Home>diy>Building & Construction>What Is EPC Construction

Building & Construction

What Is EPC Construction

Modified: December 7, 2023

Discover what EPC construction means in the context of building construction. Learn about the process, benefits, and key considerations. Choose the best EPC contractor for your project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of EPC construction! If you’re new to the field of building construction or have heard the term “EPC” being thrown around, but aren’t quite sure what it entails, you’ve come to the right place. In this article, we’ll delve into the world of EPC construction, explore its definition, examine its key components, and discuss its advantages and disadvantages. We’ll also provide you with some real-world examples of EPC construction projects to give you a better understanding of this construction methodology.

EPC stands for Engineering, Procurement, and Construction. It is a comprehensive approach to building construction that includes the design, procurement, and execution of a project from start to finish. Unlike traditional construction methods where different parties are involved in each stage, EPC construction incorporates all aspects of the project under one umbrella, ensuring seamless coordination and efficient project management.

One of the key features of EPC construction is the integration of engineering, procurement, and construction activities, which promotes synergistic collaboration and streamlines the overall project timeline. By bringing together these three crucial aspects, EPC construction offers a holistic and efficient approach to building projects, making it a popular choice for various industries.

Now that we have a basic understanding of what EPC construction entails, let’s take a closer look at its key components. Understanding these components is essential to grasp the intricate workings of EPC construction and appreciate its numerous benefits.

Key Takeaways:

- EPC construction offers a streamlined, single-point approach to project delivery, integrating engineering, procurement, and construction for efficient, cost-effective, and quality-assured results.

- While EPC construction provides numerous benefits, including streamlined project management and risk mitigation, potential drawbacks such as limited flexibility and reliance on contractor expertise should be carefully considered before implementation.

Read more: What Is An EPC In Construction

Definition of EPC Construction

EPC construction, short for Engineering, Procurement, and Construction, is a project delivery method in the construction industry where a single contractor is responsible for the entire process from design and engineering to procurement of materials and equipment, as well as the actual construction and installation. This approach offers a turnkey solution to clients, providing a streamlined and simplified construction process.

