Home>Articles>What Type Of Ladder Should Be Used When Servicing Electrical Systems

Articles

What Type Of Ladder Should Be Used When Servicing Electrical Systems

Modified: February 22, 2024

Read articles on what type of ladder you should use when servicing electrical systems to ensure safety and compliance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

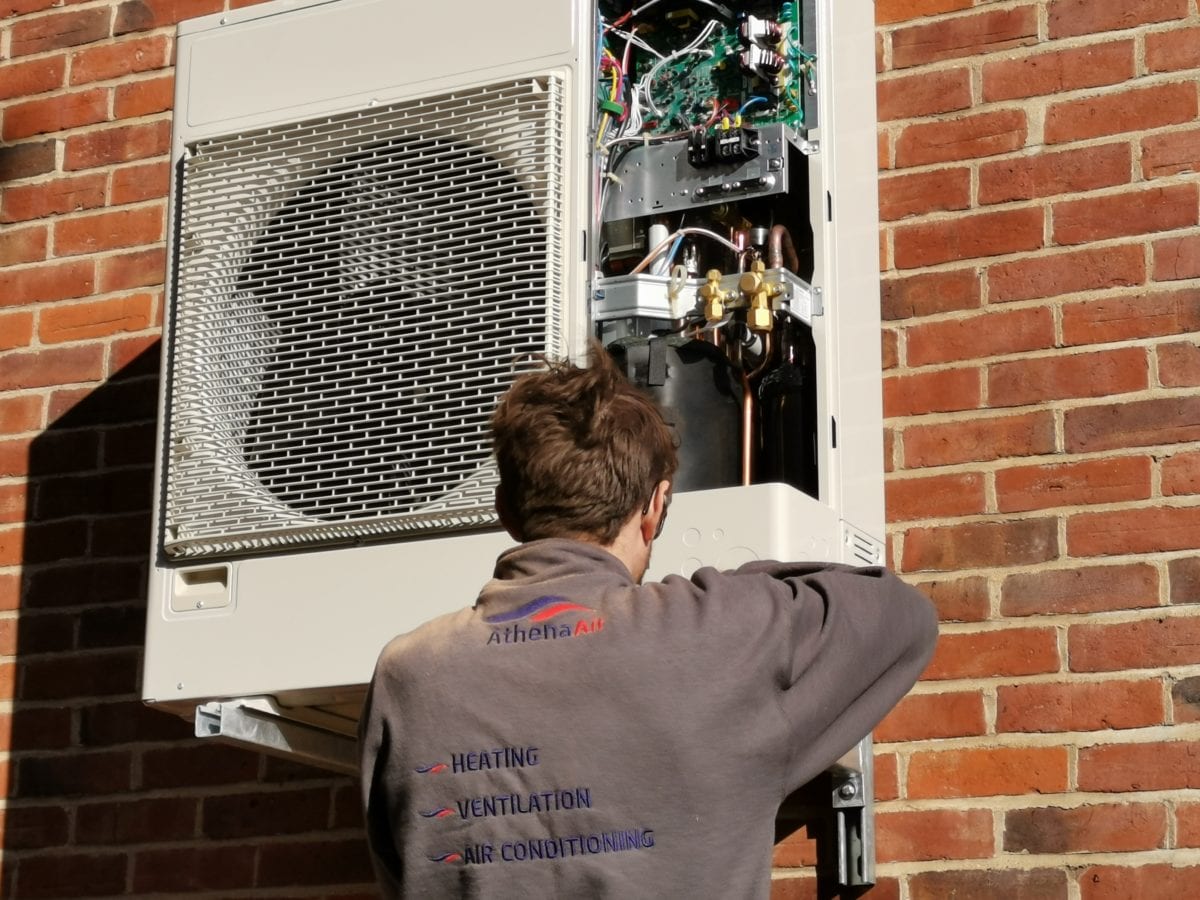

When it comes to servicing electrical systems, using the right ladder is of utmost importance. Electrical work can be dangerous and requires extra caution to protect yourself and others from potential hazards. Choosing the correct ladder for the job not only ensures safety but also increases efficiency and productivity.

