Articles

What Is ABS Used For In Plumbing

Modified: January 6, 2024

Learn about the various uses of ABS in plumbing with our informative articles. Discover how this versatile material enhances durability and efficiency in plumbing systems.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

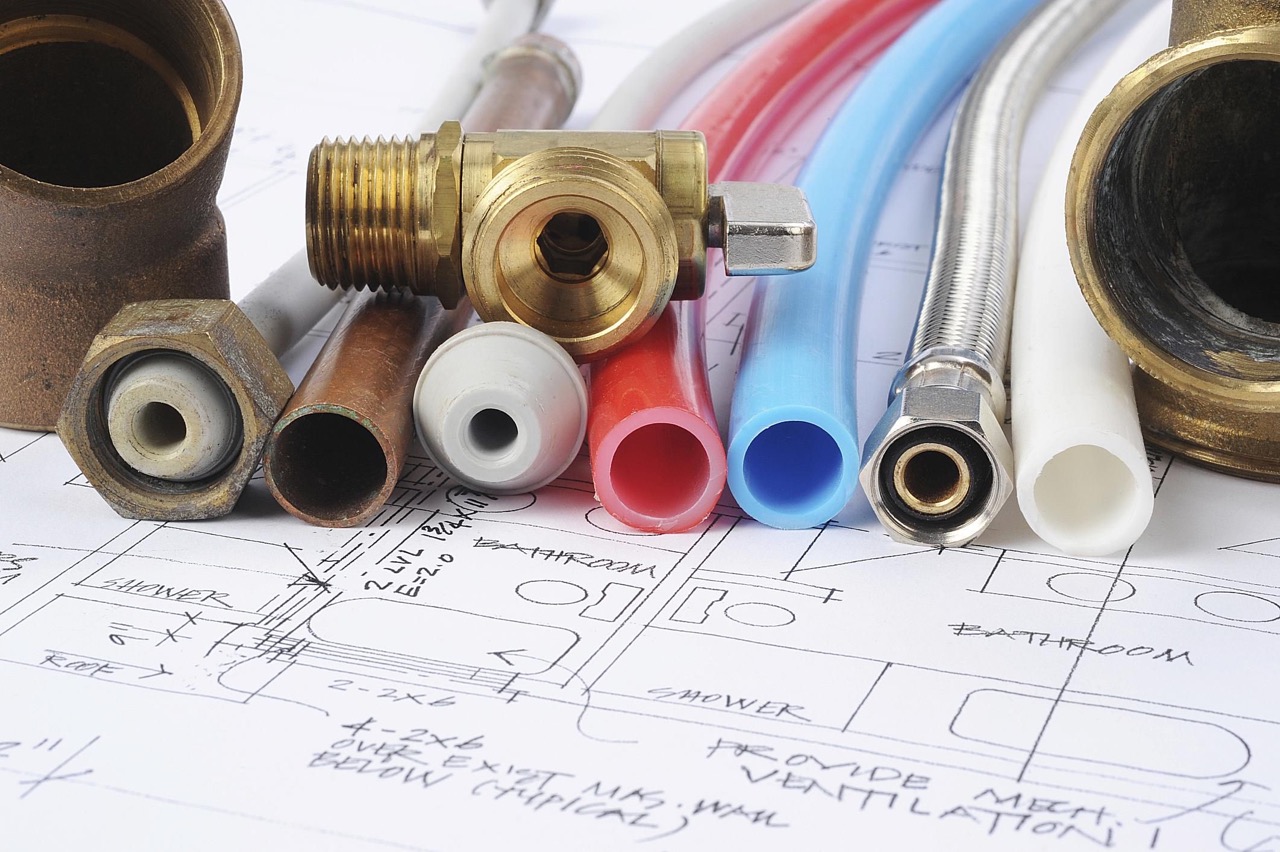

When it comes to plumbing, there are a variety of materials that can be used for the pipes and fittings. One of the most popular options is Acrylonitrile Butadiene Styrene, commonly known as ABS. ABS is a type of thermoplastic polymer that has exceptional strength and durability, making it an ideal choice for plumbing applications.

