Articles

What Tools Are Used In Plumbing

Modified: January 8, 2024

Discover the essential tools used in plumbing and learn how they can help you tackle various plumbing tasks with our informative articles.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

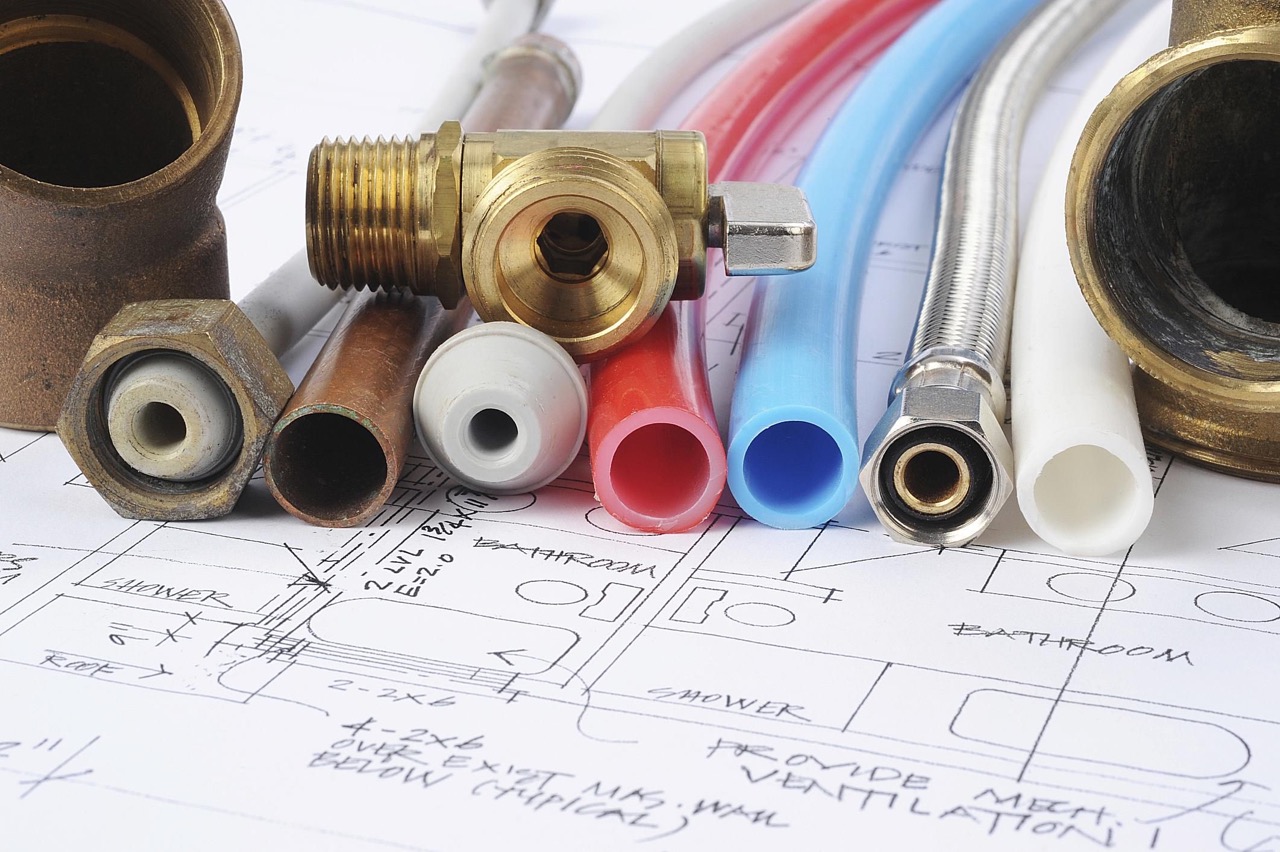

Plumbing is an essential aspect of every building structure, ensuring the proper flow and distribution of water and gas throughout. Whether it’s a leaky faucet, a clogged drain, or a broken pipe, plumbing issues can cause major disruptions and inconvenience. To address these problems effectively, plumbers rely on a range of tools specifically designed for various plumbing tasks.

In this article, we will explore the common tools used in plumbing and discuss their purpose and functionality. We will also explore specialized plumbing tools that are used for more complex plumbing tasks. Understanding the different plumbing tools can provide valuable insight into the work done by professional plumbers and even enable homeowners to handle minor plumbing issues themselves.

Key Takeaways:

- Plumbing tools, from common wrenches and pliers to specialized drain snakes and pipe locators, equip professionals to efficiently tackle a wide range of plumbing challenges, ensuring the longevity and optimal performance of plumbing systems.

- The use of specialized plumbing tools, such as hydro jets and pipe inspection cameras, offers targeted solutions for specific plumbing tasks, providing accurate diagnostics and efficient repairs, ultimately saving time, costs, and minimizing disruptions.

Read more: What Is A Plumb Bob Used For In Surveying

Common Plumbing Tools

1. Pipe Wrench: The pipe wrench is a versatile tool used for gripping and turning pipes, fittings, and other rounded objects. It has adjustable jaws and a long handle that provides leverage, making it easier to tighten or loosen threaded pipes.

2. Plunger: The plunger is a simple yet effective tool used for unclogging drains and toilets. It consists of a rubber suction cup attached to a handle. When placed over the drain or toilet opening and pushed downward, it creates suction to dislodge blockages.

3. Adjustable Wrench: Also known as a crescent wrench, the adjustable wrench is a versatile tool used for gripping and turning nuts, bolts, and pipe fittings. Its jaws can be adjusted to fit different sizes, making it ideal for a wide range of plumbing tasks.

4. Pipe Cutter: As the name suggests, a pipe cutter is used for cutting pipes cleanly and accurately. It features a cutting wheel that rotates around the pipe, creating a continuous score mark. The pipe cutter’s knob is then tightened gradually until the pipe snaps cleanly.

5. Pipe Threader: A pipe threader is a tool used to create threaded ends on pipes, allowing them to be joined securely with other fittings. It consists of a die head that is screwed onto the end of the pipe, and then by rotating the tool, threads are created along the pipe.

6. Pliers: Pliers are versatile hand tools used in many plumbing tasks. They can grip, twist, and cut wires, as well as hold small objects securely. Different types of pliers, such as slip-joint pliers and locking pliers, are used depending on the task at hand.

