Home>diy>Building & Construction>Which Method Of Construction Is Required For Life Safety Rope

Building & Construction

Which Method Of Construction Is Required For Life Safety Rope

Modified: December 7, 2023

Discover the essential method of construction required for life safety rope in building construction. Ensure the utmost safety with the right techniques.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Construction is a complex and demanding industry that requires stringent safety measures to protect workers and ensure their well-being. One critical aspect of construction safety is the proper use of life safety ropes. These ropes serve as a lifeline for workers who perform tasks at heights or in confined spaces. They act as a vital link between the worker and their safety, providing support and protection in hazardous environments.

Life safety ropes are specially designed to withstand extreme conditions and prevent falls, making them an indispensable part of the construction industry. Choosing the right construction method for life safety ropes is crucial, as it directly impacts the performance, durability, and reliability of the ropes.

In this article, we will delve into the various methods of construction used for life safety ropes, exploring their benefits, drawbacks, and suitability for different applications. By understanding the different construction methods and their implications, construction professionals can make informed decisions to ensure the safety of their workers.

Key Takeaways:

- Kernmantle construction offers a balance of durability and flexibility, making it ideal for a wide range of applications in the construction industry, providing reliable fall protection and load-bearing capabilities.

- Dynamic construction provides excellent shock absorption during falls, making it ideal for activities with longer falls, such as lead climbing and mountaineering, enhancing worker safety in high-risk environments.

Read more: What Education Is Required For Construction

Definition of Life Safety Rope

Before diving into the construction methods of life safety ropes, it is important to have a clear understanding of what they are. Life safety ropes, also known as rescue ropes or fall arrest ropes, are specialized ropes designed to protect individuals working at heights or in confined spaces.

These ropes are typically made from strong and durable materials such as nylon, polyester, or aramid fibers, to withstand heavy loads and extreme conditions. They are purposefully engineered to provide exceptional tensile strength, abrasion resistance, and resistance to chemical and UV exposure.

Life safety ropes are not only used for securing workers at height, but they also serve as a means of rescue in emergency situations. In the event of a fall, properly attached life safety ropes can prevent or minimize injuries by arresting the fall and allowing for a controlled descent to safety.

