Articles

What Are Fittings In Plumbing

Modified: January 8, 2024

Learn about different types of fittings used in plumbing systems in our informative articles. Explore the role of fittings in ensuring proper flow and connection.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of plumbing, fittings play a crucial role in ensuring the proper installation and functioning of various plumbing systems. Whether it’s for residential or commercial purposes, understanding different types of fittings is essential for any plumber or DIY enthusiast.

Fittings are essentially connectors that join different plumbing components together, allowing for the seamless flow of liquids, gases, or solids. These fittings come in a variety of shapes, sizes, and materials to accommodate diverse plumbing needs.

In this article, we will explore some of the most common types of fittings used in plumbing systems, their purposes, and the materials typically used to make them. By gaining a better understanding of fittings, you will be empowered to make informed decisions when it comes to plumbing repairs, renovations, or installations.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Key Takeaways:

- Fittings are essential for connecting, controlling, and redirecting the flow in plumbing systems. Understanding the different types and materials empowers informed decision-making for plumbing projects.

- Common materials for fittings, such as PVC, copper, brass, and stainless steel, offer unique benefits and considerations. Proper installation techniques are crucial for leak-proof joints and optimal performance.

Read more: What Is A Compression Fitting In Plumbing

Types of Fittings

There is a wide range of fittings available in the plumbing industry, each designed for specific purposes and applications. Let’s take a closer look at some of the most commonly used fittings:

- Coupling: Couplings are used to connect two pipes of the same diameter together. They are typically threaded or slip-on fittings that provide a secure and leak-proof joint.

- Union: Unions are similar to couplings, but they allow for easy disconnection of pipes. They consist of three parts – a female end, a male end, and a nut that connects them. The nut can be tightened or loosened to disconnect the pipes when necessary.

- Elbow: Elbows are fittings that change the direction of a pipe. They come in different angles, such as 45 degrees or 90 degrees, and are used to navigate around obstacles or create bends in a plumbing system.

- Tee: A tee fitting resembles the letter “T” and is used to connect three pipes. It allows for the branching of a pipeline in different directions, making it ideal for creating junctions or dividing water flow.

- Cross: Cross fittings are similar to tee fittings but with an additional horizontal pipe. They are used when four pipes need to be connected, often in complex plumbing systems.

- Reducer: Reducers are used to connect pipes of different diameters. They are available in both concentric and eccentric configurations, allowing for a smooth transition in pipe size and maintaining the flow rate.

- Cap: Caps are fittings that seal off the end of a pipe. They are commonly used to close off unused or terminated pipe ends, providing a barrier against leaks or debris entering the plumbing system.

- Plug: Plugs are similar to caps but are designed to fit inside a pipe instead of covering the end. They are used to block the flow of liquid or gas temporarily, allowing for maintenance or repairs.

- Adapter: Adapters are fittings that enable the connection of pipes with different end types. They can have various combinations of male or female threads, slip or compression joints, or even PVC to metal connections.

