Home>diy>Building & Construction>What Is An ICF In Construction

Building & Construction

What Is An ICF In Construction

Modified: March 1, 2024

Learn all about the ICF (Insulated Concrete Form) construction method in building construction. Find out how it works and its benefits for energy efficiency and durability.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of construction, innovation is constantly pushing the boundaries of what is possible. From advanced materials to cutting-edge techniques, the construction industry is always seeking new ways to improve efficiency, durability, and sustainability. One such innovation that has gained significant attention and popularity in recent years is the use of Insulating Concrete Forms (ICFs).

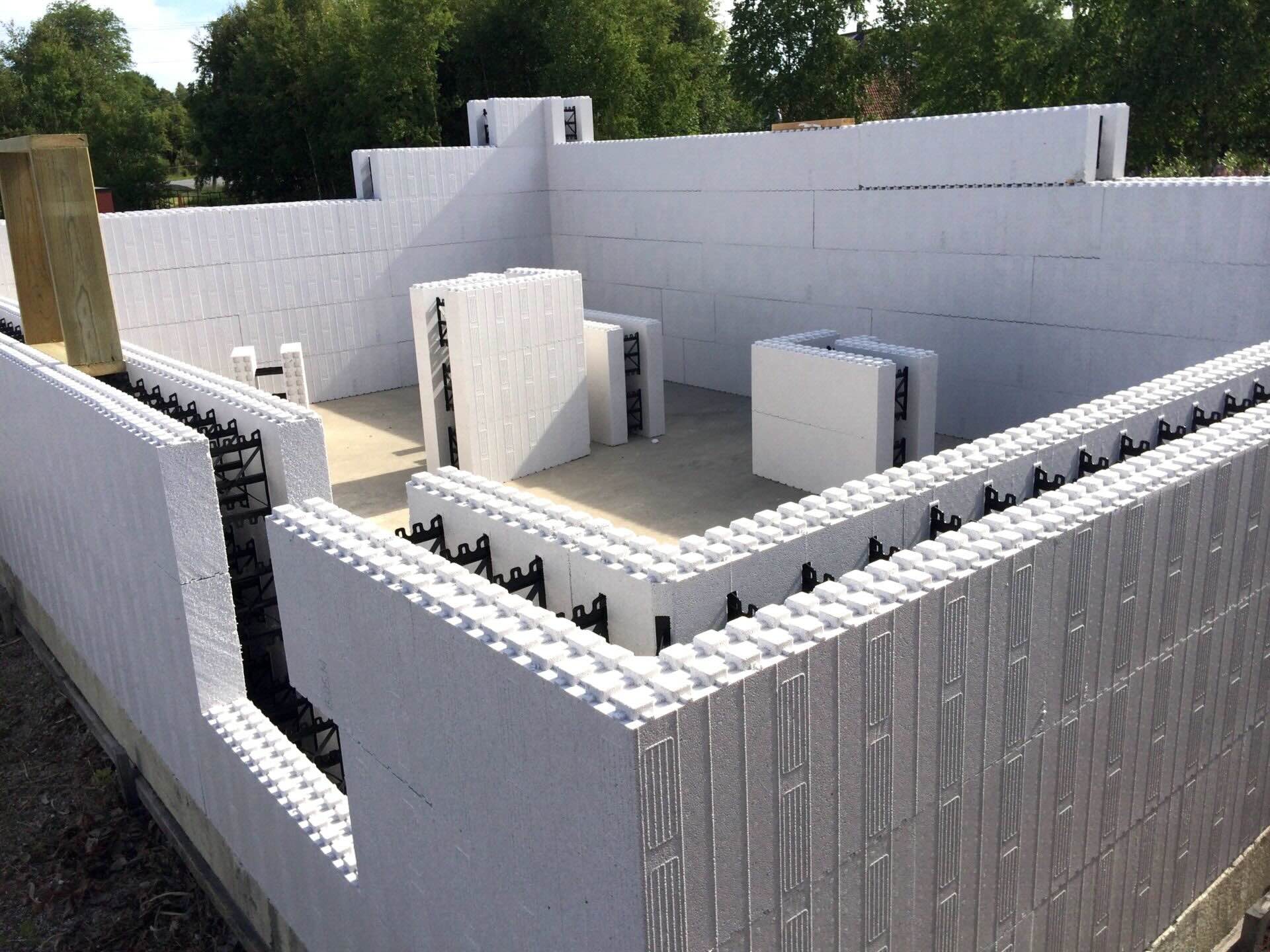

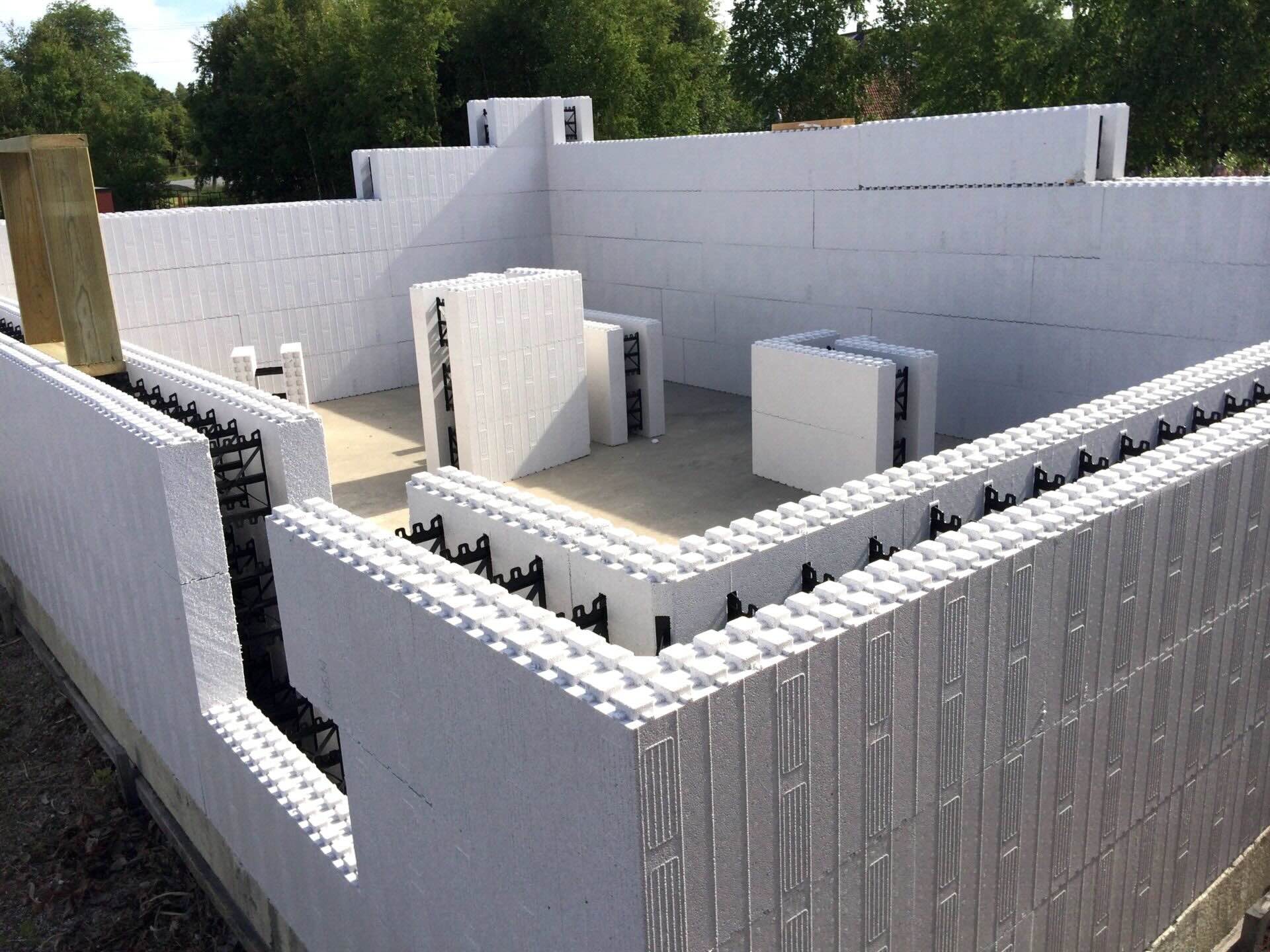

ICFs are a construction technique that combines the strength and durability of concrete with the insulating properties of expanded polystyrene (EPS) foam. This unique combination creates a building material that offers exceptional energy efficiency, sound resistance, and structural integrity.

ICFs are essentially large, hollow blocks or panels made from EPS foam. These blocks are interconnected and then filled with reinforced concrete to form the walls of a building. The EPS foam acts as both insulation and a formwork for the concrete, eliminating the need for additional insulating materials and reducing construction time and costs.

The use of ICFs in construction has become increasingly popular for a variety of reasons. Firstly, ICFs offer superior energy efficiency compared to traditional construction methods. The continuous layer of insulation provided by the EPS foam significantly reduces thermal bridging and prevents heat transfer between the interior and exterior of the building, resulting in lower energy consumption and utility bills.

In addition to energy efficiency, ICFs also provide exceptional soundproofing. The combination of concrete and EPS foam creates a barrier that helps to block out external noise, making buildings constructed with ICFs quieter and more comfortable.

The structural integrity of ICFs is another key advantage. The reinforced concrete core within the EPS foam insulation provides exceptional strength and durability, making ICF buildings highly resistant to extreme weather events such as hurricanes and earthquakes.

Furthermore, ICFs are environmentally friendly. The use of EPS foam reduces the consumption of natural resources and minimizes waste. Additionally, the energy efficiency of ICF buildings translates to reduced carbon emissions and a smaller environmental footprint.

While ICF construction offers many benefits, it is important to consider factors such as cost and design flexibility. ICFs may require a higher initial investment compared to traditional construction methods. However, the long-term energy savings and increased durability often outweigh the upfront costs.