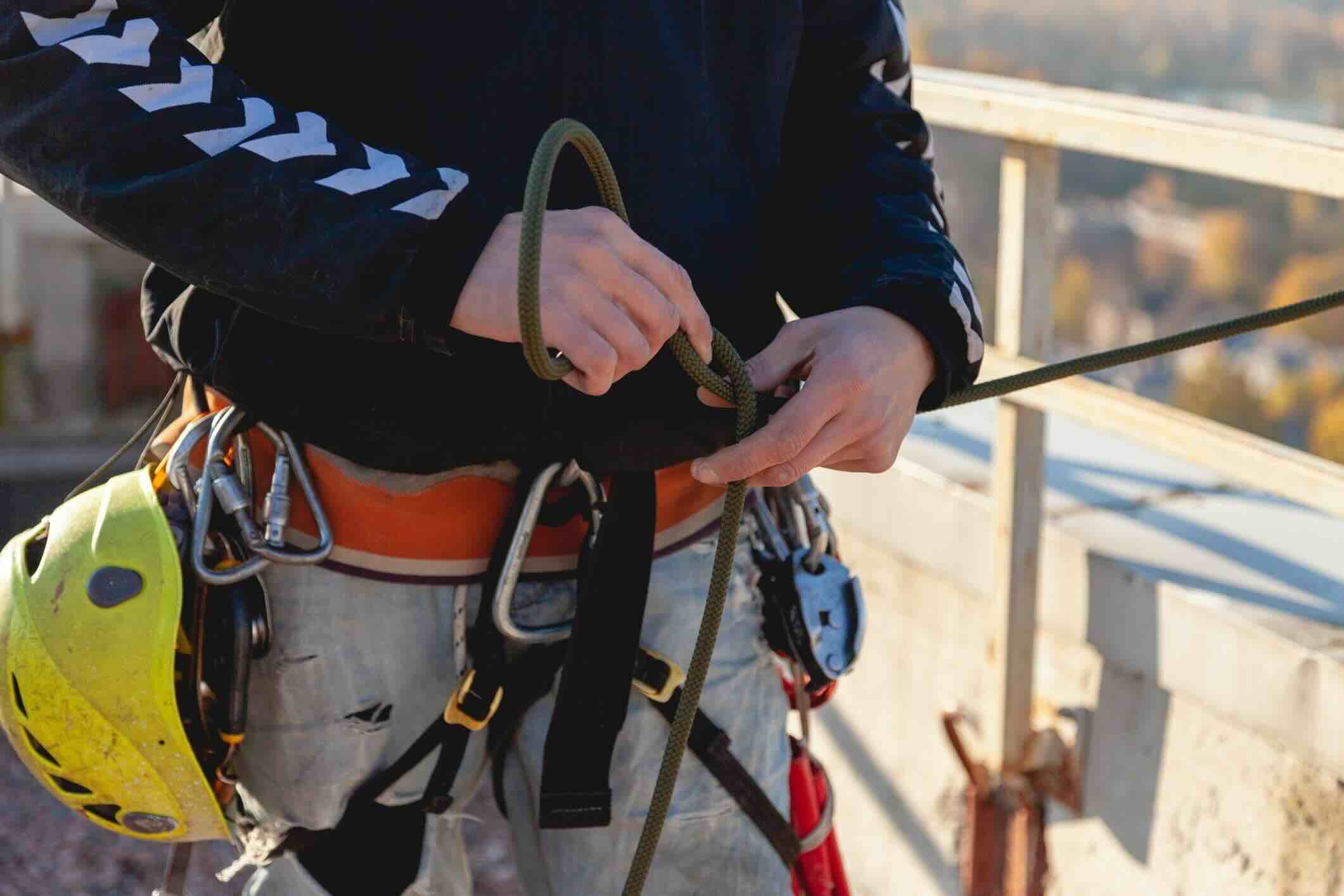

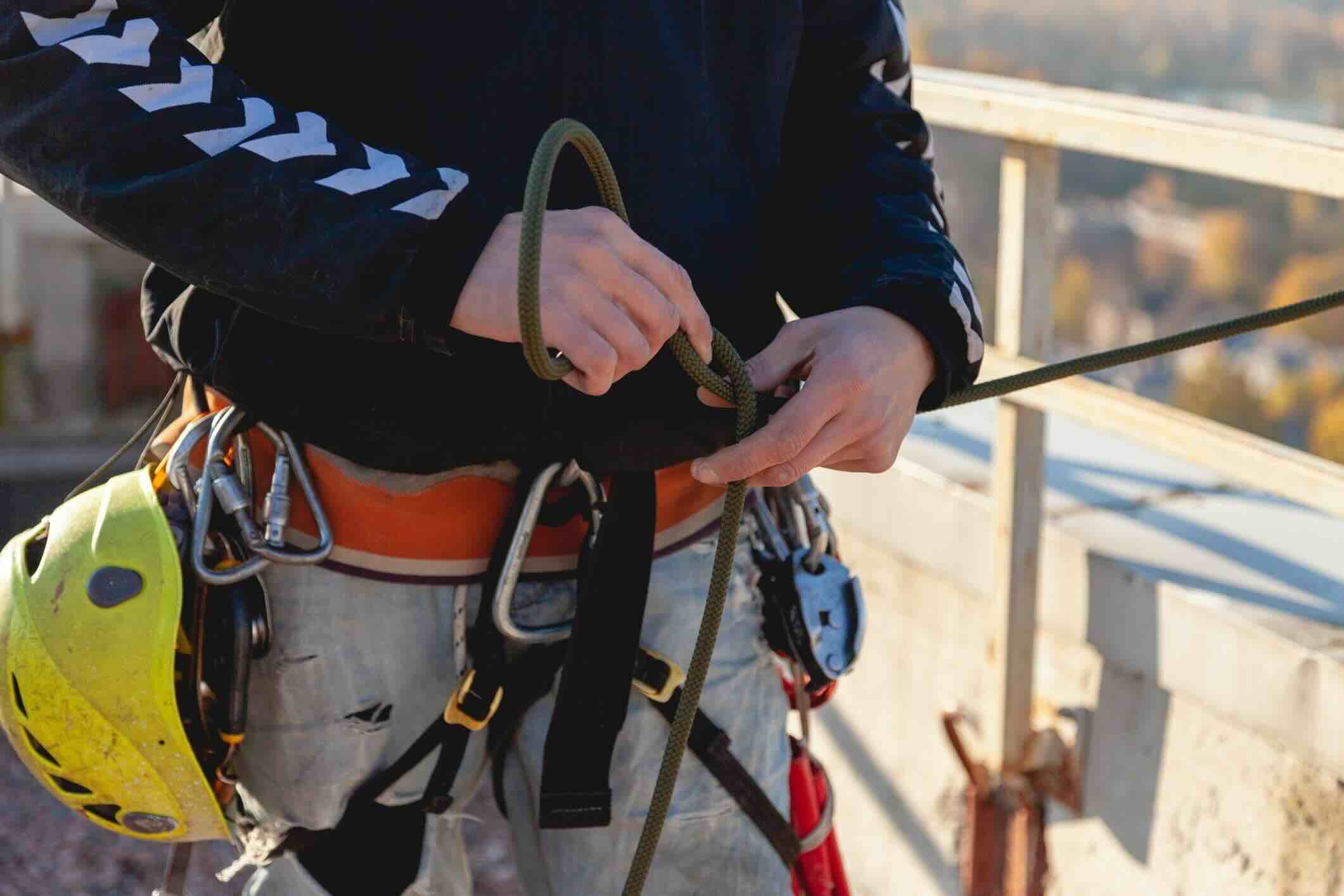

In addition to their primary function of fall protection, life safety ropes also play a crucial role in other applications such as rope access, vertical climbing, and search and rescue operations. They are often accompanied by various accessories like harnesses, carabiners, and descenders, which further enhance their functionality and overall safety.

It is important to note that not all ropes are suitable for life safety purposes. Ropes used for recreational activities or general purpose tasks may not meet the necessary standards and certifications required for life safety applications. Therefore, it is crucial to select ropes that are specifically approved and certified for life safety use to ensure the highest level of protection for workers.

Now that we have a clear understanding of what life safety ropes are and their significance in the construction industry, let’s explore the different methods of construction used to manufacture these essential safety tools.

Importance of Life Safety Rope in Construction

Safety should always be the top priority in any construction project. With the inherent risks involved in working at heights or in confined spaces, the use of life safety ropes is crucial to protect workers and prevent accidents and fatalities. Here are some key reasons why life safety ropes are of utmost importance in the construction industry:

- Fall Protection: Life safety ropes act as a lifeline to prevent falls and protect workers in high-risk areas. They provide a secure connection between the worker and an anchor point, allowing them to perform tasks with confidence and peace of mind.

