Home>Gardening & Outdoor>Outdoor Structures>What To Do With An Old Warped Plastic Resin Suncast Tool Shed

Outdoor Structures

What To Do With An Old Warped Plastic Resin Suncast Tool Shed

Modified: January 6, 2024

Discover creative ways to repurpose an old, warped Suncast tool shed made of plastic resin. Explore outdoor structure transformation ideas now!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

So, you have an old, warped plastic resin Suncast tool shed that has seen better days. Perhaps it has weathered many storms, endured extreme temperatures, or simply succumbed to the wear and tear of time. Whatever the reason, you might be wondering what to do with this seemingly dilapidated structure. Before you consider hauling it off to the landfill or letting it become a permanent eyesore in your yard, take a moment to explore the potential options for salvaging and repurposing your trusty old shed.

In this comprehensive guide, we will delve into the various strategies for dealing with an old, warped plastic resin Suncast tool shed. From assessing the extent of the damage to exploring techniques for repair and reinforcement, we will equip you with the knowledge and insights needed to breathe new life into your weathered shed. Moreover, we will venture into the realm of creative repurposing, offering innovative ideas for transforming your shed into a functional and aesthetically pleasing addition to your outdoor space.

So, roll up your sleeves and get ready to embark on a journey of shed restoration and reinvention. Whether you are a seasoned DIY enthusiast or a novice looking to explore the world of outdoor structures, this guide will provide you with the inspiration and know-how to tackle the challenge of reviving your old, warped plastic resin Suncast tool shed. Let's dive in and discover the possibilities that await your weathered shed!

Key Takeaways:

- Don’t give up on your old, warped plastic resin Suncast tool shed! Assess the damage, repair the warping with heat or pressure, and reinforce the structure for a revitalized outdoor structure.

- Get creative with repurposing! Transform your shed into a garden retreat, outdoor lounge, workshop, or storage space to breathe new life into your outdoor environment.

Read more: What To Do With An Old Shed

Assessing the Damage

Before diving into the restoration process, it’s crucial to assess the extent of the damage inflicted upon your old, warped plastic resin Suncast tool shed. Start by conducting a thorough inspection of the shed’s exterior and interior, paying close attention to any visible signs of warping, cracking, or structural compromise. Examine the roof, walls, doors, and flooring to identify areas that have been most heavily impacted by the passage of time and exposure to the elements.

Take note of any warped panels, brittle surfaces, or areas where the plastic resin material has deteriorated. Additionally, inspect the shed for signs of water damage, such as mold, mildew, or discoloration, which may indicate underlying structural issues. By conducting a meticulous assessment, you will gain a clear understanding of the challenges that lie ahead and the specific areas that require attention during the restoration process.

Furthermore, consider the shed’s overall stability and structural integrity. Are there any noticeable shifts or instabilities in the framework? Assess the doors and windows for proper alignment and functionality, as warping can often impede their operation. By evaluating these key elements, you can determine whether the shed is salvageable and identify the necessary steps to restore its functionality and visual appeal.

It’s also essential to take into account the environmental factors that have contributed to the shed’s deterioration. Consider the climate in your region, including temperature fluctuations, humidity levels, and exposure to sunlight and precipitation. These factors can play a significant role in the degradation of plastic resin materials, influencing the extent of warping and damage sustained by the shed over time.

By thoroughly assessing the damage and understanding the underlying causes, you will be better equipped to formulate a tailored approach to restoring and rejuvenating your old, warped plastic resin Suncast tool shed. With a clear understanding of the challenges at hand, you can proceed with confidence as you embark on the journey of shed restoration and transformation.

Repairing Warped Plastic Resin

When faced with a warped plastic resin Suncast tool shed, the prospect of restoring the material to its original state may seem daunting. However, with the right techniques and a bit of patience, it is possible to address the warping and rejuvenate the shed’s appearance and functionality.

