Home>diy>Building & Construction>What Is Rigging In Construction

Building & Construction

What Is Rigging In Construction

Modified: January 6, 2024

Discover the importance of rigging in building construction, its role in ensuring safety, efficiency, and productivity, and how it contributes to successful project completion.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to the construction industry, rigging plays a crucial role in ensuring the safety and success of various projects. Rigging involves the use of ropes, chains, cables, and other equipment to lift, move, and secure heavy materials and equipment. It is a specialized skill that requires expertise and knowledge to execute effectively.

In this article, we will explore the definition, importance, types, equipment, safety measures, and the role of rigging professionals in construction projects. We will also highlight the challenges and risks associated with rigging in construction.

So, whether you are a construction professional or simply curious about the inner workings of the industry, keep reading to discover the fascinating world of rigging in construction.

Key Takeaways:

- Rigging in construction is crucial for safety, efficiency, and flexibility. It involves specialized equipment and techniques to handle heavy materials, ensuring project success and regulatory compliance.

- Rigging professionals play a critical role in construction projects, from planning and equipment selection to safety compliance and problem-solving. Their expertise ensures safe and efficient operations amidst various challenges and risks.

Read more: How To Store Fishing Rigs

Definition of Rigging in Construction

Rigging in construction refers to the process of lifting, moving, and securing heavy materials and equipment using various tools and techniques. It is a critical aspect of construction projects, as it ensures the efficient and safe transportation and placement of objects that would otherwise be too heavy or difficult to handle manually.

At its core, rigging involves the use of ropes, chains, cables, slings, hoists, and other equipment to create a system that enables the controlled lifting and movement of heavy objects. This system is often referred to as a rigging setup.

Rigging setups can be complex and intricate, depending on the specific requirements of the construction project. They may involve the use of cranes, pulleys, winches, and other specialized machinery to facilitate the lifting and maneuvering of materials and equipment.

Additionally, rigging in construction also involves ensuring the stability and security of the load being lifted or moved. This includes properly securing the materials or equipment to prevent accidents or damage during transportation.

Overall, rigging is a fundamental part of construction operations, allowing construction professionals to safely handle heavy objects and efficiently complete various tasks. Without proper rigging techniques, construction projects would be considerably more challenging and potentially dangerous.

Importance of Rigging in Construction

Rigging plays a vital role in the construction industry for numerous reasons. Without proper rigging techniques, construction projects would face significant challenges and safety risks. Here are some key reasons why rigging is important in construction:

- Safety: Safety is of paramount importance in the construction industry. Rigging helps ensure the safe lifting, moving, and placement of heavy materials and equipment. By utilizing appropriate rigging methods, construction professionals can minimize the risk of accidents, injuries, and property damage.

- Efficiency: Rigging enhances the efficiency of construction projects by enabling the swift and precise handling of heavy objects. With the use of cranes, hoists, and other specialized equipment, materials can be lifted and positioned with greater ease and accuracy, saving time and labor.

- Flexibility: Rigging offers flexibility in construction projects, allowing the movement and placement of materials and equipment in various locations and positions. This flexibility is crucial for projects that require objects to be lifted to great heights, moved in tight spaces, or positioned in specific orientations.

- Cost Savings: Proper rigging techniques can result in cost savings for construction projects. By utilizing efficient rigging setups, materials can be transported and placed with minimal damage or waste, reducing the need for costly replacements or repairs.

- Complexity Handling: Many construction projects involve working with complex structures and equipment. Rigging provides the means to handle this complexity, allowing professionals to lift and position components such as steel beams, precast concrete panels, and heavy machinery with precision and care.

- Regulatory Compliance: Rigging in construction must adhere to strict safety regulations and guidelines. By following these regulations, construction companies can ensure compliance and avoid penalties or legal issues. Rigging professionals are trained to understand and implement these regulations, ensuring a safe and compliant work environment.

- Team Collaboration: Rigging requires collaboration and coordination among various members of the construction team. This fosters teamwork and communication, enhancing overall project success.

In summary, rigging plays a critical role in construction by ensuring safety, efficiency, flexibility, cost savings, complexity handling, regulatory compliance, and team collaboration. It is an indispensable aspect of construction projects, contributing to their overall success and the well-being of workers.

Types of Rigging in Construction

Rigging in construction encompasses various methods and techniques based on the specific requirements of the project. Here are some common types of rigging used in the construction industry:

- General Rigging: General rigging involves the basic lifting and moving of materials and equipment. It typically includes using slings, chains, or cables to secure the load and connect it to a crane or hoist. General rigging is commonly used for tasks like lifting and placing construction materials, such as steel beams and concrete panels.