- Emergency Situations: In the event of a fall or other emergencies, life safety ropes serve as a means of rescue. With proper training and equipment, workers can use these ropes to access and evacuate the affected individual safely and efficiently.

- Compliance with Regulations: Occupational safety regulations mandate the use of appropriate fall protection systems, including life safety ropes, in construction projects. By adhering to these regulations, construction companies ensure legal compliance and create a safer work environment for their employees.

- Enhanced Worker Confidence: Knowing that they have proper fall protection measures in place, workers can focus on their tasks without the fear of accidents or injuries. This boosts their confidence and productivity, leading to better job performance.

- Risk Reduction: Construction sites inherently involve various hazards, such as uneven surfaces, unstable structures, and adverse weather conditions. Life safety ropes help mitigate these risks by providing a reliable and secure connection, reducing the chances of accidents and injuries.

- Durable and Reliable: Life safety ropes are specifically designed and manufactured to withstand extreme conditions and heavy loads. They undergo rigorous testing and certification processes to ensure their durability and reliability in critical situations.

- Industry Best Practice: The use of life safety ropes has become a standard practice in the construction industry. Construction companies that prioritize safety and invest in quality fall protection systems, including life safety ropes, demonstrate their commitment to worker well-being and professionalism.

By understanding the importance of life safety ropes in construction and implementing proper safety measures, construction companies can create a safe and secure working environment, safeguarding the well-being of their workers and preventing accidents and tragedies on the job site.

