Home>diy>Building & Construction>What Is Trenching In Construction

Building & Construction

What Is Trenching In Construction

Modified: January 24, 2024

Learn about trenching in construction and its importance in building-construction projects. Gain insights into the process and its safety measures.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Construction is a complex process that involves careful planning, precise execution, and adherence to safety regulations. One crucial aspect of construction is trenching. Trenching plays a crucial role in various construction projects, including building foundations, installing utility lines, and creating drainage systems. Understanding what trenching is and its significance in construction is essential for any industry professional.

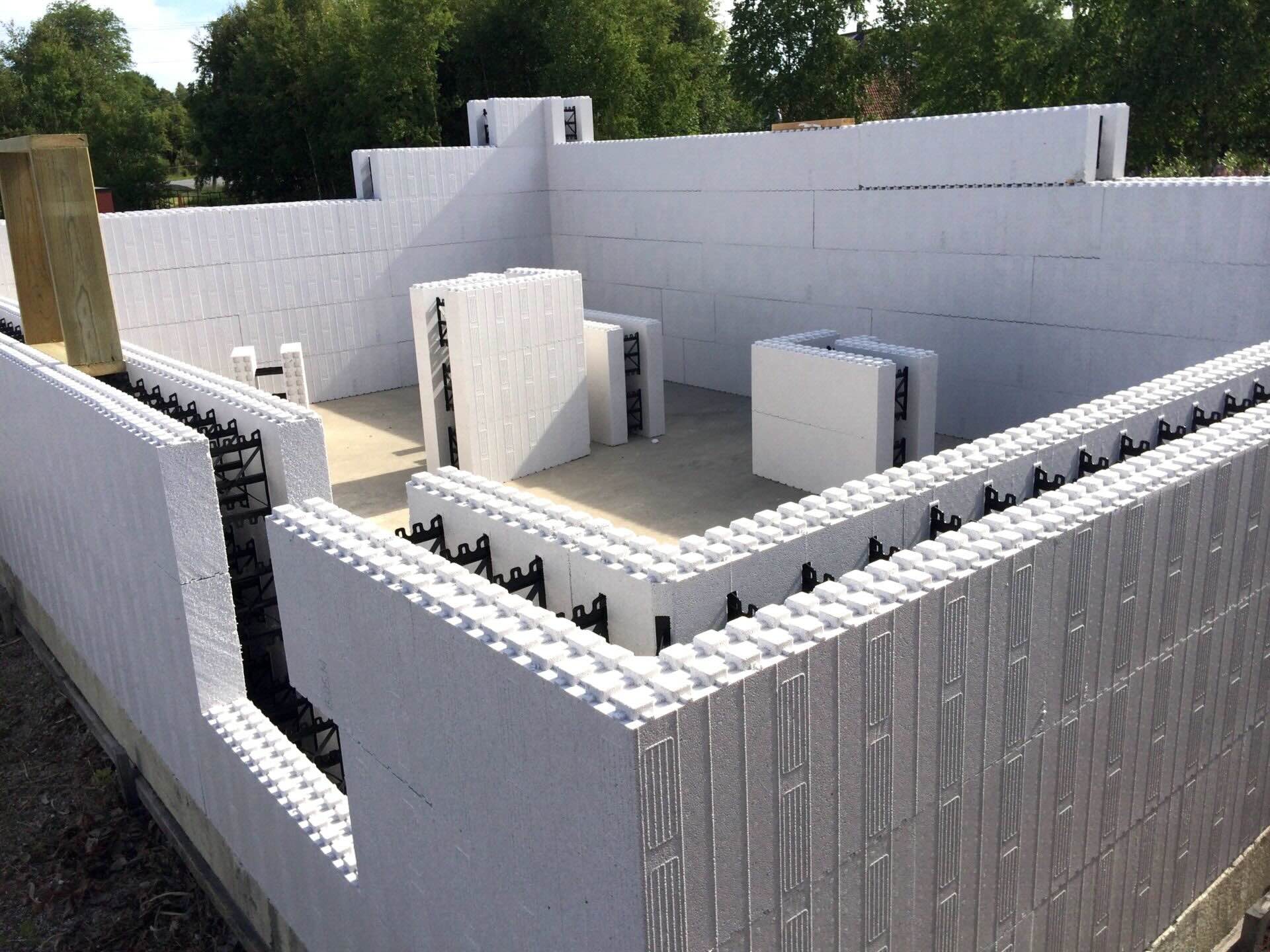

Trenching can be defined as the process of excavating a long and narrow excavation in the ground. It is typically deeper than it is wide and is used for various purposes, such as creating foundation trenches, laying pipes, cables, or conduits, and performing other underground work. Trenches are often needed to create a safe and stable base for building structures or to facilitate the installation of utilities.