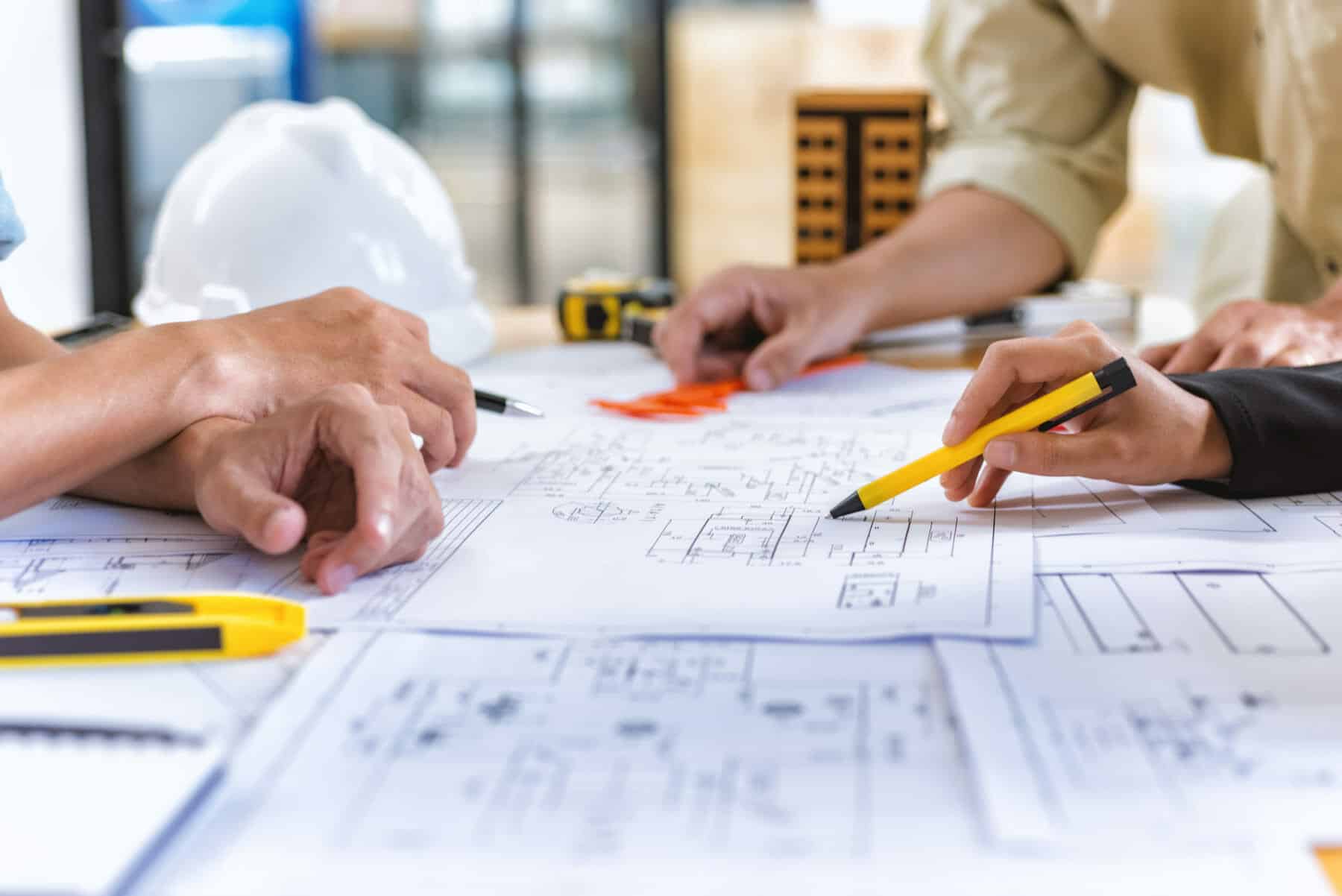

The first component of EPC construction is Engineering. During this phase, the contractor works closely with architects, engineers, and other experts to develop a detailed plan and design for the project. The engineering team takes into account various factors such as site conditions, structural integrity, and safety regulations to create a blueprint that meets the client’s requirements.

The second component is Procurement. Once the engineering design is finalized, the EPC contractor is responsible for procuring all the necessary materials, equipment, and subcontractor services required for the project. This includes sourcing and ordering materials, negotiating contracts with suppliers, and coordinating the delivery and logistics of materials to the construction site.

