Home>Articles>What To Consider When Inspecting An Electrical Cord

Articles

What To Consider When Inspecting An Electrical Cord

Modified: October 20, 2024

Learn what to look for when inspecting an electrical cord in this informative article. Discover important tips and guidelines to ensure your safety.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electrical cords are an essential part of our modern lives. From powering our electronic devices to providing lighting in our homes and workplaces, electrical cords play a crucial role in our daily activities. However, just like any other electrical component, cords can become damaged or worn over time, posing potential hazards.

Inspecting electrical cords regularly is essential to ensure their safety and prevent accidents such as electric shocks, fires, or damage to electrical equipment. By paying attention to certain signs and conducting thorough inspections, you can identify potential issues and take appropriate action to ensure the cords remain in good condition and maintain their functionality.

In this article, we will explore the key factors to consider when inspecting an electrical cord. We will cover physical damage, such as fraying or cuts, loose connections, overheating, electrical issues, and the importance of proper grounding. Understanding these aspects will help you recognize potential dangers, take necessary precautions, and keep yourself and those around you safe.

Key Takeaways:

- Regularly inspect electrical cords for physical damage, loose connections, overheating, and electrical issues to prevent accidents and ensure safety.

- Proper grounding is essential for safe operation. Test for grounding prongs and use appropriate tools to ensure effective grounding, reducing the risk of electrical hazards.

Physical damage

One of the first things to check when inspecting an electrical cord is the presence of any physical damage. Physical damage can compromise the integrity of the cord and increase the risk of electrical hazards. Here are some common types of physical damage to be on the lookout for:

Fraying or cuts

Frayed or cut insulation is a telltale sign of damage to the electrical cord. If you notice any fraying or cuts along the length of the cord, it is essential to address the issue promptly. Frayed wires can be exposed, increasing the risk of electrical shock or short circuits. Similarly, cuts in the insulation can lead to electrical leakage and potential fire hazards.

Bulges or swelling

If you observe any bulges or swelling in the cord, it may indicate internal damage or insulation breakdown. Bulges can be a result of excessive heat or physical stress, and swelling typically suggests that the cord has been subjected to excessive voltage or current flow. Both bulges and swelling are indications that the cord may be compromised and should be replaced immediately.

Exposed wiring

Exposed wiring is a severe issue as it directly exposes the conductive elements to the environment, increasing the risk of electrical shock and short circuits. If you notice any exposed wires or bare conductors in the cord, it is crucial to stop using it immediately and have it repaired or replaced by a qualified professional.

When inspecting the cord, be thorough and check along its entire length. Pay attention to both ends, as well as any areas where the cord may be bent or twisted frequently. It is essential to identify any physical damage early on and take appropriate measures to prevent potential accidents.