- Heavy Lift Rigging: Heavy lift rigging is used when handling extremely heavy loads that surpass the capabilities of typical rigging setups. It involves specialized equipment such as gantry systems, tower cranes, or heavy-duty lifting beams. Heavy lift rigging requires careful planning and execution to ensure the stability and safety of the load.

- Tower Crane Rigging: Tower cranes are commonly used in large-scale construction projects. Rigging for tower cranes involves setting up the crane and the associated lifting equipment. This includes properly attaching the crane hook or rigging assembly to the load, ensuring sufficient clearance, and maintaining stability during lifting and movement.

- Overhead Rigging: Overhead rigging refers to rigging setups that are installed above ground level. This could include installing overhead cranes, hoists, or gantry systems in warehouses, factories, or construction sites. Overhead rigging allows for efficient material handling and movement without obstructing ground-level operations.

- Scaffold Rigging: Scaffold rigging involves securing or suspending scaffolding structures using rigging equipment. It ensures the stability and safety of scaffolding systems, which are essential for workers to access elevated construction areas. Scaffold rigging may involve the use of ropes, pulleys, and hooks to suspend or secure scaffolding platforms.

- Specialized Rigging: Specialized rigging techniques are used for unique or challenging construction situations. This could include rigging for delicate or sensitive equipment, such as medical machinery or artworks. Specialized rigging may also be required for projects involving tight spaces, restricted access, or complex lifting requirements.

These are just a few examples of the types of rigging employed in construction. Each type of rigging requires specific expertise and equipment to ensure safe and efficient operations. Construction professionals must assess the project’s needs and choose the appropriate rigging method that best meets those requirements.

Equipment Used in Rigging

Rigging in construction requires the use of various equipment to ensure the safe and efficient lifting, moving, and securing of heavy materials and equipment. Here are some common types of equipment used in rigging:

- Slings: Slings are flexible straps or cables used to secure the load and connect it to the lifting equipment. They are available in different materials such as nylon, polyester, wire rope, and chain. Slings come in various configurations, including single-leg, double-leg, and multiple-leg slings, depending on the load capacity and lifting requirements.

- Wire Rope: Wire rope is a strong and durable cable made of multiple strands of wire twisted together. It is commonly used in rigging setups that require high strength and resistance to abrasion. Wire ropes come in various diameters and constructions, allowing for flexibility and load-bearing capacity.

- Chains: Chains are metal links connected together to form a sturdy and robust rigging component. They offer high strength and durability, making them suitable for heavy lifting and secure load attachment. Chains come in different grades and sizes, ensuring compatibility with various load requirements.

- Hoists: Hoists are mechanical devices used to lift and lower heavy objects. They are powered by electricity or manual operation and are commonly used in rigging setups. Hoists come in various types, including chain hoists, wire rope hoists, and lever hoists, each suited for different load capacities and lifting applications.

- Crane: Cranes are essential in many construction projects for lifting and placing heavy materials and equipment. They are available in different types, such as tower cranes, mobile cranes, and crawler cranes, each designed for specific lifting requirements. Cranes are equipped with various rigging components, including hooks, slings, and outriggers.

- Pulleys: Pulleys are grooved wheels with a central axle used to change the direction of a force or transfer the load. They are often used in rigging setups to provide mechanical advantage and facilitate the lifting and movement of heavy objects. Different types of pulleys, such as single, double, and block pulleys, can be combined to create rigging configurations with increased lifting capability.

- Come-Alongs: Come-alongs, also known as hand-operated winches, are portable devices used for pulling, tensioning, and holding loads during rigging operations. They are typically used in scenarios where a powered hoist or crane is not accessible or necessary. Come-alongs are easy to use and are commonly employed in industries like construction, forestry, and utilities.

- Shackles: Shackles are U-shaped metal connectors that are used to secure the slings or other rigging components to the load or lifting equipment. They come in different types, including anchor shackles, chain shackles, and D-shackles, each designed for specific load capacities and attachment requirements.

These are just a few examples of the equipment commonly used in rigging in construction. The selection of rigging equipment depends on factors such as load weight, lifting requirements, and safety considerations. Rigging professionals are trained to assess these factors and choose the appropriate equipment to ensure efficient and secure operations.

When rigging in construction, always ensure that the equipment is inspected and maintained regularly to prevent accidents and ensure safety on the job site.