ABS is widely used in the plumbing industry due to its numerous benefits. It is resistant to chemicals, impact, and corrosion, making it suitable for both indoor and outdoor use. Additionally, ABS is lightweight, making it easy to work with during installation. In this article, we will explore the benefits of ABS in plumbing, its various applications, and guidelines for installation, maintenance, and repair.

Before delving into the details, it’s important to note that ABS is not suitable for use in hot water systems. It has a maximum operating temperature of around 160°F (71°C), which makes it suitable for cold water applications. For hot water systems, other materials like copper or CPVC are more appropriate.

Now, let’s take a closer look at the benefits of ABS in plumbing and how it is utilized in different applications.

Key Takeaways:

- ABS is a durable, chemical-resistant material suitable for drainage, venting, and non-pressurized water supply systems. Its ease of installation and maintenance make it an excellent choice for plumbing applications.

- Regular maintenance, prompt repairs, and adherence to building codes are essential for maximizing the efficiency and longevity of ABS plumbing systems. Consult professionals and local regulations for specific guidelines.

Read more: What Is Plumbing Tape Used For

Benefits of ABS in Plumbing

ABS offers several advantages that make it a popular choice for plumbing applications. Here are the key benefits of using ABS:

- Durability: ABS is known for its exceptional durability. It can withstand high impact and pressure, making it resistant to cracks and leaks. This ensures the longevity of the plumbing system.

- Chemical resistance: ABS is highly resistant to chemicals and acids, making it suitable for various plumbing applications. It can be used in systems where aggressive chemical solutions are used, such as industrial setups or laboratories.

- Corrosion resistance: Unlike metal pipes, ABS is not prone to corrosion. This makes it an excellent choice for both underground and above-ground plumbing installations, where it needs to withstand moisture, soil, and other corrosive elements.

- Lightweight: ABS is significantly lighter than metal pipes, making it easier to handle and install. Its lightweight nature also reduces the labor and transportation costs associated with plumbing projects.

- Easy installation: ABS pipes are designed with a bell and spigot system, allowing for easy and secure connections. The material is also easy to cut and shape, providing flexibility during installation and reducing the time and effort required.

- Quiet operation: ABS pipes have excellent soundproofing properties, minimizing noise from flowing water. This is particularly beneficial in residential buildings where noise reduction is a priority.

- Low thermal conductivity: ABS has low thermal conductivity, meaning it is an effective insulator. This helps prevent heat loss in cold water systems and reduces the likelihood of condensation forming on the pipe surfaces.

In addition to these benefits, ABS is also eco-friendly as it can be recycled. This makes it a sustainable choice for plumbing projects.

Now that we understand the advantages of ABS in plumbing, let’s explore its various applications.

Various Applications of ABS in Plumbing

ABS is a versatile material that finds wide-ranging applications in the field of plumbing. Its excellent properties make it suitable for various types of plumbing systems. Let’s explore some of the common applications of ABS:

- Drainage Systems: ABS pipes are commonly used in drainage systems to carry away wastewater from sinks, showers, toilets, and other fixtures. The smooth interior surface of ABS pipes prevents clogs and ensures the smooth flow of waste.

- Venting Systems: ABS pipes are also utilized for venting systems in plumbing. These pipes help maintain proper air pressure in the drainage system, preventing the buildup of sewer gases and unpleasant odors in the building.

- Water Supply Systems: Though ABS is primarily used for drainage and venting, it can also be used in non-pressurized water supply systems. This includes applications such as irrigation systems, pool plumbing, and rainwater harvesting systems.

- Bathroom and Kitchen Plumbing: In residential and commercial buildings, ABS pipes and fittings are extensively used in bathroom and kitchen plumbing. They are used to connect sinks, showers, bathtubs, and toilets to the drainage system effectively.

- Septic Systems: ABS pipes are commonly used in septic systems for piping effluent away from the septic tank to the drainage field. The durability and chemical resistance of ABS make it an ideal choice for this application.

- Irrigation Systems: ABS pipes are often used in irrigation systems, particularly for underground piping. They can withstand exposure to soil and moisture without corroding, making them a reliable choice for transporting water to plants and grass.

- Industrial Applications: ABS pipes are frequently used in industrial settings for various plumbing needs. They are suitable for transporting chemicals, wastewater, and other liquids commonly found in industrial processes.

