Home>Home Appliances>Home Automation Appliances>Pneumatic Thermostat: How It Works

Home Automation Appliances

Pneumatic Thermostat: How It Works

Published: January 1, 2024

Learn how a pneumatic thermostat works and its role in home automation appliances. Explore the benefits and functionality of this essential component.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Read more: How To Work A Thermostat For Heating

Introduction

Welcome to the world of pneumatic thermostats! In the realm of home automation and appliance technology, pneumatic thermostats play a crucial role in maintaining comfortable and consistent indoor temperatures. These ingenious devices have been a staple in heating, ventilation, and air conditioning (HVAC) systems for decades, offering reliable temperature control in various residential and commercial settings.

Pneumatic thermostats are renowned for their robustness and efficiency, providing a cost-effective solution for temperature regulation. As we delve into the intricacies of pneumatic thermostats, you'll gain a comprehensive understanding of their inner workings, components, advantages, and applications. Whether you're a homeowner seeking insights into HVAC systems or a technology enthusiast eager to explore the evolution of thermostat technology, this article will unravel the fascinating world of pneumatic thermostats.

Join us on this enlightening journey as we unravel the mechanisms and benefits of pneumatic thermostats, shedding light on their pivotal role in modern temperature control systems. Let's embark on an exploration of the captivating realm of pneumatic thermostats, where innovation meets practicality to create a harmonious indoor environment.

Key Takeaways:

- Pneumatic thermostats use air pressure to control temperature, offering reliability and cost-effectiveness in HVAC systems. They work without external power sources, making them resilient and durable for consistent temperature regulation.

- Pneumatic thermostats have advantages like reliability, durability, and cost-effectiveness, but also limitations such as limited precision and susceptibility to air leaks. They find applications in commercial buildings, hospitals, and historic renovations, contributing to comfortable indoor environments.

What is a Pneumatic Thermostat?