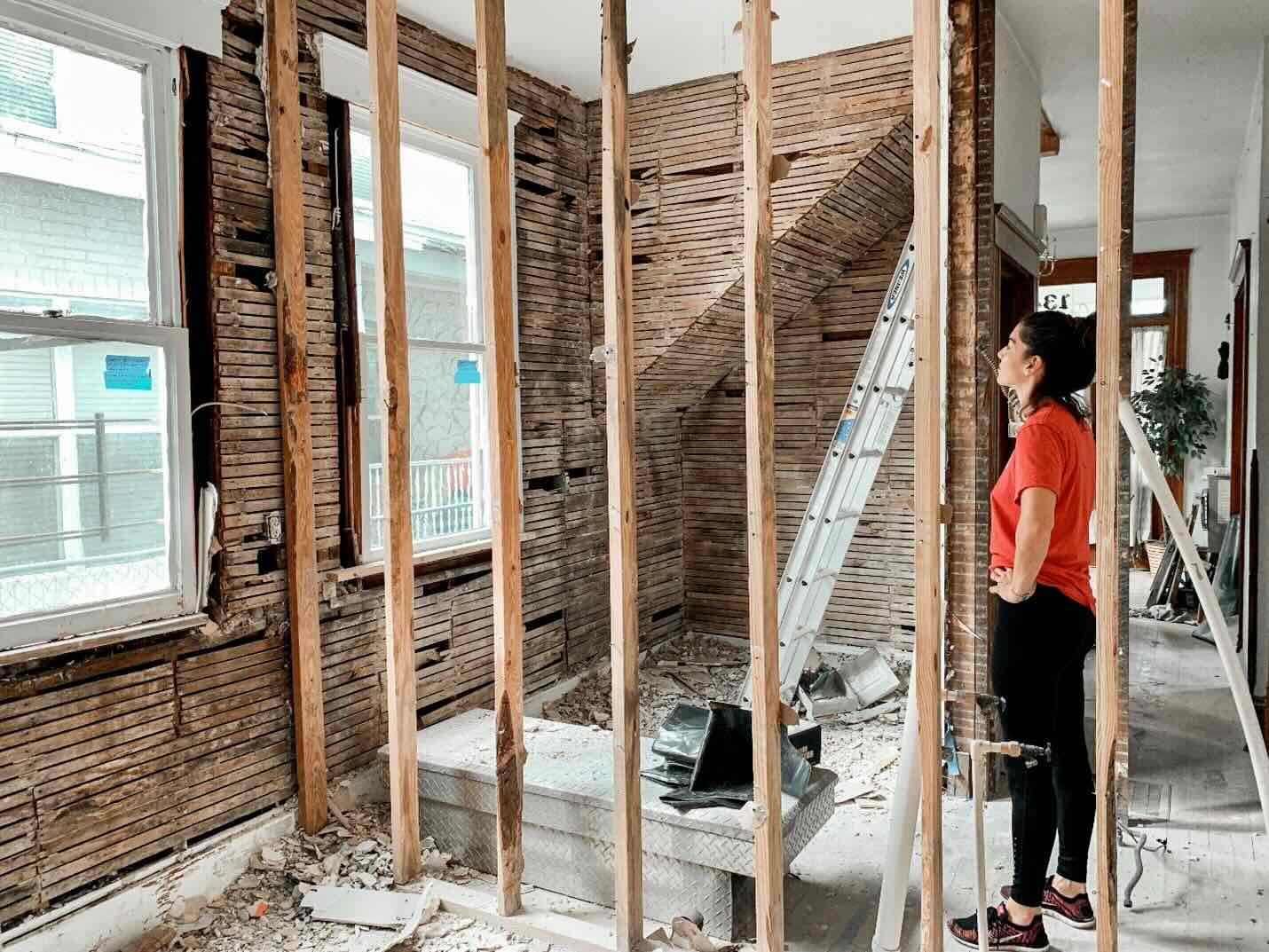

The final component of EPC construction is Construction. This phase involves the actual building and installation of the project as outlined in the engineering design. The EPC contractor oversees the construction activities, ensuring that work is carried out according to the specifications and on schedule. They are also responsible for managing subcontractors, coordinating inspections, and maintaining quality control throughout the construction process.

EPC construction is often preferred for complex and large-scale projects that require a high level of technical expertise and coordination. It offers several benefits compared to traditional construction methods. One of the main advantages is the single-point responsibility. With the EPC approach, the client has a single contact point throughout the project, eliminating the need to coordinate between multiple contractors and reducing the risk of miscommunication or delays.

Furthermore, the integrated nature of EPC construction ensures better project control and optimization. The close collaboration between the engineering, procurement, and construction teams allows for efficient planning and resource allocation, resulting in improved cost management and timely project completion.

However, it is important to note that EPC construction may not be suitable for all projects. Its success heavily relies on the capabilities and experience of the EPC contractor. Therefore, careful consideration should be given to the selection of a reputable and qualified EPC contractor who has a proven track record in delivering successful projects.

Now that we have a clear understanding of what EPC construction entails, let’s explore its advantages and disadvantages in more detail.

Key Components of EPC Construction

EPC construction, which stands for Engineering, Procurement, and Construction, encompasses three essential components that are integral to the success of any project. These components work together to ensure a seamless and efficient construction process from start to finish. Let’s take a closer look at each of these key components:

- Engineering: The engineering component is at the forefront of EPC construction. It involves the collaboration between architects, engineers, and other professionals to design and develop the project. This phase includes conducting feasibility studies, creating detailed blueprints, and ensuring that the design aligns with regulatory requirements and client specifications. The engineering team plays a crucial role in visualizing and conceptualizing the project before it proceeds to the construction phase.

- Procurement: The procurement component of EPC construction involves the sourcing, purchasing, and management of all necessary materials, equipment, and subcontractor services. It is the responsibility of the EPC contractor to identify reliable suppliers, negotiate contracts, and ensure that the required resources are available at the right time and place. Effective procurement management is vital to maintain project timelines, control costs, and guarantee the quality of materials and equipment used.

- Construction: The construction component is where all the planning and preparation come to life. It entails the physical realization of the project as per the approved engineering design. The EPC contractor oversees the construction process, managing the workforce, coordinating subcontractors, and implementing quality control measures. This phase includes activities such as earthworks, foundation construction, structural erection, installation of electrical and plumbing systems, and the final finishing touches that bring the project to completion.

These three components of EPC construction are interconnected and rely on each other for a successful project outcome. The engineering phase lays the foundation by developing a comprehensive design, while the procurement phase ensures that all necessary resources are acquired on time. Finally, the construction phase brings the project to life while adhering to the engineering specifications and utilizing the materials and equipment procured.

The integration of these components is a key strength of EPC construction. By having a single entity responsible for all three aspects, there is better cohesion, communication, and streamlining of activities. This results in improved project control, cost management, and overall efficiency. The EPC approach also minimizes the need for coordination between multiple contractors, reducing potential delays and conflicts.

Now that we understand the key components of EPC construction, it’s important to explore the advantages and disadvantages associated with this construction methodology.