In this article, we will explore the components of an ICF, the installation process, and the structural performance of ICF buildings. We will also discuss their energy efficiency and environmental sustainability, and provide case studies that demonstrate successful applications of ICFs in construction projects.

Overall, ICFs have revolutionized the construction industry by offering a blend of superior insulation, structural strength, and energy efficiency. This innovative technique is being embraced by builders and architects around the world as they strive to construct more sustainable and resilient buildings. So, let’s dive into the world of ICF construction and explore why it has become such a game-changer.

Key Takeaways:

- ICFs offer exceptional energy efficiency, sound resistance, and structural integrity, making them a game-changer in modern construction. Their long-term cost savings and environmental benefits make them a compelling choice for sustainable building projects.

- Successful case studies across various sectors demonstrate the effectiveness of ICF construction in delivering energy-efficient, durable, and sustainable buildings. With their design flexibility and environmental impact, ICFs are reshaping the construction industry.

Read more: What Is ICF Construction

Definition of an ICF

Insulating Concrete Forms (ICFs) are a construction system that utilizes interlocking panels or blocks made of expanded polystyrene (EPS) foam. These panels or blocks are assembled to create the walls of a building, which are then filled with reinforced concrete. The combination of EPS foam and concrete creates a highly insulated and structurally sound wall system.

The EPS foam panels or blocks are designed with integrated webs or interlocking mechanisms that allow them to fit together securely, forming a continuous and rigid structure. This design eliminates the need for additional formwork and serves as a permanent insulation layer for the building.

The EPS foam used in ICF construction is an ideal insulating material due to its low thermal conductivity. It provides reliable thermal resistance, preventing the transfer of heat or cold between the interior and exterior of the building. This insulation property helps to maintain a comfortable indoor environment and reduce the dependency on heating and cooling systems, thus lowering energy consumption and costs.

The EPS foam panels or blocks serve not only as insulation but also as a support system for the reinforced concrete. Once assembled, the panels or blocks are filled with concrete, creating a monolithic structure that delivers exceptional strength, durability, and resilience. The concrete core within the EPS foam acts as a load-bearing element, providing structural integrity and withstanding various loads and external forces.

ICFs are versatile and can be used for various types of construction projects, including residential, commercial, and industrial buildings. They can be used for both above-grade and below-grade walls and can support multiple stories. The interlocking design of the panels or blocks ensures consistent alignment, resulting in precise and uniform construction.

One of the key advantages of ICF construction is its compatibility with other building systems and materials. ICF walls can be seamlessly integrated with conventional construction techniques, such as steel or wood framing, to create hybrid structures. This flexibility allows builders and architects to combine the benefits of different construction methods and materials, optimizing performance and meeting specific project requirements.

In summary, ICFs are a construction system that combines EPS foam panels or blocks with reinforced concrete, creating highly insulated and structurally robust walls. This innovative approach offers superior energy efficiency, sound resistance, and durability, making ICFs an attractive choice for modern construction projects.

Components of an ICF

Insulating Concrete Forms (ICFs) consist of several main components that work together to create a strong and energy-efficient wall system. Understanding the components of an ICF is essential for successful construction and maximizing the benefits of this innovative construction method.

1. Expanded Polystyrene (EPS) Foam:

EPS foam is the primary component of an ICF. It is a lightweight and rigid insulation material known for its excellent thermal resistance. EPS foam panels or blocks are designed to interlock, creating a continuous formwork for the concrete and providing insulation throughout the entire wall system.

2. Interlocking Mechanism:

The EPS foam panels or blocks are designed with interlocking mechanisms, such as webs or grooves, that allow them to fit together securely. This interlocking feature ensures precise alignment during construction and provides structural stability to the wall system.

3. Reinforcement System:

To enhance the strength and durability of the ICF walls, a reinforcement system is incorporated within the foam panels or blocks. This typically consists of horizontal and vertical steel reinforcement, such as rebar or mesh, that is placed before pouring the concrete. The reinforcement system helps to distribute loads and increase the structural performance of the walls.

4. Concrete Core:

The core of an ICF wall is formed by pouring reinforced concrete into the cavity created by the EPS foam panels or blocks. The concrete fills the voids between the interlocking foam components, creating a monolithic structure that provides exceptional strength and durability. The thickness of the concrete core can vary depending on the project requirements and design.

5. Integrated Insulation:

One of the key advantages of ICF construction is the integrated insulation provided by the EPS foam panels or blocks. The foam acts as a continuous insulation layer, preventing thermal bridging and minimizing heat transfer through the walls. This results in improved energy efficiency and a more comfortable interior environment.

6. Wall Facings:

In some ICF systems, additional wall facings or coverings are used to protect the foam insulation and provide a finished surface. This can include materials such as cementitious coatings, stucco, veneers, or siding. The wall facings enhance the appearance of the building while providing added protection against weather elements.

