Home>Furniture & Design>Interior Design Trends>How To Make Glass Anti Glare

Interior Design Trends

How To Make Glass Anti Glare

Modified: August 29, 2024

Learn how to make glass anti-glare and stay on top of the latest interior design trends with our expert tips and techniques. Achieve a sleek and modern look for your space. Discover more now!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Glass is a versatile and popular material used in various applications, from windows and display screens to picture frames and tabletops. While glass offers transparency and aesthetic appeal, it is susceptible to glare, which can be a major inconvenience in many settings. Whether it's the blinding reflection on a computer monitor or the distracting glare on a framed photograph, dealing with glare can be frustrating. Fortunately, there are effective methods for making glass anti-glare, providing a solution to this common issue.

In this comprehensive guide, we will explore the process of making glass anti-glare, offering practical insights and step-by-step instructions. By understanding the problem with glare, identifying the materials needed, and following a systematic approach, you can effectively reduce or eliminate glare on glass surfaces. Whether you are a DIY enthusiast, a professional in the glass industry, or simply someone seeking to improve the functionality of glass in your environment, this guide will equip you with the knowledge and techniques to create anti-glare glass.

Glare reduction is a valuable enhancement for various applications, including residential, commercial, and industrial settings. By addressing the issue of glare, you can improve visibility, reduce eye strain, and enhance the overall user experience. Whether you are looking to upgrade the glass on your electronic devices, picture frames, or architectural elements, the process of making glass anti-glare can significantly enhance the functionality and aesthetics of glass surfaces.

In the following sections, we will delve into the details of understanding the problem with glare, identifying the materials needed for making glass anti-glare, and providing a comprehensive step-by-step guide to achieve optimal results. By following this guide, you will gain the knowledge and confidence to effectively transform standard glass into anti-glare glass, unlocking its full potential in various applications.

Key Takeaways:

- Transform standard glass into anti-glare glass by applying a specialized coating solution and following a step-by-step guide. This reduces glare, enhances visual clarity, and improves user experience in various settings.

- Gather essential materials like the anti-glare coating solution, microfiber cleaning cloth, and protective gloves to make glass anti-glare. Test the treated glass under different lighting conditions to ensure effectiveness.

Read more: How To Stop Sun Glare On Outdoor Tv

Understanding the Problem with Glare

Glare, often characterized by the excessive and unwanted reflection of light on a smooth surface, is a common issue associated with glass. This phenomenon occurs when light rays strike a glass surface and are reflected at various angles, causing visual discomfort and reduced visibility. The problem with glare extends across diverse settings, impacting electronic displays, framed artwork, architectural windows, and other glass surfaces. Understanding the underlying factors contributing to glare is essential in devising effective solutions to mitigate its effects.

The primary cause of glare on glass is the reflection of light, which can be attributed to the smooth and non-absorbent nature of glass surfaces. When light from external sources or indoor illumination interacts with glass, a portion of the light is reflected, creating a mirror-like effect that hampers visibility and causes discomfort. This phenomenon is particularly pronounced in environments with intense or directional lighting, such as offices, retail spaces, and residential areas with large windows.

Glare not only affects visual clarity but also contributes to eye strain and discomfort, especially when prolonged exposure is involved. In the context of electronic devices, such as smartphones, tablets, and computer monitors, glare can significantly impede screen visibility, leading to reduced productivity and user dissatisfaction. Furthermore, in architectural and interior design, glare can detract from the aesthetic appeal of glass elements and compromise the overall ambiance of a space.

The impact of glare extends beyond individual inconvenience, as it can also affect safety and functionality in various applications. For instance, glare on automotive windshields can impair driving visibility, posing potential hazards on the road. In commercial and retail environments, glare on glass display cases and storefront windows can diminish the visual impact of merchandise and affect the overall customer experience.

By recognizing the multifaceted nature of the problem with glare, it becomes evident that addressing this issue is crucial for enhancing visual comfort, safety, and functionality across diverse contexts. The quest for anti-glare solutions stems from the need to optimize the performance and aesthetics of glass, ensuring that its transparency and reflective properties are harnessed without compromising user experience.

Understanding the problem with glare serves as the foundation for exploring effective strategies to make glass anti-glare, empowering individuals and industries to overcome the challenges associated with excessive reflections on glass surfaces. In the subsequent sections, we will delve into the materials and techniques required to transform standard glass into anti-glare glass, offering practical insights and actionable steps to achieve optimal results.