The primary purpose of trenching in construction is to provide access to the underground and create a space for installing utilities or building foundations. Trenches are meticulously excavated to the required depth and width, taking into account the specific requirements of the project. Trenching is often necessary for projects such as residential and commercial construction, road construction, plumbing installations, and electrical work.

There are several types of trenches used in construction, each serving a specific purpose. The most common types of trenches include:

- Foundation Trenches: These trenches are excavated to provide a stable base for building foundations. They are typically deeper and wider than other types of trenches and require careful planning and execution.

- Utility Trenches: Utility trenches are created to install or repair underground utilities such as water pipes, sewer lines, electrical cables, or telecommunications cables. These trenches are narrower and shallower compared to foundation trenches.

- Drainage Trenches: Drainage trenches are designed to control the flow of water, prevent flooding, and redirect water away from structures. These trenches are typically narrow and shallow, with the goal of effectively draining water from the surrounding area.

- Trenches for Underground Structures: In some cases, trenches are excavated to allow the construction of underground structures such as tunnels or basements. These trenches require specialized engineering and construction techniques.

Key Takeaways:

- Trenching is a crucial aspect of construction, providing access to the underground for utilities and stable foundations. Understanding trenching types, safety measures, and best practices is essential for successful and safe project completion.

- Trenching presents challenges and risks such as soil conditions, utility obstacles, and trench collapses. Prioritizing thorough planning, protective systems, and continuous improvement fosters a culture of safety and minimizes potential hazards.

Read more: How To Dig Trench For Electrical Conduit

Definition of Trenching

Trenching is the process of excavating a long and narrow trench in the ground, typically for the purpose of constructing foundations, installing utility lines, or creating drainage systems. It involves the careful removal of soil, rocks, and other materials to create a channel that serves a specific construction or maintenance purpose.

The depth and width of a trench can vary depending on the specific project requirements. Trenches can range from shallow cuts in the ground to deep excavations, depending on the intended use and engineering specifications. The width of a trench is typically narrower than its depth, ensuring stability and efficient installation of utilities or structures.

Trenching is an essential aspect of construction, as it allows for the installation of vital infrastructure such as water and sewer lines, electrical cables, and telecommunications networks. It provides a safe and accessible space to lay these utilities underground, protecting them from damage and ensuring efficient use of space.

Furthermore, trenching is crucial for building foundations. Before construction can begin, trenches are excavated to a specific depth to accommodate the footings and foundation walls. These trenches provide the necessary stability and support for the structure, ensuring it can withstand the weight and forces placed upon it.

The process of trenching involves several steps. It starts with the marking of the excavation area, where the depth and width of the trench are determined based on the project requirements and local regulations. Once marked, the soil is then excavated using various tools and equipment, such as excavators, backhoes, or trenchers.

During the excavation process, it is crucial to ensure proper sloping, shoring, or benching techniques to prevent soil collapse and protect workers’ safety. The excavated soil is then either temporarily stockpiled or removed from the site, depending on the project specifications and local regulations.

Once the trench is excavated, additional steps may be necessary, such as the installation of utilities, reinforcing the trench walls with temporary or permanent structures, or backfilling the trench once the required work is complete.

Overall, trenching is a critical process in construction that enables the installation of underground utilities, foundations, and drainage systems. It requires careful planning, adherence to safety guidelines, and efficient execution to ensure successful project completion.