7. Mechanical Fasteners:

During the construction process, mechanical fasteners are used to secure the ICF panels or blocks together. These fasteners ensure a tight connection between the foam components, maintaining structural integrity throughout the walls. Common mechanical fasteners include plastic ties, screws, and clips, which are specifically designed for use with ICF systems.

Understanding the components of an ICF is crucial for successful construction and efficient utilization of this technology. By integrating EPS foam, interlocking mechanisms, reinforcement systems, concrete cores, integrated insulation, wall facings, and mechanical fasteners, ICFs provide a robust and energy-efficient solution for modern building construction.

Benefits of Using ICFs in Construction

Insulating Concrete Forms (ICFs) offer a wide range of benefits that make them a compelling choice for construction projects. From energy efficiency to increased durability, ICFs provide numerous advantages over traditional building methods. Let’s explore the key benefits of using ICFs:

1. Superior Energy Efficiency:

ICFs are renowned for their exceptional thermal performance. The EPS foam insulation provides a continuous and highly effective barrier against heat transfer, reducing energy consumption for heating and cooling. This translates into lower utility bills and a more sustainable building.

2. Enhanced Insulation:

Due to the integrated insulation provided by the EPS foam, ICF walls offer superior insulation compared to traditional methods. The continuous layer of insulation eliminates thermal bridging, which occurs when heat passes through materials with low insulation value. This results in a more comfortable and consistent indoor environment.

3. Sound Resistance:

ICFs not only provide excellent thermal insulation but also offer substantial soundproofing capabilities. The combination of concrete and EPS foam creates a barrier that effectively blocks out external noise, reducing sound transmission and creating quieter living or working spaces.

4. Structural Integrity:

ICF construction results in structurally robust walls. The reinforced concrete core within the EPS foam walls provides exceptional strength and durability, ensuring the building can withstand severe weather conditions, such as hurricanes or earthquakes. This makes ICF structures more resilient and long-lasting.

5. Improved Fire Resistance:

ICF walls have inherent fire-resistant properties due to the use of concrete. Concrete does not burn, making it an excellent material for minimizing fire risks. Additionally, the EPS foam in ICFs is treated with fire-retardant additives, further enhancing the fire resistance of the wall system.

6. Design Flexibility:

ICF construction offers architects and builders greater design versatility compared to traditional methods. The interlocking foam panels or blocks can be easily modified or adjusted to accommodate various architectural styles and shapes. ICF walls can also be combined with other building systems, allowing for hybrid construction.

7. Environmental Sustainability:

ICFs contribute to environmental sustainability in several ways. The use of EPS foam insulation reduces the consumption of natural resources, as foam is a manufactured material. Additionally, the energy efficiency of ICF buildings leads to reduced carbon emissions and a smaller ecological footprint compared to conventional construction techniques.

8. Faster Construction:

ICF construction can be faster compared to traditional methods. The interlocking foam panels or blocks provide a ready-to-use formwork for the concrete, saving time and labor. Moreover, ICFs eliminate the need for additional insulation and reduce the number of on-site trades required, streamlining the construction process.

9. Cost Savings:

Although the initial investment for ICF construction may be higher than traditional methods, the long-term cost savings can be significant. The energy efficiency of ICF buildings leads to lower heating and cooling costs over time. Additionally, the durability and reduced maintenance requirements can result in reduced repair and replacement expenses.

Overall, the benefits of using ICFs in construction are compelling. From energy efficiency and increased durability to sound resistance and design flexibility, ICFs offer a sustainable and practical solution for modern building projects.

Comparison of ICFs to Traditional Construction Methods

When considering construction methods, it is essential to compare the advantages and disadvantages of different approaches. Insulating Concrete Forms (ICFs) have gained popularity due to their numerous benefits, but how do they compare to traditional construction methods? Let’s explore the key points of comparison:

1. Energy Efficiency:

ICFs offer superior energy efficiency compared to traditional construction methods. The continuous layer of insulation provided by the EPS foam significantly reduces thermal bridging and heat transfer, resulting in lower energy consumption for heating and cooling. Traditional methods often require additional insulation to achieve similar levels of energy efficiency.

2. Sound Resistance:

ICFs have inherent soundproofing capabilities due to the combination of concrete and EPS foam insulation. They provide better sound resistance compared to traditional methods, which may require additional measures such as additional insulation or sound-deadening materials.

3. Structural Integrity:

ICF walls are known for their exceptional strength and durability. The reinforced concrete core within the EPS foam provides a robust and resilient structure, offering increased resistance to extreme weather events. Traditional methods may require additional reinforcement or measures to achieve similar structural integrity.

4. Construction Speed:

ICF construction can be faster compared to traditional methods. The interlocking foam panels or blocks serve as ready-to-use formwork for the concrete, reducing the time and labor required for constructing wall systems. Traditional methods often involve multiple stages and trades, which can result in longer construction schedules.

5. Design Flexibility:

ICFs offer greater design flexibility compared to traditional methods. The interlocking foam panels or blocks can be easily modified or adjusted to accommodate various architectural styles and shapes. Traditional methods may have more limitations and require additional steps to achieve similar design flexibility.