Advantages of EPC Construction

EPC construction, which stands for Engineering, Procurement, and Construction, offers several advantages compared to traditional construction methods. This comprehensive approach to project delivery provides numerous benefits for clients, contractors, and stakeholders involved. Let’s explore some of the key advantages of EPC construction:

- Single-point Responsibility: One of the major advantages of EPC construction is the single-point responsibility it offers. With the EPC approach, clients have a single contact point for the entire project. This eliminates the need to coordinate between multiple contractors and consultants, reducing the risk of miscommunication and delays. Clients can have peace of mind knowing that one entity is accountable for all aspects of the project.

- Streamlined Project Management: EPC construction provides a streamlined project management process. By integrating engineering, procurement, and construction activities, there is better coordination and communication between the different teams involved. This leads to improved project control, efficient resource allocation, and optimized scheduling. The streamlined approach minimizes the risk of cost overruns, delays, and disputes commonly associated with traditional construction methods.

- Cost and Time Efficiency: EPC construction is known for its cost and time efficiency. With a single entity responsible for engineering, procurement, and construction, there is better control over project costs. The EPC contractor can leverage their expertise and industry connections to source materials and services at competitive prices. Additionally, the close integration of activities enables efficient planning and eliminates the need for extensive coordination, resulting in faster project delivery.

- Quality Control: EPC construction places a strong emphasis on quality control. The integration of engineering, procurement, and construction activities ensures that quality standards are maintained at each stage of the project. The EPC contractor is responsible for ensuring that materials meet the required specifications and that construction work adheres to the approved design. This comprehensive approach leads to enhanced quality control and reduced risks of rework or defects.

- Risk Mitigation: EPC construction helps to mitigate risks associated with construction projects. By having a single entity responsible for the entire project, there is a clear accountability structure in place. The EPC contractor assumes the risks associated with design, procurement, and construction, reducing the potential burden on clients. This integrated approach allows for proactive risk management and quicker problem-solving, resulting in a more resilient and successful project outcome.

These advantages make EPC construction an attractive option for a wide range of projects, particularly those with complex requirements and tight timelines. The comprehensive nature of EPC construction promotes efficiency, cost savings, and quality assurance, ultimately leading to client satisfaction and successful project delivery.

However, it is important to note that EPC construction may not be suitable for every project. The selection of a reputable and experienced EPC contractor is crucial to ensure the successful implementation of this methodology. Clients should carefully evaluate the contractor’s track record, capabilities, and expertise before engaging in an EPC project.

Now that we understand the advantages of EPC construction, let’s explore some of the potential disadvantages associated with this construction methodology.

EPC construction stands for Engineering, Procurement, and Construction. It is a popular contracting model in the construction industry where a single contractor is responsible for the design, procurement, and construction of a project. This can help streamline the process and reduce the risk of delays and cost overruns.

Disadvantages of EPC Construction

While EPC (Engineering, Procurement, and Construction) construction offers numerous advantages, it is important to consider its potential disadvantages as well. Understanding these drawbacks will allow clients and stakeholders to make an informed decision when deciding on the appropriate construction methodology. Let’s examine some of the key disadvantages of EPC construction:

- Limited Flexibility: EPC construction contracts often have strict contractual agreements regarding scope changes. If the client desires modifications or additional features during the course of the project, it may lead to delays and increased costs. This restricted flexibility can be a disadvantage for clients who expect or anticipate changes in their project requirements.

- Inadequate Representation of Client Interests: In EPC construction, the contractor assumes the responsibility for all project activities, including design and procurement. While this leads to streamlined execution, it may result in a potential conflict of interest. The contractor’s priority is to protect their own interests, sometimes at the expense of fully representing the client’s best interests. Clients must carefully review and negotiate the contractual terms to ensure their needs and objectives are met.

- Reliance on Contractor Expertise: In EPC construction, clients rely heavily on the expertise of the contractor for all aspects of the project. This places the onus on selecting a competent and experienced contractor. If the contractor lacks the necessary skills or resources, it may result in delays, cost escalation, or compromised quality. Thorough due diligence is required when selecting an EPC contractor to mitigate these risks.

- Potential for Higher Costs: While EPC construction can offer cost savings through optimized procurement and resource utilization, there is a potential for higher costs as well. If the contractor faces unexpected challenges or encounters changes in material prices, these additional costs may be passed on to the client. Inadequate cost estimates or unforeseen circumstances can lead to budget overruns, affecting the financial viability of the project.

- Less Control Over Project Execution: EPC construction involves the transfer of project execution responsibilities to the contractor. While this can streamline the process, it also means that clients have less control over day-to-day decision-making and construction activities. Regular communication and transparency between the client and contractor are vital to ensure project objectives are met and the client’s vision is executed effectively.

Understanding these potential disadvantages allows stakeholders to consider the specific needs of their project and evaluate whether EPC construction is the most suitable approach. It is important to weigh the advantages and disadvantages and assess the specific requirements and constraints of each project before making a decision.

