Home>diy>Building & Construction>Which Construction Adhesive Is Best

Building & Construction

Which Construction Adhesive Is Best

Modified: January 9, 2024

Find the best construction adhesive for your building construction projects. Compare different options and make an informed choice.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of construction adhesive! When it comes to building and construction projects, one key element that holds everything together is the proper adhesive. Whether you’re constructing a new building, renovating a space, or simply working on a DIY project, having the right adhesive is essential for ensuring the structural integrity and longevity of your construction.

In this article, we will explore the different types of construction adhesives available in the market and their suitability for various applications. From wood to concrete, metal to plastic, construction adhesives provide the necessary bonding strength to join materials together securely.

Not all adhesives are created equal, and selecting the best one for your project can be a daunting task. With a wide range of options available, it’s important to understand the factors to consider when choosing a construction adhesive. Factors such as strength, durability, application method, environmental impact, and cost must be carefully evaluated to ensure the right adhesive is selected.

By the end of this article, you will have a comprehensive understanding of construction adhesives, enabling you to make an informed choice for your specific building needs. So, let’s dive into the world of construction adhesives and discover which one is best for you!

Key Takeaways:

- Choose the right construction adhesive by considering factors such as bonding strength, environmental impact, and cost to ensure a reliable, sustainable, and cost-effective solution for your building projects.

- Prioritize surface preparation, application techniques, and adherence to manufacturer guidelines for optimal results when using construction adhesives. Consider the environmental impact and cost-effectiveness to make informed decisions.

Read more: What Is The Best Construction Adhesive

Purpose of Construction Adhesive

Construction adhesives play a vital role in building and construction projects, serving as a bonding agent that holds various materials together. Unlike mechanical fasteners, such as nails or screws, construction adhesives create a strong and continuous bond across surfaces, ensuring stability and durability.

The primary purpose of construction adhesive is to provide a reliable and long-lasting bond between different materials, such as wood, concrete, metal, or plastic. It eliminates the need for traditional fasteners, which can weaken the structural integrity of the materials over time due to potential rusting, warping, or loosening.

By using construction adhesive, builders and contractors can achieve seamless and strong connections between materials, resulting in a more stable and efficient construction. It allows for greater flexibility in design and construction, as adhesive can create bonds in areas where traditional fasteners may not be practical or effective.

Construction adhesives are also resistant to common environmental factors, such as moisture, temperature fluctuations, and vibrations. This resistance ensures that the bond remains intact and reliable even in challenging conditions, making them suitable for both interior and exterior applications.

Additionally, construction adhesives provide structural reinforcement, enhancing the load-bearing capacity of the materials being bonded. This is particularly important in construction projects where weight distribution and support are critical factors.

Another purpose of construction adhesive is to act as a sealant, filling in gaps and preventing air or water infiltration. This not only improves the appearance of the construction but also helps in maintaining energy efficiency by reducing drafts and preventing water damage.

In summary, the purpose of construction adhesive is to create a strong, durable, and flexible bond between different materials, providing structural integrity, load-bearing capacity, and resistance to environmental factors. With the right construction adhesive, builders can enhance the overall quality and longevity of their construction projects.

Factors to Consider When Choosing Construction Adhesive

Choosing the right construction adhesive for your project is crucial to ensure a successful and long-lasting bond. With a wide variety of options available in the market, it’s important to consider several factors before making your selection. Here are some key factors to keep in mind:

- Substrate Compatibility: One of the primary factors to consider is the compatibility of the adhesive with the materials you are bonding. Different construction adhesives are designed for specific substrates such as wood, concrete, metal, or plastic. Ensure that the adhesive you choose is suitable for the materials you are working with to ensure optimal bonding.

- Strength and Durability: Assessing the strength and durability of the adhesive is crucial for the longevity and reliability of your construction. Consider the intended load-bearing capacity and the type of stress the bond will be subjected to. Make sure the adhesive has the required strength to withstand the specific demands of your project.