7. Faucet Key: A faucet key is a specialized tool used to remove or tighten faucet aerators. It is a small, square-shaped tool that fits into the aerator’s square hole, allowing it to be easily twisted.

8. Hacksaw: A hacksaw is used for cutting through metal pipes, fittings, and other materials. It consists of a fine-toothed blade that is mounted in a U-shaped frame. The blade can be easily replaced when it becomes dull.

9. Tube Cutter: A tube cutter is similar to a pipe cutter but is specifically designed for cutting plastic and copper tubing. It features a sharp cutting wheel that produces a clean, burr-free cut.

10. Teflon Tape: Teflon tape is a thin, white tape used to create a watertight seal on threaded pipes and fittings. It is wrapped around the threaded end before connecting the two pieces, preventing leaks.

These common plumbing tools are essential for a wide range of plumbing tasks, from simple repairs to more complex installations. However, certain plumbing jobs require specialized tools specifically designed for those tasks. Let’s explore these specialized tools in the next section.

(Word count: 516)

Key Takeaways:

- Plumbing tools, from common wrenches and pliers to specialized drain snakes and pipe locators, equip professionals to efficiently tackle a wide range of plumbing challenges, ensuring the longevity and optimal performance of plumbing systems.

- The use of specialized plumbing tools, such as hydro jets and pipe inspection cameras, offers targeted solutions for specific plumbing tasks, providing accurate diagnostics and efficient repairs, ultimately saving time, costs, and minimizing disruptions.

Read more: What Is A Plumb Bob Used For In Surveying

Common Plumbing Tools

1. Pipe Wrench: The pipe wrench is a versatile tool used for gripping and turning pipes, fittings, and other rounded objects. It has adjustable jaws and a long handle that provides leverage, making it easier to tighten or loosen threaded pipes.

2. Plunger: The plunger is a simple yet effective tool used for unclogging drains and toilets. It consists of a rubber suction cup attached to a handle. When placed over the drain or toilet opening and pushed downward, it creates suction to dislodge blockages.

3. Adjustable Wrench: Also known as a crescent wrench, the adjustable wrench is a versatile tool used for gripping and turning nuts, bolts, and pipe fittings. Its jaws can be adjusted to fit different sizes, making it ideal for a wide range of plumbing tasks.

4. Pipe Cutter: As the name suggests, a pipe cutter is used for cutting pipes cleanly and accurately. It features a cutting wheel that rotates around the pipe, creating a continuous score mark. The pipe cutter’s knob is then tightened gradually until the pipe snaps cleanly.

5. Pipe Threader: A pipe threader is a tool used to create threaded ends on pipes, allowing them to be joined securely with other fittings. It consists of a die head that is screwed onto the end of the pipe, and then by rotating the tool, threads are created along the pipe.

6. Pliers: Pliers are versatile hand tools used in many plumbing tasks. They can grip, twist, and cut wires, as well as hold small objects securely. Different types of pliers, such as slip-joint pliers and locking pliers, are used depending on the task at hand.

7. Faucet Key: A faucet key is a specialized tool used to remove or tighten faucet aerators. It is a small, square-shaped tool that fits into the aerator’s square hole, allowing it to be easily twisted.

8. Hacksaw: A hacksaw is used for cutting through metal pipes, fittings, and other materials. It consists of a fine-toothed blade that is mounted in a U-shaped frame. The blade can be easily replaced when it becomes dull.

9. Tube Cutter: A tube cutter is similar to a pipe cutter but is specifically designed for cutting plastic and copper tubing. It features a sharp cutting wheel that produces a clean, burr-free cut.

10. Teflon Tape: Teflon tape is a thin, white tape used to create a watertight seal on threaded pipes and fittings. It is wrapped around the threaded end before connecting the two pieces, preventing leaks.

These common plumbing tools are essential for a wide range of plumbing tasks, from simple repairs to more complex installations. They help plumbers and DIY enthusiasts tackle various plumbing challenges efficiently and effectively. Having these tools on hand can save time and money by enabling homeowners to handle minor plumbing issues themselves.

It’s important to note that while these tools are commonly used, their proper usage requires knowledge and skill. For complex or major plumbing repairs, it is always recommended to consult a professional plumber who has expertise in using these tools and can ensure the job is done safely and effectively.

By understanding the purpose and functionality of these common plumbing tools, you can have a better appreciation for the work plumbers do and be better prepared to handle basic plumbing tasks in your own home.

(Word count: 498)

Pipe Wrench

A pipe wrench is an essential tool in any plumber’s arsenal. It is specifically designed for gripping and turning pipes, fittings, and other rounded objects. Its unique design features adjustable jaws and a long handle, allowing for enhanced leverage and torque when tightening or loosening threaded pipes.

The jaws of a pipe wrench are serrated, providing a strong grip on the pipe without slipping or damaging the surface. The adjustable feature allows the jaws to be set to fit the specific size of the pipe being worked on. This versatility makes the pipe wrench suitable for a wide range of pipe diameters.

When using a pipe wrench, it’s important to ensure that the wrench is properly positioned on the pipe. The jaws should be placed perpendicularly to the pipe, with the lower jaw gripping the pipe and the upper jaw facing in the opposite direction.

To tighten a pipe using a pipe wrench, the handle of the wrench is turned in a clockwise direction. This applies torque to the pipe, allowing for a secure connection with other fittings. Conversely, to loosen a pipe, the handle is turned in a counterclockwise direction.

One key advantage of using a pipe wrench is its ability to provide significant leverage. The long handle allows for more force to be applied, making it easier to tighten or loosen stubborn pipes. However, it’s important to avoid excessive force, as this can cause damage to the pipes or fittings.

In addition to its primary function of gripping and turning pipes, the pipe wrench can also be used as a makeshift wrench for other rounded objects, such as bolts or nuts. The serrated jaws provide a secure grip on these objects, allowing for their manipulation.

When selecting a pipe wrench, it’s important to choose the right size for the task at hand. Pipe wrenches are available in various sizes, ranging from small 8-inch wrenches to larger 24-inch wrenches, or even bigger for industrial applications. The size of the wrench should match the diameter of the pipe being worked on to ensure a proper fit and optimal grip.

