Home>Home Appliances>Heating & Cooling>How Does Underfloor Propane Forced Hot Air Heating Work

Heating & Cooling

How Does Underfloor Propane Forced Hot Air Heating Work

Modified: October 20, 2024

Discover how underfloor propane forced hot air heating works and learn about the benefits of this efficient heating and cooling system. Find out how it can improve your home's comfort and energy efficiency.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Underfloor propane forced hot air heating is a modern and efficient method of heating residential and commercial spaces. This innovative heating system utilizes propane as a fuel source to generate hot air, which is then distributed through underfloor vents to provide consistent and comfortable warmth throughout the building. Unlike traditional heating systems, underfloor propane forced hot air heating offers several advantages, including improved energy efficiency, even heat distribution, and reduced operating costs. In this article, we will delve into the workings of underfloor propane forced hot air heating, explore its components, and discuss its advantages and disadvantages. Additionally, we will address maintenance and safety considerations associated with this heating system, providing a comprehensive understanding of its functionality and practical implications.

Key Takeaways:

- Underfloor propane forced hot air heating uses propane to create consistent warmth throughout buildings. It’s energy-efficient, eliminates cold spots, and looks sleek without bulky radiators.

- Regular maintenance and safety measures are crucial for underfloor propane forced hot air heating. They ensure efficient performance, indoor comfort, and the well-being of occupants.

Overview of Underfloor Propane Forced Hot Air Heating

Underfloor propane forced hot air heating is a cutting-edge heating solution that has gained popularity for its efficiency and even heat distribution. This system utilizes propane, a clean-burning and energy-efficient fuel, to generate hot air, which is then distributed through vents installed beneath the floor. The warm air rises naturally, ensuring consistent and comfortable heating throughout the space.