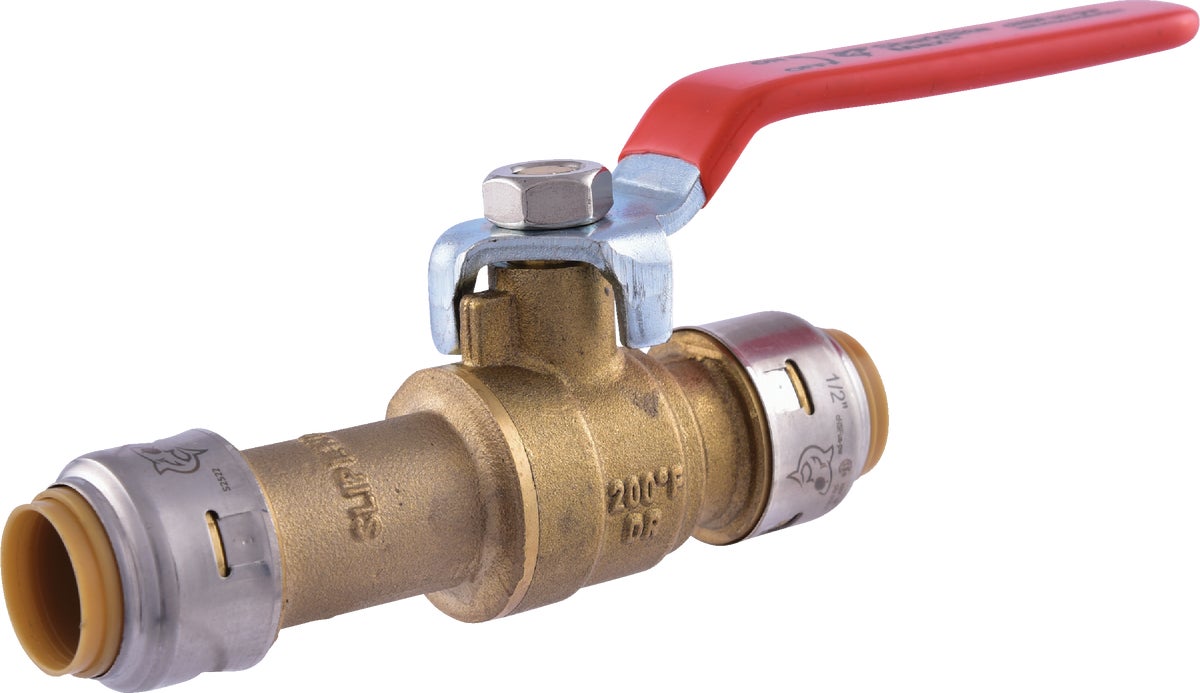

- Valve: While not strictly a fitting, valves are crucial components in plumbing systems. They control the flow of fluids or gases and can stop or regulate the flow as needed. Different types of valves include ball valves, gate valves, and check valves.

- Nipple: Nipples are short lengths of threaded pipes used to extend or connect fittings. They can have male or female threads on both ends and are often used in tight spaces or when additional length is needed.

These are just a few examples of the many fittings available in plumbing. It’s important to note that there are specialized fittings for specific applications, such as compression fittings for flexible piping or quick-connect fittings for easy installation.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Coupling

A coupling is a type of fitting used to connect two pipes of the same diameter together. It provides a secure and leak-proof joint, ensuring the smooth flow of liquids, gases, or solids through the plumbing system.

Couplings come in various designs, including threaded, slip-on, or compression fittings. Threaded couplings have internal and external threads that allow for easy installation by screwing the pipes together. Slip-on couplings, on the other hand, slide over the pipe ends and are secured using clamps or fasteners. Compression couplings use a compression nut and ferrules to create a tight seal.

When selecting a coupling, it’s essential to consider the material it’s made from. Common options include brass, stainless steel, PVC, or copper. Choosing the right material depends on factors such as the type of fluid or gas being transported, the operating temperature, and any potential chemical reactions.

Couplings are widely used in plumbing systems for various applications. They are commonly employed in repairing or extending existing pipelines, connecting fixtures such as sinks or toilets to the main water supply, or even in irrigation systems. In addition, couplings are essential in situations where there is a need to disconnect and reconnect pipes easily, as they allow for simple disassembly and reassembly without compromising the integrity of the joint.

Proper installation is crucial to ensure the effectiveness of the coupling. Pipe ends should be clean, smooth, and free from any defects or debris. For threaded couplings, applying plumber’s tape or sealant to the threads can further enhance the seal and prevent leaks. Slip-on couplings should be securely fastened with clamps or compression couplings tightened adequately to ensure a leak-proof connection.

In summary, couplings are versatile fittings used in plumbing systems to join two pipes together. They are available in various designs and materials, allowing for flexibility and compatibility with different pipe sizes and applications. By selecting and installing the right coupling for the job, you can ensure a reliable and efficient plumbing system.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Union

A union is a type of fitting that is similar to a coupling but provides the additional advantage of easy disconnection of pipes. It consists of three parts – a female end, a male end, and a nut that connects them.

The female end of the union has internal threads, while the male end has external threads that match the female end. The nut is threaded onto the male end, allowing for the secure tightening of the union. When the nut is loosened, it can be easily unscrewed to disconnect the union and separate the pipes.

Unions are commonly used in plumbing systems where there is a need for occasional disconnection. This can be beneficial in situations such as repairs, maintenance, or changes to the plumbing layout. Instead of having to cut and reassemble pipes, unions allow for an efficient and hassle-free disconnection without compromising the integrity of the joint.

Like couplings, unions are available in various materials such as brass, stainless steel, PVC, or copper. The material selection should be based on factors such as the type of fluid or gas being transported, the operating temperature, and any potential chemical reactions. Brass and stainless steel unions are commonly used for their durability and resistance to corrosion.