Whether you are a professional electrician or a homeowner embarking on a DIY electrical project, understanding the different types of ladders available for electrical system servicing is essential. In this article, we will delve into the importance of using the correct ladder and discuss the factors to consider when selecting one. We will also explore the various types of ladders commonly used for electrical work and compare the benefits of fiberglass and aluminum options. Additionally, we will provide safety guidelines to follow when using ladders for electrical system servicing.

By the end of this article, you will have a clear understanding of the importance of selecting the right ladder and the knowledge to choose the most suitable ladder for your electrical work needs, ensuring safety and efficiency every step of the way.

Key Takeaways:

- Choosing the correct ladder for electrical work is crucial for safety, efficiency, and compliance with regulations. Factors such as height, material, and stability features must be considered to ensure a secure and productive working environment.

- Whether it’s a step ladder, extension ladder, or combination ladder, prioritizing safety guidelines is essential. Regular inspection, proper setup, and caution around electrical hazards are key to minimizing accidents and creating a safe work environment.

Importance of using the correct ladder for electrical system servicing

When it comes to working with electrical systems, safety should always be the top priority. Using the correct ladder is crucial in ensuring a safe and secure working environment. Here are a few reasons why choosing the right ladder is so important when servicing electrical systems:

1. Electrical hazards

Working with electrical systems comes with inherent risks. A faulty ladder can increase the chances of accidents and electrocution. Using a ladder made from non-conductive material, such as fiberglass, can significantly minimize the risk of electric shock. Non-conductive ladders offer insulation, preventing the transfer of electricity and providing an extra layer of safety.

2. Stability and support

Electrical work often requires reaching heights and working in unstable positions. Using a ladder that is designed specifically for the job ensures stability and support. Ladders with anti-slip steps, wide bases, and secure locking mechanisms provide a stable platform for working. This reduces the risk of falls and gives you the confidence needed to carry out your tasks effectively.

3. Access to hard-to-reach areas

Electrical systems are often installed in hard-to-reach areas such as ceilings, roofs, and high walls. Having the right ladder can provide you with the necessary height and reach to access these areas safely. Extension ladders or combination ladders that can be adjusted to different heights are ideal for reaching elevated locations in electrical system servicing.

4. Comfort and efficiency

Choosing a ladder that suits your comfort and working style is vital for maintaining efficiency. The right ladder allows you to work comfortably without straining your body. Adjustable ladders with multiple positions or ladders with built-in platforms provide ergonomic support, enabling you to work for longer durations without discomfort. Comfortable working conditions enhance your productivity and minimize the chances of mistakes caused by fatigue or distraction.

