Home>Home Appliances>Laundry Appliances>What Is The Drum Of A Washing Machine

Laundry Appliances

What Is The Drum Of A Washing Machine

Modified: August 26, 2024

Learn about the drum of a washing machine and its role in laundry appliances. Find out how it impacts the washing process and overall performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

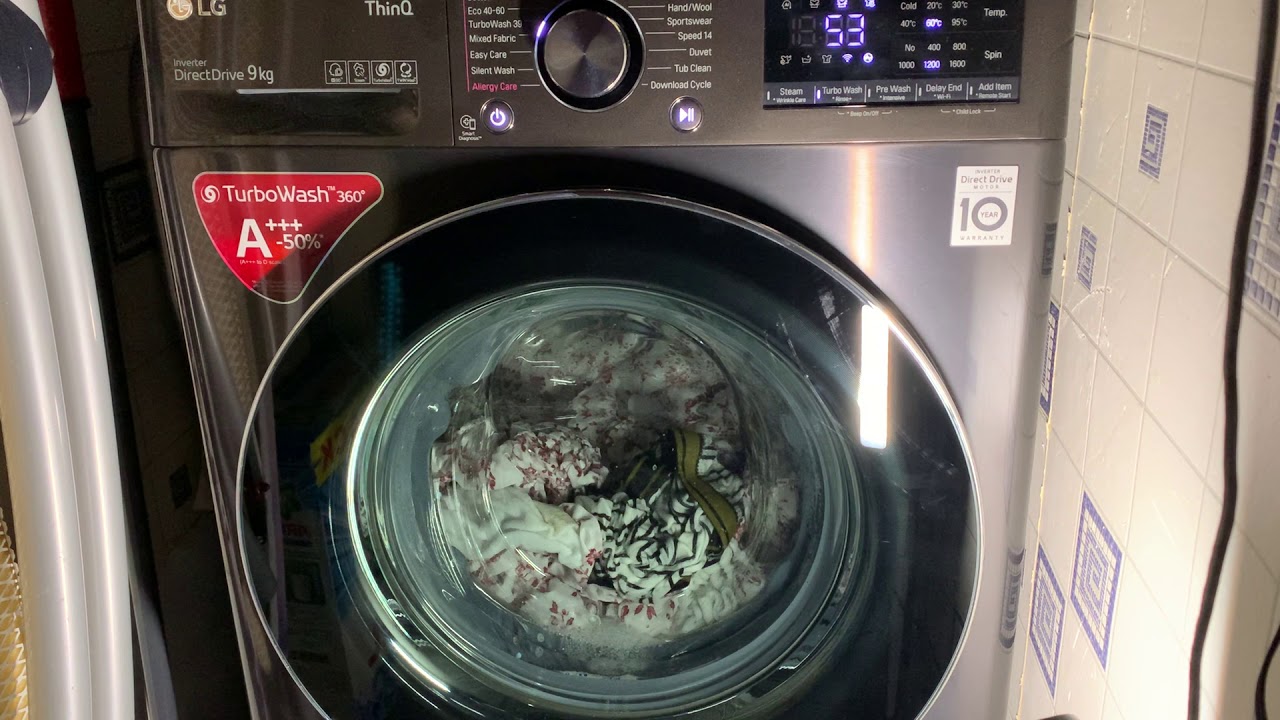

The drum of a washing machine is a crucial component that plays a pivotal role in the cleaning process. It serves as the container where the clothes are placed for washing. Understanding the significance of the drum is essential for comprehending the overall functionality of a washing machine.

The drum, also known as the tub, is the central part of the washing machine where the clothes are loaded. It is designed to hold the garments during the washing, rinsing, and spinning cycles. The drum's capacity varies depending on the size and model of the washing machine, with larger drums accommodating more laundry.

As the heart of the washing machine, the drum undergoes rigorous movement and rotation to ensure thorough cleaning of the clothes. Its design and construction directly impact the efficiency and effectiveness of the washing process. Therefore, gaining insight into the drum's function, types, materials, and maintenance is essential for optimizing the performance and longevity of the washing machine.

Understanding the drum's significance provides a foundation for comprehending the intricate mechanics of a washing machine. By delving into the details of the drum, one can gain a deeper appreciation for the engineering and technology that contribute to the seamless operation of this household appliance.

Key Takeaways:

- The drum of a washing machine is like the heart of the appliance, helping to clean clothes by moving them around with water and detergent, and then spinning to remove excess water for faster drying.

- Different types of drums, like stainless steel and plastic, offer unique benefits for durability and performance, giving consumers options to choose based on their specific needs and preferences.

Read more: What Is A Washer Drum

The Function of the Drum

The drum of a washing machine serves a multifaceted role in the laundry process, encompassing various stages from washing to rinsing and spinning. Its primary function is to hold the clothes during the entire washing cycle, facilitating the movement and interaction of the garments with water, detergent, and other cleaning agents. The drum's rotation creates the necessary agitation to dislodge dirt and stains from the fabric, ensuring a thorough cleaning process.