Materials Needed for Making Glass Anti-Glare

Creating anti-glare glass involves the use of specialized materials designed to modify the surface properties of standard glass, thereby reducing or eliminating the reflective effects that contribute to glare. The process of making glass anti-glare requires careful consideration of the materials involved, ensuring that they are effective, safe, and compatible with the intended application. By assembling the necessary materials, you can embark on the journey of transforming standard glass into a functional and visually comfortable anti-glare surface.

Anti-Glare Coating Solution

The cornerstone of making glass anti-glare lies in the application of a specialized coating solution designed to alter the surface characteristics of the glass. This coating is formulated to minimize light reflection and enhance light transmission, thereby mitigating the effects of glare. The anti-glare coating solution is typically available in liquid form and is specifically engineered to adhere to glass surfaces, forming a thin, transparent layer that effectively reduces the reflective properties of the glass.

Microfiber Cleaning Cloth

Prior to applying the anti-glare coating solution, it is essential to prepare the glass surface by ensuring it is clean and free from any contaminants or residues. A high-quality microfiber cleaning cloth is an indispensable tool for this purpose, as it facilitates the removal of dust, fingerprints, and other impurities that may interfere with the adhesion and effectiveness of the anti-glare coating. The microfiber material is gentle on glass surfaces and helps achieve a pristine, lint-free cleaning result.