Purpose of Trenching in Construction

Trenching serves several important purposes in construction projects, playing a vital role in the successful completion of various tasks. Let’s explore the key purposes of trenching in construction:

1. Installation of Utility Lines: One of the primary purposes of trenching is to provide a space for the installation of underground utility lines. Trenches are excavated to accommodate water pipes, sewer lines, electrical cables, telecommunications networks, and other essential utilities. By placing these utilities underground, trenching helps protect them from external forces and reduces the risk of damage.

2. Creation of Building Foundations: Another significant purpose of trenching is to create the foundation for buildings and other structures. Trenches are excavated to a specific depth and width to accommodate the footings and foundation walls. These trenches provide a stable and secure base, ensuring the structural integrity of the building and its ability to withstand vertical and lateral loads.

3. Drainage Solutions: Trenching is often employed to create effective drainage systems. Trenches can be excavated to control the flow of water, redirect it away from structures, and prevent flooding. These drainage trenches are designed to channel water to desired locations, ensuring the longevity and safety of the surrounding infrastructure.

4. Access for Maintenance and Repairs: Trenching also provides convenient access for maintenance and repairs. By creating underground channels, utility lines can be easily accessed for maintenance, inspection, and necessary repairs. Trenching allows professionals to reach the utilities without causing disruption to the surface area, minimizing inconvenience and ensuring efficient maintenance procedures.

5. Trenchless Technology: In recent years, trenchless technology has gained popularity in the construction industry. This innovative approach eliminates or minimizes the need for traditional trenching. Methods such as horizontal directional drilling and pipe bursting allow utilities to be installed or repaired without extensive trenching. This approach significantly reduces the impact on the surrounding environment and minimizes disturbances.

6. Uncover Geotechnical Information: Trenching can also be used to gather geotechnical information about the soil and geological conditions. By excavating trenches, engineers and geotechnical experts can evaluate the soil composition, its strength, and any potential hazards or challenges that may arise during construction. This information helps inform the design and construction process, ensuring the safety and stability of the project.

In summary, trenching in construction serves various purposes, including the installation of utility lines, creation of building foundations, implementation of drainage systems, access for maintenance and repairs, utilization of trenchless technology, and uncovering geotechnical information. Understanding the importance and purpose of trenching allows construction professionals to plan and execute projects effectively, ensuring successful outcomes and long-lasting infrastructure.

Types of Trenches

Trenches are a common feature in construction projects, serving different purposes depending on the specific requirements of the project. Here are the main types of trenches used in construction:

- Foundation Trenches: Foundation trenches are excavated to provide a stable base for building foundations. These trenches are typically deeper and wider than other types of trenches, allowing for the placement of footings and foundation walls. Foundation trenches require precise planning and execution to ensure proper support for the structure.

- Utility Trenches: Utility trenches are created to house and protect various underground utilities. These may include water pipes, sewer lines, electrical cables, telecommunications wires, or gas lines. Utility trenches are narrower and shallower compared to foundation trenches, as their primary purpose is to accommodate the installation, maintenance, or repairs of these services.

- Drainage Trenches: Drainage trenches are designed to manage the flow of water and prevent flooding. These trenches are typically narrow and shallow, focusing on collecting and redirecting water away from structures. Drainage trenches incorporate different features such as perforated pipes, gravel, and filters to enhance water flow and filtration.

- Trenches for Underground Structures: Some construction projects require the creation of trenches to accommodate underground structures like tunnels, basements, or storage vaults. These trenches are typically larger and more complex, involving specialized engineering and construction techniques. They are designed to provide the necessary space and support for the underground structures.

- Slot Trenches: Slot trenches are narrow and shallow trenches commonly used for minor utility installations or repairs. They are typically less extensive than utility trenches and are often created using handheld tools or small excavation equipment.

- French Drains: French drains are a specific type of drainage trench designed to effectively manage groundwater and excess surface water. These trenches are typically filled with gravel or perforated pipes to allow water to filter through and be directed away from structures.

- Keyway Trenches: Keyway trenches are primarily used in concrete construction to provide a secure connection between two concrete elements. These trenches are created along the edges of one section of concrete, allowing the other section to fit into the trench, creating a stronger bond when the concrete sets.

- Pipeline Trenches: Pipeline trenches are long, narrow excavations created specifically for the installation of pipelines. These trenches ensure the proper alignment and support of the pipelines, protecting them from external forces and potential damage.