Read more: How To Rig Aerial Hammock

Safety Measures in Rigging

Ensuring safety is paramount in rigging operations within the construction industry. Proper safety measures must be implemented to prevent accidents, injuries, and property damage. Here are some fundamental safety measures in rigging:

- Training and Certification: Rigging professionals should undergo comprehensive training and acquire relevant certifications to develop the necessary skills and knowledge for safe rigging operations. This includes understanding rigging techniques, load capacity calculations, equipment inspections, and safety protocols.

- Pre-Job Planning: Before starting any rigging operation, proper planning is crucial. This includes identifying potential hazards, determining load requirements, assessing structural integrity, and developing a detailed rigging plan. The plan should consider factors such as load weight, lifting points, rigging configuration, and communication protocols.

- Inspection of Equipment: Rigging equipment must be thoroughly inspected before each use to ensure its integrity and functionality. This includes checking slings, cables, chains, hooks, hoists, and other components for signs of wear, damage, or defects. Any damaged equipment should be immediately removed from service and replaced.

- Proper Load Attachments: Rigging professionals should ensure proper load attachments to prevent load slippage or detachment during lifting or movement. This includes using the appropriate slings, shackles, hooks, or other securing devices and verifying their load capacity before use. The load should be properly balanced and centered to maintain stability.

- Clear Communication: Effective communication is crucial during rigging operations to ensure the coordination and safety of the entire team. This includes using clear hand signals or radio communication between the rigging crew, crane operator, and other personnel involved. All personnel should be aware of their roles and responsibilities during the rigging process.

- Proper Lifting Techniques: Rigging professionals must be trained in proper lifting techniques to avoid strains, sprains, or other musculoskeletal injuries. This includes maintaining a stable stance, using the appropriate body mechanics, and avoiding sudden movements or jerks during lifting or movement of loads.

- Securing the Work Area: The work area should be properly secured to protect workers and bystanders from potential hazards. This includes restricting access to the area, providing clear signage, and implementing barricades or safety barriers to prevent unauthorized entry.

- Frequent Inspections: Regular inspections of rigging equipment, including slings, cables, chains, and hoists, should be conducted to identify any signs of wear, damage, or deterioration. Additionally, inspections should also evaluate the structural integrity of the lifting equipment, such as cranes or hoisting machinery.

- Adherence to Regulations: It is essential to follow all applicable safety regulations, guidelines, and industry standards during rigging operations. This includes compliance with local, state, and federal safety regulations, as well as manufacturer’s instructions and best practices.

- Continuous Training and Improvement: Rigging professionals should continuously update their skills and knowledge through ongoing training programs and staying informed about the latest advancements and safety practices in the field of rigging.

By implementing these safety measures, construction companies and rigging professionals can create a safe work environment, mitigate potential risks, and prevent accidents and injuries during rigging operations.

Role of Rigging Professionals in Construction Projects

Rigging professionals play a crucial role in construction projects, ensuring the safe and efficient lifting, moving, and securing of heavy materials and equipment. Their expertise and knowledge are vital to the success of construction operations. Here are some key roles and responsibilities of rigging professionals in construction projects:

- Rigging Planning and Design: Rigging professionals participate in the planning and design phase of construction projects. They assess project requirements, evaluate load capacities, and develop rigging plans that consider factors such as load weight, lifting points, rigging configurations, and safety measures. Their expertise ensures the efficient and safe execution of rigging operations.

- Equipment Selection and Inspection: Rigging professionals are responsible for selecting the appropriate rigging equipment for each task. They consider factors like load capacity, load type, and equipment specifications. Rigging professionals also conduct thorough inspections of the equipment before use to ensure its integrity and functionality, removing any damaged or unsafe equipment from service.

- Load Attachments and Rigging Setup: Rigging professionals properly attach the load to the rigging equipment, ensuring secure connections and proper balance. They determine the optimal rigging setup, considering the load requirements, lifting points, and access limitations. Rigging professionals are trained to create stable and safe rigging configurations that prevent load slippage or detachment during lifting or movement.

- Collaboration with Crane Operators and Team Members: Rigging professionals work closely with crane operators and other team members involved in construction projects. They communicate effectively to ensure seamless coordination during rigging operations. This includes clear communication of load movements, proper signals, and adherence to safety protocols. Rigging professionals also collaborate in establishing safe work areas and maintaining a safe working environment.

- Safety Compliance: Rigging professionals are well-versed in safety regulations, guidelines, and industry standards related to rigging. They ensure compliance with local, state, and federal safety regulations, as well as industry-specific standards. Rigging professionals implement safety measures, conduct safety inspections, and promote a safety-conscious culture within the construction project.