Read more: How To Make Iridescent Glass

Protective Gloves

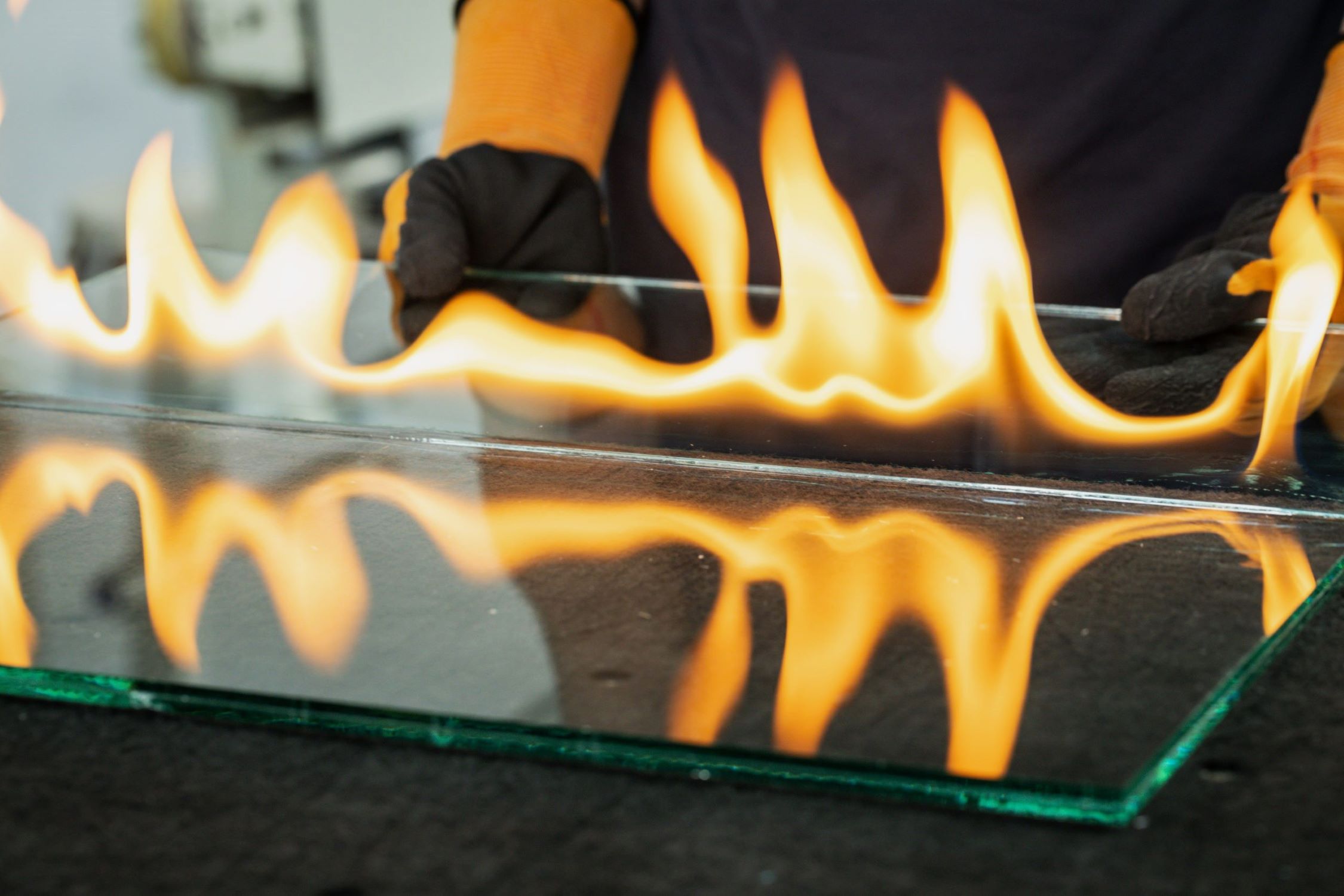

When working with the anti-glare coating solution, it is important to prioritize safety and minimize direct skin contact with the chemical compounds present in the solution. Protective gloves, such as nitrile or latex gloves, serve as a crucial protective measure, shielding the skin from potential irritation or adverse reactions. By wearing protective gloves during the application process, you can ensure a safe and controlled handling of the anti-glare coating solution, promoting a secure and comfortable working environment.

Applicator or Spray Bottle

To facilitate the uniform and precise application of the anti-glare coating solution onto the glass surface, an applicator or spray bottle is essential. The choice of applicator may vary based on personal preference and the specific characteristics of the anti-glare coating solution. Whether utilizing a foam applicator, microfiber pad, or spray bottle with a fine mist nozzle, the goal is to achieve an even distribution of the coating solution across the glass surface, ensuring consistent coverage and optimal anti-glare performance.

Protective Mask (Optional)

In situations where the application of the anti-glare coating solution may generate airborne particles or fumes, the use of a protective mask is recommended to safeguard respiratory health. While some anti-glare coating solutions are designed to minimize volatile emissions, the inclusion of a protective mask as a precautionary measure can contribute to a safe and comfortable working environment, particularly in enclosed or poorly ventilated spaces.

By gathering these essential materials, you can prepare for the process of making glass anti-glare with confidence and precision. Each component plays a critical role in the successful application of the anti-glare solution, ensuring that the resulting glass surface exhibits enhanced visual clarity and reduced reflective disturbances. With the materials in hand, you are poised to embark on the transformative journey of creating anti-glare glass, unlocking its full potential in diverse applications.

Step-by-Step Guide to Making Glass Anti-Glare

-

Prepare the Glass Surface: Begin by ensuring that the glass surface is thoroughly cleaned and free from any dust, fingerprints, or residues. Use a microfiber cleaning cloth to gently wipe the glass, achieving a pristine and smooth surface for the application of the anti-glare coating solution.

-

Assemble the Necessary Materials: Gather the anti-glare coating solution, protective gloves, and an applicator or spray bottle for the application process. If deemed necessary based on the characteristics of the coating solution, have a protective mask on hand to ensure a safe working environment.

-

Shake the Coating Solution: If the anti-glare coating solution is provided in liquid form, carefully shake the container to ensure uniform dispersion of the active ingredients. This step is crucial in preparing the solution for effective application onto the glass surface.

-

Apply the Anti-Glare Coating Solution: Using the selected applicator or spray bottle, apply a thin and even layer of the anti-glare coating solution onto the glass surface. Ensure comprehensive coverage, working methodically to minimize the formation of streaks or uneven patches.

-

Allow for Drying and Curing: After the application of the anti-glare coating solution, allow the glass to dry and cure according to the manufacturer's recommendations. This may involve a specified duration for air drying or the application of additional curing methods to optimize the performance of the anti-glare coating.

-

Inspect and Test the Anti-Glare Glass: Once the coating has dried and cured, inspect the glass surface to ensure that the anti-glare properties have been effectively established. Test the glass under various lighting conditions to assess the reduction in glare and the enhancement of visual clarity.

-

Perform Any Necessary Touch-Ups: If any areas of the glass surface require additional attention or touch-ups, carefully reapply the anti-glare coating solution as needed. This step ensures that the anti-glare properties are consistently maintained across the entire glass surface.

-

Final Evaluation and Application: Upon confirming the successful transformation of the glass into anti-glare glass, proceed to integrate the treated glass into its intended application. Whether it is a display screen, picture frame, architectural window, or other relevant use, the anti-glare glass is now ready to deliver enhanced visual comfort and functionality.

By following this step-by-step guide, you can effectively make glass anti-glare, harnessing the transformative potential of specialized coating solutions to mitigate glare and optimize the performance of glass surfaces. This systematic approach empowers individuals and professionals to achieve superior visual clarity and user experience, unlocking the full potential of glass in diverse applications.