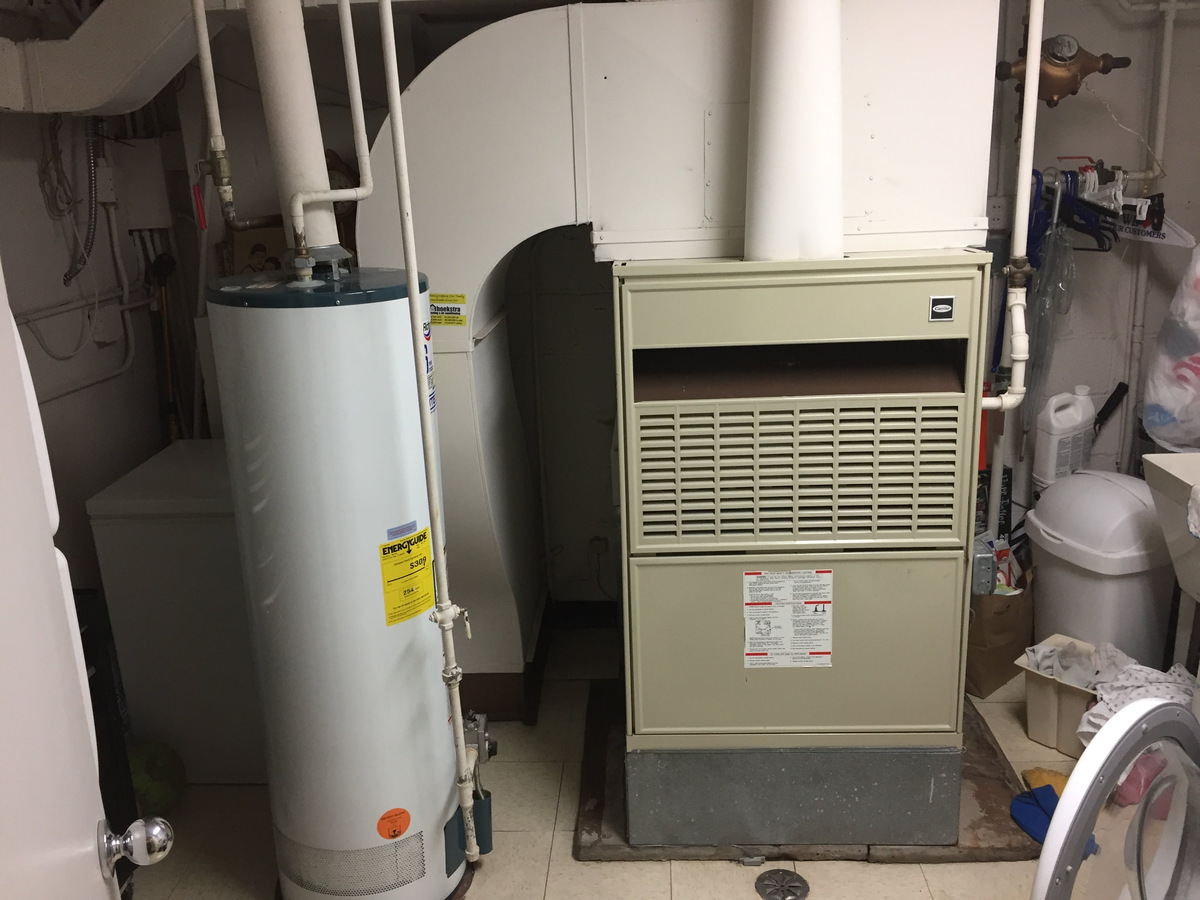

One of the key components of this heating system is the propane furnace, which serves as the heart of the operation. The furnace efficiently burns propane to produce hot air, which is then propelled through a network of ducts to the underfloor vents. These vents are strategically positioned to optimize heat distribution, ensuring that every corner of the building receives an equal amount of warmth.

Underfloor propane forced hot air heating offers a range of benefits, making it an attractive option for both residential and commercial properties. It provides rapid and efficient heating, allowing occupants to enjoy a comfortable environment in a short amount of time. Additionally, the even distribution of heat eliminates cold spots, creating a consistently cozy atmosphere throughout the building.

Furthermore, this heating system is known for its energy efficiency, as propane is a cost-effective fuel source that burns cleanly, minimizing environmental impact. The use of underfloor vents also eliminates the need for bulky radiators or visible heating units, contributing to a more aesthetically pleasing interior space.

In terms of installation, underfloor propane forced hot air heating can be seamlessly integrated into both new construction projects and existing buildings. The flexibility of this system makes it a versatile option for various architectural designs and layouts.

Overall, underfloor propane forced hot air heating represents a modern and efficient approach to indoor climate control. Its ability to deliver consistent warmth, energy efficiency, and aesthetic advantages makes it a compelling choice for those seeking a reliable and effective heating solution.

Components of Underfloor Propane Forced Hot Air Heating System

The underfloor propane forced hot air heating system comprises several essential components that work in harmony to deliver efficient and consistent warmth throughout a building. Understanding these components is crucial for comprehending the functionality and benefits of this innovative heating system.

-

Propane Furnace: At the core of the underfloor propane forced hot air heating system is the propane furnace. This furnace serves as the primary heat source, efficiently burning propane to produce hot air. Equipped with advanced combustion technology, the furnace ensures optimal fuel utilization, resulting in cost-effective and environmentally friendly heat generation.

-

Thermostat: A crucial component of the system is the thermostat, which acts as the control center for regulating the indoor temperature. Modern thermostats are equipped with programmable features, allowing users to set customized heating schedules to align with their daily routines. This level of control not only enhances comfort but also contributes to energy savings by optimizing heating patterns.