When installing a union, it is important to ensure proper alignment of the pipes and tight connections. The pipe ends should be clean, smooth, and free from any defects or debris. Plumber’s tape or sealant can be applied to the threads to enhance the seal and prevent leaks. The nut should be tightened securely using a wrench, but excessive force should be avoided to prevent damage to the fitting.

Unions are versatile fittings that offer convenience and flexibility in plumbing systems. They provide an easily detachable joint that allows for quick and efficient disconnection of pipes. Whether it’s for repairs, modifications, or maintenance, unions are an essential component in any plumbing toolkit.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Elbow

Elbows are fittings that are used to change the direction of a pipe. They are designed with a curved shape, typically in angles of 45 degrees or 90 degrees, although other angles are available. Elbows are crucial in navigating around obstacles or creating bends in a plumbing system.

Elbows come in different configurations and materials to accommodate various plumbing needs. Common materials used for elbows include PVC, copper, brass, and stainless steel. The material choice depends on factors such as the fluid or gas being transported, the temperature, and any potential corrosion concerns.

When selecting an elbow, it is essential to consider the angle of the bend needed and the flow requirements of the plumbing system. A 90-degree elbow creates a right-angle turn, while a 45-degree elbow provides a gentler turn. It’s important to choose the appropriate angle to prevent restrictions or disruptions to the flow of liquids, gases, or solids in the pipes.

Elbows are commonly used in a wide range of plumbing applications. They are often employed in residential and commercial plumbing systems for routing water supply lines, vent stacks, and waste lines. For example, in kitchens and bathrooms, elbows are used to connect pipes to sinks, faucets, toilets, or showers, allowing for the necessary bends to fit within the available space and accommodate the desired fixtures and fittings.

During installation, it is important to ensure proper alignment and secure connections when using elbows. Pipe ends should be clean, properly prepared, and free from any defects or debris. Depending on the material and joint type, elbows may require solvent cement, soldering, or mechanical connections such as compression fittings or threaded connections. Following manufacturer guidelines for installation is highly recommended to ensure a leak-free and structurally sound joint.

Elbows are versatile fittings that play a crucial role in plumbing systems. By allowing for changes in direction, they enable efficient and effective routing of pipes around obstacles and optimize the flow of fluids. With the right choice and installation of elbows, plumbing systems can be properly configured to meet the needs of any residential or commercial setting.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Read more: What Is A Street Elbow Fitting In Plumbing

Tee

A tee fitting is a type of plumbing fitting that resembles the letter “T” and is used to connect three pipes together. It consists of a straight section with an equal-sized branch protruding from the middle, forming the shape of a “T”. Tees are widely used in plumbing systems to create junctions or divide the flow of liquids, gases, or solids.

Tees are available in different configurations, including threaded, soldered, or compression fittings. Threaded tees have internal and external threads that allow for easy installation by screwing the pipes together. Soldered tees are joined by melting solder around the joints, creating a strong and leak-proof connection. Compression tees use nuts and ferrules to compress the pipes and create a tight seal.

When selecting a tee fitting, it is important to consider the size and type of pipes being connected. Tees come in various sizes to accommodate different pipe diameters, and they can be found in materials such as PVC, copper, brass, or stainless steel. Choosing the appropriate tee size and material ensures a proper fit and a reliable connection.

Tee fittings are commonly used in plumbing systems for a variety of applications. In residential plumbing, tees are used to connect water supply lines to fixtures such as sinks, toilets, and showers. They allow for the branching of the water supply, ensuring adequate water flow to each fixture. In irrigation systems, tees are used to split water flow to different zones or sections of the garden or landscape.

During installation, it is essential to ensure proper alignment and secure connections. Pipe ends should be clean, prepared, and free from any defects or debris. Threaded tees should be tightly screwed onto the pipes, while soldered or compression tees require proper soldering or compression fittings for a leak-free joint.

It’s important to note that tees are not used for flow control. Instead, they are used to divide or redirect flow. If flow control is needed, additional valves, such as ball valves or gate valves, can be installed in conjunction with tee fittings.

In summary, tee fittings are a fundamental component of plumbing systems, allowing for the efficient distribution of fluids or gases. By choosing the right tee fitting and ensuring proper installation, plumbing systems can be configured to meet the demands of various applications in both residential and commercial settings.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Cross

A cross fitting is a type of plumbing fitting that is similar to a tee fitting but with an additional horizontal pipe. It is designed in the shape of a “+” sign, allowing for the connection of four pipes in a cross configuration. Cross fittings are commonly used in plumbing systems where multiple branches or lines need to be connected.