In summary, the pipe wrench is a versatile and essential tool in plumbing. Its adjustable jaws and long handle provide the leverage and grip necessary for tightening or loosening pipes. By using a pipe wrench correctly and selecting the appropriate size, plumbers can efficiently and effectively tackle various plumbing tasks.

Plunger

A plunger is a simple yet highly effective tool used for unclogging drains and toilets. It consists of a rubber suction cup attached to a handle. When properly used, a plunger can provide the necessary force to dislodge blockages and restore the normal flow of water.

There are two main types of plungers: a cup plunger and a flange plunger. A cup plunger is typically used for sinks and tubs, while a flange plunger is designed specifically for toilets. Both types work on the same principle of creating suction and pressure to remove obstructions.

Using a plunger involves creating a tight seal over the drain or toilet opening. To do this, ensure that the rubber cup or flange is pressed firmly against the surface, forming a seal. This will prevent air from escaping and allow for the proper suction action.

For sink and tub drains, fill the basin with enough water to cover the rubber cup. This water will aid in creating the necessary seal and provide additional pressure when plunging.

Using a firm grip on the handle, push the plunger down forcefully, then pull upwards swiftly. This motion creates a suction effect that dislodges the clog and allows water to flow freely again. Repeat this plunging action several times, ensuring that the seal remains intact.

When using a plunger on a toilet, extra care must be taken. Place the flange into the toilet bowl drain, ensuring that the seal is tight and covers the opening completely. Gently push the plunger down and then pull up in a quick motion, similar to plunging a sink or tub drain. Repeat this process with firm but controlled force.

If the plunger is unable to clear the blockage after several attempts, it may be necessary to try alternative methods or seek professional help from a plumber. It’s important to avoid using chemicals or other abrasive materials that may damage the plumbing system.

After successfully unclogging the drain or toilet, it’s a good practice to run water to ensure the blockage is fully cleared. This will help flush away any remaining debris and restore the normal flow.

Having a plunger handy in your home is useful for handling minor clogs and blockages. It is a cost-effective tool that can save you from having to call a plumber for simple plumbing issues. Regular maintenance and proper usage of a plunger can help prevent future clogs and maintain the efficiency of your plumbing system.

Remember, safety is important when working with plumbing tools. Always follow proper instructions and take appropriate precautions to prevent any accidents or injuries.

By understanding how to use a plunger correctly, you can confidently tackle common drain and toilet clogs, saving time and money in the process.

Read more: What Is A Plumbing Emergency

Adjustable Wrench

An adjustable wrench, also known as a crescent wrench, is a versatile tool that is essential for any plumber’s toolkit. This tool is used for gripping and turning nuts, bolts, and pipe fittings of various sizes.

The adjustable wrench gets its name from its ability to adjust the width of its jaws to fit different sizes of nuts or bolts. This is accomplished by a movable jaw that slides along a worm gear mechanism. By turning the knurled adjusting nut, the size of the jaw opening can be increased or decreased.

Using an adjustable wrench is straightforward. First, loosen the adjusting nut to create enough space for the nut or bolt you need to turn. Position the adjustable wrench on the nut or bolt, ensuring that the jaws are seated securely.

To tighten a nut or bolt, rotate the wrench handle in a clockwise direction. This applies torque and allows for secure fastening. Conversely, to loosen a nut or bolt, rotate the wrench handle counterclockwise.

The long handle of an adjustable wrench provides leverage, making it easier to turn nuts and bolts that may be tightly secured. However, it’s important to avoid applying excessive force, as this may damage the fastener or result in injury.

Adjustable wrenches come in various sizes, typically ranging from 6 inches to 24 inches in length. It’s important to choose the right size wrench for the job at hand. Using a wrench that is too small may not provide a secure grip, while a wrench that is too large may not fit properly.

In addition to gripping and turning nuts and bolts, an adjustable wrench can also be used for some plumbing tasks. It can be utilized to tighten or loosen pipe fittings, especially those with hexagonal shapes. However, for rounded objects like pipes, a pipe wrench or other specialized tools may be more suitable.

Note: When using an adjustable wrench, it’s important to position it properly on the nut or bolt to prevent slipping and damaging the surfaces. Ensuring that the jaw of the wrench is fully engaged and seated securely will help maintain a tight grip.

The adjustable wrench is a versatile tool that is highly useful in plumbing and various other applications. Its adjustable jaws and leverage provide flexibility and efficiency when working with different nut and bolt sizes. By adding an adjustable wrench to your toolkit, you’ll be well-equipped to handle a wide range of plumbing tasks with ease.

Remember to always follow safety precautions when using hand tools, and if a plumbing task requires expertise beyond your abilities, it’s best to consult a professional plumber.

Pipe Cutter

A pipe cutter is a specialized tool designed for cleanly and accurately cutting pipes. It is an essential tool for plumbers and DIY enthusiasts working on plumbing installations, repairs, or modifications.

As the name suggests, a pipe cutter is specifically designed to cut through pipes of various materials, such as copper, PVC, or steel. It consists of a cutting wheel mounted on a frame or handle, along with a mechanism for adjusting and tightening the wheel.

The cutting wheel of a pipe cutter is usually made of hardened steel or other durable materials. It is designed to create a continuous score mark on the surface of the pipe, gradually deepening as the cutter is rotated around the pipe.

Using a pipe cutter requires proper technique to ensure clean and precise cuts. Before starting, ensure that the pipe is securely clamped or held in place to prevent movement during the cutting process.

First, adjust the pipe cutter to fit the diameter of the pipe being cut. This is done by loosening the adjustment wheel and positioning the cutting wheel around the pipe until it lightly touches the surface. Then, tighten the adjustment wheel to secure the cutter in place.

Once the cutter is properly adjusted, rotate it around the pipe while applying downward pressure. The cutting wheel will score the surface of the pipe, gradually creating a groove. Continue rotating the cutter and applying pressure until the pipe is cut through completely.

It’s important to maintain a steady and even pressure while cutting to ensure a clean and straight cut. It may be necessary to rotate the cutter multiple times, gradually tightening the adjustment wheel with each rotation, to achieve a complete cut.

After cutting through the pipe, use a deburring tool or file to remove any sharp edges or burrs from the cut end. This will ensure a smooth and safe connection when installing fittings or joining pipes together.