-

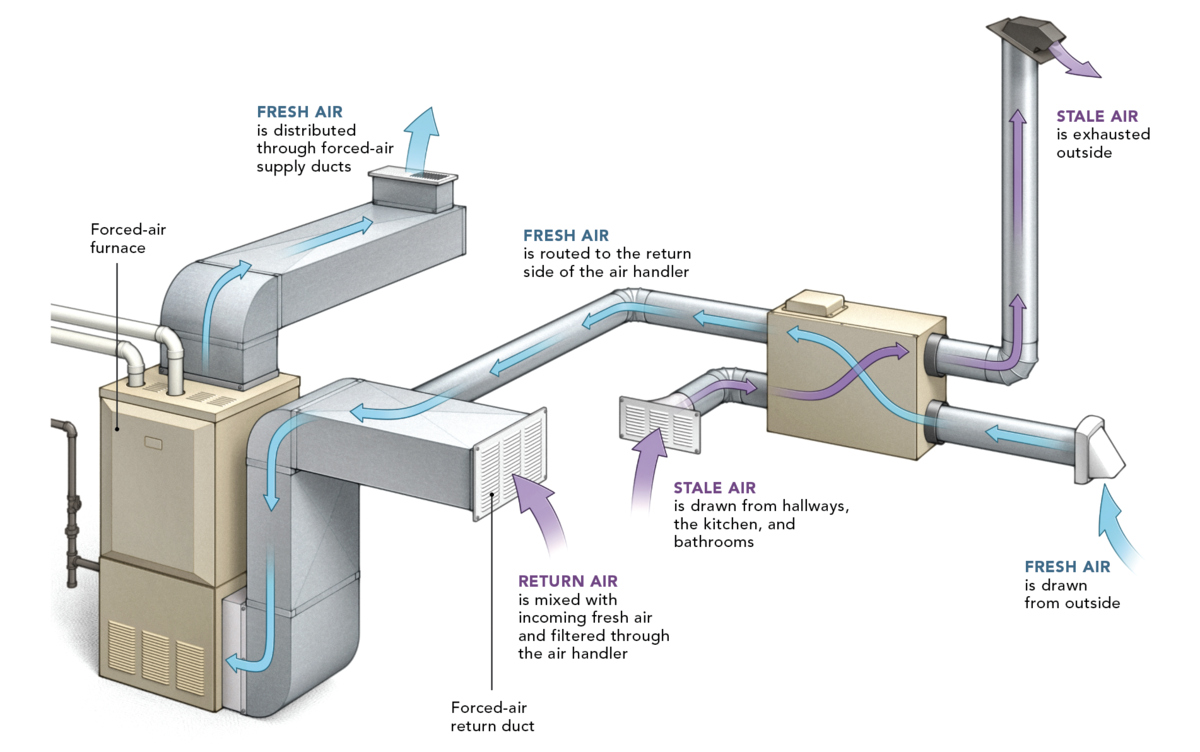

Ductwork: The ductwork forms a network of channels that facilitate the distribution of hot air generated by the propane furnace. These ducts are meticulously designed to deliver heated air to underfloor vents strategically positioned throughout the building. The seamless integration of ductwork ensures efficient heat transfer and consistent warmth in every area of the space.

-

Underfloor Vents: Underfloor vents play a pivotal role in the underfloor propane forced hot air heating system. These vents are strategically installed beneath the flooring, allowing the heated air to rise naturally and disperse evenly throughout the rooms. By utilizing the natural convection process, underfloor vents eliminate the need for visible heating units, contributing to a clean and uncluttered interior aesthetic.

-

Air Filters and Purifiers: To maintain indoor air quality and ensure the longevity of the system, air filters and purifiers are integrated into the underfloor propane forced hot air heating system. These components effectively remove dust, allergens, and impurities from the circulated air, promoting a healthy and comfortable indoor environment.

-

Safety Features: The system incorporates various safety features, including carbon monoxide detectors and automatic shut-off mechanisms, to safeguard occupants against potential hazards. These safety measures underscore the commitment to providing not only efficient heating but also a secure and worry-free experience for users.

The seamless integration of these components forms a robust and reliable underfloor propane forced hot air heating system. By harmonizing advanced technology with efficient design, this heating solution offers unparalleled comfort, energy efficiency, and peace of mind for residential and commercial spaces.

How Underfloor Propane Forced Hot Air Heating Works

Underfloor propane forced hot air heating operates on a simple yet effective principle, leveraging the power of propane combustion to generate and distribute warmth throughout a building. The process begins with the propane furnace, the central component responsible for producing hot air. When the heating system is activated, the propane furnace ignites, initiating the combustion process. As propane burns, it releases a significant amount of heat energy, which is harnessed to elevate the temperature of the air within the furnace.

Once the air reaches the desired temperature, it is propelled through a network of ducts that traverse the building. These ducts are strategically positioned to ensure comprehensive coverage, allowing the heated air to reach every corner of the space. The efficient design of the ductwork facilitates the seamless transfer of warmth, optimizing energy utilization and minimizing heat loss.

As the hot air travels through the ducts, it eventually reaches the underfloor vents installed throughout the building. These vents are strategically positioned beneath the flooring, allowing the heated air to rise naturally and disperse evenly into the rooms. This natural convection process ensures that the warmth is distributed consistently, eliminating cold spots and creating a comfortable indoor environment.

The utilization of underfloor vents is a key feature of this heating system, as it eliminates the need for visible radiators or heating units, contributing to a clean and unobtrusive interior aesthetic. Additionally, the absence of bulky heating equipment maximizes usable space within the building, enhancing both functionality and visual appeal.

The entire process is regulated by a thermostat, which serves as the control center for maintaining the desired indoor temperature. Modern thermostats are equipped with programmable features, allowing users to customize heating schedules to align with their daily routines. This level of control not only enhances comfort but also contributes to energy savings by optimizing heating patterns.