Read more: How To Make Glass Into Mirror

Testing and Applying the Anti-Glare Glass

Once the anti-glare coating solution has been successfully applied and the glass surface has undergone the necessary drying and curing processes, it is essential to conduct thorough testing to evaluate the effectiveness of the anti-glare properties. This critical phase ensures that the transformed glass surface exhibits the desired reduction in glare and enhanced visual clarity, validating the success of the anti-glare application process.

Testing Under Various Lighting Conditions

To assess the performance of the anti-glare glass, it is imperative to subject the treated surface to diverse lighting conditions representative of its intended application environment. This includes testing the glass under natural daylight, artificial indoor lighting, and potentially challenging scenarios involving direct or oblique light sources. By observing the glass from different angles and under varying illumination, the impact of the anti-glare treatment on glare reduction and light transmission can be comprehensively evaluated.

Visual Clarity and Distortion Assessment

In addition to glare reduction, the visual clarity and distortion characteristics of the anti-glare glass should be carefully examined. This involves scrutinizing the glass surface for any visual anomalies, such as waviness, color shifts, or image distortion, which may compromise the overall viewing experience. By conducting a detailed visual assessment, any potential issues related to the application of the anti-glare coating can be identified and addressed to ensure optimal performance.

User Experience Validation

Incorporating user feedback and subjective evaluations is integral to the testing phase, as it provides valuable insights into the practical impact of the anti-glare glass on user experience. By soliciting feedback from individuals interacting with the treated glass surface, whether in the context of electronic displays, framed artwork, or architectural elements, the real-world effectiveness of the anti-glare properties can be gauged. This user-centric approach contributes to refining the anti-glare application process and ensuring that it aligns with the expectations and needs of end users.

Read more: How To Make Glass Ornaments

Integration into the Intended Application

Upon successful testing and validation of the anti-glare properties, the treated glass can be seamlessly integrated into its intended application. Whether it is installed as a protective cover for electronic displays, incorporated into picture frames to enhance visual clarity, or utilized in architectural windows to minimize glare, the anti-glare glass now serves as a valuable enhancement, delivering superior functionality and user comfort.

By meticulously testing and applying the anti-glare glass, the transformative impact of the anti-glare coating solution is realized, elevating the performance and usability of glass surfaces across diverse applications. The culmination of this process marks the successful integration of anti-glare technology, empowering individuals and industries to harness the full potential of glass while mitigating the challenges associated with glare.

Conclusion

In conclusion, the process of making glass anti-glare presents a transformative opportunity to address the pervasive issue of glare on glass surfaces. By understanding the underlying factors contributing to glare and recognizing its impact across diverse settings, individuals and industries can leverage specialized coating solutions to effectively mitigate the reflective disturbances and enhance visual comfort. The journey of creating anti-glare glass encompasses meticulous preparation, precise application, thorough testing, and seamless integration, culminating in the realization of enhanced functionality and user experience.

The materials essential for making glass anti-glare, including the anti-glare coating solution, microfiber cleaning cloth, protective gloves, and applicator or spray bottle, form the foundation for a systematic and successful application process. By assembling these materials and adhering to a step-by-step guide, individuals can embark on the transformative journey of transforming standard glass into anti-glare glass, unlocking its full potential in diverse applications.

The step-by-step guide provides a comprehensive framework for the application of the anti-glare coating solution, emphasizing the importance of thorough surface preparation, precise application techniques, and meticulous testing to validate the effectiveness of the anti-glare properties. This systematic approach empowers individuals and professionals to achieve superior visual clarity and user experience, ensuring that the anti-glare glass delivers on its promise of reduced glare and enhanced functionality.

The testing and validation phase plays a pivotal role in confirming the success of the anti-glare application process, encompassing comprehensive assessments of glare reduction, visual clarity, distortion characteristics, and user experience validation. By subjecting the treated glass to diverse lighting conditions and soliciting user feedback, the real-world effectiveness of the anti-glare properties is evaluated, contributing to the refinement and optimization of the application process.

Ultimately, the successful integration of anti-glare glass into its intended application marks the culmination of a transformative journey, where the inherent challenges associated with glare are effectively addressed, and the full potential of glass surfaces is realized. Whether enhancing electronic displays, framed artwork, architectural windows, or other relevant applications, the anti-glare glass serves as a valuable enhancement, delivering superior functionality and user comfort.

In essence, the process of making glass anti-glare transcends the conventional limitations of glass surfaces, offering a pathway to harness the transformative potential of specialized coating solutions and optimize the performance of glass in diverse contexts. By embracing this approach, individuals and industries can elevate the functionality, safety, and visual appeal of glass, paving the way for enhanced user experiences and improved quality of life.

Frequently Asked Questions about How To Make Glass Anti Glare

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make Glass Anti Glare”