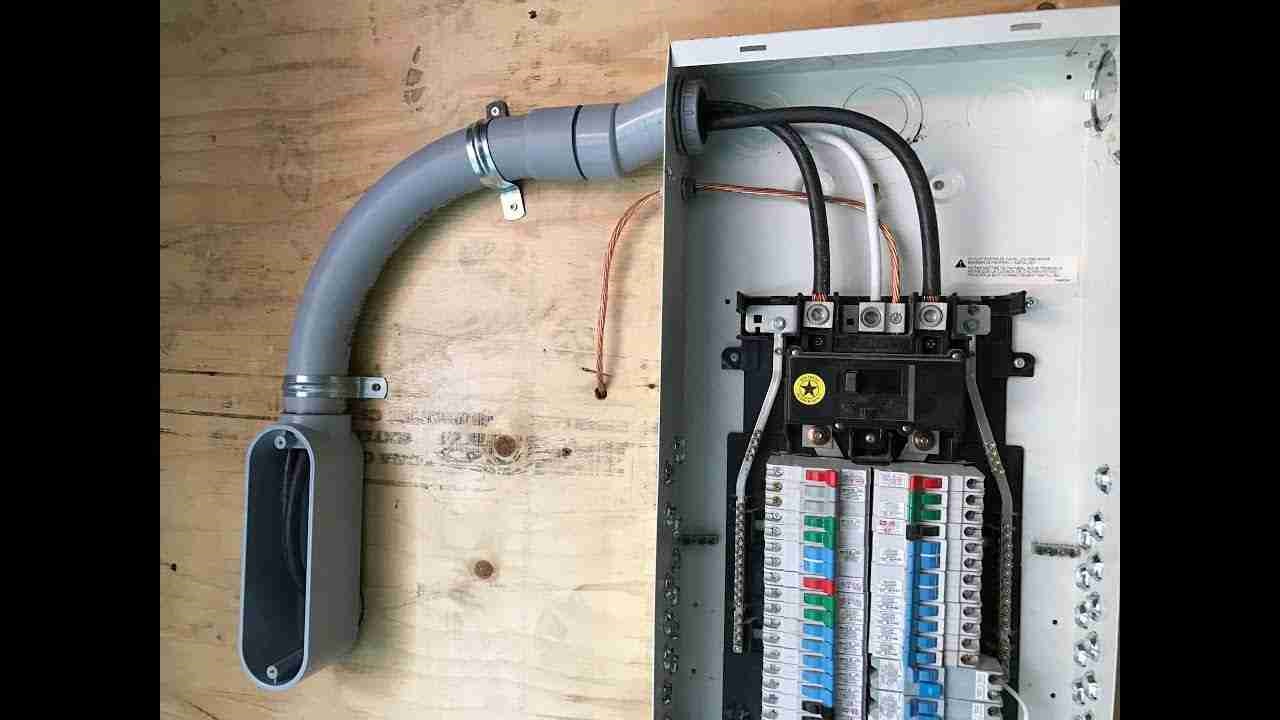

5. Compliance with regulations and standards

Using the correct ladder that adheres to safety regulations and standards is essential for professionals and businesses in the electrical field. Compliance with these regulations not only ensures the safety of workers but also protects employers from legal liabilities. It is important to familiarize yourself with relevant safety standards and guidelines, such as those set by OSHA (Occupational Safety and Health Administration), to ensure you use the correct ladder that meets the required standards.

Investing in the right ladder for electrical system servicing is an investment in your safety and the quality of your work. By selecting the correct ladder, you mitigate risks, improve your efficiency, and maintain compliance with safety regulations. Remember, when it comes to electrical work, there is no room for compromise when it comes to safety.

Factors to consider when selecting a ladder for electrical work

Choosing the right ladder for electrical work involves considering several important factors. By taking these factors into account, you can ensure that the ladder you select meets your specific needs and provides a safe and efficient working environment. Here are some key considerations when selecting a ladder for electrical system servicing:

1. Height and reach: Assess the maximum height you need to reach for your electrical work. This will help determine whether you need a step ladder, an extension ladder, or a combination ladder. Additionally, consider the reach required to access hard-to-reach areas, such as high ceilings or walls, and choose a ladder that can provide the necessary elevation.

2. Weight capacity: Determine the weight capacity your ladder needs to support, taking into account your own weight, as well as any tools or equipment you may need to carry while working. It is crucial to choose a ladder that can safely support your weight to prevent accidents or ladder damage.

3. Material: Consider the material from which the ladder is made. Fiberglass ladders are non-conductive and ideal for electrical work as they provide insulation against electrical shocks. Alternatively, aluminum ladders are lightweight and durable but conductive, so caution must be exercised when working near electrical systems.

4. Stability and safety features: Safety should be a top priority when selecting a ladder for electrical work. Look for features such as anti-slip steps, wide and stable bases, and secure locking mechanisms to ensure stability and minimize the risk of falls. Ladders with additional safety features like handrails or built-in platforms can provide extra stability and comfort.

5. Portability and storage: Consider the portability and storage requirements of the ladder. If you need to frequently transport the ladder or have limited storage space, opt for lightweight and foldable options that can be easily carried and stored.

6. Ease of use: Select a ladder that is easy to set up and adjust. Features like rung locks or telescopic mechanisms can make it more convenient to extend or retract the ladder to the desired height. Additionally, consider the overall maneuverability and ease of moving the ladder around your work area.

7. Durability and maintenance: Look for a ladder that is built to withstand regular use and has a long lifespan. Consider factors like corrosion resistance and the overall build quality of the ladder. Additionally, check if the ladder requires any specific maintenance or care to ensure its longevity.

By evaluating these factors, you can make an informed decision in selecting the right ladder for your electrical work needs. Remember to prioritize safety, durability, and functionality to create a secure and efficient working environment for yourself or your team.