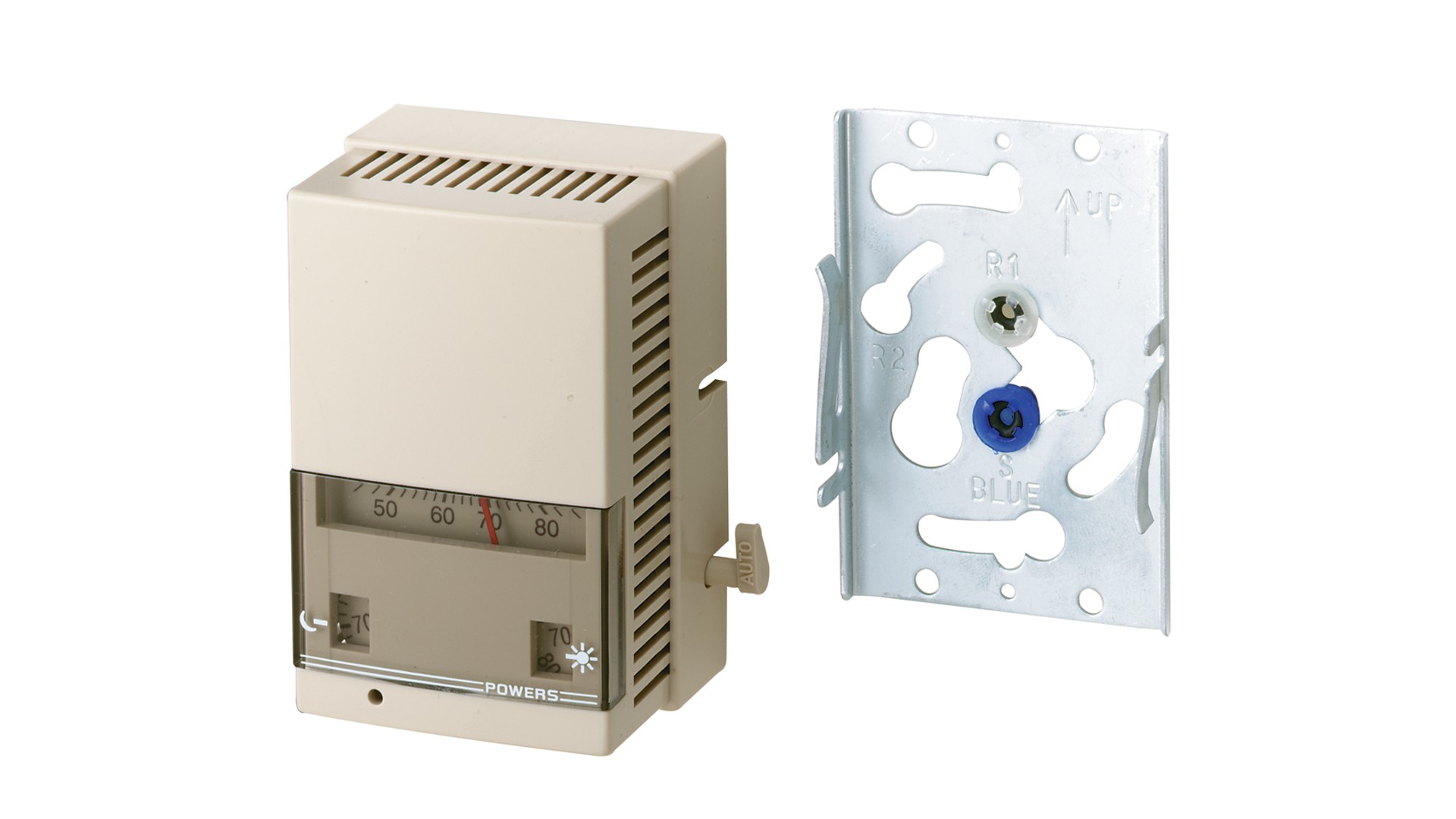

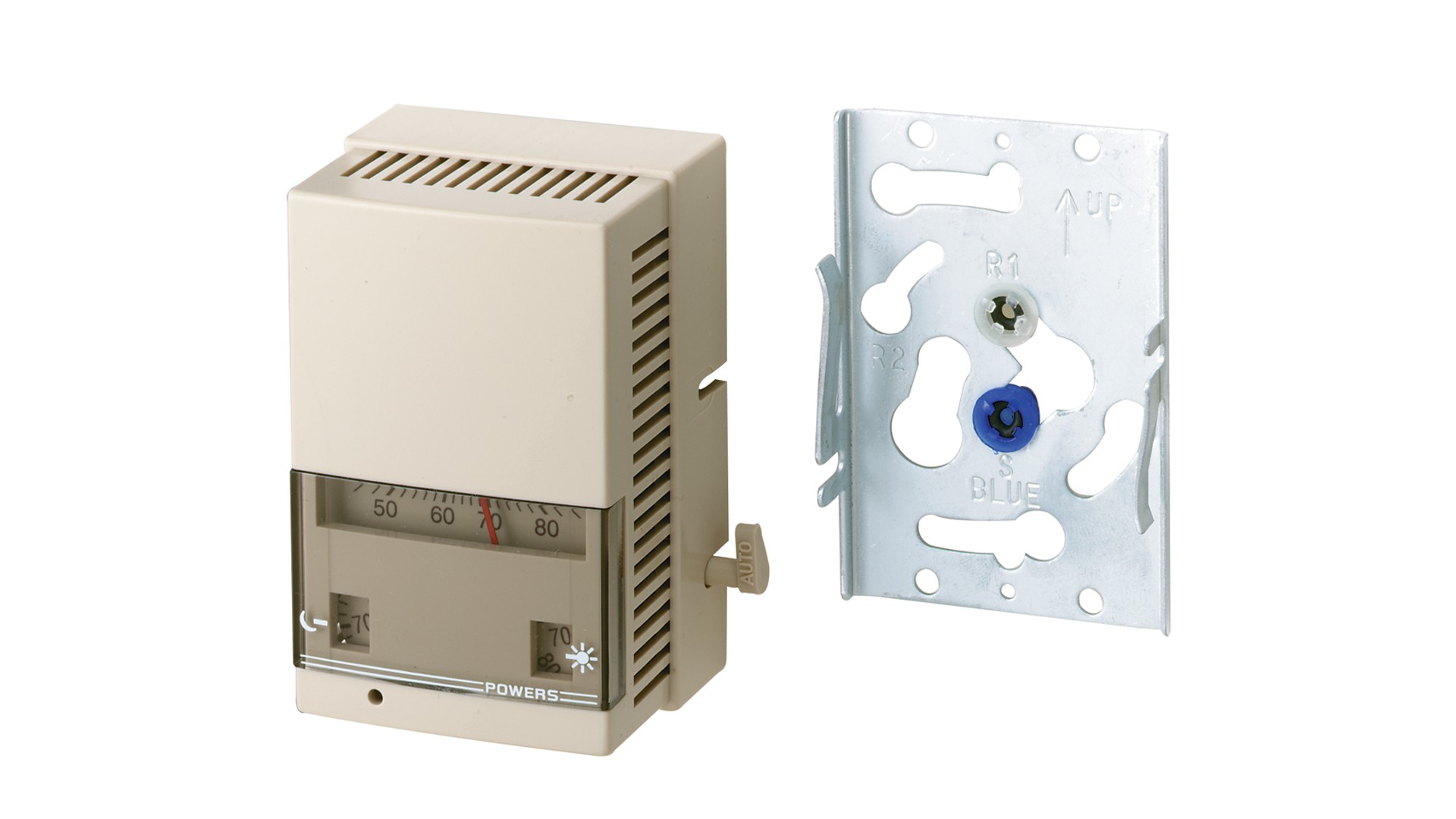

A pneumatic thermostat is a specialized device used to regulate temperature in HVAC systems by utilizing air pressure differentials. Unlike traditional electronic thermostats that rely on electrical signals, pneumatic thermostats operate through the manipulation of air pressure to achieve precise temperature control. These devices are widely employed in commercial and industrial settings, where they offer a reliable and cost-effective means of maintaining comfortable indoor environments.

At the core of a pneumatic thermostat is a pneumatic control system, which comprises a network of air-filled tubes, pressure controllers, and actuators. The system functions by transmitting changes in temperature to the air pressure within the control network, prompting responsive adjustments to heating and cooling equipment. This pneumatic approach to temperature regulation has proven to be remarkably resilient and efficient, making pneumatic thermostats a preferred choice in many HVAC applications.

One of the defining features of pneumatic thermostats is their ability to operate without the need for external power sources. This self-sufficiency makes them exceptionally reliable, as they can continue functioning even during electrical outages. Furthermore, pneumatic thermostats are known for their simplicity and durability, requiring minimal maintenance and offering long-term stability in temperature control systems.

As pneumatic thermostats continue to evolve, modern iterations integrate advanced features such as proportional control and enhanced sensitivity, further enhancing their performance and adaptability. With their ability to withstand harsh environmental conditions and deliver consistent temperature management, pneumatic thermostats have earned a well-deserved reputation as resilient and effective components of HVAC systems.

By harnessing the principles of pneumatic control, these thermostats contribute to energy efficiency and occupant comfort, making them indispensable elements in the realm of heating and cooling technology. Their versatility and reliability have solidified their position as key instruments in achieving optimal indoor climate control, ensuring that occupants can enjoy comfortable temperatures in various settings.

Components of a Pneumatic Thermostat

Understanding the intricate components of a pneumatic thermostat is essential for comprehending its functionality and significance within HVAC systems. These thermostats consist of several key elements that work in harmony to facilitate precise temperature regulation and control. Let’s explore the fundamental components that constitute a pneumatic thermostat:

- Sensing Element: At the heart of a pneumatic thermostat is the sensing element, which detects changes in temperature and initiates the corresponding adjustments within the control system. This component is designed to accurately measure the ambient temperature, serving as the catalyst for regulating the air pressure within the pneumatic network.