Factors to Consider for Life Safety Rope Construction Method

When it comes to selecting the appropriate construction method for life safety ropes, several crucial factors need to be considered. These factors play a significant role in determining the suitability, performance, and overall safety of the ropes. Here are some key considerations to keep in mind:

- Strength and Load Capacity: The construction method should ensure that the life safety ropes have sufficient strength and load capacity to withstand the forces exerted during falls or rescue operations. It is crucial to select a construction method that provides the required tensile strength and durability.

- Elongation and Shock Absorption: Life safety ropes should have controlled elongation and shock absorption properties to minimize the impact on the worker in the event of a fall. The construction method should ensure that the ropes have the necessary flexibility and shock-absorbing capabilities to reduce the risk of injury.

- Abrasion Resistance: Construction sites often involve rough surfaces, edges, and abrasive materials, which can cause friction and wear on the life safety ropes. The construction method should incorporate features to enhance the ropes’ resistance to abrasion and prolong their lifespan.

- Resistance to Chemicals and UV Exposure: Exposure to chemicals, weather elements, and ultraviolet (UV) radiation can degrade the performance and lifespan of life safety ropes. The construction method should involve the use of materials or treatments that enhance the ropes’ resistance to these detrimental factors.

- Flexibility and Handling: Life safety ropes should be easy to handle, maneuver, and tie knots. The construction method should ensure that the ropes have the necessary flexibility and pliability to facilitate smooth handling and knotting, without compromising their strength and integrity.

- Certifications and Standards: It is important to select life safety ropes that meet industry-recognized certifications and standards for performance, quality, and safety. The construction method should align with these certifications and ensure that the ropes meet the necessary requirements.

- Budget and Cost: Construction projects often have budget constraints, and the choice of construction method will impact the cost of life safety ropes. It is essential to strike a balance between cost-effectiveness and the necessary safety features to meet project requirements.

By considering these factors and consulting with reputable rope manufacturers, construction professionals can make informed decisions regarding the most suitable construction method for their specific application. A comprehensive understanding of these factors will help ensure that the selected life safety ropes meet the required safety standards, provide optimal performance, and enhance worker safety in the construction industry.

Methods of Construction for Life Safety Rope

There are various methods of construction used to manufacture life safety ropes, each with its own unique characteristics and suitability for different applications. Understanding these methods can help construction professionals choose the most appropriate type of life safety rope for their specific needs. Here are four common methods of construction:

-

Kernmantle Construction

Kernmantle construction is one of the most widely used methods for life safety ropes. It consists of a complex structure with a hard-wearing, high-strength outer sheath (mantle) that encloses a load-bearing core (kern). The mantle provides protection against abrasion and external elements, while the kern provides the rope’s strength and load-bearing capacity. This construction method allows for excellent handling, flexibility, and durability, making kernmantle ropes suitable for a wide range of applications, including rope access, rescue operations, and rock climbing.

-

Static Construction

Static construction involves the use of a single continuous filament or twisted strands to create a life safety rope. These ropes are designed to have minimal stretch, providing stability and reducing the impact of a fall. Static ropes excel in environments where minimal elongation is required, such as technical rescues and caving. However, it is important to note that these ropes may not be suitable for situations where shock absorption is critical, as they lack the ability to absorb energy during a fall.

-

Dynamic Construction

Dynamic construction ropes are specifically designed to have a significantly higher degree of stretch compared to static ropes. This stretch allows for energy absorption during a fall, reducing the impact on the worker and minimizing the risk of injury. Dynamic ropes are commonly used in activities such as lead climbing, sport climbing, and mountaineering, where the potential for longer falls exists. The elasticity of dynamic ropes makes them ideal for situations where shock absorption is paramount.

-

Hybrid Construction

Hybrid construction is a combination of different materials and construction methods to achieve specific characteristics in life safety ropes. This method can involve combining different types of fibers, such as nylon and aramid, or incorporating different construction techniques, such as combining the properties of static and dynamic ropes. Hybrid ropes are designed to provide a balance of strength, flexibility, elongation, and shock absorption, making them versatile and suitable for a wide range of applications where specific performance requirements need to be met.