In summary, underfloor propane forced hot air heating operates by efficiently harnessing the heat energy produced through propane combustion and distributing it through a network of ducts to underfloor vents. This innovative approach ensures consistent and comfortable warmth throughout the building, while also offering energy efficiency and aesthetic advantages.

Tip: Underfloor propane forced hot air heating works by using a propane-powered furnace to heat air, which is then circulated through ducts and released into the living space through vents in the floor. Regular maintenance and proper ventilation are essential for safety and efficiency.

Advantages of Underfloor Propane Forced Hot Air Heating

Underfloor propane forced hot air heating offers a multitude of advantages that make it a compelling choice for residential and commercial heating needs. These advantages encompass various aspects, including efficiency, comfort, aesthetics, and environmental impact.

One of the primary advantages of underfloor propane forced hot air heating is its exceptional energy efficiency. Propane, known for its clean-burning properties, allows the system to operate with minimal environmental impact while maximizing fuel utilization. This efficiency translates to cost savings for users, as the system optimizes energy consumption without compromising on heating performance.

Moreover, the even distribution of heat facilitated by underfloor vents eliminates cold spots, ensuring consistent warmth throughout the building. This balanced heat distribution enhances comfort and eliminates the need for supplementary heating sources, providing a uniform and cozy indoor environment.

The integration of underfloor vents also contributes to the aesthetic appeal of interior spaces. By eliminating the need for visible radiators or heating units, underfloor propane forced hot air heating allows for unobstructed interior design, maximizing usable space and creating a clean and uncluttered environment.

Additionally, the rapid heating capabilities of this system enable occupants to enjoy a comfortable indoor environment in a short amount of time. The efficient generation and distribution of hot air ensure that spaces are quickly warmed, enhancing convenience and usability.

Furthermore, underfloor propane forced hot air heating aligns with modern lifestyle demands through its programmable thermostat features. Users can customize heating schedules to match their daily routines, optimizing energy usage and further enhancing cost-effectiveness.

From an environmental perspective, the use of propane as a fuel source contributes to reduced greenhouse gas emissions, aligning with sustainable heating practices. The clean-burning nature of propane minimizes air pollutants, promoting a healthier indoor environment and reducing the system's overall environmental impact.

In summary, underfloor propane forced hot air heating offers a range of advantages, including energy efficiency, consistent warmth, aesthetic benefits, rapid heating capabilities, programmable features, and environmental sustainability. These advantages position this heating system as a modern, efficient, and environmentally conscious choice for indoor climate control.

Read more: When Did Forced Air Heating Start?

Disadvantages of Underfloor Propane Forced Hot Air Heating

While underfloor propane forced hot air heating offers numerous benefits, it is important to consider potential disadvantages associated with this heating system. Understanding these drawbacks provides a comprehensive perspective for individuals considering the implementation of this technology in their residential or commercial spaces.

One notable disadvantage of underfloor propane forced hot air heating is the potential for air stratification. Due to the natural convection process utilized by this heating system, there is a possibility that the heated air may stratify, leading to a noticeable temperature difference between the lower and upper regions of the living space. This stratification can result in a less uniform distribution of warmth, potentially creating discomfort for occupants and necessitating additional measures to mitigate temperature differentials.

Another consideration is the initial installation cost of underfloor propane forced hot air heating systems. While these systems offer long-term energy efficiency and cost savings, the upfront investment for equipment and installation may be higher compared to traditional heating systems. This initial cost can be a deterrent for some individuals or businesses, especially when considering budget constraints or the need for immediate cost savings.

Furthermore, underfloor propane forced hot air heating systems require regular maintenance to ensure optimal performance and safety. The components of the system, including the propane furnace, ductwork, and underfloor vents, need to be inspected, cleaned, and serviced at regular intervals. This maintenance requirement adds to the overall operational cost and necessitates ongoing attention to uphold the system's efficiency and longevity.

In addition, the reliance on propane as a fuel source introduces considerations related to fuel availability and storage. While propane is widely accessible, ensuring a consistent supply and proper storage of the fuel is essential for uninterrupted heating. This aspect requires proactive management and planning to avoid potential disruptions in heating due to fuel shortages or logistical challenges.

Lastly, underfloor propane forced hot air heating systems may pose challenges for retrofitting in existing buildings. The installation of underfloor vents and ductwork in established structures can be complex and may require significant modifications to the building's infrastructure. This aspect can present logistical and cost challenges for individuals or businesses seeking to upgrade their heating systems in older properties.