- Application Method: Construction adhesives come in various forms, including tubes, cartridges, or cans. Consider the preferred application method for your project. Some adhesive types require a caulking gun or specialized application tools, while others can be applied directly from the container. Choose an application method that is convenient and suitable for your project needs.

- Curing Time: The curing time refers to the duration it takes for the adhesive to fully bond and achieve its maximum strength. Consider the time constraints of your project and choose an adhesive with a curing time that aligns with your construction schedule. Keep in mind that some adhesives may require additional time for complete curing, which may impact the timeline of your project.

- Environmental Impact: If sustainability is a concern, consider the environmental impact of the construction adhesive. Look for eco-friendly options that have low or no volatile organic compounds (VOCs) and meet green building standards. Choosing an adhesive that minimizes harm to the environment can contribute to a greener and more sustainable construction process.

- Temperature and Moisture Resistance: Evaluate the environmental conditions in which the adhesive will be used. If your project will undergo extreme temperatures or exposure to moisture, choose an adhesive specifically designed for these conditions. Adhesives with high-temperature resistance or waterproof properties will ensure a reliable bond that can withstand challenging environments.

- Ease of Use: Consider the ease of application and clean-up when selecting a construction adhesive. Some adhesives may require additional steps or special precautions, while others offer convenient application and easy clean-up options. Choosing an adhesive that fits your level of expertise and provides a smooth application process can save time and effort.

- Cost: Lastly, consider your budget when choosing a construction adhesive. Different adhesives vary in price, and while cost should not be the sole determinant, it is important to balance quality and affordability. Compare the performance and benefits of different adhesives with their price to make an informed decision.

By carefully evaluating these factors, you can make an informed decision and choose the most suitable construction adhesive for your project. Remember that different applications may require different adhesives, so it’s essential to assess the specific needs and demands of your construction before making your selection.

Types of Construction Adhesives

When it comes to construction adhesives, there are several different types available, each designed for specific applications and materials. Understanding the types of construction adhesives will help you choose the most suitable one for your project. Here are some common types:

- Multi-Purpose Adhesive: This type of adhesive is versatile and can be used for a wide range of materials, such as wood, metal, concrete, and plastics. It provides a strong and durable bond, making it a popular choice for general construction and repair projects.

- Wood Adhesive: Designed specifically for bonding wood to wood, wood adhesives come in different forms such as carpenter’s glue, wood glue, or PVA glue. They offer excellent bonding strength and are resistant to moisture, making them ideal for woodworking projects.

- Construction Epoxy: Epoxy adhesives are known for their exceptional strength and durability. They are commonly used for bonding materials such as concrete, metal, ceramics, and glass. Epoxy adhesives provide high resistance to temperature, chemicals, and impact, making them suitable for heavy-duty applications.

- Concrete Adhesive: Concrete adhesive, also known as masonry adhesive, is specifically formulated for bonding concrete and masonry materials. It offers excellent adhesion and durability, making it ideal for projects such as concrete repair, stone veneer installation, or attaching concrete blocks.

- Structural Adhesive: Structural adhesives are designed for high-load applications and provide exceptional strength and bonding performance. They are commonly used for bonding metal, composite materials, or other high-strength substrates. Structural adhesives are often used in the construction of bridges, buildings, or other load-bearing structures.

- Foam Adhesive: Foam adhesive is specifically formulated for bonding foam insulation panels or other foamed materials. It is designed to provide a strong bond while also preventing moisture or air penetration between the foam panels, ensuring energy efficiency and insulation performance.

- Roofing Adhesive: Roofing adhesives are used in the installation of roofing materials, such as shingles or membranes. They provide a strong bond that withstands environmental factors like temperature fluctuations, UV exposure, and moisture. Roofing adhesives help to seal and secure roofing materials, ensuring long-lasting protection against leaks and other weather-related issues.

These are just a few examples of the types of construction adhesives available in the market. It’s important to consult the manufacturer’s guidelines and product specifications to ensure you choose the appropriate adhesive for your specific application. By selecting the right type of construction adhesive, you can ensure a secure and reliable bond between materials, enhancing the overall quality and longevity of your construction project.