6. Fire Resistance:

ICFs provide inherent fire resistance due to the use of concrete, which does not burn. The EPS foam in ICFs is also treated with fire-retardant additives, enhancing the fire resistance of the wall system. Traditional methods may require additional fireproofing measures, such as fire-resistant coatings or materials.

7. Cost Considerations:

The cost of ICF construction can vary depending on factors such as location, project size, and design complexity. While the initial investment for ICFs may be higher than traditional methods, the long-term cost savings can be significant. The energy efficiency of ICF buildings reduces heating and cooling costs over time. Traditional methods may have lower upfront costs, but higher long-term operational expenses.

8. Environmental Sustainability:

ICFs contribute to environmental sustainability due to their energy efficiency and reduced carbon emissions. The use of EPS foam insulation reduces the consumption of natural resources. Traditional methods may have a higher environmental impact due to greater energy consumption and waste generation during construction.

It is important to note that the choice between ICFs and traditional methods depends on project-specific requirements and priorities. Factors such as budget, design preferences, energy efficiency goals, and construction timeline should all be considered when making a decision.

Overall, ICFs offer several advantages over traditional construction methods, including superior energy efficiency, sound resistance, structural integrity, and design flexibility. By considering these factors, builders and architects can make informed decisions and choose the most suitable approach for their construction projects.

Read more: What Is Pre-Construction In Construction

Types of Insulating Concrete Forms

Insulating Concrete Forms (ICFs) come in various types, each with its own unique features and construction methods. Understanding the different types of ICFs is crucial in selecting the most appropriate system for a construction project. Let’s explore some of the common types of ICFs:

1. Flat Wall ICFs:

Flat wall ICFs are the most basic and widely used type of ICF system. They consist of flat EPS foam panels that are connected using interlocking mechanisms. These panels are stacked and secured to create a continuous formwork for the concrete. Flat wall ICFs offer versatility and can be used for both residential and commercial applications.

2. Screen Grid ICFs:

Screen grid ICFs are similar to flat wall ICFs, but they incorporate a reinforced grid pattern within the foam panels. The grid pattern provides additional strength and stability to the wall system, making it suitable for larger and taller structures that require enhanced structural performance.

3. Waffle Grid ICFs:

Waffle grid ICFs feature a unique pattern of interconnected EPS foam blocks or panels. The pattern resembles a waffle, with deep cavities that provide added insulation and structural stability. Waffle grid ICFs are popular for their ease of construction and enhanced energy efficiency.

4. Post and Beam ICFs:

Post and beam ICFs combine the benefits of ICF construction with the use of traditional posts and beams. This system incorporates posts and horizontal beams made of steel or wood, which are embedded within the EPS foam walls. Post and beam ICFs offer design flexibility and can create unique architectural features while still providing the benefits of ICFs.

5. Plank ICFs:

Plank ICFs are characterized by long, interlocking EPS foam planks that are stacked and connected to form the walls. The planks offer increased flexibility in terms of design, as they can be easily cut and adjusted to achieve various shapes and angles. Plank ICFs are commonly used for curved or irregular wall configurations.

6. Insulating Concrete Block ICFs:

Insulating Concrete Block ICFs consist of pre-formed hollow blocks made of EPS foam. These blocks have interlocking features and are stacked and filled with concrete to form the walls. Insulating concrete block ICFs offer the advantage of using standardized blocks, which can speed up construction and simplify the assembly process.

7. IntegraSpec ICFs:

IntegraSpec ICFs are a patented ICF system that utilizes lightweight and self-supporting EPS foam panels. The panels have a patented interlocking system that allows for quick and easy assembly. IntegraSpec ICFs are known for their strength, durability, and ease of installation.

Each type of ICF has its own advantages and considerations, depending on the specific requirements of the project. It is important to consult with experienced professionals and manufacturers to determine the most suitable ICF system for a construction project.

By selecting the appropriate type of ICF, builders and architects can harness the benefits of this innovative construction method and create energy-efficient, durable, and environmentally friendly structures.

When working with an ICF (Insulated Concrete Form) in construction, make sure to properly brace and support the forms during concrete pouring to prevent bulging or shifting. This will ensure a strong and stable structure.

Installation Process of an ICF

The installation process of Insulating Concrete Forms (ICFs) involves several key steps that ensure a proper and successful construction. While specific details may vary based on the chosen ICF system, the general process remains consistent. Let’s explore the typical installation process of ICFs:

1. Site Preparation:

The first step in the installation process is the preparation of the construction site. This includes clearing the area, leveling the ground, and ensuring proper drainage. It is important to follow local building codes and obtain any necessary permits before proceeding.

2. Foundation Construction:

The foundation is the base upon which the ICF walls will be constructed. The foundation is typically made of poured concrete or other suitable materials. It must be sturdy, level, and able to support the weight of the ICF wall system.