It is essential to consult with reputable rope manufacturers and consider the specific requirements of the construction project when selecting the construction method for life safety ropes. Each method has its advantages and limitations, and the choice will depend on factors such as the working environment, load capacity, required elongation, and desired level of shock absorption.

By understanding the different construction methods available, construction professionals can choose the most suitable life safety ropes to ensure optimal performance and enhance worker safety in various construction applications.

Kernmantle Construction

Kernmantle construction is a widely used and highly regarded method for manufacturing life safety ropes. This construction method consists of a complex structure that combines a durable outer sheath, known as the mantle, with a load-bearing core, known as the kern.

The mantle is typically made from strong and abrasion-resistant fibers such as nylon or polyester. It serves as the protective layer that shields the kern from external elements, such as sharp edges or corrosive substances. The mantle also provides the rope with essential features like abrasion resistance, UV resistance, and resistance to chemical exposure, extending the rope’s lifespan and maintaining its integrity in harsh conditions.

The kern, on the other hand, is the inner core of the rope responsible for carrying the load. It is constructed using high-strength fibers such as aramid or polyethylene. The kern provides the rope with the necessary tensile strength, ensuring it can withstand heavy loads and operational demands.

One of the key advantages of kernmantle construction is the balance it strikes between strength and flexibility. The combination of the robust mantle and the strong kern provides excellent resistance to abrasion and impact, making kernmantle ropes highly durable and long-lasting. At the same time, the construction method allows for flexibility and easy handling, making the ropes more manageable during use.

Kernmantle ropes are widely used in various industries, including construction, rock climbing, rope access, and rescue operations. Their versatility and performance make them suitable for tasks that require a robust rope capable of withstanding challenging conditions while providing reliable fall protection and load-bearing capabilities.

Furthermore, kernmantle ropes often feature a distinctive pattern on the outer sheath, which helps users identify wear and damage. This pattern, known as the tracer, serves as a visual indicator, alerting users to potential issues and prompting them to retire the rope if necessary.

It is worth mentioning that not all kernmantle ropes are the same, as they can vary in terms of materials used, construction techniques, and certifications. It is crucial to choose ropes from reputable manufacturers and ensure they meet industry standards and certifications for quality, safety, and performance.

In summary, kernmantle construction is a highly reliable and widely used method for manufacturing life safety ropes. Its combination of a strong outer mantle and load-bearing inner core provides ropes with exceptional durability, flexibility, and load-bearing capabilities. By selecting kernmantle ropes from reputable manufacturers, construction professionals can ensure the safety and well-being of workers operating at heights or in confined spaces.

Static Construction

Static construction is a method used for manufacturing life safety ropes that are designed to have minimal stretch or elongation when subjected to a load or force. This construction method involves using a single continuous filament or twisted strands to create the rope, resulting in a rigid and stable structure.

Static ropes are primarily used in applications where minimal elongation is required, such as technical rescues, caving, and work positioning. These ropes are engineered to provide stability and control, as they do not stretch significantly under load. The lack of elongation means that the length of the rope remains relatively constant, allowing for precise positioning and control during tasks.

The advantage of static ropes lies in their ability to maintain stability and limit movement, which can be advantageous in certain work scenarios. They are often used in situations where absolute precision and minimal deviation are critical, such as working on a vertical surface or conducting delicate operations.

However, it’s important to note that the lack of elongation in static ropes also means they have limited shock-absorbing capabilities. In scenarios where falls or sudden impacts can occur, the rigid nature of static ropes may result in higher forces being transferred to the user, potentially increasing the risk of injury. Therefore, it is crucial to assess the specific requirements of the task and the potential hazards involved to determine if static ropes are suitable for the job.

When working with static ropes, it is essential to adhere to proper anchoring and belaying techniques to ensure the safety of users. Static ropes are typically paired with devices such as descenders or belay devices that allow for controlled descent or controlled lowering of a person. These devices, combined with proper training and techniques, can maximize the effectiveness and safety of using static ropes.

It’s worth noting that static ropes should only be used in circumstances where their minimal elongation is an advantage. In other situations where shock absorption or dynamic movement is desired, alternative construction methods, such as dynamic or hybrid constructions, may be more appropriate.