Pipe cutters come in different types and sizes, depending on the specific application and pipe material. Some pipe cutters are designed for smaller pipes, while others are capable of cutting larger diameters. It’s important to choose the appropriate size and type of cutter for your specific needs.

Using a pipe cutter offers several advantages over alternative cutting methods, such as using a hacksaw or reciprocating saw. Pipe cutters provide cleaner and more precise cuts, minimizing the risk of uneven or jagged edges. Additionally, they allow for faster and more efficient cutting, saving time and effort.

By having a quality pipe cutter in your toolkit, you can confidently tackle plumbing projects that involve cutting and modifying pipes. However, it’s essential to wear appropriate safety gear, such as safety glasses and gloves, when using a pipe cutter to protect yourself from any potential hazards.

Remember, if you are unsure of how to use a pipe cutter or if a plumbing task requires professional expertise, it’s best to consult a licensed plumber who can handle the job safely and effectively.

Pipe Threader

A pipe threader is a specialized tool used in plumbing and pipefitting to create threaded ends on pipes. This threading allows pipes to be securely joined with other fittings, ensuring a tight and leak-free connection.

Threaded pipes are commonly used in plumbing systems for various purposes, such as connecting different sections of pipes, attaching fixtures like faucets or showerheads, or joining pipes to valves or other plumbing components.

A pipe threader consists of a die head, a system for holding and rotating the die head, and a handle for controlling the threading process. The die head contains threading dies on its internal surface, which cut the threads onto the pipe as it is rotated.

The threading process begins by selecting the appropriate die head and inserting it into the holding system of the pipe threader. The die head is then positioned onto the end of the pipe, ensuring it is aligned properly for threading.

Once the die head is secured, the handle of the pipe threader is turned, causing the die head to rotate around the pipe. As the dies make contact with the pipe, they cut into the material, gradually creating the threads along the pipe’s surface.

It’s important to apply consistent pressure and rotate the handle smoothly and evenly to ensure even threading. The pipe may need to be turned in reverse occasionally to clear any chips or debris produced during the threading process.

After completing the threading process, the pipe can be joined with a compatible fitting. The threaded end of the pipe is screwed into the fitting until it is secure and tight. Teflon tape or pipe dope may be used on the threaded connection to create a watertight seal.

Pipe threaders are available in manual or electric versions, with electric models offering greater speed and convenience for large-scale projects. Electric pipe threaders typically feature a motor-driven threading system, allowing for faster and more efficient threading.

Using a pipe threader requires knowledge and experience to ensure proper threading and avoid damaging the pipe or creating faulty connections. It is crucial to follow the manufacturer’s instructions and guidelines when operating a pipe threader.

Pipe threaders are not commonly found in the average homeowner’s toolkit, as they are specialized tools used primarily by professional plumbers and pipefitters. However, in some cases, homeowners may need to thread pipes for specific projects or repairs, and renting a pipe threader from a tool rental store may be a viable option.

Proper and accurate threading is crucial to ensure a secure, leak-free plumbing system. If you are unsure about using a pipe threader or have complex plumbing needs, it’s recommended to seek the expertise of a professional plumber who can efficiently handle the threading process to ensure safe and reliable connections.

Pliers

Pliers are versatile hand tools that are widely used in plumbing and many other industries. They are designed to grip, twist, cut, and hold objects securely. With their adjustable jaws and strong grip, pliers are essential for various plumbing tasks.

There are different types of pliers available, each designed with specific features and functionalities. Some common types of pliers used in plumbing include slip-joint pliers, groove-joint pliers, locking pliers, and needle-nose pliers. Each type has its own unique design and purpose, making them suitable for different plumbing applications.

Slip-joint pliers, also known as adjustable pliers, have an adjustable pivot point that allows the jaws to be adjusted to grasp objects of different sizes. They are commonly used for gripping and turning nuts, bolts, and fittings in plumbing tasks. Slip-joint pliers are versatile tools that can handle a wide range of sizes, making them a staple in any plumber’s toolbox.

Groove-joint pliers, also referred to as channel-lock pliers, have an adjustable jaw that can be moved to several positions along the slip joint. This mechanism allows for a wider jaw opening, enabling the pliers to grip larger objects. Groove-joint pliers are commonly used when working with larger diameter pipes or fittings that require a stronger grip.

Locking pliers, also known as Vise-Grips, have a built-in locking mechanism that allows them to firmly grip objects and hold them in place. This feature makes them ideal for tasks that require a secure hold, such as removing stubborn or rusted pipes or fasteners. Locking pliers are also useful when additional leverage is needed to turn or twist objects.

Needle-nose pliers have long, thin jaws that come to a point, resembling the shape of a needle. They are designed for precision work and are ideal for reaching into tight spaces or handling small objects. Needle-nose pliers are commonly used for tasks like bending wires, manipulating small parts, and working on delicate plumbing components.

When using pliers, it’s important to choose the right type of pliers for the specific task and ensure they are used correctly. It’s also crucial to position the pliers properly on the object being gripped to avoid slipping and causing damage.

Additionally, pliers should be kept clean and in good condition to ensure optimal performance. Regularly inspect the jaws for wear or damage, and replace any worn-out or damaged pliers to maintain safe and efficient work.

Overall, pliers are versatile tools that play a vital role in plumbing projects. Their gripping, twisting, cutting, and holding capabilities make them essential for various plumbing tasks. By having a selection of pliers in your toolbox, you’ll be well-equipped to handle a wide range of plumbing jobs efficiently and effectively.

Remember to exercise caution when using pliers, and if a plumbing task exceeds your abilities or requires professional expertise, it’s best to seek the assistance of a licensed plumber.

Read more: What Is A Spud In Plumbing

Faucet Key

A faucet key is a specialized tool that is used in plumbing to remove or tighten faucet aerators. It is a small, square-shaped tool that fits into the aerator’s square hole, allowing it to be easily twisted.

Faucet aerators are small devices attached to the end of faucets that regulate the flow of water by mixing air with the water stream. Over time, mineral deposits and debris can accumulate in the aerator, leading to reduced water flow or inconsistent water pressure. In such cases, removing the aerator for cleaning or replacement becomes necessary.