Like tee fittings, cross fittings come in various configurations, including threaded, soldered, or compression fittings. Threaded cross fittings have internal and external threads that allow for easy installation by screwing the pipes together. Soldered cross fittings are joined by melting solder around the joints, creating a strong and leak-proof connection. Compression cross fittings use nuts and ferrules to compress the pipes and create a tight seal.

When selecting a cross fitting, it is crucial to consider the size and type of pipes being connected. Cross fittings are available in different sizes to accommodate various pipe diameters and materials such as PVC, copper, brass, or stainless steel.

Cross fittings are commonly used in plumbing systems that require a complex network of pipelines. They allow for the connection of multiple supply lines, making them suitable for applications such as residential or commercial plumbing, irrigation systems, or HVAC systems.

During installation, it is important to ensure proper alignment and secure connections. Pipe ends should be clean, prepared, and free from any defects or debris. Threaded cross fittings should be tightly screwed onto the pipes, while soldered or compression cross fittings require proper soldering or compression fittings for leak-free joints.

It’s important to note that cross fittings are not typically used for flow control. Instead, they are used to connect multiple lines or branches together. If flow control is needed, additional valves such as ball valves or gate valves can be installed in conjunction with cross fittings.

In summary, cross fittings are versatile components that are used in plumbing systems to create complex networks of pipelines. By choosing the right cross fitting and ensuring proper installation, plumbing systems can be configured to handle multiple lines or branches efficiently and effectively.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Reducer

A reducer is a type of plumbing fitting that is used to connect pipes of different diameters. It allows for a smooth transition in pipe size, ensuring the proper flow rate and compatibility between different sections of the plumbing system.

Reducers are available in two main configurations:

- Concentric Reducer: A concentric reducer is shaped like a cone, with one end having a larger diameter than the other. It provides a gradual reduction in pipe size, maintaining a uniform flow rate.

- Eccentric Reducer: An eccentric reducer is similar to a concentric reducer, but it has an off-center connection. This creates an offset in the pipe alignment, allowing for the redirection of flow or clearance of obstacles.

Reducers are typically made of materials such as PVC, copper, brass, or stainless steel, depending on the specific application and the compatibility of the materials being connected. The selection of the appropriate material ensures durability, resistance to corrosion, and long-term performance.

Reducers find widespread use in plumbing systems for various purposes. They can be used to connect larger water supply lines to smaller pipes leading to fixtures or appliances. In drainage systems, reducers are employed to transition from larger horizontal pipes to smaller vertical pipes. They can also be used in HVAC systems to connect different-sized ducts or in industrial applications to accommodate changes in pipe diameter.

During installation, it is important to ensure a secure and leak-free connection when using reducers. The pipe ends should be clean, properly prepared, and free from any defects or debris. Reducers may require different types of connections, including solvent cement for PVC pipes, soldering for copper pipes, or compression fittings for various materials. Following manufacturer guidelines and techniques specific to the type of connection is essential to achieve a reliable joint.

Reducers play a critical role in maintaining the integrity and optimal flow of plumbing systems. By utilizing the appropriate reducer fitting and ensuring proper installation, the transition between different pipe diameters can be achieved seamlessly, allowing for efficient and effective plumbing operations.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

When working with fittings in plumbing, always make sure to use the correct type and size for the specific application to ensure a proper and leak-free connection.

Cap

A cap is a type of plumbing fitting that is used to seal off the end of a pipe. It is designed to cover the open end of a pipe, providing a barrier against leaks, debris, or foreign substances entering the plumbing system.

Caps are typically made of materials such as PVC, copper, brass, or stainless steel, depending on the specific application and the compatibility of the materials being used in the plumbing system. The selection of the appropriate material ensures durability, resistance to corrosion, and long-term performance.

Caps are commonly used in plumbing systems for various purposes:

- Closing Unused Pipe Ends: In situations where a pipe is no longer in use or needs to be temporarily closed off, a cap is used to seal the open end. This prevents any unwanted substances from entering the pipe and ensures the integrity of the plumbing system.

- End of Pipeline: Caps are commonly used at the end of a pipeline, where no further connections need to be made. They provide a final seal, ensuring that there are no leaks or disruptions to the flow within the plumbing system.