In summary, static construction is a construction method used for manufacturing life safety ropes that offer minimal elongation. They are ideal for applications requiring stability, precise positioning, and minimal movement. However, their limited shock-absorbing capabilities make them less suitable for scenarios involving falls or sudden impacts. Proper training, equipment, and a thorough assessment of the task are essential when using static ropes to ensure worker safety and optimal performance.

Dynamic Construction

Dynamic construction is a method used to manufacture life safety ropes that are designed to have a significant degree of stretch or elongation when subjected to a load or force. These ropes are specifically engineered to absorb energy during a fall, reducing the impact on the user and minimizing the risk of injury.

The construction of dynamic ropes involves using a combination of specialized fibers and weaving techniques that provide the necessary elasticity and shock-absorbing properties. The dynamic nature of these ropes allows them to stretch considerably under load, dissipating the energy generated during a fall and reducing the forces exerted on the user’s body.

Dynamic ropes are commonly used in activities such as lead climbing, mountaineering, and other scenarios where the potential for longer falls exists. The elasticity of dynamic ropes provides a cushioning effect, mitigating the sudden jolt and reducing the risk of injury to the climber or worker.

One of the key advantages of dynamic ropes is their ability to absorb energy and distribute forces more evenly. This characteristic significantly reduces the impact on the user’s body and places less stress on the anchor points, preventing potential damage or failure. The stretch and elasticity of dynamic ropes also enhance their suitability for arresting falls and protecting against potential hazards.

However, it is important to note that the stretch and elongation properties of dynamic ropes need careful consideration when using them in certain applications. While the elasticity is beneficial in preventing injury during falls, it may introduce more rope movement and less precise positioning compared to static ropes. Therefore, dynamic ropes may not be ideal for applications where precise control and minimal deviation are required.

As with any life safety rope, it is crucial to select dynamic ropes that meet industry standards and certifications for quality, safety, and performance. Reputable manufacturers provide dynamic ropes that undergo rigorous testing, ensuring their compliance with safety regulations and providing users with peace of mind.

In summary, dynamic construction is a construction method used for manufacturing life safety ropes with significant stretch and elongation properties. These ropes are designed to absorb energy during falls, reducing the impact on the user and minimizing the risk of injury. Dynamic ropes are commonly used in activities where longer falls are possible, providing additional safety and shock absorption. However, their stretch and elasticity should be carefully considered in applications where precise control and minimal deviation are necessary.

Hybrid Construction

Hybrid construction is a versatile method used to manufacture life safety ropes that combines different materials and construction techniques to achieve specific performance characteristics. This construction method allows for the creation of ropes with a unique blend of properties, catering to the demands of varied applications.

Hybrid ropes are typically constructed by combining different types of fibers, such as nylon, aramid (e.g., Kevlar®), or polyethylene (e.g., Dyneema®). Each fiber brings its own advantages to the rope, enhancing specific aspects such as strength, flexibility, abrasion resistance, or weight reduction.

In addition to using different fibers, hybrid ropes can incorporate various construction techniques. For example, a hybrid rope may combine elements of kernmantle construction and dynamic construction to create a rope that offers both durability and enhanced shock absorption.

The benefit of hybrid construction lies in its ability to tailor the rope’s properties to meet specific requirements. By selecting the right combination of materials and construction techniques, manufacturers can create ropes that excel in certain areas, such as strength, flexibility, elongation, abrasion resistance, or weight savings.

Hybrid ropes are highly versatile and find applications across the construction industry. They are commonly used in activities such as rope access, technical rescue operations, and industrial work where a balance of different attributes is desired.

One example of a hybrid construction is the combination of nylon and aramid fibers. Nylon provides excellent strength and durability, while aramid fibers offer enhanced resistance to heat and chemicals. The combination of these fibers creates a rope that can withstand demanding conditions and offers added protection against extreme temperatures and corrosive substances.

Hybrid ropes are engineered to meet industry standards and certifications for performance and safety. When selecting hybrid ropes, it is important to consult manufacturers or suppliers with a proven track record and reputation for producing high-quality ropes.

