installing the Correct Wire Size for Dryer

Once you have determined the appropriate wire size for your dryer based on voltage and amperage requirements, there are a few steps you should follow to ensure proper installation.

1. Turn off the power: Before beginning any electrical work, make sure to turn off the power to the dryer circuit at the main electrical panel. This will prevent any potential electrical shocks or accidents while working with the wires.

2. Prepare the wires: Measure and cut the appropriate length of wire needed to connect your dryer to the electrical panel. Strip the ends of the wires to expose the bare copper for proper connections.

3. Connect the wires: Connect the wires to the dryer receptacle and the electrical panel. Follow the manufacturer’s instructions and ensure a tight and secure connection. Use wire connectors or wire nuts to twist the wires together and secure them.

4. Grounding: Make sure to properly ground the dryer. Connect the grounding wire to the ground terminal on the dryer receptacle and the grounding bar in the electrical panel. This ensures the safety of your dryer and protects against electrical faults.

5. Secure the wire: Use wire staples or cable clamps to secure the wire along its path from the electrical panel to the dryer receptacle. This prevents the wire from being accidentally damaged or exposed, ensuring long-term safety and reliability.

6. Test the installation: Once the wire is properly installed, turn on the power and test the dryer to ensure it is functioning correctly. Check for any signs of electrical issues, such as sparks or unusual noises. If you notice any problems, immediately turn off the power and consult a licensed electrician for assistance.

7. Seal the connections: Lastly, it is important to protect the connections from moisture and other external elements. Use electrical tape or heat shrink tubing to seal and insulate the wire connections. This helps prevent any potential damage or short circuits.

Remember, if you are uncertain or uncomfortable with any aspect of the installation process, it is always best to consult a licensed electrician. They have the knowledge and expertise to ensure a safe and effective installation of the correct wire size for your dryer.

By following these steps and adhering to proper wiring practices, you can install the correct wire size for your dryer, ensuring safe and reliable operation for years to come.

Read more: What Size Wire For EV Charger

Conclusion

Selecting and installing the correct wire size for your dryer is essential for ensuring safe and efficient operation. By understanding the voltage and amperage requirements of your dryer and considering factors such as distance, wire insulation, wire material, and location, you can make an informed decision when determining the appropriate wire gauge.

Determining the correct wire gauge involves referencing the amperage rating of your dryer, consulting electrical codes and guidelines, and considering the length of the wire to minimize voltage drop. It is crucial to follow the recommendations provided by manufacturers and electrical regulations to ensure a safe and compliant installation.

When installing the wire for your dryer, make sure to turn off the power, properly prepare and connect the wires, ensure proper grounding, secure the wire, and test the installation to ensure everything is functioning correctly. Sealing the connections with electrical tape or heat shrink tubing will provide additional protection against moisture and other potential hazards.

However, if you have any doubts or lack the necessary expertise, it is always advisable to consult a licensed electrician. They have the knowledge and experience to guide you throughout the process and ensure a safe and reliable installation.

In conclusion, selecting and installing the correct wire size for your dryer is a vital step in maintaining safety and efficiency. By considering the various factors and following proper wiring practices, you can enjoy worry-free operation of your dryer while ensuring compliance with electrical regulations. So, take the time to research and consult professionals as needed, and enjoy the peace of mind that comes with a properly installed and correctly sized wire for your dryer.

Frequently Asked Questions about What Size Wire For Dryer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Size Wire For Dryer”