The versatility and reliability of ABS make it an excellent choice for these different plumbing applications. However, it is essential to ensure that ABS is used within its recommended operating temperature and pressure limits for each specific application.

Now that we have explored the various applications of ABS in plumbing, let’s move on to understanding its specific uses in drainage systems, venting systems, and water supply systems.

ABS in Drainage Systems

ABS pipes play a crucial role in drainage systems by efficiently carrying wastewater away from various fixtures in residential, commercial, and industrial buildings. Here’s why ABS is commonly used in drainage systems:

Durability: ABS pipes are renowned for their strength and durability. They are resistant to cracks and leaks, ensuring the long-lasting performance of the drainage system. This is especially important in drainage systems where pipes are exposed to continuous water flow and potential impacts from solid waste.

Corrosion Resistance: ABS is highly resistant to corrosion, making it an ideal material for drainage piping. This is particularly beneficial in below-ground drainage applications, where the pipes are exposed to damp soil and potentially corrosive elements.

Smooth Interior Surface: ABS pipes have a smooth interior surface, which prevents the buildup of debris and waste materials. This not only ensures a clear pathway for wastewater flow but also minimizes the chances of clogs and blockages in the drainage system.

Flexibility: ABS pipes are flexible, allowing for easy installation in various configurations. They can be easily cut, joined, and maneuvered to accommodate the specific layout and design requirements of the drainage system. This flexibility also makes repairs and modifications more convenient.

Chemical Resistance: ABS pipes are resistant to a wide range of chemicals commonly found in wastewater and drainage systems. This makes them suitable for both residential and industrial applications where aggressive chemical solutions may be present.

Noise Reduction: The smooth interior surface of ABS pipes helps minimize noise from flowing wastewater. This is particularly beneficial in residential buildings where noise reduction is crucial for creating a comfortable living environment.

Ease of Maintenance: ABS pipes are easy to clean and maintain. Due to their smooth surface, they are less likely to accumulate debris, reducing the need for frequent maintenance. In case of blockages or maintenance requirements, ABS pipes are easily accessible and can be repaired or replaced with minimal disruption.

Overall, the durability, corrosion resistance, smooth interior surface, and flexibility of ABS pipes make them an excellent choice for drainage systems. However, it is important to ensure proper installation and adhere to building codes and regulations to maximize the efficiency and performance of the drainage system.

Now, let’s explore the specific use of ABS in venting systems.

ABS in Venting Systems

ABS pipes are widely used in venting systems to maintain proper air pressure and prevent the buildup of sewer gases in plumbing systems. Here’s why ABS is commonly utilized in venting systems:

Chemical Resistance: ABS pipes are highly resistant to chemicals, including those found in sewer gases. This makes them suitable for venting systems, where they come in contact with potentially corrosive gases and vapors.

Durability: ABS pipes are known for their strength and durability, ensuring the venting system’s long-lasting performance. They can withstand the constant flow of air and the occasional pressure changes that occur in the plumbing system.

Corrosion Resistance: ABS is resistant to corrosion, making it a reliable choice for venting systems. The pipes can maintain their structural integrity and function effectively even when exposed to moisture and potentially corrosive elements.

Soundproofing: ABS pipes have excellent soundproofing properties. This is beneficial in venting systems, as it helps minimize noise transmission from the plumbing system to the surrounding rooms or spaces.

Easy Installation: ABS pipes are easy to install in venting systems, thanks to their lightweight and flexible nature. They can be easily cut and joined, allowing for a seamless installation process that saves time and effort.

Code Compliance: ABS pipes are widely accepted and approved by building codes and regulations for use in venting systems. This gives homeowners and professionals peace of mind knowing that their venting systems are in compliance with industry standards.

Proper venting is essential to maintain the performance and safety of a plumbing system. ABS pipes, with their chemical resistance, durability, corrosion resistance, soundproofing capabilities, and ease of installation, are the preferred choice for venting systems in residential and commercial buildings.

Now, let’s delve into the specific use of ABS in water supply systems.

When using ABS in plumbing, make sure to use the appropriate solvent cement and primer for a secure and leak-free joint. Always follow the manufacturer’s instructions for best results.