The faucet key is specifically designed to engage with the aerator’s square hole and provide the necessary leverage to loosen or tighten it. By inserting the appropriate end of the faucet key into the aerator, you can easily turn the aerator clockwise to remove it or counterclockwise to install or tighten it.

A faucet key is essential for maintaining and cleaning faucets, as it allows you to access the aerator without causing any damage. Regularly removing and cleaning the aerator helps to improve water flow and prevent clogs caused by accumulated debris or mineral buildup.

Additionally, a faucet key can be particularly useful when dealing with low water pressure issues. Sometimes, the aerator may become clogged with sediments or small particles, causing a decrease in water flow. By using the faucet key to remove the aerator, you can thoroughly clean it and restore the full functionality of your faucet.

When using a faucet key, it’s important to ensure that you have the correct size and type of key that matches the aerator on your specific faucet. Different faucets may have different aerator designs and sizes, so it’s crucial to choose the right key to avoid damaging the aerator or the faucet itself.

A faucet key is a handy tool that enables you to easily remove, clean, and maintain the aerator in your faucets. By keeping your aerators clean and free from debris, you can enjoy optimal water flow and maintain the efficiency of your plumbing system.

If you are unsure about using a faucet key or experiencing complex plumbing issues, it is always recommended to seek the assistance of a professional plumber who can handle the task safely and effectively.

When working on plumbing projects, it’s essential to have the right tools on hand. Some common tools used in plumbing include pipe wrenches, adjustable wrenches, pliers, pipe cutters, and a plumber’s snake. Having these tools readily available will make any plumbing job much easier and more efficient.

Hacksaw

A hacksaw is a versatile cutting tool commonly used in plumbing and various other industries. It consists of a fine-toothed blade that is mounted in a U-shaped frame, along with a handle for grip and control.

The primary function of a hacksaw is to cut through various materials, including metal pipes, fittings, rods, and other objects. The fine teeth on the blade enable precise and clean cuts, making it suitable for plumbing tasks that require accuracy.

When using a hacksaw for plumbing, it’s important to follow proper techniques to ensure efficient and safe cutting:

- Select the appropriate blade: Hacksaw blades come in different types and sizes, each designed for specific materials and cutting applications. Choose a blade that is suitable for cutting metal pipes and fittings.

- Secure the workpiece: When using a hacksaw, it’s crucial to stabilize the workpiece to prevent it from moving or vibrating during cutting. Use clamps or a vise to secure the pipe or fitting to a workbench or another stable surface.

- Proper blade orientation: Ensure that the blade is properly inserted in the hacksaw frame, with the teeth facing forward. The teeth should be pointing away from the handle to facilitate smooth cutting.

- Avoid excessive pressure: Apply steady and controlled pressure on the hacksaw handle as you move the blade back and forth. Let the saw blade do the cutting, without forcing or pushing too hard, to prevent blade breakage and ensure smooth cutting.

- Use fluid or lubricant: Lubricating the blade with cutting fluid or oil can help reduce friction, prolong the blade’s life, and improve cutting efficiency. Apply lubricant to the area being cut periodically to keep the cutting process smooth.

- Cutting technique: Position the hacksaw blade at a slight angle to the pipe or fitting. Start the cut with a light back-and-forth motion to initiate a groove. Gradually increase the cutting stroke, using the full length of the blade, to create a clean and even cut.

- Personal protective equipment: When using a hacksaw, it’s important to wear appropriate safety gear, such as safety glasses and gloves, to protect yourself from potential hazards like metal chips or sparks.

Regularly inspect the hacksaw blade for signs of wear or damage. Replace the blade if it becomes dull, bent, or broken to ensure optimal cutting performance.

A hacksaw is a valuable tool for plumbers, allowing them to make precise cuts on metal pipes and fittings. By using proper techniques and maintaining the blade, you can confidently complete plumbing tasks requiring cutting with efficiency and accuracy.

If you are unsure about using a hacksaw or need assistance with complex plumbing projects, it’s recommended to seek the guidance of a professional plumber who can ensure the task is performed safely and effectively.

Tube Cutter

A tube cutter is a specialized tool designed specifically for cutting plastic and copper tubing with precision and ease. It is an essential tool in plumbing and is commonly used for tasks such as installing new water lines, repairing or replacing pipes, and fitting connections.

A tube cutter consists of a cutting wheel mounted on a frame, with a handle for grip and control. The cutting wheel is sharp and designed to create a clean, burr-free cut on the tubing material.

Using a tube cutter is relatively simple and requires a few steps to achieve an accurate cut:

- Select the appropriate tube cutter: There are different types and sizes of tube cutters available, each designed for specific materials and tube diameters. Choose a tube cutter that is suitable for the type and size of tubing you are working with.

- Mark the cut: Measure the length of tubing you need and use a marker to mark the cutting point clearly. This will ensure accuracy and help guide the tube cutter.

- Open the tube cutter: Adjust the tube cutter to the appropriate diameter for the tubing by loosening the adjustment knob. Open the cutter just enough to fit around the tubing.

- Place the tube cutter: Position the tube cutter around the tubing at the marked cutting point, ensuring that the cutting wheel is aligned with the mark.

- Apply pressure and rotate: Apply gentle pressure on the handle of the tube cutter, pressing the cutting wheel against the tubing. Begin rotating the cutter around the tubing, maintaining a smooth and steady motion.

- Continue rotating and cutting: As you rotate the tube cutter, gradually increase the pressure to maintain a consistent cutting depth. Keep rotating until you have completed a full revolution around the tubing.

- Finalize the cut: Tighten the adjustment knob of the tube cutter slightly to ensure a clean cut. This will help prevent any uneven or jagged edges.

- Deburr if necessary: After cutting, use a deburring tool or a file to remove any burrs or rough edges from the cut end of the tubing. This will ensure a smooth and even surface before connecting fittings or joining pipes.

Tube cutters provide several advantages over alternative cutting methods, such as sawing or using a utility knife. They offer precise and clean cuts, reducing the risk of damaging the tubing or affecting the integrity of the plumbing system. Tube cutters also allow for faster and more efficient cutting, saving time and effort.

It’s important to maintain the tube cutter and replace the cutting wheel when it becomes dull or worn to ensure optimal cutting performance. Always follow the manufacturer’s instructions and guidelines for maintenance and blade replacement.