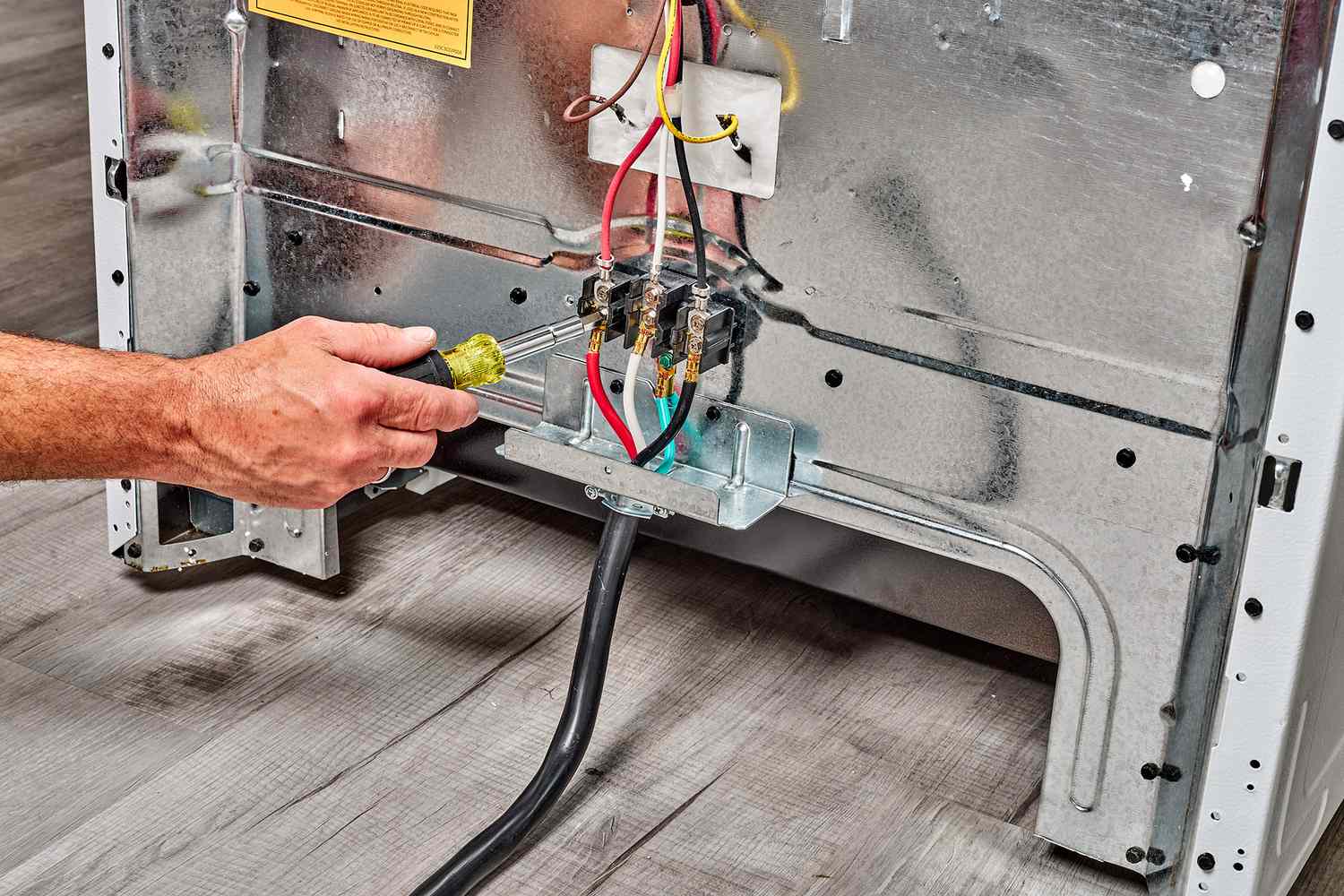

Loose connections

In addition to physical damage, it is crucial to inspect the connections of the electrical cord. Loose or damaged connections can lead to poor electrical conductivity, increased resistance, and potential hazards. Here are some aspects to consider when inspecting the connections:

Loose or damaged prongs

Prongs are the metal pins at the end of a plug that connect to an outlet. Loose or damaged prongs can result in poor electrical contact, leading to power fluctuations or even electrical sparks. Inspect the prongs for any signs of bending, chipping, or looseness. If you find any issues, it is advisable to replace the plug rather than attempting to repair it.

Loose or damaged plugs

The plug itself can also experience wear and tear over time. Check for any signs of looseness or damage, such as cracks or discoloration. Loose or damaged plugs can cause intermittent power loss, electrical arcing, or even electrical shock if not addressed promptly. Replace any damaged plugs to ensure a secure and reliable connection.

Loose or damaged connectors

If your electrical cord has connectors, such as those found on extension cords or power strips, inspect them for any signs of looseness or damage. Loose or damaged connectors can lead to poor electrical contact and increase the risk of overheating or electrical arcing. Consider replacing any faulty connectors to maintain a safe and stable electrical connection.

During the inspection, ensure that all connections are secure and firmly in place. Give each connection a gentle tug to check for any looseness. Additionally, look for any signs of corrosion or rust, as these can also interfere with electrical conductivity. Maintaining tight and intact connections will help prevent potential electrical hazards and maintain the reliability of your electrical cord.

Overheating

Overheating is a serious issue that can occur in electrical cords and should not be ignored. Excessive heat buildup can lead to insulation breakdown, fires, or damage to connected devices. When inspecting an electrical cord, be vigilant for the following signs of overheating:

Hot spots on the cord

Run your hand along the length of the cord while it is in use or has recently been in use. If you detect any unusually hot areas, it may indicate overheating. Hot spots can develop due to insufficient insulation or an overload of electrical current passing through the cord. Overheating can lead to structural damage, including melting or degradation of the cord’s insulation.

Discoloration or melting of the cord

Inspect the entire length of the cord for any discoloration or melting. Discoloration can appear as darkened or charred areas on the cord’s outer covering. Melting may be observed as a deformity or loss of the cord’s original shape. These signs indicate that the cord has been subjected to excessive heat, potentially compromising its safety and integrity.

Burning smell

If you detect a distinct burning odor coming from the cord, it is crucial to address the issue immediately. A burning smell suggests that the insulation or other internal components of the cord may be experiencing thermal stress or damage. Continuing to use the cord in such a compromised state can lead to electrical failures or fires.

If you notice any of these signs of overheating, it is important to stop using the cord immediately. Replace the cord with a new one that can handle the electrical load, and investigate the cause of the overheating, such as overloading the cord with too many devices or using it for purposes it is not designed for.