- Problem Solving and Troubleshooting: Rigging professionals possess the skills and knowledge to solve complex rigging problems. They are capable of troubleshooting issues that may arise during rigging operations, such as unexpected load shifts or equipment malfunctions. Rigging professionals make quick assessments and implement solutions to ensure the safety and efficiency of the rigging process.

- Continuous Professional Development: Rigging professionals stay up-to-date with advancements in rigging techniques, equipment, and safety practices. They engage in continuous professional development through training programs, certifications, and industry conferences. Rigging professionals strive to enhance their skills and knowledge to deliver the highest level of service in construction projects.

The role of rigging professionals is critical in construction projects as they contribute to the overall safety, efficiency, and success of the operations. Their expertise ensures that heavy materials and equipment are handled with care and precision, minimizing the risks associated with lifting and moving operations.

Challenges and Risks Associated with Rigging in Construction

Rigging in construction can be a complex and challenging task that involves various risks and potential hazards. Here are some of the common challenges and risks associated with rigging in construction:

- Heavy Loads: Rigging professionals often work with heavy loads that require careful planning and execution. Improper load calculations or inadequate rigging setups can lead to accidents, injuries, and structural damage.

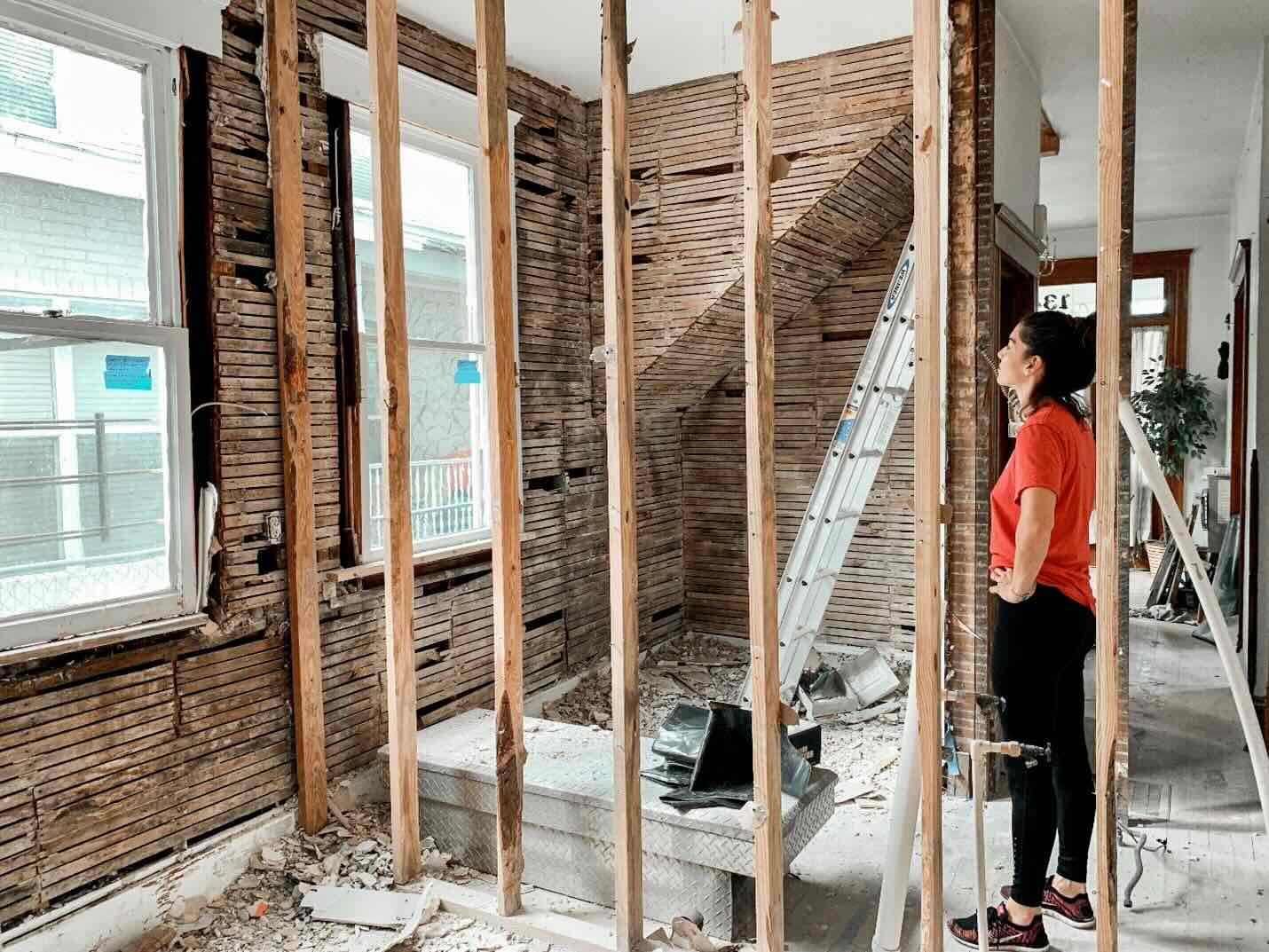

- Restricted Access: Some construction sites have limited space and restricted access, making it challenging to position the lifting equipment and maneuver the load. Rigging professionals must carefully navigate these constraints while maintaining safety standards.