Types of ladders commonly used for electrical system servicing

When it comes to electrical system servicing, there are several types of ladders to choose from. Each type offers its own advantages and is suited for different tasks and working conditions. Understanding the different types of ladders available can help you make an informed decision when selecting the right ladder for your electrical work. Here are three commonly used types of ladders:

1. Step ladders: Step ladders are one of the most common types of ladders used for electrical system servicing. They are self-supporting and feature a hinged design, allowing the ladder to stand freely without the need for support from a wall or other surface. Step ladders are ideal for indoor electrical work, maintenance tasks, and low-height installations. They come in various sizes, typically ranging from 4 to 12 feet in height.

2. Extension ladders: Extension ladders are designed to provide access to elevated areas. These ladders consist of two or more sections that can be extended or retracted to adjust the ladder’s height. Extension ladders are commonly used when working on overhead electrical fixtures, outdoor electrical systems, or when reaching higher ceilings, roofs, or walls. They can reach greater heights compared to step ladders, with typical sizes ranging from 16 to 40 feet.

3. Combination ladders: Combination ladders are versatile ladders that can be used as both step ladders and extension ladders. These ladders feature a pivot or hinge mechanism that allows them to transform into different configurations. Combination ladders provide flexibility for various electrical system servicing needs, as they can be used as step ladders for lower heights or extended as extension ladders for tasks requiring greater reach. With combination ladders, you can enjoy the benefits of two ladder types in one.

These three types of ladders provide the foundation for selecting the most suitable ladder for your electrical work. Depending on the specific task and working conditions, one type may be more advantageous than the others. It is important to assess the height requirements, space limitations, and portability needs before deciding on the type of ladder to use.

Additionally, consider the weight capacity, material, stability features, and safety guidelines when choosing a ladder. Each ladder type may have its own set of safety features, such as non-slip steps, wide bases, and secure locking mechanisms. Prioritize safety and select a ladder that meets your needs while providing a secure and stable platform for electrical system servicing.

By understanding the different types of ladders available and their specific applications, you can make an informed decision and have the right ladder on hand for a wide range of electrical work scenarios.

Step ladders

Step ladders are a popular choice for electrical system servicing due to their stability, ease of use, and versatility. These self-supporting ladders feature a hinged design that allows them to stand freely without the need for support from a wall or other surface. Step ladders have a symmetrical shape, with two sets of steps and a top platform or tray for holding tools and equipment. Here are some key features and benefits of step ladders:

1. Stability: Step ladders are known for their stability, providing a secure platform for working on electrical systems. They have a wide and stable base that prevents wobbling or tipping, ensuring your safety while working at height. Some step ladders also come with stabilizer bars or non-slip feet, further enhancing their stability.

2. Easy to set up: Step ladders are incredibly easy to set up and use. They require no assembly or additional support, making them a convenient option for quick electrical tasks. Simply open the ladder and lock it into place to create a secure working platform.

3. Versatility: Step ladders come in various heights, ranging from 4 to 12 feet, making them suitable for a wide range of electrical tasks. Whether you need to change light fixtures, inspect electrical connections, or perform routine maintenance, step ladders offer a stable and accessible solution for indoor electrical work.

4. Compact and portable: Step ladders are compact and lightweight, making them easy to transport and store. They can be folded and stored in tight spaces, which is particularly beneficial for those with limited storage areas. Their portability allows for convenient movement throughout the worksite.

5. Additional features: Many step ladders come with additional features to enhance safety and convenience. Some models have built-in tool trays or platforms to hold tools and equipment, keeping them within reach while you work. Other features may include hand grips or handrails for added stability and ease of climbing up and down the ladder.

When using a step ladder for electrical system servicing, remember to follow safety guidelines. Ensure that the ladder is fully opened and locked into position before stepping on it. Avoid overreaching by positioning yourself in the center of the ladder, and always maintain three points of contact (either two feet and one hand or two hands and one foot) while working on the ladder.

Step ladders are a valuable tool for electrical work, providing stability, versatility, and ease of use. By selecting the appropriate step ladder for your specific task and following safety guidelines, you can efficiently and safely carry out electrical system servicing with confidence.

When servicing electrical systems, always use a non-conductive ladder made of fiberglass or wood. Metal ladders can conduct electricity and pose a serious safety hazard.