One approach to repairing warped plastic resin involves utilizing heat to soften the material, allowing it to be reshaped and restored to its intended form. This can be achieved using a heat gun or a similar heating device to carefully apply heat to the warped areas of the shed. As the resin becomes pliable, gently manipulate the affected panels back into their original shape, taking care to avoid overheating or causing damage to the material.

Another method for addressing warping involves the use of weighted pressure to gradually flatten and reshape the affected areas. By placing heavy objects, such as weights or sandbags, onto the warped sections of the shed, you can encourage the material to regain its intended form over time. This technique requires patience and periodic adjustments to the positioning of the weights, allowing the resin to gradually conform to its original dimensions.

In addition to these approaches, there are specialized products available, such as plastic resin repair kits, designed to address warping and damage in plastic materials. These kits often include materials for filling, reinforcing, and reshaping the affected areas, providing a comprehensive solution for restoring the integrity of the shed’s exterior surfaces.

It’s important to note that while these techniques can be effective in addressing warping, they require careful execution and an understanding of the specific characteristics of plastic resin materials. Additionally, it’s essential to prioritize safety when working with heat-based methods, ensuring proper ventilation and protective equipment to minimize risks.

By employing these repair techniques, you can take proactive steps to address the warping of your old plastic resin Suncast tool shed, breathing new life into its weathered exterior and setting the stage for further restoration efforts.

If your old Suncast tool shed is warped, try using a heat gun to soften the plastic and reshape it back into place. Be sure to work slowly and carefully to avoid damaging the shed further.

Reinforcing the Structure

As you embark on the journey of restoring an old, warped plastic resin Suncast tool shed, reinforcing the structure is a critical step in ensuring its long-term stability and functionality. Warping and deterioration can compromise the shed’s structural integrity, necessitating strategic interventions to fortify its framework and enhance its resilience against future wear and tear.

One effective method for reinforcing the shed’s structure involves the strategic placement of internal bracing and support elements. By identifying areas of the shed that have been most heavily impacted by warping and instability, you can introduce additional bracing, such as wooden or metal supports, to bolster the framework and mitigate the effects of deformation.

Moreover, the application of reinforcing materials, such as fiberglass or resin-based coatings, can provide an added layer of strength and stability to the shed’s surfaces. These materials can be strategically applied to the interior and exterior of the shed, serving to counteract the effects of warping and enhance the overall durability of the structure.

Additionally, consider the implementation of targeted repairs and reinforcements to specific components, such as doors, windows, and roofing elements. Addressing any areas of misalignment, damage, or weakness in these components can contribute to the overall structural integrity of the shed, ensuring that it remains functional and resilient in the face of environmental pressures.

Furthermore, evaluating the foundation and anchoring of the shed is crucial in reinforcing its stability. Ensure that the shed is securely anchored to the ground, utilizing appropriate anchoring systems or foundation supports to prevent shifting and instability. By addressing foundational concerns, you can enhance the overall robustness of the shed’s structure and mitigate the risk of further warping and degradation.

By implementing these strategic measures for reinforcing the structure, you can effectively combat the effects of warping and deterioration, setting the stage for a revitalized and resilient plastic resin Suncast tool shed. With a focus on enhancing stability and durability, you can breathe new life into your weathered shed and ensure its continued functionality for years to come.

Repurposing the Shed

While the restoration of an old, warped plastic resin Suncast tool shed is a commendable endeavor, you may find that repurposing the structure offers a creative and practical alternative to traditional restoration efforts. Repurposing provides an opportunity to transform the shed into a versatile and functional space that aligns with your evolving needs and preferences.