By using a tube cutter correctly, you can achieve accurate cuts on plastic and copper tubing, facilitating easier installation and repairs in your plumbing projects. If you are unsure about using a tube cutter or need assistance with complex plumbing tasks, it’s best to consult a professional plumber who can provide guidance and ensure a successful outcome.

Teflon Tape

Teflon tape, also known as plumber’s tape or thread seal tape, is a thin, white tape that is widely used in plumbing applications to create a watertight seal on threaded pipes and fittings. It is an essential tool for preventing leaks and ensuring a secure connection between pipes.

Teflon tape is made from a flexible material called polytetrafluoroethylene (PTFE), which provides excellent sealing properties. It is resistant to chemicals and can withstand high temperatures, making it suitable for use in plumbing systems.

The primary purpose of Teflon tape is to lubricate and seal the threads of pipe fittings, preventing water or gas from escaping through the connection. The tape is wrapped around the threads of the male fitting before it is screwed into the female fitting. As the fitting is tightened, the tape compresses and fills any gaps or imperfections in the threads, creating a tight and reliable seal.

Using Teflon tape is relatively simple, and it offers several benefits:

- Clean and dry the threads: Before applying Teflon tape, ensure that the threads of the pipe fittings are clean and dry. This will help the tape adhere properly and create an effective seal.

- Start at the end of the fitting: Begin by wrapping the Teflon tape around the exposed end of the male fitting. Hold the end of the tape against the threads and make a few wraps, covering them completely.

- Wrap in a clockwise direction: Continue wrapping the tape in a clockwise direction, ensuring that each wrap overlaps the previous one by about half of the tape’s width.

- Apply tension but avoid excessive stretching: Apply gentle tension to the tape as you wrap it around the fitting, but be careful not to stretch or tear it. Stretching the tape excessively may result in poor sealing performance.

- Complete the wrapping: Continue wrapping until you have covered all the threaded area. Make sure to wrap the tape snugly and evenly, maintaining consistent pressure throughout.

- Tear or cut the tape: Once you have completed the wrapping, tear or cut the tape from the roll, ensuring a clean and straight edge.

- Screw the fitting into place: Insert the male fitting into the female fitting and tighten it securely. The Teflon tape will compress, creating a secure and leak-free connection.

One key advantage of Teflon tape is its versatility. It can be used with a wide range of pipe materials and is compatible with many types of fluids and gases commonly found in plumbing systems.

It is important to note that Teflon tape is not a substitute for proper fitting and connection preparation. It should be used in conjunction with appropriate plumbing techniques, such as correctly sized fittings and properly cleaned and prepared pipe threads.

By using Teflon tape when assembling threaded connections, you can significantly reduce the risk of leaks and ensure the integrity of your plumbing system. However, if you encounter complex plumbing issues or are unsure about proper tape application, it’s best to consult a professional plumber for assistance.

Read more: How To Use Plumbing Tape

Specialized Plumbing Tools

In addition to the common plumbing tools we discussed earlier, there are several specialized tools that are used for more specific plumbing tasks. These tools are designed to tackle unique challenges and provide plumbers with greater efficiency and accuracy. Let’s explore some of these specialized plumbing tools:

- Drain Snake: A drain snake, also known as a plumbing auger or drain auger, is a flexible tool used to clear clogs and blockages in drains and pipes. It features a long, coiled wire or cable that can be inserted into the drain to break up and remove obstructions.

- Pipe Inspection Camera: A pipe inspection camera is a small, waterproof camera attached to a long, flexible cable. It is used to visually inspect the inside of pipes and identify any issues, such as clogs, leaks, or damaged sections. The camera footage is usually viewed on a screen, allowing plumbers to assess the condition and make informed decisions for repairs or maintenance.

- Hydro Jet: A hydro jet, also known as a sewer jetter, is a powerful tool used for drain and sewer line cleaning. It uses high-pressure water streams to blast away stubborn clogs, debris, and buildup inside pipes. Hydro jetting is an effective method for clearing blockages and restoring proper water flow.

- Pipe Locator: A pipe locator, also known as a pipe and cable locator, is a device used to accurately locate the position and depth of buried pipes and cables. It uses electromagnetic signals or ground-penetrating radar technology to detect the presence of underground utilities, helping plumbers avoid damaging existing pipes during excavation or construction.

- Pipe Freezing Kit: A pipe freezing kit is used to temporarily freeze a section of pipe to create an isolation point without shutting off the entire water supply. This is a valuable tool for making repairs or modifications on live plumbing systems where shutting off the main water supply is not feasible or desirable.

These specialized plumbing tools enable plumbers to address specific challenges more effectively and efficiently. They allow for precise inspection, cleaning, locating, and repair of plumbing systems, saving time, reducing costs, and minimizing disruption to the plumbing infrastructure.

While specialized plumbing tools can be highly beneficial, it’s important to note that they often require specialized training and knowledge to ensure safe and proper usage. It’s recommended to consult professional plumbers or receive proper training and guidance before attempting to use these tools on your own.

By combining the use of both common and specialized plumbing tools, plumbers are equipped to handle a wide range of plumbing issues, from routine maintenance to complex repairs. Their expertise and the right tools ensure that plumbing systems are installed, maintained, and repaired to the highest standards.

Drain Snake

A drain snake, also known as a plumbing auger or drain auger, is a specialized tool used by plumbers to clear clogs and blockages in drains and pipes. It is an invaluable tool when other methods, such as plunging or chemical cleaners, fail to resolve the issue.

The drain snake consists of a long, flexible cable or wire with a corkscrew-like auger at one end. The cable is inserted into the drain or pipe, and by rotating and pushing it forward, the auger can break up or dislodge the obstruction, allowing for the restoration of proper water flow.

Using a drain snake requires some skill and technique to ensure effective results:

- Insert the snake: Insert the tip of the drain snake into the drain opening or access point. Push it gently but firmly to feed the cable further into the pipe.

- Rotate the auger: Once the snake is inserted, rotate the auger clockwise. This rotational motion helps the corkscrew end of the auger to grab onto the blockage and break it apart.