Read more: What Type Of Wire Should Be Used In Conduit

Extension ladders

Extension ladders are an essential tool for electrical system servicing, particularly when working on elevated areas such as ceilings, roofs, and high walls. These ladders consist of two or more sections that can be extended or retracted to adjust the ladder’s height. Extension ladders offer greater reach compared to step ladders, making them ideal for tasks that require accessing overhead electrical fixtures or working at higher elevations. Here are some key features and benefits of extension ladders:

1. Adjustable height: Extension ladders can be extended to reach various heights depending on your specific needs. They are designed with multiple sections that can be easily extended or retracted using mechanisms like ropes, pulleys, or locking systems. This adjustability allows you to reach the desired height for your electrical work, ensuring accessibility to overhead fixtures or higher installations.

2. Versatility: Extension ladders are highly versatile and can be used for various electrical system servicing tasks. Whether you need to install or repair outdoor electrical systems, access high ceilings, or work on roofing installations, an extension ladder provides the necessary height and reach to complete these tasks safely and efficiently.

3. Lightweight and portable: Despite their extended reach, extension ladders are designed to be lightweight and portable. They are typically made from aluminum or fiberglass, both of which are lightweight materials. This makes it easier to maneuver and transport the ladder to different job sites, providing flexibility for your electrical work needs.

4. Stability and safety features: Extension ladders prioritize stability and safety. They have sturdy rungs and wide base sections that ensure a secure footing. Many extension ladders also come with anti-slip feet or non-slip rungs to provide additional traction, reducing the risk of accidents. Additionally, built-in stabilizer bars or wall hooks can be used to secure the ladder and prevent it from sliding or tipping over.

5. Durability: Extension ladders are built to withstand regular use and outdoor conditions. They are made from strong and durable materials such as aluminum or fiberglass, which are corrosion-resistant and can withstand exposure to the elements. This durability ensures that your extension ladder will have a long lifespan and continue to serve you reliably for years to come.

To ensure safety while using an extension ladder, always follow the manufacturer’s guidelines and safety recommendations. Take care when extending or retracting the ladder and ensure that the rung locks or locking mechanisms are securely engaged. Make sure the ladder is set up on stable ground, and consider using a ladder stabilizer or outriggers if working on uneven surfaces or windy conditions.

Extension ladders are an indispensable tool for accessing elevated areas during electrical system servicing. Their adjustable height and stability make them a reliable choice for various tasks. By selecting a high-quality extension ladder and practicing proper safety measures, you can efficiently and safely carry out electrical work at higher elevations with ease.

Combination ladders

Combination ladders are versatile tools that offer the functionality of both step ladders and extension ladders. These ladders feature a pivot or hinge mechanism that allows them to transform into different configurations. Combining the benefits of two ladder types, combination ladders provide flexibility for a wide range of electrical system servicing needs. Here are some key features and benefits of combination ladders:

1. Step ladder configuration: In their closed position, combination ladders function as step ladders. They have a symmetrical design with two sets of steps and a top platform or tray. This configuration makes them suitable for lower-height indoor electrical work or tasks that require a stable and freestanding platform.

2. Extension ladder configuration: Combination ladders can be extended to function as extension ladders. The ladder sections can be unlocked and extended to reach elevated areas for overhead electrical work or accessing higher installations. This configuration provides the necessary height and reach needed for various electrical system servicing tasks.

3. Adjustable height: Combination ladders offer adjustable height features, allowing you to customize the ladder’s height based on your specific requirements. This adjustability makes them versatile and suitable for different electrical work scenarios where varying heights are involved.

4. Portability: Combination ladders are designed to be lightweight and portable, enabling easy transportation between job sites or around work areas. Many combination ladders are foldable, making them compact and space-efficient for storage or transport in vehicles.

5. Stability and safety: Combination ladders prioritize stability and safety, just like their individual ladder counterparts. They feature wide bases, anti-slip steps, secure locking mechanisms, and other safety features to ensure stability and reduce the risk of accidents while working at heights.

6. Versatility: Combination ladders are incredibly versatile, making them suitable for a wide range of electrical system servicing tasks. They can adapt to different heights and configurations, allowing you to easily switch between step ladder and extension ladder modes as needed for various projects.