Comparison of Different Construction Adhesives

When selecting a construction adhesive, it’s essential to compare the different options available to determine which one best suits your project’s needs. Here, we will compare various construction adhesives based on their key characteristics:

- Bonding Strength: Different construction adhesives offer varying levels of bonding strength. Epoxy adhesives, for example, provide exceptional strength and can withstand heavy loads. Wood adhesives, on the other hand, are specifically formulated for wood-to-wood bonding and offer reliable strength for woodworking projects.

- Materials Compatibility: Consider the materials you are working with and ensure that the adhesive is compatible with those materials. Some adhesives are versatile and can bond various surfaces, while others are designed for specific materials such as wood, metal, or concrete.

- Curing Time: The time it takes for an adhesive to fully cure can vary. Some adhesives dry quickly, allowing you to move on with your project, while others may require a longer curing time. Consider the project timeline and choose an adhesive that fits within your construction schedule.

- Application Method: Construction adhesives are available in different forms, such as tubes, cartridges, or cans. Some adhesives require the use of a caulking gun or other application tools, while others can be applied directly from the container. Consider the convenience and ease of application, as well as the required tools for each adhesive type.

- Resistance to Environmental Factors: Evaluate the environmental conditions the adhesive will be exposed to. Some adhesives offer excellent resistance to moisture, temperature fluctuations, and UV exposure, making them suitable for both interior and exterior applications. Ensure the adhesive you choose can withstand the specific environmental challenges your project may face.

- Durability: Durability is an important factor, especially for long-term construction projects. Consider the adhesive’s ability to withstand impact, vibrations, or harsh chemicals. Epoxy adhesives and structural adhesives, for example, offer exceptional durability and are commonly used in heavy-duty applications.

- Cost: Cost is often a significant consideration when choosing a construction adhesive. Different adhesives come at different price points, depending on their quality and performance. Evaluate the overall cost of the adhesive, considering both the upfront cost and the long-term benefits it offers.

- Accessibility: Depending on your location and project requirements, the availability of certain adhesives may vary. Ensure that the adhesive you choose is readily accessible and can be easily procured when needed. This is particularly important for larger construction projects where a sufficient quantity of adhesive may be required.

By comparing these key characteristics, you can identify the construction adhesive that aligns best with your project’s requirements. It’s important to prioritize the factors that are most crucial for your specific application and strike a balance between performance, cost, and ease of use. Consulting with professionals and considering their recommendations based on their experience can also be beneficial in making an informed decision.

Remember that every construction project is unique, and selecting the right construction adhesive is essential for ensuring the success and longevity of your construction endeavors.

When choosing a construction adhesive, consider the specific materials you will be bonding and the environmental conditions it will be exposed to. Look for adhesives that are waterproof, weather-resistant, and suitable for the materials you are working with.

Read more: How To Remove Construction Adhesive

Strength and Durability of Construction Adhesives

The strength and durability of construction adhesives are vital factors to consider when selecting the right adhesive for your project. These characteristics play a significant role in determining the longevity and reliability of the bond between materials. Let’s take a closer look at the strength and durability of construction adhesives:

Bonding Strength: The bonding strength of an adhesive refers to its ability to create a strong and secure bond between materials. Different types of construction adhesives offer varying levels of bonding strength. Epoxy adhesives, for example, are known for their exceptional strength and ability to withstand heavy loads. Wood adhesives, such as carpenter’s glue, provide reliable strength for woodworking projects. Structural adhesives offer high bonding strength and are commonly used in load-bearing applications.

Shear Strength: Shear strength refers to the ability of an adhesive to resist forces acting parallel to the surface being bonded. It is an important characteristic for adhesives used in applications where there are shear or bending forces. Construction adhesives with high shear strength can effectively withstand stresses and forces applied in different directions, ensuring the stability and durability of the bond.