In summary, hybrid construction is a method used to manufacture life safety ropes by combining different materials and construction techniques. This approach allows for the creation of ropes with tailored properties to meet specific application requirements. Hybrid ropes offer versatility and excel in areas such as strength, flexibility, abrasion resistance, or weight reduction. By selecting hybrid ropes from reputable manufacturers, construction professionals can ensure the safety and performance of their workers in a wide range of applications.

Read more: Which Bed Frame Requires A Box Spring

Comparison of Construction Methods

When choosing a construction method for life safety ropes, it is essential to understand the differences and characteristics of each method. Here is a comparison of the four common construction methods:

-

Kernmantle Construction

- Provides excellent durability and resistance to abrasion.

- Offers a balance of strength and flexibility.

- Well-suited for a wide range of applications, including rope access, rescue operations, and rock climbing.

- Distinctive tracer pattern helps identify wear and damage.

-

Static Construction

- Minimal elongation and stretch under load.

- Provides stability, making it suitable for precise positioning tasks.

- Commonly used in technical rescues, caving, and work positioning.

- Less effective in shock absorption compared to dynamic ropes.

-

Dynamic Construction

- Offers significant stretch and elongation properties.

- Excellent shock absorption and energy dissipation during falls.

- Preferred for activities with longer falls, such as lead climbing and mountaineering.

- Less precise in positioning compared to static ropes.

-

Hybrid Construction

- Combines different materials and construction techniques for specific performance characteristics.

- Allows for customization of ropes to meet specific requirements.

- Versatile and suitable for various applications in construction and other industries.

- Offers a blend of attributes, such as strength, flexibility, abrasion resistance, or weight savings.

Each construction method has its strengths and suitability for different applications. Kernmantle construction is known for its durability, flexibility, and use in a wide range of activities. Static construction provides stability and precise positioning but lacks shock absorption. Dynamic construction offers excellent shock absorption and is ideal for activities with longer falls. Hybrid construction allows for customization and a combination of desired characteristics.

When selecting a construction method, it is crucial to consider the specific requirements of the job, such as the working environment, load capacity, desired elongation, and shock absorption needs. It is also important to consult with reputable rope manufacturers to ensure compliance with industry standards and certifications for quality and safety.

By understanding the pros and cons of each construction method, construction professionals can make informed decisions and choose the most suitable life safety ropes for their specific applications, ensuring optimal performance and enhancing worker safety.

When selecting a life safety rope, look for ropes that meet the standards set by organizations such as the National Fire Protection Association (NFPA) or the European Committee for Standardization (CEN). These standards ensure that the rope is constructed to withstand the forces and conditions encountered in life safety situations.

Conclusion

Choosing the right construction method for life safety ropes is crucial to ensure the safety and well-being of workers in the construction industry. Each construction method has its own unique characteristics and suitability for different applications, allowing construction professionals to select ropes that align with the specific demands of their projects.

Kernmantle construction offers a balance of durability and flexibility, making it ideal for a wide range of applications. Static construction provides stability and precise positioning, while dynamic construction offers excellent shock absorption during falls. Hybrid construction allows for customization and combines different materials and techniques to meet specific performance requirements.

When considering the construction method, it is important to carefully assess the factors such as strength, elongation, abrasion resistance, and shock absorption needed for the task at hand. Adhering to industry standards and certifications is essential to ensure the quality and safety of the ropes selected.

Life safety ropes play a vital role in fall protection and rescue operations, and their proper use can greatly reduce the risk of accidents and injuries in the construction industry. By selecting ropes that are specifically designed and certified for life safety applications, construction professionals demonstrate their commitment to worker safety and adhere to regulatory requirements.

Ultimately, the construction method chosen for life safety ropes should meet the demands of the working environment, provide the necessary strength and durability, and align with the specific requirements of the project. By considering these factors and consulting with reputable manufacturers, construction professionals can make informed decisions, ensuring the safety and well-being of their workers.

In conclusion, understanding the different methods of construction for life safety ropes allows construction professionals to make educated choices regarding the most suitable ropes for their projects. By prioritizing worker safety and selecting the right life safety ropes, construction companies can create a safe working environment, mitigate risks, and ultimately enhance the success of their projects.

Frequently Asked Questions about Which Method Of Construction Is Required For Life Safety Rope

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Method Of Construction Is Required For Life Safety Rope”