In summary, while underfloor propane forced hot air heating offers compelling advantages, including energy efficiency and consistent warmth, it is important to consider potential drawbacks such as air stratification, initial installation costs, maintenance requirements, fuel considerations, and retrofitting challenges. By weighing these factors, individuals and businesses can make informed decisions regarding the suitability of this heating system for their specific needs and circumstances.

Maintenance and Safety Considerations for Underfloor Propane Forced Hot Air Heating

Ensuring the optimal performance and safety of underfloor propane forced hot air heating systems involves diligent maintenance practices and adherence to essential safety considerations. By prioritizing maintenance and safety measures, users can uphold the efficiency and reliability of the heating system while safeguarding the well-being of occupants.

Regular maintenance is paramount for underfloor propane forced hot air heating systems. Scheduled inspections and servicing of the propane furnace, ductwork, underfloor vents, and associated components are essential to identify and address potential issues proactively. This proactive approach not only sustains the system's efficiency but also mitigates the risk of malfunctions or safety hazards.

The propane furnace, serving as the heart of the heating system, requires meticulous attention during maintenance. Inspecting the combustion chamber, burners, and ignition system ensures proper functionality and optimal fuel combustion. Additionally, cleaning or replacing air filters and purifiers is crucial for maintaining indoor air quality and preventing the accumulation of dust and allergens within the ductwork.

The ductwork, responsible for distributing heated air, should undergo regular inspections to detect any obstructions, leaks, or damage that may impede airflow or compromise efficiency. Ensuring the integrity of the ducts is essential for seamless heat transfer and consistent warmth throughout the building.

Furthermore, underfloor vents must be kept free from obstructions to facilitate unimpeded airflow. Regular cleaning and inspection of the vents prevent blockages and ensure the natural convection process operates efficiently, promoting even heat distribution.

In addition to maintenance practices, safety considerations are integral to the operation of underfloor propane forced hot air heating systems. Installing carbon monoxide detectors in proximity to the heating system provides an added layer of safety, alerting occupants to any potential presence of this odorless and harmful gas. Furthermore, automatic shut-off mechanisms integrated into the system offer a safeguard against malfunctions or irregularities, minimizing the risk of hazardous situations.

Users of underfloor propane forced hot air heating systems should also prioritize professional inspections and servicing by qualified technicians. Engaging certified professionals for comprehensive system evaluations and maintenance procedures ensures adherence to safety standards and regulatory requirements, contributing to the long-term reliability and safety of the heating system.

By embracing a proactive approach to maintenance and safety, users can optimize the performance of underfloor propane forced hot air heating systems while fostering a secure and comfortable indoor environment for occupants. Regular maintenance and stringent safety measures are fundamental pillars in sustaining the efficiency, reliability, and safety of this innovative heating solution.

Conclusion

In conclusion, underfloor propane forced hot air heating represents a modern and efficient solution for indoor climate control, offering a host of benefits that cater to the diverse needs of residential and commercial spaces. This innovative heating system harnesses the power of propane combustion to generate and distribute consistent warmth throughout buildings, providing a comfortable and inviting environment for occupants.

The seamless integration of components, including the propane furnace, thermostat, ductwork, underfloor vents, and safety features, forms a robust and reliable heating system that prioritizes energy efficiency, even heat distribution, and aesthetic advantages. The utilization of propane as a clean-burning fuel source aligns with sustainable heating practices, minimizing environmental impact and promoting healthier indoor air quality.

Despite its numerous advantages, it is important to acknowledge potential drawbacks associated with underfloor propane forced hot air heating, such as air stratification, initial installation costs, maintenance requirements, fuel considerations, and retrofitting challenges. Understanding these aspects enables individuals and businesses to make informed decisions regarding the suitability of this heating system for their specific needs and circumstances.

Furthermore, the emphasis on maintenance and safety considerations underscores the commitment to sustaining the efficiency and reliability of underfloor propane forced hot air heating systems. By prioritizing regular maintenance, safety measures, and professional inspections, users can ensure the optimal performance of the heating system while safeguarding the well-being of occupants.

Overall, underfloor propane forced hot air heating stands as a compelling choice for those seeking an efficient, reliable, and environmentally conscious heating solution. Its ability to deliver consistent warmth, energy efficiency, and aesthetic advantages positions it as a modern and versatile option for indoor climate control, catering to the evolving demands of today's residential and commercial spaces.

Frequently Asked Questions about How Does Underfloor Propane Forced Hot Air Heating Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does Underfloor Propane Forced Hot Air Heating Work”