- Temporary Closure: Caps can also be used for temporary closure during maintenance or repairs. They provide a convenient and reliable method of preventing any unwanted flow during the servicing of the plumbing system.

During installation, it is important to ensure a proper fit and a secure connection when using caps. The pipe end should be clean, properly prepared, and free from any defects or debris. Caps typically have a threaded or slip-on design. Threaded caps can be easily screwed onto the pipe, providing a secure and leak-proof seal. Slip-on caps are installed by sliding them over the pipe end and securing them with clamps or fasteners.

It is worth noting that caps are not intended for flow control. They are solely designed to provide a seal and closure for pipe ends. If flow control is required, appropriate valves should be installed within the plumbing system.

In summary, caps are essential fittings used in plumbing systems to seal off the end of a pipe. They provide a barrier against leaks and protect the integrity of the plumbing system by preventing the entry of debris or foreign substances. By selecting the appropriate cap and ensuring proper installation, the functionality and reliability of the plumbing system can be maintained.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Read more: How To Tighten Plumbing Fittings

Plug

A plug is a type of plumbing fitting that is used to block the flow of liquid or gas temporarily. It is designed to fit inside a pipe and is used to seal off the opening, preventing any substance from flowing through the plumbing system.

Plugs are commonly made of materials such as PVC, rubber, or metal, depending on the specific application and the compatibility of the materials used in the plumbing system. The selection of the appropriate material ensures durability, flexibility, and resistance to corrosion.

Plugs are used in plumbing systems for various purposes:

- Temporary Blockage: Plugs are often used for temporary blockage during plumbing work or repairs. They provide a reliable seal, preventing any flow through the pipe and allowing work to be carried out without the need to shut down the entire system.

- Pressure Testing: Plugs are also used for pressure testing in plumbing systems. By inserting a plug into a pipe and sealing it securely, pressure can be applied to test the integrity of the pipeline and identify any potential leaks or weaknesses.

- Preventing Leaks: Plugs are used to prevent leaks in pipes that are no longer in use or need to be temporarily sealed off. By inserting a plug, any potential leaks are eliminated, ensuring the integrity of the plumbing system.

During installation, it is important to ensure a proper fit and a secure seal when using plugs. The pipe end should be clean, properly prepared, and free from any defects or debris. Plugs typically have a tapered design, allowing for easy insertion into the pipe. Some plugs have a wing nut or a compression feature that can be tightened to create a secure seal.

It is important to note that plugs are not intended for permanent closures or flow control. They are temporary fittings used to seal off a pipe for a specific purpose. If a permanent closure or flow control is required, other permanent fittings or valves should be used.

In summary, plugs are essential fittings used in plumbing systems to block the flow of liquid or gas temporarily. They provide a reliable seal, allowing for temporary closure and pressure testing. By selecting the appropriate plug and ensuring proper installation, specific sections of the plumbing system can be effectively sealed off when needed.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Adapter

An adapter is a type of plumbing fitting that enables the connection of pipes with different end types or sizes. It serves as a bridge between two pipes, allowing for a seamless transition and compatibility between different sections of the plumbing system.

Adapters are commonly made of materials such as PVC, brass, stainless steel, or copper, depending on the specific application and the compatibility of the materials being connected. The selection of the appropriate material ensures durability, corrosion resistance, and long-term performance.

Adapters come in various configurations and types to accommodate different pipe end types or sizes. Some common types of adapters include:

- Male to Female Adapter: This type of adapter has a male thread on one end and a female thread on the other, enabling the connection of pipes with different genders or thread types.

- Male to Male Adapter: This type of adapter has a male thread on both ends, allowing for the connection of two pipes with male threads.

- Female to Female Adapter: This type of adapter has a female thread on both ends, allowing for the connection of two pipes with female threads.

- PVC to Metal Adapter: This type of adapter is designed to connect PVC pipes to metal pipes or fittings, ensuring a secure and leak-proof joint.

- Compression Adapter: This type of adapter uses compression fittings to connect pipes of different sizes or materials, providing a reliable and watertight connection.

Adapters are commonly used in various plumbing systems for different purposes:

- Transitioning from one pipe material to another, such as connecting PVC pipes to copper pipes.

- Connecting different pipe sizes or diameters, allowing for smooth flow and compatibility between sections of the plumbing system.

- Adapting pipe threads with different genders or types, ensuring a secure connection between pipes with different threading systems.