- Controller: The controller acts as the command center of the pneumatic thermostat, processing the input from the sensing element and orchestrating the necessary responses to maintain the desired temperature. It governs the modulation of air pressure and coordinates the actions of other components to achieve optimal temperature control.

- Actuator: An integral part of the pneumatic thermostat, the actuator translates the commands from the controller into mechanical actions that adjust the heating and cooling equipment. By converting pneumatic signals into physical movements, the actuator plays a pivotal role in fine-tuning the HVAC system’s output to align with the desired temperature settings.

- Air Lines and Tubing: The pneumatic control network relies on a series of air lines and tubing to convey air pressure changes throughout the system. These channels facilitate the transmission of pneumatic signals, enabling seamless communication between the sensing element, controller, actuator, and other interconnected components.

- Pressure Regulators: To maintain precision and stability in temperature regulation, pneumatic thermostats incorporate pressure regulators that ensure consistent air pressure levels within the control system. These regulators optimize the responsiveness and accuracy of the thermostat, contributing to dependable and efficient temperature management.

- Dampers and Valves: Dampers and valves serve as the gatekeepers of airflow within HVAC ductwork, modulating the passage of heated or cooled air to achieve the desired temperature balance. Pneumatic thermostats leverage these components to regulate the distribution of conditioned air, enabling seamless adjustments to match the occupants’ comfort requirements.

By harmonizing these essential components, pneumatic thermostats empower HVAC systems to maintain optimal indoor temperatures with precision and reliability. The seamless coordination of sensing, control, and actuation mechanisms underscores the effectiveness of pneumatic thermostats in creating comfortable and conducive environments for occupants.

How Does a Pneumatic Thermostat Work?

Delving into the operational intricacies of a pneumatic thermostat unveils a fascinating interplay of pneumatic principles and mechanical precision. Understanding the inner workings of these devices elucidates their pivotal role in orchestrating seamless temperature regulation within HVAC systems. Let’s unravel the mechanics of how a pneumatic thermostat operates:

1. Sensing and Detection: The process commences with the sensing element of the pneumatic thermostat, which diligently monitors the ambient temperature. As the temperature fluctuates, the sensing element swiftly detects these changes, initiating the cascade of pneumatic responses necessary to maintain the desired temperature setting.

2. Pneumatic Control System: Upon detecting temperature variations, the sensing element transmits pneumatic signals to the controller, which serves as the nerve center of the thermostat. The controller meticulously interprets the input from the sensing element and formulates precise commands to modulate the air pressure within the pneumatic control network.

3. Actuation and Adjustment: The controller’s directives are swiftly conveyed to the actuator, which translates the pneumatic signals into mechanical actions. This prompts the actuator to adjust the heating and cooling equipment, fine-tuning their output to align with the desired temperature parameters. The seamless coordination between the controller and actuator ensures swift and accurate adjustments to maintain optimal indoor temperatures.

4. Pneumatic Transmission: The pneumatic control system relies on a network of air lines and tubing to propagate the pressure differentials initiated by the sensing element and controller. These channels facilitate the transmission of pneumatic signals, enabling the seamless exchange of information between the thermostat’s components and the HVAC system’s heating and cooling elements.

5. Regulation and Optimization: Pressure regulators play a crucial role in maintaining stability and precision within the pneumatic control system. By ensuring consistent air pressure levels, these regulators optimize the responsiveness and accuracy of the thermostat, contributing to reliable and efficient temperature management.

By orchestrating this intricate interplay of sensing, control, and actuation, pneumatic thermostats uphold the delicate balance of indoor temperature regulation. Their ability to harness pneumatic principles and mechanical precision enables them to deliver consistent and reliable temperature control, fostering comfortable and conducive environments for occupants.