Preventing overheating is essential for the safety of your electrical system and connected devices. Regularly monitoring your cords for signs of overheating will help you identify potential issues early on and take appropriate measures to avoid electrical hazards.

Electrical issues

When inspecting an electrical cord, it is essential to keep an eye out for any electrical issues that may indicate potential hazards. These issues can range from visible abnormalities to more subtle signs. Here are some common electrical issues to be aware of:

Flickering or dimming lights

If you notice that the lights connected to the electrical cord are flickering or dimming, it may indicate an electrical problem. Flickering or dimming lights can be a sign of an overloaded circuit or a loose connection within the cord. Addressing this issue promptly can prevent potential damage to the cord and electrical devices.

Short circuits

Short circuits occur when a current bypasses its regular path and flows through an unintended connection. This can happen when exposed wires touch each other or come into contact with conductive surfaces. Signs of a short circuit include sparks or popping sounds coming from the cord or even a tripped circuit breaker or blown fuse. If you observe any of these signs, it is crucial to immediately stop using the cord and have it inspected by a professional electrician.

Electrocution risks

Inspecting for any electrocution risks is vital to ensure the safety of anyone coming into contact with the electrical cord. Look for loose wires, exposed conductors, or signs of damaged insulation. Additionally, check if the cord has any exposed metal parts, such as in damaged plugs or connectors, which can increase the risk of electric shock. Taking measures to address these risks, such as replacement or repair, is necessary to prevent accidents.

Remember, electrical issues should never be taken lightly. If you encounter any signs of electrical problems, it is crucial to address them promptly and, if necessary, seek professional assistance. Regular inspections and maintenance of your electrical cords will help ensure their safe and efficient operation, minimizing the risk of electrical hazards.

Proper grounding

Proper grounding is crucial for the safe operation of electrical cords and the devices they power. Grounding helps protect against electrical shocks, reduces the risk of electrical fires, and ensures the stability of the electrical system. When inspecting an electrical cord, it is important to pay attention to its grounding. Here are a couple of important aspects to consider:

Checking for grounding prong

Many electrical cords, especially those with three-prong plugs, have a grounding prong. The grounding prong, often referred to as the “third prong,” is a crucial safety feature. It provides a path for electrical current to flow safely to the ground in the event of a fault or electrical surge. When inspecting the cord, ensure that the grounding prong is intact and not bent, broken, or missing. A damaged or missing grounding prong may compromise the safety of the electrical system and should be addressed promptly.

Testing for proper grounding

In addition to visually inspecting the grounding prong, it is also important to test the cord for proper grounding using a ground fault circuit interrupter (GFCI) tester or a multimeter. These tools can help determine if the electrical system is effectively grounded. Follow the manufacturer’s instructions for testing and use the appropriate tool for accurate results.

Remember that proper grounding not only protects you and your electrical devices but also ensures compliance with electrical codes and regulations. If you are unsure about the grounding of your electrical cord or system, it is best to consult a certified electrician who can perform professional testing and make any necessary adjustments or repairs.

By paying attention to proper grounding, you can help maintain a safer electrical environment and reduce the risk of electrical hazards.

Conclusion

Regularly inspecting your electrical cords is a crucial part of maintaining a safe and reliable electrical system. By being vigilant and proactive in identifying potential issues, you can prevent accidents, protect your electrical devices, and ensure the safety of yourself and others. Here are some key takeaways from this article:

- Physically inspect your electrical cords for fraying, cuts, bulges, or exposed wiring. Replace any cords with signs of physical damage.

- Check for loose or damaged connections, such as prongs, plugs, and connectors. Tighten or replace any faulty connections to ensure electrical conductivity.

- Be mindful of the signs of overheating, such as hot spots, discoloration, or a burning smell. Stop using overheating cords and replace them promptly.

- Pay attention to electrical issues like flickering or dimming lights, short circuits, or potential electrocution risks. Promptly address these issues to prevent further damage or accidents.

- Ensure proper grounding by checking the grounding prongs on your cords and testing for effective grounding using the appropriate tools.

Remember, if you ever have doubts about the safety of an electrical cord or are unsure of how to address an issue, it is always best to consult a qualified electrician. Their expertise and guidance can help ensure the proper functioning of your electrical system and maintain a safe environment.

By regularly inspecting your electrical cords and taking necessary precautions, you can greatly reduce the risk of electrical accidents, protect your valuable devices, and enjoy peace of mind knowing that your electrical system is functioning safely and efficiently.

Frequently Asked Questions about What To Consider When Inspecting An Electrical Cord

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What To Consider When Inspecting An Electrical Cord”