Each type of trench serves a specific purpose in construction, ensuring the stability, functionality, and longevity of the built structures. Construction professionals carefully evaluate the project requirements to determine the appropriate type and dimensions of trenches for their specific needs.

Trenching Equipment and Tools

Trenching is a complex process that requires the use of specialized equipment and tools. These tools and machines are designed to excavate, shape, and support trenches efficiently and safely. Here are some of the common equipment and tools used in trenching:

- Excavators: Excavators are heavy machinery commonly used in trenching. These machines have a bucket attachment that can dig and remove large volumes of soil quickly. Excavators come in different sizes, ranging from compact mini-excavators for smaller projects to large hydraulic excavators for more extensive trenching jobs.

- Backhoes: Backhoes are versatile machines that combine the capabilities of a loader and an excavator. They have a digging bucket at the back and a loader bucket at the front. Backhoes are commonly used in smaller trenching projects, as they can easily maneuver in tight spaces and perform various excavation tasks.

- Trenchers: Trenchers are specialized machines designed specifically for trenching. They have a digging chain or a rotating cutting wheel that cuts through the ground, creating trenches of a precise depth and width. Trenchers come in different sizes and can be used for various trenching applications, including utility trenches and drainage trenches.

- Hand Tools: Various hand tools are also used in trenching for smaller-scale or more precise excavation. Shovels, spades, and picks are commonly used to remove soil and shape the trench walls. Trenching bars, also known as trenching shovels, can be used to break up compacted soil or rocks within the trench.

- Trench Boxes: Trench boxes, also called trench shields or trench shoring systems, are temporary structures used to support the walls of a trench and prevent soil collapse. These protective systems are crucial in ensuring the safety of workers within the trench. Trench boxes come in different sizes and types, depending on the depth and conditions of the trench.

- Pneumatic Tools: Pneumatic tools, such as jackhammers or pneumatic drills, may be utilized to break through hard surfaces or remove obstacles within the trench. These tools are powered by compressed air and can facilitate the excavation process in challenging conditions.

- Surveying Equipment: Surveying equipment, such as total stations and GPS devices, may be used during the trenching process to ensure accurate alignment and measurements. This equipment helps professionals verify the proper depth, width, and location of the trench according to the project specifications and design plans.

It is essential to operate trenching equipment and tools safely and in accordance with manufacturer guidelines. Proper training and understanding of the equipment are crucial to prevent accidents and ensure efficient and effective trenching operations.

Additionally, personal protective equipment (PPE) should be worn by workers involved in trenching activities. This includes hard hats, high-visibility vests, safety goggles, gloves, and safety boots. Safety protocols and guidelines must be followed at all times to minimize risks and ensure a safe working environment.

By utilizing the appropriate equipment and tools for trenching, construction professionals can achieve precise and efficient results while prioritizing safety during the excavation process.

When trenching in construction, always ensure that the trench is properly shored and sloped to prevent collapse and ensure worker safety. Additionally, be sure to locate and avoid any underground utilities before digging.

Read more: How Much To Dig A Trench For Electrical Wire

Trenching Safety Measures

Trenching is a critical process in construction, but it also carries inherent risks. Excavating deep and narrow trenches poses potential hazards to workers and can result in serious accidents if proper safety measures are not followed. Here are some essential trenching safety measures to ensure the well-being of workers and minimize the risk of incidents:

- Proper Planning and Evaluation: Before starting any trenching project, thorough planning and evaluation should be conducted. This includes assessing the soil conditions, determining the appropriate trench dimensions, and identifying any potential hazards or obstructions. Proper planning allows for effective risk management and the implementation of appropriate safety measures.

- Protective Systems: Trenches typically require protective systems to prevent soil collapse and protect workers within the trench. Common protective systems include trench boxes, shoring, and benching techniques. These systems are designed to provide stability to the trench walls and prevent cave-ins. It is essential to ensure that trenches are properly supported and that workers are trained in the appropriate installation and use of protective systems.