- Apply forward pressure: As you rotate the snake, apply gentle forward pressure to help the auger move further into the pipe. Continue feeding the cable while maintaining a steady momentum.

- Break through the clog: As the cable encounters the clog, the auger should gnaw through or break it apart, allowing water to flow freely. You may feel the resistance decrease or encounter some debris coming back with the cable.

- Retract the snake: Once the clog is cleared, retract the snake by rotating it counterclockwise. This motion helps bring the cable back while maintaining control and preventing any mess.

- Clean the cable: After using the drain snake, it’s crucial to clean the cable thoroughly. This includes removing any debris or residue that may have collected on the auger or wrapped around the cable.

It’s important to note that using a drain snake may not be suitable for all types of plumbing systems or situations. Certain pipe materials and fixtures may be sensitive to the use of a drain snake or require specialized attachments.

A drain snake is a valuable tool for plumbers because it can effectively clear a wide range of clogs caused by hair, grease, soap residue, or other debris. It is commonly used in bathroom and kitchen drains, as well as in mainline sewer pipes.

While it’s possible to purchase or rent a drain snake for DIY use, be cautious and avoid using excessive force, as this can result in damage to the pipes. If you are unsure or unable to clear a stubborn clog with a drain snake on your own, it’s wise to consult a professional plumber who can utilize their expertise and the proper tools to resolve the issue.

Pipe Inspection Camera

A pipe inspection camera, also known as a plumbing camera or sewer camera, is a specialized tool that allows plumbers to visually inspect the inside of pipes and identify any issues or damage. It consists of a small, waterproof camera attached to a long, flexible cable, which is inserted into the pipe.

The primary purpose of a pipe inspection camera is to provide a clear view of the interior of pipes, helping plumbers locate blockages, assess the condition of pipes, and identify any potential problems. The camera footage is typically transmitted to a screen, allowing the plumber to observe and analyze the pipe’s condition in real-time.

Using a pipe inspection camera offers several advantages:

- Accurate identification of problems: The camera allows plumbers to directly visualize the inside of pipes and accurately identify issues such as blockages, leaks, corrosion, tree root intrusion, or broken sections.

- Precise location of problems: Pipe inspection cameras often come with locators that can pinpoint the exact location of issues or defects within the pipe. This information is crucial for planning repairs or conducting targeted maintenance.

- Non-destructive inspection: Pipe inspection cameras eliminate the need for invasive exploratory methods, such as excavating or cutting into walls or floors. This reduces unnecessary damage and minimizes disruption during the inspection process.

- Time and cost efficiency: By identifying the exact source and nature of the problem before starting the repairs, pipe inspection cameras help save time and prevent unnecessary repairs, thus reducing costs.

- Documentation and record-keeping: Pipe inspection cameras can record video or capture images during the inspection. This documentation serves as a valuable reference for future inspections, insurance claims, or property assessments.

Pipe inspection cameras are commonly used in a variety of plumbing situations, including residential, commercial, and industrial settings. They are especially effective for inspecting underground sewer pipes, drain lines, ventilation ducts, and other hard-to-reach areas.

It’s important to note that pipe inspection cameras require expertise and experience to operate effectively. Professional plumbers are trained to interpret the camera footage and analyze the condition of the pipes accurately. They can also provide recommendations for repairs or maintenance based on their findings.

If you suspect issues with your plumbing system, such as persistent blockages, foul odors, or slow drainage, consulting a professional plumber with access to pipe inspection cameras can help identify the root cause and provide targeted solutions. Their expertise, coupled with the use of pipe inspection cameras, ensures a comprehensive assessment and effective resolution of plumbing problems.

Hydro Jet

A hydro jet, also known as a sewer jetter, is a powerful and specialized tool used in plumbing for drain and sewer line cleaning. It utilizes a high-pressure water stream to clear obstructions, debris, and buildup from pipes, restoring optimal flow and function.

The hydro jet consists of a high-pressure pump, a water reservoir (usually connected to a truck-mounted unit), and a hose with a specially designed nozzle. The pump pressurizes water and propels it through the hose, where it is directed towards the clogged or dirty pipe.

Hydro jetting offers several advantages over traditional drain cleaning methods:

- Effective clog removal: The high-pressure water stream generated by the hydro jet can break up and remove stubborn clogs, such as tree roots, grease, scale, or mineral deposits. It provides a more thorough and efficient cleaning than other methods.

- Safe and non-invasive: Hydro jetting is a non-invasive technique, meaning it does not require digging, excavating, or using harsh chemicals. It is a safe method that minimizes potential damage to pipes and surrounding structures.

- Full pipe cleaning: Hydro jetting not only removes clogs but also thoroughly cleans the interior of pipes. The high-pressure water stream scours the pipe walls, removing accumulated debris, grease, and other contaminants.

- Versatility in pipe sizes and materials: Hydro jetting is suitable for a wide range of pipe sizes and materials, including PVC, cast iron, clay, and more. The pressure of the water can be adjusted to accommodate different pipe dimensions.

- Preventive maintenance: Hydro jetting is not only used for clearing existing clogs but also for preventive maintenance. Regular hydro jetting helps to prevent clogs from forming and keeps pipes clean and free-flowing.

Using a hydro jet requires specialized training and expertise. Professionals know how to operate the equipment safely and effectively, ensuring that the high-pressure water stream is directed appropriately and does not cause any damage to the plumbing system.

It’s important to note that hydro jetting may not be suitable for all plumbing situations. Delicate or compromised pipes may be more susceptible to damage from the high-pressure water, and an inspection may be needed to determine if hydro jetting is the appropriate solution.

If you are experiencing recurrent clogs or slow drainage, or if you suspect a buildup of debris or grease within your plumbing system, it’s advisable to consult a professional plumber who can assess the issue and determine if hydro jetting is the right approach. Their expertise, combined with the power of hydro jetting technology, allows for efficient and thorough cleaning, ensuring the optimal performance of your drain and sewer lines.

Read more: What Is Flux Used For In Plumbing

Pipe Locator

A pipe locator, also known as a pipe and cable locator or underground utility locator, is a specialized tool used in plumbing to accurately locate the position and depth of buried pipes. It is an essential device for identifying underground plumbing lines and preventing damage during excavation or construction projects.