- Unpredictable Weather Conditions: Weather conditions can significantly impact rigging operations. High winds, rain, or extreme temperatures can affect load stability, visibility, and overall safety. Rigging professionals must closely monitor weather forecasts and adjust their plans accordingly.

- Equipment Malfunctions: Rigging equipment, such as cranes, slings, and hoists, can experience malfunctions or breakdowns. This can result in accidents, delays, and damages. Regular inspections, maintenance, and prompt repairs are crucial to mitigate equipment-related risks.

- Communication Challenges: Clear and effective communication is essential during rigging operations. However, noisy environments, distance, and lack of proper communication protocols can impede communication between rigging professionals, crane operators, and other team members, increasing the risk of accidents or misinterpretation of signals.

- Structural Integrity: Rigging professionals must assess the structural integrity of buildings, scaffolding, and other supporting structures before rigging operations. Failure to identify weak or unstable structures can lead to collapses or accidents during lifting and moving operations.

- Human Error: Mistakes or errors in rigging operations can have serious consequences. From improper load attachments to disregarding safety protocols, human error can endanger the lives of workers and result in property damage. Rigging professionals must remain vigilant and follow established procedures to mitigate these risks.

- Compliance with Safety Regulations: Rigging professionals must adhere to safety regulations and guidelines relevant to their work. Failure to comply with these regulations can lead to legal consequences, fines, and reputational damage for construction companies.

- Worker Fatigue: Rigging operations can be physically demanding and require sustained focus. Fatigue, caused by long hours of work or lack of rest breaks, can impair judgment and reaction time, increasing the risk of accidents. Proper scheduling and rest periods are crucial to mitigate this risk.

- Environmental Considerations: Rigging professionals must account for the environmental impact and potential hazards associated with their operations. This includes ensuring proper disposal of hazardous materials, preventing pollution, and protecting natural resources during rigging activities.

Addressing these challenges and risks requires proper training, adherence to safety protocols, vigilant monitoring of equipment and work conditions, and open communication among the rigging crew and other team members. By staying aware of these potential challenges and mitigating risks proactively, construction projects can be carried out safely and efficiently.

Conclusion

Rigging is an indispensable aspect of the construction industry, facilitating the safe and efficient lifting, moving, and securing of heavy materials and equipment. Rigging professionals, armed with their expertise and knowledge, play a crucial role in ensuring the success and safety of construction projects.

Throughout this article, we have explored the definition of rigging in construction and its importance in the industry. We have discussed the various types of rigging, including general rigging, heavy lift rigging, tower crane rigging, scaffold rigging, and specialized rigging. Additionally, we have examined the equipment used in rigging, such as slings, wire ropes, chains, hoists, cranes, pulleys, come-alongs, and shackles.

Safety is paramount in rigging operations, and we have highlighted the essential safety measures and considerations. These include training and certification, thorough equipment inspections, clear communication, proper load attachments, and adherence to safety regulations.

Rigging professionals bring their expertise to construction projects, taking on roles such as rigging planning and design, equipment selection and inspection, load attachments, collaboration with crane operators and team members, safety compliance, problem-solving, and continuous professional development.

However, rigging in construction does pose challenges and risks. These challenges include working with heavy loads, restricted access, unpredictable weather conditions, equipment malfunctions, communication barriers, structural integrity, human error, compliance with safety regulations, worker fatigue, and environmental considerations.

In conclusion, rigging in construction is a complex but essential discipline that requires meticulous planning, skilled execution, and a strong commitment to safety. Rigging professionals play a crucial role in mitigating risks, ensuring the efficiency and success of construction projects, and safeguarding the well-being of workers.

By prioritizing safety, staying updated on industry best practices, and collaborating effectively, rigging professionals contribute to the overall progress and positive outcomes of construction projects. Their expertise and dedication make construction sites safer, more efficient, and provide a solid foundation for successful project completion.

Frequently Asked Questions about What Is Rigging In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Rigging In Construction”