- Enabling the connection of pipes to specific fittings or fixtures that require a different end type or size.

During installation, it is important to ensure a proper fit and a secure connection when using adapters. The pipe ends should be clean, properly prepared, and free from any defects or debris. Depending on the type of adapter, the connection method may involve tightening threads, using compression fittings, or applying solvent cement or sealants as recommended by the manufacturer.

In summary, adapters are versatile fittings used in plumbing systems to bridge the gap between different pipe end types or sizes. They provide a seamless transition and compatibility, allowing for the smooth flow of liquids, gases, or solids. By selecting the appropriate adapter and ensuring proper installation, different sections of the plumbing system can be effectively connected and unified.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Valve

A valve is a crucial plumbing fitting that controls the flow of fluids or gases within a plumbing system. It is designed to start, stop, or regulate the flow, allowing for precise control and efficient operation.

Valves come in various types, each serving a specific purpose and function. Some common types of valves used in plumbing systems include:

- Ball Valve: A ball valve uses a ball with a hole in the center to control the flow. When the ball is aligned with the pipe, the flow is open, and when the ball is turned perpendicular to the pipe, the flow is closed.

- Gate Valve: A gate valve has a gate or a wedge that slides up and down to control the flow. When the gate is fully raised, the flow is open, and when the gate is fully lowered, the flow is closed.

- Globe Valve: A globe valve uses a disk or a plug that moves up and down to control the flow. By adjusting the position of the disk or plug, the flow can be regulated.

- Check Valve: A check valve allows the flow in one direction and prevents backflow. It uses a flap or a ball that moves freely to allow flow in one direction and closes to prevent flow in the opposite direction.

- Pressure Reducing Valve: A pressure reducing valve is used to regulate and control the pressure of water or gas within a plumbing system. It ensures a consistent and safe pressure throughout the system.

- Thermostatic Valve: A thermostatic valve is used to control and regulate the temperature of water flow. It allows for precise temperature adjustments, ensuring comfort and safety.

Valves are made from various materials such as brass, stainless steel, or PVC, depending on the specific application, fluid or gas type, and compatibility with other materials within the plumbing system.

Valves are used in plumbing systems for a wide range of applications, including:

- Controlling the flow of water in faucets, showers, or toilets.

- Shutting off water supply lines during repairs or emergencies.

- Diverting water flow between different fixtures or sections of the plumbing system.

- Regulating the pressure of water or gas within the system.

- Preventing backflow or the contamination of water supply.

Proper installation and maintenance of valves are essential for their optimal performance. Valves should be installed according to manufacturer guidelines, ensuring proper alignment, secure connections, and adequate sealing. Regular inspection and lubrication of valves can help prevent leaks, ensure smooth operation, and extend the lifespan of the valve.

In summary, valves are critical components in plumbing systems, providing control, regulation, and safety. By utilizing the appropriate type of valve and ensuring proper installation, plumbing systems can operate efficiently and effectively, meeting the specific needs of residential, commercial, or industrial settings.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Nipple

A nipple is a type of plumbing fitting that is a short length of pipe with male threads on both ends. It is used to extend or connect two fittings or pipes with female threads together, creating a secure and leak-proof joint.

Nipples are typically made of materials such as PVC, copper, brass, or stainless steel, depending on the specific application and the compatibility of the materials being connected. The selection of the appropriate material ensures durability, corrosion resistance, and long-term performance.

Nipples come in various lengths, diameters, and threads to accommodate different plumbing needs. They can have both ends tapered to create a tight seal or have one end threaded and the other end non-threaded for specific applications.

Nipples are commonly used in plumbing systems for various purposes:

- Extending Pipe Length: Nipples are used to extend the length of a pipe when needed. They allow for additional distance between fittings or pipes, ensuring the proper fit and alignment within the plumbing system.

- Connecting Fittings: Nipples act as connectors between fittings with female threads. They allow for secure attachment, creating a reliable and leak-proof joint.

- Transitioning Pipe Sizes: Nipples are used to transition between pipes of different diameters. By using nipples of appropriate lengths and sizes, the flow can be smoothly transferred between different-sized pipes.

- Creating Close Connections: Nipples are used to create tight and close connections within the plumbing system. They eliminate the need for excessive pipe bends or extensions, optimizing space and maintaining efficient flow.