Pipe locators work by using different technologies to detect and trace the path of pipes. The most common methods include electromagnetic signals and ground-penetrating radar technology:

Electromagnetic Pipe Locators: These locators utilize electromagnetic signals to identify the presence and location of metallic pipes. The locator unit generates a signal that is applied to a conductive pipe or a tracer wire. By using a handheld receiver, the operator can detect the signal and trace the path of the pipe.

Ground-Penetrating Radar (GPR) Pipe Locators: GPR technology uses radar waves to detect subsurface objects, including pipes. The radar waves are emitted into the ground, and the GPR unit records the reflections caused by buried structures. By interpreting the radar data, the operator can determine the location and depth of the pipes.

Pipe locators offer several benefits in plumbing and excavation projects:

- Precise pipe location: Pipe locators provide accurate information about pipe locations, allowing for more targeted excavation and construction work. This reduces the risk of accidentally damaging underground pipes.

- Minimized disruptions: By precisely locating pipes, the need for unnecessary excavation or trenching is reduced. This helps to minimize disruptions to the surrounding area and reduce the impact on the environment.

- Time and cost efficiency: Pipe locators save time and money by facilitating efficient and targeted digging. Contractors can avoid costly repairs, project delays, and potential legal liabilities resulting from accidental pipe damage.

- Compliance with regulations: Many jurisdictions have regulations in place to prevent damage to underground utilities. The use of pipe locators helps contractors meet these regulations and ensures compliance with safety standards.

It’s important to note that pipe locators require expertise and training to use effectively. Professionals who operate these devices are familiar with the equipment and can interpret the results accurately.

If you are planning excavations, construction projects, or need to identify the location of buried pipes, it’s recommended to consult a professional plumbing service or contractor with access to pipe locators. Their expertise, combined with the use of pipe locating technology, ensures the precise detection and protection of underground plumbing infrastructure.

Pipe Freezing Kit

A pipe freezing kit is a specialized tool used in plumbing to temporarily freeze a section of pipe, creating an isolation point without shutting off the entire water supply. It is a valuable tool for making repairs or modifications on live plumbing systems where shutting off the main water supply is not feasible or desirable.

A pipe freezing kit typically includes insulated jackets or clamps encased with freeze plugs, along with a refrigerant. The freeze plugs are designed to absorb the cold temperature from the refrigerant, thereby freezing the water inside the section of pipe.

Using a pipe freezing kit offers several benefits:

- Continuity of water supply: With a pipe freezing kit, you can work on a specific section of pipe without disrupting the water supply to the rest of the building or system. This is especially useful in commercial or residential settings where water interruptions can cause inconveniences or disruptions.

- Time and cost efficiency: By avoiding the need to shut down the entire water system, pipe freezing kits save time and money. Repairs or modifications can be completed rapidly, minimizing downtime and reducing labor costs.

- Prevent water damage: Temporary freezing of the pipe prevents water flow, minimizing the risk of leaks or flooding during repairs. This is particularly advantageous in situations where the damaged section of the pipe cannot be easily isolated or drained.

- Safe and convenient: Pipe freezing kits are designed to be simple and safe to use, allowing plumbers to create an isolation point quickly and effectively. The equipment is portable and can be easily transported to different job sites.

When using a pipe freezing kit, it’s important to follow the manufacturer’s instructions carefully and take necessary safety precautions. Some key steps involved in freezing a pipe include:

- Inspect the pipe and identify the section that needs to be frozen. Ensure that the freezing plugs are properly sized to fit and seal the pipe.

- Securely attach the insulated jackets or clamps with freeze plugs on both sides of the section to be frozen.

- Connect the refrigerant supply to the freezing plugs. The refrigerant will flow through the plugs, absorbing heat from the pipe and causing the water inside to freeze.

- Monitor the temperature to ensure the pipe is frozen adequately. Once the desired freezing is achieved, the repair or modification work can proceed.

- After completing the necessary tasks, remove the pipe freezing kit and allow the pipe to thaw gradually. Open nearby faucets to relieve any pressure that may build up during the thawing process.

It’s important to note that pipe freezing kits are typically used on metal pipes and may have limitations in regard to pipe material, diameter, and environmental factors. It’s recommended to consult a professional plumber with experience in using pipe freezing kits for complex plumbing projects or if you have any concerns or uncertainties.

Pipe freezing kits are valuable tools that allow plumbers to work efficiently and effectively on live plumbing systems. With proper usage and careful attention to safety, pipe freezing kits enable repairs and modifications to be carried out without disrupting the entire water supply.

Conclusion

Plumbing is a critical aspect of any building, and having the right tools for the job can make all the difference in resolving issues efficiently and effectively. In this article, we have explored a range of common and specialized plumbing tools that are essential for various plumbing tasks.

The common plumbing tools, such as pipe wrenches, plungers, adjustable wrenches, pipe cutters, and pliers, are the backbone of any plumber’s toolkit. These versatile tools enable professionals to tackle a wide range of plumbing repairs, installations, and maintenance tasks.

In addition to the common tools, specialized plumbing tools offer more targeted solutions. Drain snakes, pipe inspection cameras, hydro jets, pipe locators, and pipe freezing kits provide plumbers with advanced capabilities for handling specific challenges in drain cleaning, pipe inspection, sewer line maintenance, locating buried pipes, and making repairs on live systems.

It’s important to note that while these tools are valuable in the hands of professionals, they may require expertise, training, and experience to be used effectively and safely. If you encounter complex plumbing issues or are uncertain about using specialized tools, it is always wise to consult a professional plumber with the necessary skills and knowledge.

The use of these tools not only speeds up plumbing tasks and enhances the quality of repairs but also helps prevent further damage and potential issues in the future. By using the appropriate tools and techniques, professional plumbers can ensure the longevity and optimal performance of plumbing systems.

Whether you are a homeowner facing minor plumbing issues or a professional plumber in need of the right tools for the job, understanding the purpose and functionality of these plumbing tools is crucial. With the right tools and the expertise to use them effectively, you can handle plumbing challenges with confidence, saving time, money, and potential headaches.

Remember, when in doubt, it’s always best to consult a professional plumber who can provide proper guidance and expertise to ensure the success of your plumbing projects.

Frequently Asked Questions about What Tools Are Used In Plumbing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Tools Are Used In Plumbing”