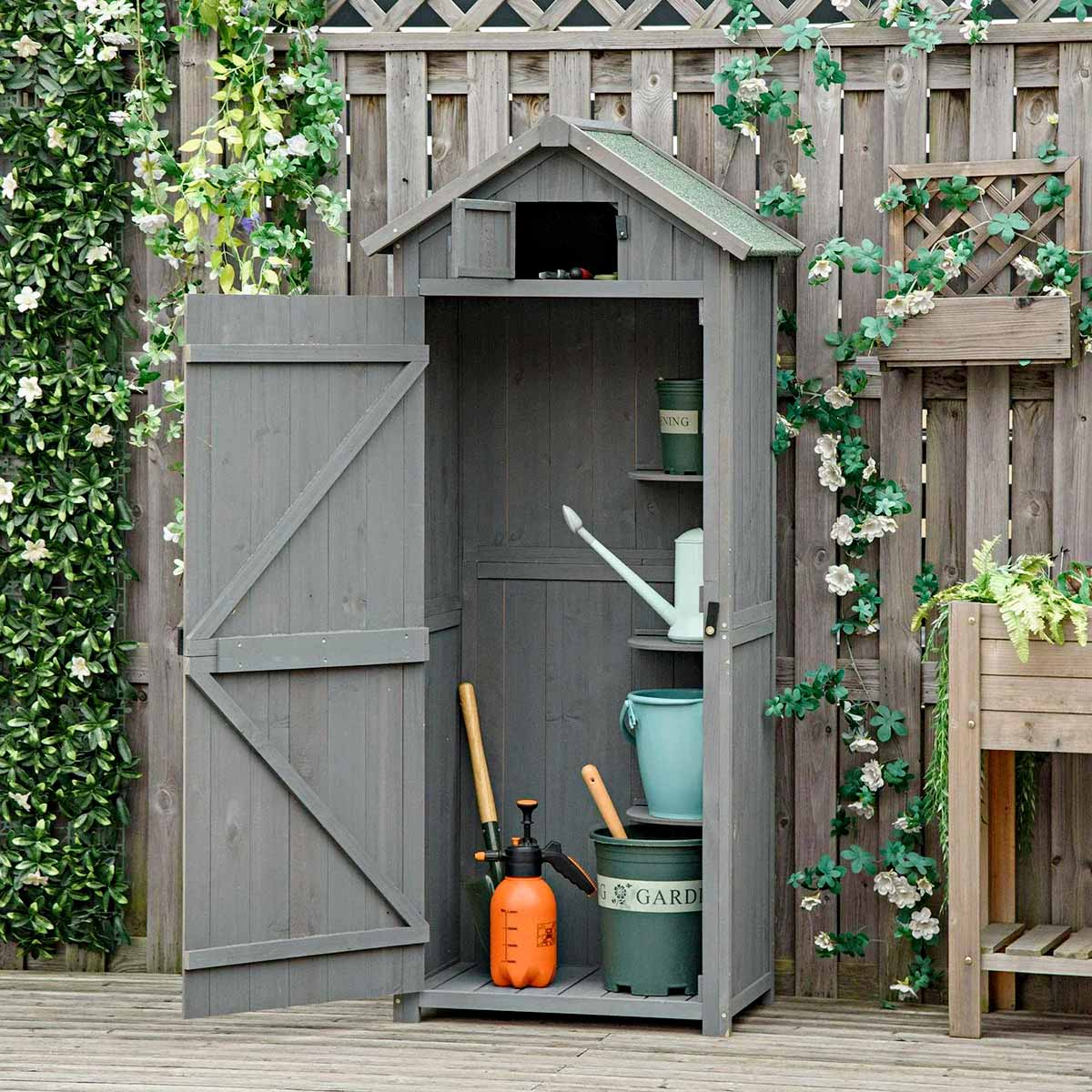

One innovative approach to repurposing the shed involves transforming it into a charming garden retreat or potting shed. By introducing shelving, work surfaces, and storage solutions tailored to gardening activities, you can create a dedicated space for nurturing plants, organizing tools, and indulging in the therapeutic joys of gardening. Consider enhancing the shed’s exterior with vibrant paint, decorative accents, and potted plants to infuse the space with a delightful touch of charm and character.