Impact Resistance: The ability of a construction adhesive to resist impact is crucial, particularly in applications where the bonded materials may be subjected to vibrations or sudden forces. Adhesives with good impact resistance can withstand sudden shocks or stresses, minimizing the risk of bond failure and ensuring the long-term durability of the construction.

Moisture Resistance: Moisture resistance is an important factor to consider, especially when working in environments with high humidity or exposure to water. Some construction adhesives are specifically formulated to resist moisture, preventing degradation and maintaining the bond’s integrity over time. Moisture-resistant adhesives are essential for applications in bathrooms, kitchens, or outdoor settings where there is a higher chance of water exposure.

Chemical Resistance: Depending on the nature of your project, you may need an adhesive that can withstand exposure to chemicals or corrosive substances. Certain construction adhesives offer excellent chemical resistance, ensuring that the bond remains strong and unaffected even in the presence of harsh chemicals. This characteristic is particularly important in applications such as chemical processing plants, laboratories, or industrial settings.

UV Resistance: If your construction project involves exterior applications or areas directly exposed to sunlight, UV resistance becomes crucial. UV-resistant construction adhesives are designed to withstand the damaging effects of ultraviolet radiation and prevent degradation or discoloration over time. This is especially important for outdoor structures, windows, or cladding materials where prolonged exposure to sunlight is expected.

Temperature Resistance: Construction adhesives may be subjected to a wide range of temperatures in different applications. Adhesives with temperature resistance can maintain their strength and bond integrity even under extreme temperature fluctuations. This characteristic is particularly important in applications that experience significant temperature variations, such as automotive, HVAC, or industrial equipment installations.

Longevity: The longevity of a construction adhesive refers to how long the bond remains strong and reliable over time. High-quality adhesives, formulated with durable and resilient materials, offer long-lasting bonds and reduce the likelihood of bond failure or deterioration. Choosing a construction adhesive with a proven track record for longevity ensures the integrity of your project for years to come.

It’s important to note that the strength and durability of a construction adhesive may also depend on factors such as application method, surface preparation, and adhered material compatibility. Following the manufacturer’s guidelines and recommendations is crucial for achieving optimal bond strength and long-term durability.

By carefully evaluating the strength and durability characteristics of construction adhesives, you can select the most appropriate adhesive for your specific project needs. Prioritize the factors that are most critical for your application and consult with professionals when necessary to ensure the success and longevity of your construction endeavors.

Application and Usage of Construction Adhesives

The application and usage of construction adhesives are critical to ensuring a successful and long-lasting bond between materials. Proper application techniques and understanding the specific requirements of each adhesive type are essential for achieving optimal results. Let’s delve into the application and usage of construction adhesives:

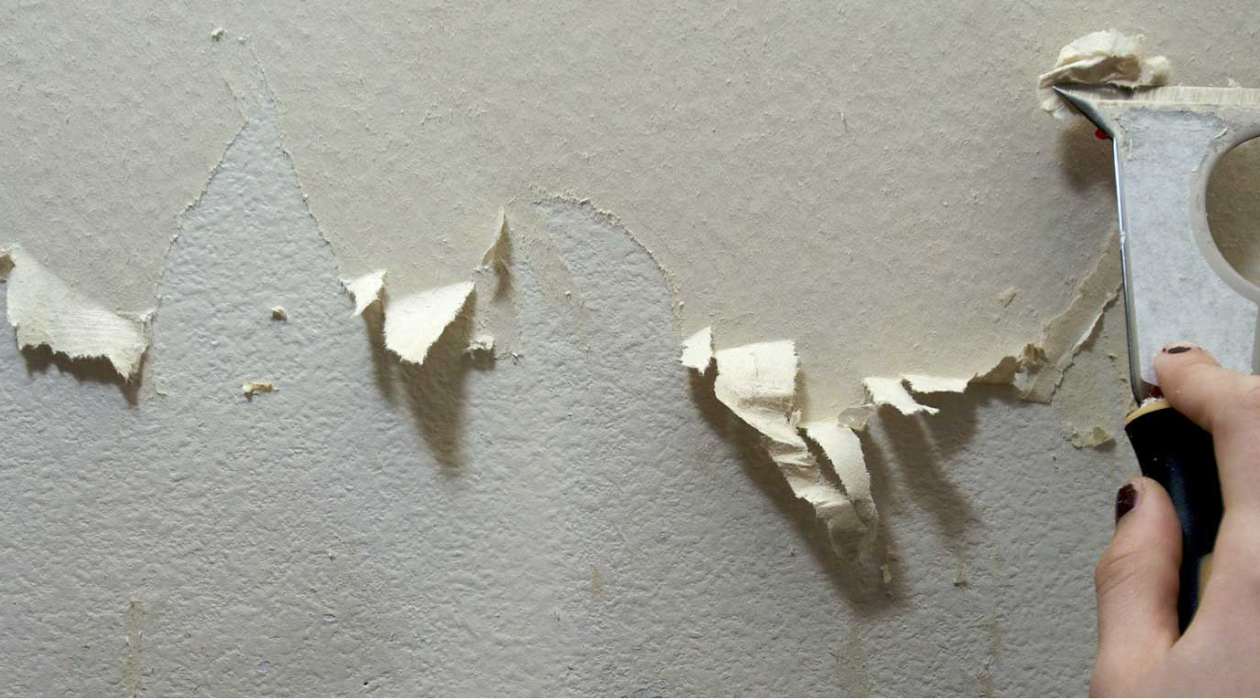

Surface Preparation: Before applying any construction adhesive, it’s crucial to properly prepare the surfaces to be bonded. Surfaces should be clean, dry, and free from dust, grease, or other contaminants that could hinder adhesion. Depending on the adhesive, surface preparation may involve sanding, priming, or using a cleaning agent to ensure maximum adhesion.

Application Method: Construction adhesives come in various forms, including tubes, cartridges, or cans. The application method may differ based on the adhesive type. Some adhesives can be directly applied from the container, while others require the use of a caulking gun or specialized application tools. It’s important to follow the manufacturer’s instructions and use the appropriate application method for the specific adhesive being used.

Application Technique: When applying construction adhesive, it’s important to apply an even and continuous bead of adhesive along the surface. Be mindful of the recommended coverage rate provided by the manufacturer to ensure a sufficient amount of adhesive is applied for proper bonding. Additionally, it’s essential to avoid excessive adhesive that may squeeze out from the bond line or interfere with the project’s aesthetics.

Assembly and Clamping: Once the adhesive is applied, quickly bring the surfaces together, aligning them as needed. For certain adhesive types, such as wood glues, clamping may be necessary to maintain pressure on the bond until the adhesive cures. Consult the manufacturer’s guidelines for recommended clamping techniques and durations. It’s important not to disturb the bond during the curing process to ensure a strong and secure connection.

Curing Time: Construction adhesives require a specified drying or curing time to achieve their maximum bonding strength. The curing time varies depending on the adhesive type, humidity levels, temperature, and other factors. It’s crucial to allow the adhesive sufficient time to cure before subjecting it to any stress or load. Consult the adhesive manufacturer’s instructions for the recommended curing time and avoid disturbing the bond prematurely.

Proper Storage and Shelf Life: Construction adhesives have a limited shelf life, and proper storage is important to maintain their effectiveness. Adhesives should be stored in a cool and dry place, away from direct sunlight or extreme temperatures. Ensure the containers are tightly sealed to prevent any air exposure. It’s also important to periodically check the expiration date and discard any expired adhesives, as they may lose their bonding properties.

Specific Usage Considerations: It’s essential to consider the specific usage requirements and limitations of each construction adhesive. Some adhesives are specifically designed for interior or exterior use, while others may have restrictions on temperature or moisture conditions. Always verify the suitability of the adhesive for your particular application and consult the manufacturer’s guidelines for any specific usage considerations.