Read more: How To Work Thermostat Controls

Advantages of Pneumatic Thermostats

Pneumatic thermostats offer a myriad of advantages that underscore their enduring relevance and effectiveness in HVAC systems. These distinctive benefits contribute to their widespread adoption in various residential, commercial, and industrial settings, solidifying their position as indispensable components of temperature control infrastructure. Let’s explore the compelling advantages of pneumatic thermostats:

- Reliability: Pneumatic thermostats are renowned for their robustness and reliability. Operating without reliance on external power sources, these thermostats continue to function seamlessly even during electrical outages, ensuring uninterrupted temperature regulation.

- Durability: Built to withstand demanding environmental conditions, pneumatic thermostats exhibit exceptional durability. Their resilience enables them to deliver consistent performance over extended periods, minimizing the need for frequent maintenance and replacements.

- Cost-Effectiveness: Pneumatic thermostats offer a cost-effective solution for temperature control, making them an economically viable choice for HVAC systems. Their efficiency and longevity translate to long-term savings and reduced operational expenses.

- Simple Installation: The straightforward installation process of pneumatic thermostats contributes to their appeal. Their ease of integration into HVAC systems streamlines the deployment process, saving time and labor costs.

- Self-Contained Operation: Operating independently of external power sources, pneumatic thermostats are self-contained units. This autonomy enhances their reliability and ensures continuous temperature regulation, unaffected by electrical disruptions.

- Compatibility: Pneumatic thermostats seamlessly integrate with a wide range of heating, ventilation, and air conditioning equipment, demonstrating remarkable compatibility with diverse HVAC configurations.

- Proven Technology: With a history of successful implementation and consistent performance, pneumatic thermostat technology has stood the test of time, instilling confidence in its reliability and efficacy.

- Resilience to Electrical Interference: The absence of electrical components in pneumatic thermostats renders them immune to electromagnetic interference, ensuring uninterrupted operation in environments where electrical disturbances may pose challenges to electronic devices.

By embodying these advantageous qualities, pneumatic thermostats continue to be valued for their dependability, longevity, and cost-efficient operation. Their ability to deliver consistent and precise temperature control, coupled with their resilience and compatibility, cements their status as indispensable assets in the realm of HVAC technology.

When installing a pneumatic thermostat, make sure to properly calibrate the air pressure to ensure accurate temperature control. This will help maintain a comfortable and energy-efficient environment.

Disadvantages of Pneumatic Thermostats

While pneumatic thermostats offer a range of benefits, they also present certain limitations that warrant consideration when evaluating their suitability for specific HVAC applications. Understanding these disadvantages provides a comprehensive perspective on the practical implications of employing pneumatic thermostats in temperature control systems. Let’s explore the notable disadvantages of pneumatic thermostats:

- Limited Precision: Pneumatic thermostats may exhibit limited precision in temperature regulation compared to their electronic counterparts. The pneumatic control system’s responsiveness may not match the exactitude achieved by advanced electronic thermostats.

- Complexity of Calibration: Achieving precise calibration in pneumatic thermostats can be more intricate than in electronic models, requiring meticulous adjustments to optimize their performance and accuracy.

- Susceptibility to Air Leaks: The pneumatic control network of these thermostats is susceptible to air leaks, which can compromise the accuracy and responsiveness of the temperature control system, necessitating regular maintenance to address potential leaks.

- Dependency on Air Pressure: Pneumatic thermostats rely on air pressure differentials to effect temperature adjustments, making them vulnerable to fluctuations in air pressure that may impact their performance and consistency.

- Limited Programmability: The programmability of pneumatic thermostats may be limited compared to electronic models, constraining the range of advanced scheduling and temperature management features available in electronic thermostats.

- Environmental Sensitivity: Environmental factors such as temperature variations and airborne contaminants can influence the pneumatic control system, potentially affecting the thermostat’s precision and reliability.

- Compatibility with Modern Controls: In some instances, integrating pneumatic thermostats with modern control systems and building automation technologies may present challenges, particularly in environments where advanced electronic controls are prevalent.