3. ICF Panel or Block Assembly:

The next step is to assemble the ICF panels or blocks. The interlocking mechanisms or connections on the panels or blocks allow them to fit securely together. Care must be taken to ensure proper alignment and tight connections between the panels or blocks.

4. Reinforcement Placement:

Once the ICF panels or blocks are assembled, the next step is to place the reinforcement material. This can include horizontal and vertical steel reinforcement, such as rebar or mesh. The reinforcement helps to distribute loads and increase the structural strength of the ICF walls.

5. Window and Door Openings:

If there are any window or door openings in the ICF walls, they need to be properly framed and reinforced. Additional support may be required to ensure structural integrity and accommodate the installation of windows and doors later in the process.

6. Electrical and Plumbing Installation:

Prior to pouring the concrete into the ICF wall system, it is important to install any necessary electrical wiring and plumbing. Conduit and piping can be embedded within the foam or attached to the surface of the foam using appropriate fasteners.

7. Concrete Pouring:

Once all the necessary preparations are complete, it is time to pour the concrete into the ICF wall system. The concrete is typically poured in sections or lifts, starting from the bottom and working upwards. Vibrators may be used to ensure proper consolidation of the concrete within the ICF cavities.

8. Concrete Curing and Finishing:

After the concrete has been poured, it needs time to cure and properly set. The curing process typically takes several days, during which the concrete gains strength. Once the concrete is cured, the surface can be finished according to the desired appearance, whether by painting, stucco, or other finishing techniques.

9. Additional Construction Steps:

After the ICF walls are in place, construction can proceed with other components of the building, such as roof installation, interior finishes, and mechanical systems. The ICF walls provide a solid and secure foundation for the remaining construction process.

It is important to note that the installation process of ICFs should be carried out by experienced professionals who have knowledge of ICF construction. This helps ensure that the installation is done correctly, meeting the required building codes and standards.

By following the proper installation process, builders and contractors can take full advantage of the benefits that ICFs offer, including energy efficiency, structural strength, and durability.

Structural Performance of ICFs

Insulating Concrete Forms (ICFs) are known for their exceptional structural performance, offering durability and resilience that surpasses traditional construction methods. The combination of reinforced concrete and EPS foam insulation creates a robust wall system that can withstand various structural loads. Let’s explore the key aspects of the structural performance of ICFs:

1. Strength and Load-Bearing Capacity:

ICF walls are built with reinforced concrete cores, providing excellent strength and load-bearing capacity. The steel reinforcement, such as rebar or mesh, within the concrete enhances its structural integrity, ensuring that the walls can withstand the forces applied to them. This makes ICFs suitable for both low-rise and high-rise constructions.

2. Resistance to Extreme Weather Conditions:

ICF walls exhibit exceptional resistance to severe weather conditions, such as hurricanes, tornadoes, and earthquakes. The reinforced concrete core within the EPS foam insulation provides substantial resistance against lateral and uplift forces. ICF structures have demonstrated superior performance in areas prone to these weather events, offering enhanced safety and protection.

3. Durability and Longevity:

The combination of concrete and EPS foam in ICF walls results in a durable and long-lasting building system. Concrete is resistant to fire, rot, pests, and moisture, while the EPS foam provides insulation and serves as a protective barrier. This durability ensures that ICF buildings maintain their strength and performance over many decades, reducing the need for frequent maintenance or repairs.

4. Sound Resistance:

ICF walls are known for their exceptional soundproofing capabilities. The dense structure of the concrete, combined with the insulation provided by the EPS foam, efficiently reduces airborne sound transmission. This makes ICF buildings quieter and more comfortable, creating a peaceful indoor environment that is ideal for residential, commercial, and institutional spaces.

5. Flexibility and Design Possibilities:

ICF construction offers design flexibility while maintaining structural integrity. The interlocking foam panels or blocks can be easily modified or adjusted to accommodate various architectural styles and shapes. ICF walls can also be combined with other building systems, allowing for creative and unique designs. The flexibility of ICFs enables architects and engineers to achieve their design vision while ensuring a strong and stable structure.

6. Thermal Mass Effect:

The thermal mass of the concrete in ICF walls contributes to their structural performance. The concrete absorbs and stores heat, helping to stabilize indoor temperatures and reduce temperature fluctuations. This thermal mass effect improves energy efficiency and reduces the reliance on heating and cooling systems, resulting in energy savings and a more comfortable living or working environment.

7. Reduced Settling and Movement:

ICF walls tend to experience minimal settling or movement over time. The EPS foam and concrete combination provides a stable and rigid structure that limits any potential shifting or settling. This reduces the risk of cracks or structural issues commonly associated with settling in traditional construction methods.

The structural performance of ICFs has been proven through extensive testing and real-world applications. ICF buildings have demonstrated their strength, durability, and resilience in various climates and conditions. By choosing ICF construction, builders and architects can have confidence in the structural integrity and long-term performance of their projects.