- Sloping and Benching: Properly sloping or benching the sides of the trench is crucial in preventing soil collapse. The angle of the slope or the width of the bench depends on soil type and stability as well as the depth of the trench. Following the appropriate sloping or benching specifications helps maintain the stability of the excavated trench walls.

- Access and Egress: Every trench should have proper access and egress points to allow workers to enter and exit safely. Ladders, ramps, or other means of access should be provided at intervals not exceeding 25 feet (7.6 meters) horizontally and 5 feet (1.5 meters) vertically. These access points need to be well-maintained, free from debris, and easily accessible to all workers within the trench.

- Protection from Falling Objects: Falling objects, equipment, or materials pose a significant risk in trenching activities. Workers should wear appropriate head protection, such as hard hats, to guard against falling tools or debris. Additionally, safety barricades or toe boards should be installed around the trench to prevent objects from accidentally falling into the excavation.

- Inspections: Regular inspections of the trench and the surrounding area are essential to identify any potential hazards or changes in conditions. Inspections should be carried out by competent personnel before each shift and after any occurrence that may affect the stability or safety of the trench. Any identified issues should be promptly addressed to maintain a safe working environment.

- Training and Education: All workers involved in trenching activities must receive appropriate training and education on trenching safety measures. They should be familiar with the proper use of equipment, protective systems, and emergency procedures. Ongoing training and regular communication regarding safety practices ensure that workers are well-prepared and knowledgeable about potential risks and best practices.

- Emergency Preparedness: Adequate planning and preparation for emergencies are critical in trenching operations. An emergency action plan should be developed, detailing procedures to follow in the event of an incident, such as a cave-in, equipment failure, or hazardous substance exposure. All workers must be informed of the plan and regularly trained on their roles and responsibilities in emergency situations.

Trenching safety is a shared responsibility between employers, supervisors, and workers. It requires strict adherence to safety protocols, continuous training, and proactive hazard identification and mitigation. By implementing these safety measures, construction professionals can ensure a secure working environment and minimize the potential risks associated with trenching activities.

Regulations and Guidelines for Trenching

Due to the significant hazards associated with trenching, various regulations and guidelines have been put in place to ensure the safety of workers and promote safe trenching practices. These regulations are enforced by government agencies and industry organizations to protect workers and prevent accidents. Here are some key regulations and guidelines that apply to trenching operations:

- Occupational Safety and Health Administration (OSHA): OSHA, a federal agency in the United States, sets and enforces standards to ensure safe and healthy working conditions. OSHA has specific regulations related to trenching and excavation, known as the OSHA Excavation Standards (29 CFR Part 1926, Subpart P). These standards outline requirements for protective systems, access and egress, inspections, and other safety measures for excavations.

- Health and Safety Executive (HSE): In the United Kingdom, the Health and Safety Executive provides guidelines and regulations relating to trenching and excavation work. Their guidelines cover various aspects, including risk assessments, protective systems, control measures, and competent personnel requirements. Compliance with these guidelines is crucial for ensuring the safety of workers and preventing accidents.

- Canadian Centre for Occupational Health and Safety (CCOHS): CCOHS provides resources and guidelines for trenching safety in Canada. Their guidelines focus on hazard identification, safe work practices, and protective systems. Compliance with these guidelines is essential for employers and workers involved in trenching activities in Canada.

- National Utility Contractors Association (NUCA): NUCA is an industry organization in the United States that promotes safety and advocates for the utility construction and excavation industry. They have developed guidelines and best practices for trench safety known as the Trench Safety Stand Down. These guidelines emphasize the importance of training, awareness, and compliance with standards to prevent accidents in trenching operations.

- International Organization for Standardization (ISO): ISO has published standards related to trenching and excavation work, such as ISO 23125:2020 – “Earthmoving machinery – Trenchers and tractors for construction, agriculture, and forestry – Terminology and commercial specifications.” These standards provide guidance on terminology, specifications, and best practices for trenching equipment and processes.

It is essential for construction professionals and employers to familiarize themselves with the specific regulations and guidelines applicable in their region. Compliance with these regulations is not only a legal requirement but also crucial for ensuring the safety of workers and reducing the risks associated with trenching operations.