- Upfront Installation Costs: While pneumatic thermostats offer long-term cost savings, their initial installation costs may be higher due to the need for specialized pneumatic control infrastructure and components.

By acknowledging these limitations, stakeholders can make informed decisions regarding the integration of pneumatic thermostats into HVAC systems, weighing the trade-offs between their advantages and disadvantages in relation to specific operational requirements and environmental conditions.

Applications of Pneumatic Thermostats

Pneumatic thermostats find diverse and impactful applications across a spectrum of residential, commercial, and industrial environments, leveraging their unique attributes to deliver reliable and efficient temperature control. The adaptability and resilience of pneumatic thermostats make them well-suited for a range of HVAC scenarios, where their distinct advantages address specific operational needs. Let’s explore the notable applications of pneumatic thermostats:

- Commercial Buildings: Pneumatic thermostats are extensively employed in commercial structures, including office complexes, retail establishments, and educational institutions. Their reliability and cost-effectiveness make them ideal for maintaining comfortable indoor environments in these settings.

- Industrial Facilities: The durability and resilience of pneumatic thermostats render them valuable assets in industrial facilities, where they contribute to the regulation of temperatures in manufacturing plants, warehouses, and production environments.

- Hospitals and Healthcare Facilities: Pneumatic thermostats play a crucial role in healthcare facilities, ensuring precise temperature control in patient rooms, operating theaters, and specialized medical spaces where environmental conditions are critical.

- Hotels and Hospitality: The reliable performance and compatibility of pneumatic thermostats make them well-suited for hospitality establishments, where they facilitate consistent climate management in guest rooms, lobbies, and public areas.

- Residential Settings: While electronic thermostats are prevalent in modern homes, pneumatic thermostats continue to be utilized in certain residential contexts, particularly in older properties and apartment buildings where existing pneumatic HVAC systems are in place.

- Schools and Educational Facilities: Pneumatic thermostats contribute to creating conducive learning environments in schools and educational institutions, fostering optimal temperatures in classrooms, libraries, and administrative areas.

- Retail Environments: Retail spaces benefit from the cost-effective and dependable temperature regulation provided by pneumatic thermostats, ensuring comfortable conditions for shoppers and employees alike.

- Historic Buildings and Renovations: Pneumatic thermostats are often retained or integrated into the HVAC systems of historic buildings and renovation projects, preserving their functionality and compatibility with existing infrastructure.

The versatility and reliability of pneumatic thermostats make them indispensable in a wide array of environments, where their ability to deliver consistent and accurate temperature control contributes to the comfort and well-being of occupants. By catering to the unique demands of diverse settings, pneumatic thermostats continue to play a vital role in shaping optimal indoor climates across various sectors.

Conclusion

As we conclude our exploration of pneumatic thermostats, it becomes evident that these ingenious devices are pivotal components in the realm of HVAC technology, offering a blend of resilience, reliability, and cost-effectiveness. Their ability to harness pneumatic principles to achieve precise temperature regulation underscores their enduring relevance in diverse residential, commercial, and industrial settings. The advantages and limitations of pneumatic thermostats present a comprehensive portrait of their practical implications, guiding stakeholders in their decision-making processes.