Energy Efficiency and Environmental Sustainability of ICFs

Insulating Concrete Forms (ICFs) not only offer exceptional structural performance but also provide substantial energy efficiency and contribute to environmental sustainability. From reduced energy consumption to minimized environmental impact, ICFs offer significant benefits in terms of energy efficiency and environmental sustainability. Let’s explore these aspects in more detail:

1. Excellent Thermal Insulation:

ICFs are renowned for their outstanding thermal insulation properties. The continuous layer of EPS foam insulation forms a barrier that significantly reduces heat transfer through the walls. This greatly reduces the energy required to heat or cool the building, resulting in reduced energy consumption and lower utility bills for the occupants.

2. Reduced Thermal Bridging:

Thermal bridging occurs when heat escapes or enters a building through materials with low insulation value. ICFs eliminate thermal bridging due to the continuous insulation provided by the EPS foam. This results in a more consistent indoor temperature and reduces energy loss through the building envelope.

3. Energy Savings and Cost Reductions:

By significantly reducing heat loss or gain, ICFs lead to substantial energy savings over the lifespan of a building. The reduced energy consumption translates into lower heating and cooling costs for occupants. While the upfront cost of ICF construction may be higher, these long-term energy savings can offset the initial investment and result in cost reductions over time.

4. Sustainable Insulation Material:

The EPS foam used in ICFs is manufactured from expanded polystyrene. This material has a low impact on natural resources as it is predominantly made from air. Furthermore, EPS foam manufacturing processes have reduced their reliance on ozone-depleting substances, making it an environmentally responsible choice for insulation.

5. Reduced Carbon Emissions:

ICFs contribute to reduced carbon emissions and a smaller carbon footprint. The energy efficiency of ICF buildings leads to lower energy demand, resulting in reduced reliance on fossil fuel-based energy sources. This can help mitigate greenhouse gas emissions and combat climate change.

6. Waste Reduction and Environmental Impact:

ICFs minimize waste during the construction process. The EPS foam panels or blocks are precisely cut and assembled, generating minimal scrap materials. Additionally, the use of ICFs reduces the need for additional insulation materials, such as fiberglass or foam boards, which can generate waste. This waste reduction contributes to a cleaner and more sustainable construction site.

7. Indoor Air Quality:

ICF constructions help create a healthier indoor environment. The airtightness of ICF walls minimizes air infiltration, reducing the entry of pollutants, dust, and allergens. This improves the overall indoor air quality, supporting the health and well-being of building occupants.

8. Longevity and Reduced Lifecycle Impact:

ICF buildings are known for their durability and longevity. The combination of concrete and EPS foam forms a robust structure that can withstand the test of time. The extended lifespan of ICF buildings reduces the need for frequent renovations or rebuilds, thereby minimizing their overall environmental impact.

ICFs offer significant energy efficiency and environmental sustainability advantages, making them a responsible choice for construction projects. By reducing energy consumption, minimizing waste, and lowering carbon emissions, ICFs help create buildings that are both environmentally conscious and cost-effective in the long run.

Read more: What Is Construction

Cost Considerations of Using ICFs

While Insulating Concrete Forms (ICFs) offer numerous benefits, it is important to consider the cost implications of using this innovative construction method. ICF construction typically requires a higher initial investment compared to traditional construction methods. However, it is essential to evaluate the long-term cost savings and overall value that ICFs provide. Let’s explore the cost considerations of using ICFs:

1. Initial Cost:

The upfront cost of ICF construction is generally higher than traditional methods. This is primarily due to the materials involved, such as the EPS foam panels or blocks and the steel reinforcement. Additionally, specialized tools and skilled labor may be required for ICF installation, which can further contribute to upfront costs.

2. Energy Savings:

One of the significant cost saving factors associated with ICFs is their energy efficiency. The continuous insulation provided by the EPS foam reduces the energy required for heating and cooling the building. Over time, these energy savings can offset the initial investment and result in significant cost reductions in terms of utility bills.

3. Reduced Maintenance and Repair:

ICF buildings generally require less maintenance compared to traditional construction methods. The durability and resistance to common issues like rot, pests, and moisture damage minimize the need for frequent repairs or replacements. This reduction in maintenance costs can contribute to long-term cost savings.

4. Extended Lifespan:

ICF buildings are known for their longevity, which can result in cost savings over time. The combination of reinforced concrete and EPS foam creates a durable and resilient structure that can withstand various weather conditions. The extended lifespan of ICF buildings reduces the need for costly renovations or rebuilding, further contributing to cost savings.

5. Insurance Premiums:

ICF buildings may qualify for lower insurance premiums due to their superior strength and resistance to fire, storms, and other hazards. Insurance companies often consider the reduced risk associated with ICF construction, leading to potential cost savings in insurance coverage.

6. Design and Flexibility:

ICF construction offers design flexibility, which can contribute to overall cost considerations. The interlocking foam panels or blocks can be easily modified or adjusted to accommodate various architectural styles and shapes. This flexibility can potentially reduce design costs and make it easier to meet specific project requirements.