In addition to regulatory compliance, it is recommended to follow industry best practices and engage in ongoing training and education. Promoting a safety culture within the organization and implementing comprehensive safety programs can further enhance the protection of workers involved in trenching activities.

By adhering to these regulations and guidelines, construction professionals can create a safe working environment, mitigate risks, and ensure the successful and secure completion of trenching projects.

Common Challenges and Risks in Trenching

Trenching is a crucial process in construction, but it also presents various challenges and inherent risks. Understanding these challenges and risks is important for construction professionals to effectively mitigate them and ensure the safety of workers. Here are some common challenges and risks associated with trenching:

- Soil Conditions: The type and condition of the soil can pose significant challenges during trenching. Different types of soil, such as clay, sand, or rock, have different stability characteristics. Excavating in unstable soil can cause walls to collapse, leading to cave-ins and trapping workers. Unpredictable soil conditions, such as loose or water-saturated soil, can increase the risk of cave-ins and make trenching operations more challenging.

- Underground Utilities and Obstacles: Trenching involves working in close proximity to existing underground utilities, such as water pipes, sewer lines, gas lines, or electrical cables. Accidental damage to these utilities can result in service disruptions, environmental hazards, or even life-threatening situations. Additionally, encountering unexpected obstacles, such as old foundations or buried debris, can slow down progress and pose risks to workers and equipment.

- Trench Collapse: One of the most significant risks in trenching is the potential for trench collapse or cave-in. This can occur due to unstable soil, inadequate protective systems, or natural forces such as heavy rain. Trench collapses can result in burial or entrapment of workers, leading to serious injuries or fatalities. Proper protective systems, consistent inspections, and adherence to safety protocols are critical to prevent trench collapses.

- Working at Height: Depending on the depth of the trench, workers may need to work at significant heights. This includes climbing ladders, working on scaffolding, or using aerial lift equipment. Working at height presents additional risks of falls, especially if proper fall protection measures are not in place. Falls from heights can lead to severe injuries or fatalities, underscoring the importance of comprehensive fall prevention measures.

- Heavy Machinery and Equipment: Trenching often involves the use of heavy machinery and equipment, such as excavators, backhoes, or trenchers. Operating and maneuvering these equipment require specialized training and skills. Improper use or handling of machinery can result in accidents, injuries, or damage to property. Adequate training, regular maintenance, and following manufacturer guidelines are crucial to ensure safe handling of equipment.

- Poor Visibility: Low visibility conditions can add to the risks in trenching operations. Factors such as inclement weather, darkness, or dust can impair visibility, making it difficult for workers to identify hazards or coordinate tasks effectively. Adequate lighting, reflective signage, and protocols for working in low visibility conditions are necessary to minimize the risks associated with poor visibility.

- Lack of Proper Training and Communication: Insufficient training and ineffective communication among workers can increase the likelihood of accidents in trenching operations. Workers must receive thorough training on trenching safety, proper use of equipment, emergency procedures, and hazard identification. Clear communication channels and regular safety meetings enable effective coordination and ensure that everyone is aware of potential risks and safety protocols.

Addressing these challenges and risks requires a proactive and comprehensive approach to safety. Employers and construction professionals should prioritize proper planning, risk assessments, effective protective systems, and ongoing training. Adherence to regulatory standards, industry best practices, and consistent communication and supervision can significantly mitigate the risks associated with trenching, ensuring the well-being of workers and the successful completion of projects.

Trenching Best Practices

Trenching is a critical process in construction that requires careful planning, execution, and adherence to safety guidelines. By following best practices, construction professionals can ensure efficient and safe trenching operations. Here are some essential trenching best practices:

- Thorough Planning: Before starting any trenching project, thorough planning is essential. This includes conducting site assessments, identifying potential hazards, evaluating soil conditions, and determining the appropriate trench dimensions. Adequate planning allows for effective risk management and the implementation of appropriate safety measures.

- Training and Competency: All workers involved in trenching activities should receive comprehensive training on trenching safety, equipment operation, and emergency procedures. Workers should be competent in identifying hazards, installing and using protective systems, and responding to emergency situations. Regular refresher training should be provided to ensure up-to-date knowledge and skills.