When using a combination ladder, it is important to familiarize yourself with the specific locking and unlocking mechanisms to ensure proper and secure operation. Follow the manufacturer’s instructions and safety guidelines for adjusting and transforming the ladder between configurations.

A combination ladder offers the convenience of two ladder types in one tool, providing flexibility and versatility for your electrical system servicing needs. With their adjustable height options, stability, and easy maneuverability, combination ladders are a valuable asset in providing a safe and efficient working environment for a variety of electrical tasks.

Fiberglass vs. aluminum ladders for electrical work

When it comes to selecting a ladder for electrical work, one important consideration is the material from which the ladder is made. Two common options are fiberglass and aluminum ladders. Each material has its own set of advantages and considerations. Let’s compare fiberglass and aluminum ladders in the context of electrical system servicing:

Fiberglass ladders:

Fiberglass ladders are a popular choice for electrical work due to their non-conductive properties. Here are some key characteristics of fiberglass ladders:

1. Non-conductive: Fiberglass ladders are non-conductive, meaning they do not conduct electricity. This is a crucial safety feature when working with electrical systems, as it reduces the risk of electric shock. Non-conductivity provides an extra layer of protection for electrical workers, particularly when working near live wires or electrical circuitry.

2. Insulation: Fiberglass is an excellent insulating material. Unlike aluminum, which is conductive, fiberglass ladders provide insulation against electrical currents. This insulation helps to prevent accidental electrical contact and reduces the risk of electrical accidents while working on electrical fixtures or systems.

3. Durability: Fiberglass is a strong and durable material, capable of withstanding regular use and exposure to the elements. Fiberglass ladders also offer good resistance to chemicals, moisture, and UV rays, making them suitable for both indoor and outdoor electrical work. With proper care and maintenance, fiberglass ladders have a long lifespan.

4. Heavier weight: Fiberglass ladders tend to be heavier compared to aluminum ladders. This weight can be both an advantage and a disadvantage. The added weight provides stability and sturdiness, ensuring a secure footing while working at heights. However, it can also make fiberglass ladders more difficult to maneuver and transport, especially for individuals who require a lightweight option.

Aluminum ladders:

Aluminum ladders are lightweight and versatile, offering their own set of advantages for electrical work. Here are some key characteristics of aluminum ladders:

1. Lightweight and portable: Aluminum ladders are known for their lightweight nature, making them easy to carry and transport. This lightweight quality is advantageous when it comes to maneuverability, particularly for individuals who need to move the ladder frequently or work in different locations. Aluminum ladders are popular for their convenience and ease of use.

2. Strength: Although aluminum is not non-conductive like fiberglass, aluminum ladders are still strong and sturdy. They offer good load-bearing capacity and stability when properly used. Aluminum ladders are often used for light to medium-duty electrical work, where non-conductivity is not a primary concern.

3. Corrosion resistance: Aluminum ladders possess natural resistance to corrosion, making them suitable for outdoor use and areas where moisture may be present. This resistance allows aluminum ladders to maintain their integrity and durability over time, even when exposed to various environmental conditions.

4. Conductivity: Unlike fiberglass, aluminum is a conductive material. Electrical workers must exercise caution when using aluminum ladders near electrical systems or live wires. It is crucial to inspect the working area thoroughly and use appropriate safety measures such as wearing rubber-soled shoes and avoiding contact between the ladder and live electrical components.

Ultimately, the choice between fiberglass and aluminum ladders for electrical work depends on the specific requirements, working conditions, and safety considerations of the job. If non-conductivity is a priority, fiberglass is the preferred option. However, if weight and portability are significant factors, aluminum ladders may be more suitable. It is crucial to prioritize safety and select the ladder that best meets the needs of the electrical task at hand.

Safety guidelines when using ladders for electrical system servicing

Working with ladders for electrical system servicing requires adherence to strict safety guidelines to prevent accidents and ensure a secure working environment. Whether you are using a step ladder, extension ladder, or combination ladder, following these safety precautions is essential. Here are some important safety guidelines to keep in mind:

1. Inspect the ladder:

- Before each use, carefully inspect the ladder for any damage, such as cracks, bent rungs, or loose parts. Do not use a ladder that appears to be defective or in poor condition.