During installation, it is important to ensure a proper fit and a secure connection when using nipples. The pipe ends and threaded nipples should be clean, properly prepared, and free from any defects or debris. Plumber’s tape or thread sealant can be used to enhance the seal and prevent leaks when connecting threaded nipples.

It is important to select the appropriate nipple length and diameter to ensure a proper fit and alignment within the plumbing system. Incorrectly sized or mismatched nipples may result in leaks, reduced flow, or difficulty in assembly.

In summary, nipples are versatile plumbing fittings used to extend, connect, or transition pipes within a plumbing system. By selecting the right size, material, and installation method, nipples create secure and reliable connections, ensuring the proper flow and integrity of the system.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Read more: How To Loosen Plumbing Fittings

Common Materials Used for Fittings

When it comes to plumbing fittings, there are several common materials that are used, each with its own characteristics and suitability for different applications. The choice of material depends on factors such as the type of fluid or gas being transported, the operating temperature, and any potential chemical reactions that may occur.

Here are some of the most commonly used materials for fittings:

- PVC (Polyvinyl Chloride): PVC fittings are popular due to their affordability, lightweight nature, and resistance to corrosion. They are commonly used in residential plumbing systems, irrigation systems, and swimming pool installations. PVC fittings are available in various sizes and configurations, making them versatile and easy to work with.

- Copper: Copper fittings are known for their durability, resistance to corrosion, and ability to handle high temperatures and pressures. They are commonly used in water supply systems, heating systems, and gas lines. Copper fittings have a long lifespan and can be easily soldered to create leak-proof joints.

- Brass: Brass fittings are valued for their strength, durability, and resistance to corrosion. They are commonly used in plumbing systems for both residential and commercial applications. Brass fittings offer excellent compatibility with a wide range of materials, making them suitable for various plumbing needs.

- Stainless Steel: Stainless steel fittings are known for their excellent corrosion resistance, making them ideal for both indoor and outdoor applications. They are commonly used in plumbing systems where durability, hygiene, and longevity are important, such as in the food and beverage industry or corrosive environments.

- Cast Iron: Cast iron fittings are known for their strength and durability. They are commonly used in drainage and sewage systems, where resistance to corrosion and structural integrity are critical. Cast iron fittings are highly resilient and can handle heavy loads, making them suitable for underground applications.

- Plastic: Plastic fittings, such as polypropylene or polyethylene, are lightweight, affordable, and resistant to corrosion. They are commonly used in applications where chemical resistance is important, such as in laboratories or industrial settings. Plastic fittings are often used in the transportation of water, chemicals, or gases.

When selecting fittings, it is important to carefully consider the material’s properties and suitability for the specific application. Factors such as pressure rating, temperature range, and compatibility with other materials should be taken into account to ensure a secure and long-lasting plumbing system.

In summary, plumbing fittings are made from a variety of materials, each with its own unique characteristics and advantages. The choice of material should align with the specific requirements of the plumbing system to ensure optimal performance, durability, and compatibility.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Conclusion

Fittings are a vital component of plumbing systems, serving to connect, control, and redirect the flow of liquids, gases, and solids. They play a crucial role in ensuring the efficient and reliable operation of plumbing systems, whether in residential, commercial, or industrial settings.

In this article, we have explored some of the most commonly used fittings in plumbing systems. From couplings and unions to elbows, tees, crosses, reducers, caps, plugs, adapters, valves, and nipples, each fitting has its own purpose and functionality. By understanding the different types of fittings, their uses, and the materials they are made from, you can make informed decisions when it comes to plumbing repairs, renovations, or installations.

When selecting fittings, it’s important to consider factors such as the size, material, and compatibility with other components of the plumbing system. Proper installation techniques, including cleaning, preparing, and securing connections, are essential to ensure leak-proof joints and optimal performance.

Furthermore, we’ve discussed the common materials used for fittings, such as PVC, copper, brass, stainless steel, and plastic. Each material has its own benefits and considerations, including corrosion resistance, durability, temperature tolerance, and chemical compatibility.

In conclusion, fittings are the connectors that bring plumbing systems together. They enable the seamless flow of liquids, gases, and solids, allowing for the proper functioning of various applications. By understanding the different types of fittings and their materials, you can ensure the successful completion of plumbing projects, whether you’re a professional plumber or a DIY enthusiast.

Inputs: {‘title’: ‘What Are Fittings In Plumbing’}

Frequently Asked Questions about What Are Fittings In Plumbing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Fittings In Plumbing”