- Protective Systems: The proper installation and use of protective systems are crucial in ensuring worker safety during trenching. This includes implementing appropriate shoring, benching, or other protective measures to prevent soil collapse. The selection and installation of protective systems should be carried out by qualified personnel following industry standards and manufacturer guidelines.

- Inspections: Regular inspections of the trench and associated equipment are vital to identify potential hazards and ensure compliance with safety guidelines. Inspections should be conducted by competent personnel before each shift and after any occurrence that may affect the stability or safety of the trench. Any identified issues should be promptly addressed to maintain a safe working environment.

- Clear Communication: Effective communication among workers is crucial for the safe execution of trenching operations. Clear communication channels should be established and maintained, ensuring that everyone involved in the project is aware of the specific tasks, hazards, and safety procedures. Regular safety meetings and toolbox talks foster communication and allow for sharing of best practices and lessons learned.

- Proper Equipment Use and Maintenance: Only trained and authorized personnel should operate trenching equipment. Proper use and regular maintenance of equipment are essential to prevent malfunctions or accidents. Regular inspections, lubrication, and servicing of equipment should be conducted, following manufacturer recommendations. Any damaged or faulty equipment should be repaired or replaced promptly.

- Personal Protective Equipment (PPE): Workers engaged in trenching activities must wear appropriate personal protective equipment (PPE) at all times. This includes hard hats, high-visibility vests, safety goggles, gloves, and safety boots. The use of respiratory protection, hearing protection, and fall protection equipment should be considered based on the specific hazards present.

- Emergency Preparedness: Adequate planning and preparation for emergencies are crucial in trenching operations. An emergency action plan should be developed, detailing procedures to follow in the event of an incident, such as a trench collapse or equipment failure. All workers must be informed of the plan, trained on their roles and responsibilities, and have access to emergency communication devices.

- Continuous Improvement: Regular evaluation and improvement of trenching processes and safety practices are essential. Assessing the effectiveness of implemented measures, analyzing incidents or near misses, and seeking feedback from workers contribute to a culture of continuous improvement. Lessons learned should be shared and incorporated into future trenching projects to enhance safety performance.

By following these best practices, construction professionals can ensure the efficient and safe execution of trenching operations. It is crucial to prioritize worker safety, adhere to regulatory requirements, and foster a culture of continuous improvement in trenching practices.

Read more: What Is Pre-Construction In Construction

Conclusion

Trenching is an integral part of construction projects, playing a vital role in creating foundations, installing utilities, and facilitating proper drainage. It involves careful planning, precise execution, and compliance with safety regulations to ensure successful and safe outcomes.

In this article, we have explored the definition of trenching and its significance in construction. Trenching provides access to the underground, allowing for the installation of utilities and the creation of stable foundations. We have discussed different types of trenches, including foundation trenches, utility trenches, drainage trenches, and trenches for underground structures.

Moreover, we have explored the equipment and tools commonly used in trenching, such as excavators, backhoes, trenchers, and protective systems like trench boxes. It is essential to use the appropriate equipment and implement proper safety measures to ensure worker protection and efficient trenching operations.

We have also covered the importance of trenching safety measures, including proper planning and evaluation, the use of protective systems, regular inspections, and training and education. Adhering to regulations and guidelines set by organizations such as OSHA, HSE, and CCOHS is essential for maintaining a safe working environment.

Additionally, we have discussed the common challenges and risks associated with trenching, such as soil conditions, underground utilities, trench collapses, working at height, heavy machinery, and poor visibility. Identifying and mitigating these risks through proper planning, training, and communication is crucial for ensuring the well-being of workers and preventing accidents.

Lastly, we have highlighted the best practices in trenching, including thorough planning, training and competency, proper use of protective systems, regular inspections, clear communication, and continuous improvement. Following these best practices is essential for promoting a culture of safety and minimizing the risks associated with trenching operations.

In conclusion, trenching is a complex process that requires expertise, careful consideration, and adherence to safety guidelines. By understanding the importance of trenching, implementing proper safety measures, and following best practices, construction professionals can ensure efficient, safe, and successful trenching operations, contributing to the overall success of construction projects.

Frequently Asked Questions about What Is Trenching In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Trenching In Construction”