By following proper application techniques, adhering to curing times, and considering the specific usage recommendations, you can ensure the optimal performance and longevity of your construction adhesive. Remember to prioritize safety by using proper protective equipment, such as gloves or goggles, as recommended by the manufacturer.

When in doubt, consulting with professionals or seeking guidance from the adhesive manufacturer can provide valuable insight and help achieve the best results for your specific construction project.

Environmental Impact of Construction Adhesives

As the construction industry continues to prioritize sustainability and environmental responsibility, considering the environmental impact of construction adhesives is crucial. Several factors contribute to the overall environmental impact of these adhesives. Let’s explore some key considerations:

Volatile Organic Compounds (VOCs): VOCs are chemicals that have a high vapor pressure at room temperature, and they are a major concern when it comes to the environmental impact of construction adhesives. Some adhesives may contain high levels of VOCs, which can contribute to indoor and outdoor air pollution. Look for adhesives labeled as low VOC or have low VOC content to minimize their impact on air quality.

Emissions and Smell: Certain construction adhesives emit strong odors during the curing process, which can be unpleasant and potentially harmful. Choosing adhesives with low odor emissions can create a more comfortable and healthier environment for construction workers or occupants of the building.

Waste Generation: Construction adhesive containers and packaging contribute to waste generation. Opt for adhesives that come in recyclable packaging or consider using bulk options to reduce packaging waste. Proper disposal of adhesive containers is important to minimize their impact on the environment.

Sustainability and Eco-Friendliness: Many manufacturers are now focusing on developing eco-friendly adhesives that have a reduced environmental impact. These adhesives are often formulated with bio-based or renewable materials and have a lower carbon footprint compared to traditional adhesives. Look for adhesives that are certified with eco-labels like Green Seal or UL Environment to ensure their sustainability credentials.

Health and Safety: In addition to considering the environmental impact, it’s important to assess the health and safety aspects of construction adhesives. Ensure that the adhesives you choose comply with health and safety regulations and do not contain harmful substances, such as lead or asbestos.

Recyclability and Reusability: Not all construction adhesives are recyclable or reusable. However, some manufacturers are developing adhesives that can be recycled or allow for the disassembly and reusability of bonded materials. Considering these factors can further reduce the environmental impact and promote sustainable practices in the construction industry.

Green Building Certifications: For projects seeking green building certifications, such as LEED (Leadership in Energy and Environmental Design), it’s important to choose construction adhesives that meet the required environmental criteria. Adhesives that are certified under recognized environmental standards can contribute to achieving green building certifications and demonstrate a commitment to sustainability.

By actively considering the environmental impact of construction adhesives, you can make more sustainable choices for your construction projects. Look for adhesives that have low VOC content, reduced odor emissions, recyclable packaging, and sustainable certifications. Prioritizing the use of eco-friendly construction adhesives contributes to a greener construction industry and a healthier environment for all.

Cost Analysis of Construction Adhesives

When it comes to construction projects, cost analysis is a crucial factor in decision-making. The cost of construction adhesives can vary depending on various factors, including the type of adhesive, brand, quantity required, and the scale of the project. Here are some key aspects to consider when conducting a cost analysis of construction adhesives:

Upfront Cost: The upfront cost of construction adhesives is the initial price you pay for the product. Different adhesives have different price points, depending on their quality, strength, and performance. It’s important to compare the upfront cost of various adhesives to ensure it fits within your project budget.

Coverage Rate: The coverage rate refers to the area a specific quantity of adhesive can cover. It’s essential to understand the coverage rate to determine the amount of adhesive required for your project. Calculating the coverage rate helps estimate the total quantity of adhesive needed, which in turn affects the overall cost of the project.

Efficiency and Waste Reduction: Consider the efficiency of the adhesive and how it can contribute to reducing waste. Adhesives that require minimal overlap or allow for easy cleanup can help minimize material waste and reduce overall project costs.

Adhesive Performance: While cost is an important consideration, it should not be the sole determinant. Evaluating the performance and durability of the adhesive is equally crucial. Investing in a high-quality adhesive may incur a higher upfront cost, but it can result in long-term savings by minimizing the need for repairs or replacements.