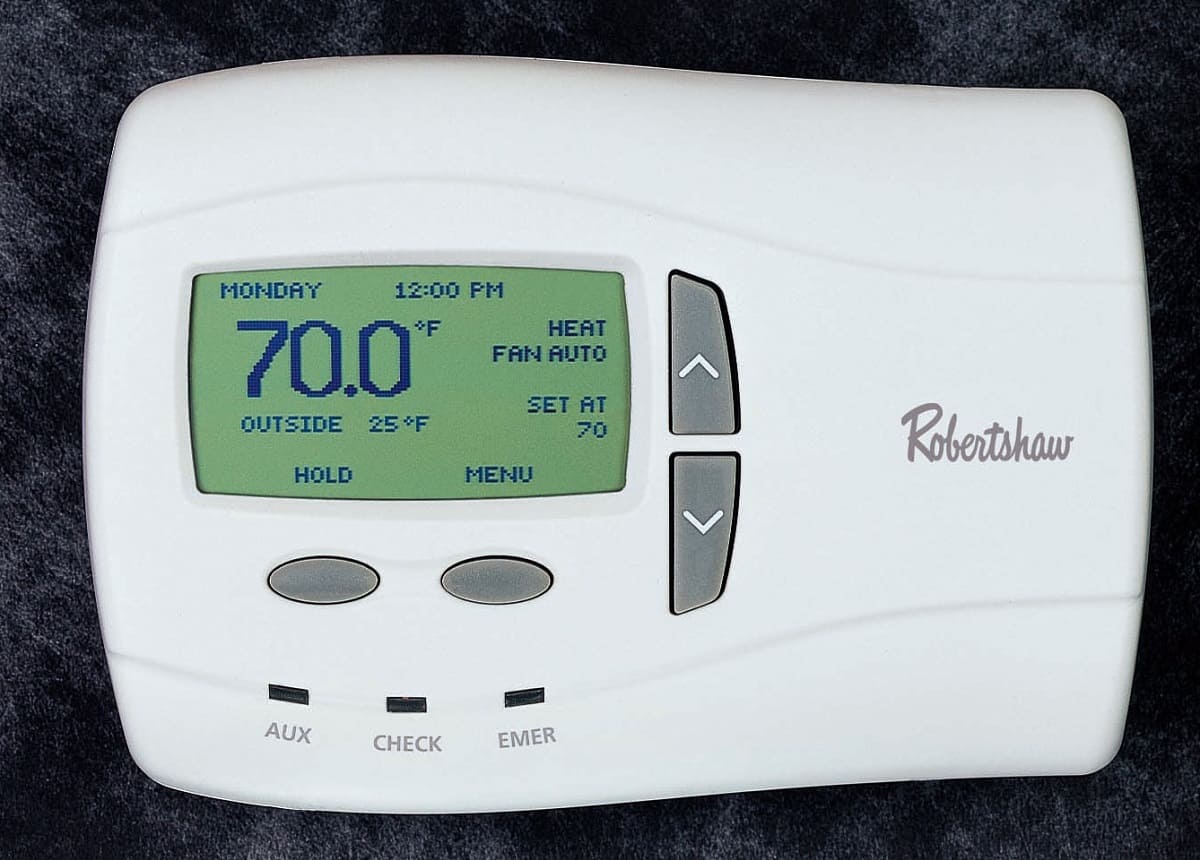

From their self-contained operation and compatibility with various HVAC configurations to their applications in critical environments such as healthcare facilities and industrial settings, pneumatic thermostats continue to demonstrate their adaptability and value. While electronic thermostats have gained prominence in modern HVAC systems, pneumatic thermostats persist in specific contexts, particularly where their unique attributes align with operational requirements and infrastructure compatibility.

The evolution of pneumatic thermostat technology has seen the integration of advanced features, enhancing their precision and responsiveness. Their enduring presence in the HVAC landscape is a testament to their proven track record and ability to deliver consistent and reliable temperature control. By embracing the advantages and addressing the limitations of pneumatic thermostats, stakeholders can leverage their attributes to create comfortable and conducive indoor environments.

As technology continues to advance, pneumatic thermostats remain an integral part of the HVAC ecosystem, contributing to energy efficiency, occupant comfort, and operational stability. Their enduring legacy and adaptability position them as indispensable assets in the pursuit of optimal indoor climate control. Whether in commercial buildings, industrial facilities, or residential settings, pneumatic thermostats continue to play a vital role in shaping comfortable and sustainable indoor environments.

As we reflect on the enduring relevance of pneumatic thermostats, their impact on temperature regulation and HVAC efficiency serves as a testament to their enduring legacy in the realm of home automation and appliance technology.

Frequently Asked Questions about Pneumatic Thermostat: How It Works

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Pneumatic Thermostat: How It Works”