During the washing phase, the drum's rotational motion, combined with the influx of water and detergent, generates a dynamic environment within the machine. This movement causes the clothes to rub against each other, aiding in the removal of soil and grime. The drum's design incorporates perforations or apertures that allow water and detergent to penetrate the fabric, enhancing the cleaning action.

Following the washing stage, the drum facilitates the rinsing process by draining the soapy water and introducing fresh water to eliminate any residual detergent. The rinsing cycle, often repeated multiple times, ensures that the clothes are thoroughly cleansed of detergent and dirt particles. The drum's ability to hold and agitate the garments in a water-filled environment is instrumental in achieving optimal rinsing results.

Once the washing and rinsing phases are completed, the drum initiates the spinning cycle, where it rapidly rotates to extract excess water from the clothes. This centrifugal force expels the water through the perforations in the drum, significantly reducing the moisture content in the laundry. The efficient spinning action of the drum expedites the drying process and contributes to shorter drying times, particularly when using a dryer or line drying the clothes.

In essence, the drum of a washing machine functions as the vessel for the entire laundry process, orchestrating the intricate choreography of washing, rinsing, and spinning. Its design and operational capabilities are pivotal in ensuring that the clothes emerge clean, refreshed, and ready for the next phase of the laundry routine. Understanding the pivotal role of the drum provides insight into the intricate mechanics that underpin the efficiency and effectiveness of modern washing machines.

Types of Drums in Washing Machines

The evolution of washing machines has led to the development of various types of drums, each designed to cater to specific laundry needs and technological advancements. Understanding the different types of drums in washing machines provides valuable insight into the diverse options available to consumers. Here are some common types of drums found in modern washing machines:

-

Porcelain-Coated Steel Drums: These drums are constructed from steel and coated with a layer of porcelain, offering a durable and smooth surface for the laundry. The porcelain coating prevents rusting and corrosion, ensuring longevity and resistance to wear and tear. Additionally, the smooth surface reduces friction, allowing the clothes to move more freely during the washing and spinning cycles.

-

Stainless Steel Drums: Renowned for their durability and resistance to rust and corrosion, stainless steel drums are a popular choice in modern washing machines. The robust nature of stainless steel ensures longevity and reliability, making it an ideal option for heavy-duty laundry loads. Furthermore, the smooth surface of stainless steel drums contributes to gentler treatment of the clothes, minimizing wear and tear.

-

Plastic Drums: Washing machines equipped with plastic drums offer a lightweight and cost-effective alternative. The use of high-quality plastics in drum construction provides durability and resistance to chemical and moisture damage. Plastic drums are also known for their shock-absorbing properties, reducing noise and vibration during the washing process.

-

Polinox Drums: Utilizing advanced materials, such as polycarbonate and fiberglass, polinox drums offer a unique blend of strength and lightweight design. These drums are engineered to withstand high-speed rotations and heavy loads, ensuring efficient washing and spinning performance. The innovative composition of polinox drums contributes to energy efficiency and reduced wear on the washing machine's components.

-

Hybrid Drums: Combining the benefits of different materials, hybrid drums integrate elements of steel, plastic, and other advanced composites to optimize performance and durability. These hybrid designs aim to enhance the washing experience by leveraging the strengths of various materials, such as the robustness of steel and the lightweight properties of plastic.

The diverse array of drum types reflects the continuous innovation and technological advancements in the realm of washing machines. Each type offers distinct advantages in terms of durability, performance, and energy efficiency, catering to the diverse preferences and requirements of consumers. By understanding the characteristics and benefits of different drum types, individuals can make informed decisions when selecting a washing machine that aligns with their specific needs and lifestyle.

The variety of drum options underscores the dynamic nature of the laundry appliance industry, where continuous research and development drive the evolution of washing machine technology. As consumers seek enhanced efficiency, durability, and convenience in their household appliances, the diversity of drum types in washing machines reflects the industry's commitment to meeting and exceeding consumer expectations.

Materials Used for Making Drums

The materials utilized for constructing washing machine drums play a pivotal role in determining the durability, performance, and overall quality of the appliance. Manufacturers employ a diverse range of materials, each with distinct properties and advantages, to meet the varying demands of consumers. Understanding the materials used for making drums provides valuable insight into the engineering and design considerations that underpin the functionality of washing machines.

Stainless Steel

Stainless steel stands out as a premier choice for drum construction due to its exceptional durability, resistance to corrosion, and longevity. The robust nature of stainless steel ensures that the drum can withstand the rigors of frequent use and heavy laundry loads. Additionally, its smooth surface minimizes friction, allowing the clothes to move freely during the washing and spinning cycles. The non-porous nature of stainless steel also contributes to enhanced hygiene, as it inhibits the growth of bacteria and mold, ensuring a clean and sanitary laundry environment.