Alternatively, repurposing the shed as a cozy outdoor lounge or relaxation retreat can provide a tranquil escape within your outdoor environment. Incorporate comfortable seating, ambient lighting, and personalized decor to cultivate a welcoming atmosphere for unwinding and enjoying moments of serenity amidst nature. Whether used for reading, meditation, or social gatherings, the repurposed shed can become a cherished sanctuary within your outdoor oasis.

Furthermore, repurposing the shed as a creative workshop or hobby space offers a dedicated setting for pursuing artistic endeavors, DIY projects, or crafting activities. Customize the interior with versatile storage solutions, workbenches, and inspiring decor to foster a space that fuels creativity and innovation. Embrace the opportunity to tailor the repurposed shed to your specific interests and hobbies, creating a personalized haven for pursuing your passions.

For those seeking additional storage capacity, repurposing the shed as a functional storage annex can provide a practical solution for housing seasonal items, outdoor equipment, or recreational gear. By optimizing the interior layout and implementing efficient storage systems, the repurposed shed can serve as a valuable extension of your storage capabilities, contributing to a well-organized outdoor environment.

Ultimately, the process of repurposing the shed presents a canvas for creativity and ingenuity, allowing you to reimagine the structure in alignment with your lifestyle and aspirations. Whether transformed into a tranquil retreat, a vibrant garden haven, a creative workshop, or a practical storage space, the repurposed shed embodies the potential for reinvention and renewal within your outdoor domain.

Read more: What Is A Resin Shed

Conclusion

As we conclude our exploration of the possibilities for dealing with an old, warped plastic resin Suncast tool shed, it becomes evident that the journey of restoration and repurposing offers a wealth of opportunities for revitalizing this weathered structure. From assessing the extent of the damage to implementing repair and reinforcement strategies, and finally, to considering the creative potential of repurposing, the process of transforming the shed transcends mere restoration, evolving into a narrative of reinvention and renewal.

By carefully assessing the damage inflicted upon the shed and understanding the underlying causes of warping and deterioration, you gain the insights needed to formulate a tailored approach to restoration. Through techniques such as heat manipulation, weighted pressure, and specialized repair materials, the process of repairing warped plastic resin emerges as a tangible and achievable endeavor, breathing new life into the shed’s weathered exterior.

Furthermore, reinforcing the structure stands as a pivotal step in fortifying the shed’s stability and resilience, addressing the effects of warping and degradation with strategic interventions. By introducing internal bracing, reinforcing materials, and targeted repairs, the shed undergoes a transformation that transcends mere restoration, emerging as a resilient and enduring structure within your outdoor domain.

However, the journey does not culminate with structural reinforcement; it expands into the realm of creative possibility through the process of repurposing. Whether transformed into a serene garden retreat, a vibrant outdoor lounge, a creative workshop, or a practical storage space, the repurposed shed embodies the potential for reinvention and renewal, aligning with your evolving needs and aspirations.

Ultimately, the restoration and repurposing of an old, warped plastic resin Suncast tool shed transcend the realm of mere refurbishment, evolving into a narrative of transformation and creativity. As you embark on this journey, you embrace the opportunity to breathe new life into a weathered structure, infusing it with functionality, charm, and purpose within your outdoor environment. The old shed becomes a canvas for reinvention, a testament to the boundless potential for renewal within your outdoor domain.

So, whether you choose to restore the shed to its former glory or embark on a journey of creative repurposing, the possibilities for transforming this weathered structure are as vast and varied as your imagination. Embrace the journey of restoration and reinvention, and witness the metamorphosis of the old, warped plastic resin Suncast tool shed into a cherished and functional asset within your outdoor space.

Frequently Asked Questions about What To Do With An Old Warped Plastic Resin Suncast Tool Shed

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What To Do With An Old Warped Plastic Resin Suncast Tool Shed”