- Check that all locking mechanisms, hinges, and rung locks are secure and functioning properly.

- Ensure that the ladder is clean and free from any debris that could cause slips or instability.

2. Choose the right ladder and height:

- Select the appropriate ladder and height for the task at hand. Consider factors such as the required reach, weight capacity, and working conditions.

- Ensure that the ladder is tall enough to safely reach the desired working area, but not so tall that it becomes unstable or difficult to maneuver.

3. Set up the ladder correctly:

- Place the ladder on a firm, level surface. Avoid uneven or slippery terrain that could cause the ladder to shift or tip over.

- If working outdoors or on soft ground, use ladder stabilizers or leg levelers to provide additional stability and prevent sinking.

- Ensure that the ladder is fully extended or opened and locked into position before stepping on it. Do not exceed the ladder’s recommended weight capacity.

4. Maintain three points of contact:

- Always have three points of contact with the ladder: either two hands and one foot or two feet and one hand.

- Avoid overreaching or leaning too far to one side. Keep your body centered between the ladder’s side rails to maintain balance and stability.

- If you need to reach further, reposition the ladder rather than stretching or leaning excessively.

5. Use appropriate personal protective equipment (PPE):

- Wear proper footwear with non-slip soles to enhance traction and reduce the risk of slipping.

- Consider using personal protective equipment such as gloves, safety glasses, and a hard hat, depending on the specific requirements of the electrical task.

6. Be cautious of electrical hazards:

- Be aware of the presence of live electrical wires or systems in the vicinity of your work area.

- When using aluminum ladders, practice caution to avoid direct contact with electrical components. Take necessary precautions to prevent electrical shock, such as wearing protective gloves, insulating the ladder, or keeping a safe distance from live wires.

7. Do not exceed the ladder’s weight capacity:

- Each ladder has a specific weight capacity that should not be exceeded. Take into account your weight, the weight of your tools or equipment, and any additional load on the ladder.

- Using a ladder beyond its weight limit can significantly compromise its stability, leading to accidents and injury.

8. One person at a time:

- Do not allow multiple individuals on a single ladder simultaneously.

- Only one person should be on the ladder at a time to maintain stability and reduce the risk of accidents.

9. Ensure proper storage and maintenance:

- After use, store the ladder in a clean and dry area, away from direct sunlight or harsh weather conditions.

- Regularly clean and inspect the ladder for any signs of damage or wear, and address any issues promptly.

By following these safety guidelines when using ladders for electrical system servicing, you can significantly reduce the risk of accidents and create a safer work environment for yourself and those around you. Remember, safety should always be the top priority when working at heights or near electrical systems.

Read more: When To Use Conduit For Electrical Wiring

Conclusion

Choosing the correct ladder is essential when it comes to servicing electrical systems safely and efficiently. By considering factors such as height requirements, weight capacity, material, and stability features, you can select the most suitable ladder for your electrical work needs.

Step ladders provide stability and versatility for indoor electrical tasks, while extension ladders offer the necessary height and reach for working on elevated areas. Combination ladders combine the benefits of both step ladders and extension ladders, providing flexibility and adaptability to different electrical work scenarios.

In terms of material, fiberglass ladders offer non-conductive properties and insulation, reducing the risk of electric shock. Aluminum ladders, on the other hand, are lightweight, portable, and resistant to corrosion. The choice between fiberglass and aluminum ultimately depends on your specific safety requirements and working conditions.

Regardless of the ladder type or material chosen, it is important to follow safety guidelines when using ladders for electrical system servicing. Regularly inspect the ladder for any damage, set it up correctly on a stable surface, maintain three points of contact, and be cautious of electrical hazards. Adhering to these safety precautions will help ensure a secure working environment and minimize the risk of accidents.

Remember, safety should always be the top priority when working at heights or near electrical systems. By selecting the right ladder, following safety guidelines, and prioritizing caution, you can confidently carry out electrical system servicing, protecting yourself and others while achieving efficient and effective results.

Frequently Asked Questions about What Type Of Ladder Should Be Used When Servicing Electrical Systems

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Type Of Ladder Should Be Used When Servicing Electrical Systems”