Read more: How To Balance A Washing Machine Drum

Porcelain-Coated Steel

Porcelain-coated steel drums combine the strength of steel with a protective porcelain layer, offering a durable and smooth surface for the laundry. The porcelain coating serves as a barrier against rust and corrosion, extending the lifespan of the drum. Furthermore, the smooth surface reduces wear and tear on the clothes, providing gentle treatment during the washing and spinning processes. This type of drum is renowned for its longevity and resistance to damage, making it a popular choice among consumers seeking a reliable and low-maintenance washing machine.

High-Quality Plastic

High-quality plastics, such as polypropylene and polycarbonate, are utilized in the construction of washing machine drums to offer a lightweight and cost-effective alternative. These materials exhibit excellent resistance to chemical and moisture damage, ensuring the longevity and structural integrity of the drum. Plastic drums are also valued for their shock-absorbing properties, which contribute to reduced noise and vibration during the washing cycle. Additionally, the lightweight nature of plastic drums facilitates ease of handling and installation, enhancing the overall user experience.

Advanced Composites

Innovative materials, including fiberglass-reinforced plastics and polycarbonate blends, are increasingly employed in the fabrication of washing machine drums. These advanced composites offer a unique combination of strength, lightweight design, and resistance to high-speed rotations. By leveraging the benefits of advanced materials, manufacturers can enhance the energy efficiency and performance of washing machines while ensuring the durability and longevity of the drums. The utilization of advanced composites underscores the industry's commitment to continuous improvement and innovation in laundry appliance technology.

Hybrid Designs

Hybrid drum designs integrate multiple materials, such as steel, plastic, and advanced composites, to optimize performance and durability. By combining the strengths of different materials, manufacturers can create drums that offer enhanced efficiency, longevity, and washing performance. These hybrid designs exemplify the industry's pursuit of innovation and excellence, catering to the evolving needs and preferences of consumers.

In summary, the materials used for making washing machine drums encompass a diverse spectrum of options, each contributing to the overall functionality, durability, and performance of the appliance. The selection of materials reflects the industry's dedication to meeting consumer demands for reliable, efficient, and long-lasting laundry appliances. By understanding the characteristics and advantages of different drum materials, consumers can make informed choices when selecting a washing machine that aligns with their specific requirements and expectations.

Read more: How To Clean The Drum Of A Washing Machine

Maintenance of the Drum

Proper maintenance of the washing machine drum is essential to ensure optimal performance, longevity, and the preservation of laundry quality. By adhering to a regular maintenance routine, individuals can mitigate potential issues, prolong the lifespan of the appliance, and uphold the efficiency of the laundry process. Here are key maintenance practices to uphold the integrity of the drum:

Cleaning the Drum

Regular cleaning of the drum is paramount to prevent the buildup of residue, detergent scum, and lint, which can compromise the washing machine's effectiveness. A simple yet effective method involves wiping the interior of the drum with a damp cloth and mild detergent to remove any accumulated debris. Additionally, running a hot water cycle with vinegar or a specialized washing machine cleaner can help dissolve mineral deposits and eliminate odors, ensuring a hygienic and odor-free drum.

Inspecting for Damage

Periodically inspecting the drum for signs of wear, corrosion, or damage is crucial for addressing potential issues before they escalate. Check for any chipped enamel (in porcelain-coated drums) or rust spots (in steel drums) and promptly address these areas to prevent further deterioration. Furthermore, examine the drum's interior for any foreign objects, such as loose coins or small items, which can cause damage during the washing cycle.

Balancing the Load

Properly distributing the laundry load within the drum is essential to prevent imbalance and minimize wear on the appliance. Overloading the drum can strain the motor and suspension system, leading to premature wear and potential malfunctions. Conversely, washing small loads may cause imbalance during the spinning cycle. Maintaining a balanced load not only safeguards the drum but also contributes to the overall stability and efficiency of the washing machine.

Read more: How To Fix A Loose Drum In A Washing Machine

Ensuring Level Installation

Ensuring that the washing machine is level and stable is imperative for the optimal functioning of the drum. A machine that is not level may cause excessive vibration and movement during the washing and spinning cycles, potentially leading to wear and misalignment of the drum. Periodically check and adjust the machine's leveling feet to maintain stability and minimize unnecessary stress on the drum and other internal components.

Addressing Unusual Noises

Unusual noises emanating from the washing machine, particularly during the spinning cycle, may indicate issues with the drum or other internal components. Promptly addressing such noises by inspecting the drum, suspension system, and motor can prevent potential damage and ensure the smooth operation of the appliance. Consulting a professional technician for thorough diagnostics and repairs is advisable if unusual noises persist.

By incorporating these maintenance practices into a regular washing machine care routine, individuals can uphold the integrity of the drum, mitigate potential issues, and optimize the performance and longevity of the appliance. Prioritizing the maintenance of the drum not only enhances the efficiency of the washing machine but also contributes to the preservation of clothing quality and the overall laundry experience.

Frequently Asked Questions about What Is The Drum Of A Washing Machine

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Drum Of A Washing Machine”