Now that we have explored the advantages and disadvantages of EPC construction, let’s take a look at some examples of notable EPC construction projects to gain a better understanding of its application in the real world.

Read more: What Is EPC In Construction

Examples of EPC Construction Projects

EPC (Engineering, Procurement, and Construction) construction has been widely used in a variety of industries for projects of different scales and complexities. Let’s take a look at some notable examples that showcase the successful application of EPC construction:

- Solar Power Plants: The construction of solar power plants often involves the use of EPC contracts. In these projects, the EPC contractor takes responsibility for the design, procurement, and construction of the entire solar power plant, including the installation of solar panels, electrical infrastructure, and grid connection. The comprehensive nature of EPC construction ensures efficient project management and timely completion of solar power plants.

- Oil and Gas Facilities: EPC construction is commonly used in the oil and gas industry for the construction of production facilities, refineries, and pipelines. These projects require complex engineering designs, specialized equipment procurement, and adherence to strict safety and environmental standards. EPC contractors play a crucial role in managing the technical aspects, ensuring compliance with regulatory requirements, and coordinating the construction activities to meet project deadlines.

- Infrastructure Projects: EPC construction is often employed for infrastructure projects such as roads, bridges, airports, and railway systems. These projects typically involve multiple components and require coordination between various engineering disciplines. EPC contractors manage the design, procurement, and construction aspects to ensure the seamless integration of different subsystems and the timely delivery of infrastructure projects.

- Industrial Complexes: The construction of industrial complexes, including manufacturing plants, chemical plants, and warehouses, often utilizes EPC contracts. These projects involve extensive engineering and design work, specialized equipment procurement, and compliance with industry-specific regulations. EPC construction provides a comprehensive approach, allowing for efficient project execution and enabling clients to have a single point of contact throughout the construction process.

- Renewable Energy Projects: EPC construction is widely employed in the construction of renewable energy projects such as wind farms and hydropower plants. These projects involve intricate engineering designs, complex procurement processes for specialized equipment, and construction activities that adhere to environmental regulations. EPC contractors leverage their expertise to ensure seamless integration and efficient delivery of renewable energy projects.

These examples highlight the versatility and effectiveness of EPC construction across various industries. The comprehensive approach of EPC construction has been successfully implemented in projects ranging from renewable energy facilities to infrastructure development.

By adopting the EPC approach, these projects benefit from streamlined project management, cost control, and efficient resource allocation, ultimately leading to successful project completion and client satisfaction.

Now that we have explored real-world examples of EPC construction projects, it’s time to conclude our comprehensive guide to EPC construction.

Conclusion

EPC (Engineering, Procurement, and Construction) construction is a comprehensive project delivery method that offers numerous benefits for clients, contractors, and stakeholders involved in the construction industry. This approach integrates the engineering, procurement, and construction components under one umbrella, providing a seamless and streamlined process from project inception to completion.

Throughout this article, we have explored the key components of EPC construction, including the crucial roles played by engineering, procurement, and construction teams. We have also discussed the advantages of EPC construction, such as single-point responsibility, streamlined project management, cost and time efficiency, quality control, and risk mitigation.

However, it is important to acknowledge that EPC construction is not without its drawbacks. The limited flexibility, potential conflicts of interest, reliance on contractor expertise, potential for higher costs, and reduced client control over project execution are important considerations when deciding on the most suitable construction methodology.

Nevertheless, EPC construction has proven to be successful in a wide range of projects across various industries. Notable examples include solar power plants, oil and gas facilities, infrastructure projects, industrial complexes, and renewable energy projects.

By leveraging the integrated approach of EPC construction, these projects have benefited from efficient project management, cost control, optimized resource allocation, and timely project completion. The comprehensive nature of EPC construction ensures that all aspects of the project are managed by a single entity, reducing coordination efforts and potential risks.

In conclusion, EPC construction offers a holistic and efficient approach to building projects. It is a widely adopted methodology in industries that require complex and large-scale projects, allowing clients to have a single point of contact and ensuring seamless coordination and efficient project delivery.

However, it is essential to carefully evaluate the specific requirements and constraints of each project before deciding on the construction methodology. EPC construction may not be suitable for every project, and the selection of a reputable and experienced EPC contractor is crucial for success.

We hope that this comprehensive guide has provided you with valuable insights into the world of EPC construction and its advantages, disadvantages, and real-world applications. Armed with this knowledge, you will be better equipped to make informed decisions and navigate the ever-changing landscape of the construction industry.

Frequently Asked Questions about What Is EPC Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is EPC Construction”