7. Local Market Factors:

The cost of ICF construction can vary based on local market factors. Factors such as the availability and cost of materials, labor rates, and construction industry competition can influence overall project costs. It is important to consider these factors when assessing the cost feasibility of using ICFs in a specific area.

While ICF construction typically involves a higher initial cost compared to traditional methods, the long-term cost savings and benefits outweigh the upfront investment. The energy efficiency, reduced maintenance, extended lifespan, and design flexibility of ICF buildings contribute to their value proposition and overall cost-effectiveness.

It is recommended to consult with experienced professionals and conduct a thorough cost analysis specific to the project to accurately evaluate the cost considerations and determine the financial viability of using ICFs.

Case Studies: Successful Applications of ICFs in Construction

Insulating Concrete Forms (ICFs) have been widely used in various construction projects around the world, showcasing their effectiveness and delivering impressive results. Let’s explore some case studies that highlight the successful applications of ICFs:

1. North Middle School – Aurora, Nebraska:

The North Middle School in Aurora, Nebraska, is a prime example of ICF construction in the education sector. The school was designed with ICF walls, providing enhanced energy efficiency, sound resistance, and durability. With its reduced energy consumption, the North Middle School has consistently achieved lower energy costs, resulting in significant savings for the school district.

2. Proud Green Home at Serenbe – Chattahoochee Hills, Georgia:

The Proud Green Home at Serenbe in Chattahoochee Hills, Georgia, is a sustainable residence built with ICFs. The home showcases the benefits of ICF construction, including improved insulation, energy efficiency, and indoor air quality. Its energy-efficient features and sustainable design have led to recognition and certifications, such as the LEED Platinum and Energy Star certifications.

3. Penticton Lakeside Resort – Penticton, British Columbia:

The Penticton Lakeside Resort in Penticton, British Columbia, utilized ICFs for their expansion project. The ICF walls provided enhanced energy efficiency, resulting in reduced energy consumption and cost savings for the resort. The project also showcased the flexibility of ICF construction, as it allowed for customization and design versatility while meeting strict building code requirements.

4. Solara Resort and Spa – Canmore, Alberta:

The Solara Resort and Spa in Canmore, Alberta, embraced ICF construction for their luxury condominium project. The ICF walls provided superior insulation and sound resistance, creating a peaceful and comfortable living environment for the residents. The energy-efficient design of the building translated into reduced utility costs and enhanced sustainability.

5. St. Thomas More Catholic Church – Lynchburg, Virginia:

The St. Thomas More Catholic Church in Lynchburg, Virginia, is a notable example of ICF construction in the religious sector. The church utilized ICF walls to create a structurally robust building with exceptional energy efficiency. The ICF construction helped create a welcoming and soundproof environment for worship, while also reducing the environmental impact of the building.

These case studies highlight the successful applications of ICFs in various sectors, including education, residential, hospitality, and religious projects. These real-world examples demonstrate the benefits of ICF construction, such as improved energy efficiency, sound resistance, durability, and sustainability.

ICFs have proven to be a reliable and effective construction method, offering long-term value and performance. As more builders and architects embrace ICFs, the number of successful case studies continues to grow, further reinforcing the advantages and potential of this innovative construction technique.

Conclusion

Insulating Concrete Forms (ICFs) have revolutionized the construction industry by offering a highly efficient and sustainable building solution. With their exceptional energy efficiency, structural performance, and environmental benefits, ICFs have become a preferred choice for builders and architects worldwide.

ICFs provide superior thermal insulation, reducing energy consumption for heating and cooling and resulting in lower utility bills for building owners. The continuous insulation and reduced thermal bridging offered by ICFs create a comfortable indoor environment and contribute to a significant reduction in carbon emissions. These energy savings, along with the durability and longevity of ICF buildings, provide long-term cost benefits and a high return on investment.

The structural performance of ICFs is outstanding, with the reinforced concrete core providing strength, load-bearing capacity, and resilience against extreme weather conditions. ICF buildings have demonstrated their ability to withstand hurricanes, earthquakes, and other adverse events, ensuring the safety and security of occupants.

ICFs also bring design flexibility to construction projects, enabling architects to create unique and aesthetically pleasing structures. The interlocking foam panels or blocks allow for various architectural styles, shapes, and design features, while maintaining the structural integrity and performance of the building.

Moreover, ICFs contribute to environmental sustainability by reducing overall energy consumption, minimizing waste generation, and promoting a healthier indoor environment. The use of EPS foam insulation reduces the consumption of natural resources, making ICFs an eco-friendly choice for construction projects.

In conclusion, ICFs have transformed the building industry by offering a wealth of benefits including energy efficiency, outstanding structural performance, design versatility, and environmental sustainability. As more professionals recognize the advantages of ICF construction, it is expected to gain even larger adoption in the coming years. Builders and architects who embrace ICFs are not only creating energy-efficient and durable buildings but also making a positive impact on the environment. With its combination of efficiency, strength, and sustainability, ICF construction is undoubtedly a game-changer in the world of modern construction.

Frequently Asked Questions about What Is An ICF In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is An ICF In Construction”