Read more: What Is Flux Used For In Plumbing

ABS in Water Supply Systems

While ABS is primarily known for its use in drainage and venting systems, it can also be utilized in non-pressurized water supply systems. Here’s why ABS is chosen for certain applications in water supply systems:

Chemical Resistance: ABS pipes have excellent resistance to a wide range of chemicals, making them suitable for transporting non-potable water. This makes ABS a suitable material for irrigation systems, pool plumbing, and rainwater harvesting systems.

Durability: ABS pipes offer exceptional durability, ensuring that the water supply system remains intact and leak-free. They can withstand the stresses and movements associated with non-pressurized water supply systems without compromising their performance.

Corrosion Resistance: ABS is highly resistant to corrosion, making it a reliable choice for non-pressurized water supply. It can withstand exposure to moist environments without deteriorating or contaminating the water being transported.

Smooth Interior Surface: The smooth interior surface of ABS pipes is advantageous in water supply systems as it helps maintain a consistent flow of water. This reduces the chances of clogs or obstructions and ensures efficient water distribution.

Flexibility: ABS pipes are flexible, allowing for easy installation in different configurations. They can be easily cut and joined, ensuring a seamless and efficient water supply system that can adapt to various project requirements.

Ease of Maintenance: ABS pipes are designed for easy maintenance and repair. In the event of any issues, ABS pipes can be accessed and repaired without extensive disruption to the water supply system.

It’s important to note that ABS should not be used in pressurized hot water systems. The maximum operating temperature for ABS is around 160°F (71°C). For pressurized hot water applications, materials like copper or CPVC are more suitable.

Overall, ABS provides a reliable and durable option for non-pressurized water supply systems. When used in conjunction with other appropriate materials, ABS pipes can effectively transport water in applications such as irrigation systems, pool plumbing, and rainwater harvesting systems.

Now that we have explored the applications of ABS in drainage systems, venting systems, and water supply systems, let’s move on to understanding the installation process of ABS plumbing systems.

Installation of ABS Plumbing Systems

The installation of ABS plumbing systems involves a series of steps to ensure a secure and efficient plumbing system. Here’s a general overview of the installation process:

1. Design and Planning: The first step is to plan the layout and design of the plumbing system. This includes determining the placement of fixtures, calculating pipe lengths, and ensuring compliance with building codes and regulations.

2. Gather Materials and Tools: Next, gather all the necessary materials and tools for the installation. This includes ABS pipes, fittings, glue, primer, cutting tools, measuring tape, and a deburring tool.

3. Cut and Fit ABS Pipes: Measure and mark the ABS pipes according to the plumbing layout. Use a cutting tool to cut the pipes to the required lengths. Make sure the ends are clean, free of burrs, and straight. Test fit the pipes and make any necessary adjustments.

4. Prepare Pipes and Fittings: Before connecting the pipes and fittings, ensure they are clean and dry. Use a primer to clean and condition the surface of the pipe and fitting, followed by applying ABS glue to both the pipe and fitting.

5. Join Pipes and Fittings: Insert the pipe into the fitting, applying a twisting motion to ensure a secure connection. Hold the joint firmly for a few seconds to allow the glue to set.

6. Support the Plumbing System: Install appropriate support brackets or hangers to secure the ABS pipes in place. This helps prevent stress and movement that could lead to pipe damage or leaks over time.

7. Test the Plumbing System: Once the installation is complete, perform a thorough check of the entire plumbing system. Test for leaks by running water through the system and inspecting all joints and connections. Make any necessary adjustments or repairs as needed.

8. Obtain Inspections and Approvals: Depending on local regulations, it is crucial to get the plumbing system inspected by the appropriate authorities to ensure compliance and obtain the necessary approvals.

9. Document and Maintain: Keep a record of the plumbing system’s layout and any changes made during the installation process. It is also essential to perform regular maintenance to ensure the longevity and efficiency of the ABS plumbing system.

It’s important to follow manufacturer guidelines, building codes, and industry best practices during the installation process. If you are unsure about any aspect of the installation, it’s recommended to consult with a professional plumber.

Now that we understand the installation process, let’s move on to discussing the maintenance and repair of ABS plumbing systems.