Application Equipment: Some construction adhesives require specialized application equipment, such as caulking guns, adhesive dispense systems, or mixing tools. These equipment costs should be factored into the overall cost analysis. Consider whether investing in or renting the necessary equipment is more cost-effective for your specific project.

Project Size: The size and scale of your construction project can impact the overall cost of adhesives. Bulk purchasing or ordering larger quantities of adhesive may offer cost savings compared to purchasing small quantities multiple times. However, it’s important to ensure that the adhesive can be used within its shelf life to avoid wastage.

Longevity and Warranty: Assess the longevity and warranty offered by the adhesive manufacturer. Adhesives that are durable and come with longer warranties may result in cost savings in the long run. A longer-lasting adhesive reduces the need for frequent repairs or reapplications, thus reducing future expenses.

Alternative Solutions: It’s worth exploring alternative adhesive solutions or considering different adhesive types to determine the most cost-effective option for your project. Consult with professionals or seek advice from adhesive experts to understand the trade-offs between cost and performance.

Overall Project Budget: Finally, when conducting a cost analysis, it’s important to consider your overall project budget. Allocate an appropriate portion of the budget for construction adhesives while ensuring that sufficient funds are available for other project requirements.

By carefully analyzing the cost aspects of construction adhesives, you can make an informed decision that aligns with your project budget and goals. Balancing the upfront cost with adhesive performance, efficiency, and long-term savings can help optimize the overall cost-effectiveness of your construction project.

Read also: 11 Incredible Construction Adhesive For 2024

Conclusion

Choosing the right construction adhesive is a critical aspect of any building or construction project. The adhesive you select plays a pivotal role in ensuring the strength, durability, and longevity of the bonds between materials. By considering various factors such as substrate compatibility, bonding strength, application method, and environmental impact, you can make an informed decision that aligns with your project requirements.

During our exploration, we discussed the purpose of construction adhesives and their significance in construction projects. We examined the factors to consider when choosing construction adhesives, such as strength, durability, application method, curing time, and cost implications. We also explored the different types of construction adhesives available, each with its unique characteristics and suitability for specific materials and applications.

Understanding the strength and durability of construction adhesives is crucial for ensuring a reliable bond. We discussed various aspects such as bonding strength, shear strength, impact resistance, moisture and temperature resistance, as well as the importance of selecting adhesives with proven longevity and performance. Additionally, we highlighted the application and usage of construction adhesives, emphasizing the significance of proper surface preparation, application techniques, curing time, and adherence to manufacturer guidelines for optimal results.

Considering the environmental impact of construction adhesives is becoming increasingly crucial in today’s construction industry. We explored the impact of volatile organic compounds (VOCs), emissions, waste generation, sustainability aspects, and eco-friendly certifications. Minimizing the environmental footprint by selecting low VOC adhesives with reduced packaging waste and recyclability contributes to a more sustainable construction process.

Lastly, conducting a cost analysis is essential in making informed decisions about construction adhesives. By considering factors such as upfront cost, coverage rate, efficiency, adhesive performance, project size, and long-term savings, you can optimize your project budget and ensure cost-effectiveness without compromising on quality.

In conclusion, selecting the right construction adhesive requires careful evaluation and consideration of various factors. By understanding the purpose, strengths, and limitations of different adhesive types, assessing their performance, environmental impact, and cost implications, you can make a well-informed decision that contributes to the success of your construction project. Prioritizing strength, durability, sustainability, and cost-effectiveness ensures that your bonds are secure, your project is sustainable, and your budget is optimized.

Remember, when in doubt, consult with professionals or adhesive manufacturers who can provide expert guidance tailored to your specific construction needs. With the right construction adhesive, you can confidently embark on your building journey and achieve successful, reliable, and long-lasting results.

Frequently Asked Questions about Which Construction Adhesive Is Best

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Construction Adhesive Is Best”