Maintenance and Repair of ABS Plumbing Systems

Maintaining and promptly addressing any issues with ABS plumbing systems is essential for their long-term functionality and durability. Here are some key maintenance and repair considerations:

1. Regular Inspections: Conduct regular inspections of the ABS plumbing system to check for any signs of leaks, damage, or corrosion. Look for water stains, dripping fittings, or any unusual odors that may indicate a problem.

2. Clearing Clogs: In case of clogs, it’s important to address them promptly to prevent further damage. Use a plunger or plumbing snake to clear minor clogs from drains. For more stubborn clogs, consider using a chemical drain cleaner, following the product instructions carefully.

3. Proper Cleaning: Clean ABS pipes with mild soap and warm water to remove any accumulated debris or dirt. Avoid using abrasive cleaners or chemicals that can damage the pipe surface over time.

4. Repairing Leaks: If you notice any leaks in the ABS plumbing system, it’s crucial to address them promptly. Identify the source of the leak and determine if a simple reapplication of ABS glue is sufficient. If the leak persists, consider replacing the affected pipe or fitting.

5. Insulating Exposed Pipes: If the ABS plumbing system is exposed to cold temperatures, consider insulating the pipes to prevent freezing. This helps protect the pipes from damage and potential bursting due to expansion of frozen water inside.

6. Avoiding Chemical Damage: While ABS pipes are resistant to many chemicals, it’s important to avoid using harsh chemicals or solvents that can deteriorate the pipe material. Use only approved cleaning agents and be cautious when using any chemicals near the plumbing system.

7. Checking Support Structures: Regularly inspect the support structures of the ABS plumbing system, such as brackets and hangers. Ensure they are secure, properly aligned, and offer sufficient support to prevent stress on the pipes and fittings.

8. Professional Help: If you encounter a complex issue or are unsure about the best approach for maintenance or repair, it’s recommended to seek the assistance of a professional plumber. They have the expertise and experience to handle any major repairs or replacements.

Remember to consult local building codes and regulations when performing maintenance or repairs on ABS plumbing systems to ensure compliance and safety.

With proper maintenance, timely repairs, and periodic inspections, ABS plumbing systems can provide reliable and long-lasting performance for your building’s plumbing needs.

Now, let’s conclude our discussion on ABS plumbing systems.

Conclusion

ABS, or Acrylonitrile Butadiene Styrene, is a versatile and durable material that is extensively used in the plumbing industry. Its numerous benefits, including durability, chemical resistance, corrosion resistance, lightweight nature, and ease of installation, make it a popular choice for various plumbing applications.

ABS is commonly used in drainage systems, venting systems, and non-pressurized water supply systems. In drainage systems, ABS pipes effectively carry wastewater away from fixtures, thanks to their durability, corrosion resistance, and smooth interior surface. In venting systems, ABS pipes help maintain proper air pressure and prevent the buildup of sewer gases, while also offering chemical resistance and soundproofing properties. For non-pressurized water supply systems, ABS is a suitable material for transporting non-potable water in applications such as irrigation, pool plumbing, and rainwater harvesting, due to its chemical resistance and durability.

The installation of ABS plumbing systems involves careful planning, precise cutting and joining of pipes, and adherence to building codes and regulations. Regular maintenance, including inspections, cleaning, and prompt repair of leaks or clogs, helps ensure the efficient and dependable performance of ABS plumbing systems.

While ABS offers numerous advantages, it is important to note that it is not suitable for use in pressurized hot water systems. For hot water applications, materials like copper or CPVC should be used instead.

In conclusion, ABS is a reliable and versatile material for plumbing systems. Its durability, chemical resistance, corrosion resistance, ease of installation, and other benefits make it an excellent choice for drainage, venting, and non-pressurized water supply applications. By following proper installation techniques, conducting regular maintenance, and addressing any issues promptly, ABS plumbing systems can provide long-lasting and efficient plumbing solutions for residential, commercial, and industrial buildings.

Thank you for taking the time to explore the benefits, applications, installation, and maintenance of ABS plumbing systems. Remember to consult with professionals or refer to local regulations for specific requirements and guidelines when working with ABS plumbing systems.

Frequently Asked Questions about What Is ABS Used For In Plumbing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is ABS Used For In Plumbing”