Home>Home Maintenance>Should You Use A Ventilation System When Stippling Polymer

Home Maintenance

Should You Use A Ventilation System When Stippling Polymer

Modified: March 6, 2024

Learn if using a ventilation system for polymer stippling is essential for your home maintenance. Enhance air quality and safety.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Stippling polymer is a popular technique used in various home improvement projects to create texture and provide a non-slip surface. It involves applying a stippling compound or polymer coating to a surface, which is then textured using specialized tools or brushes. This technique is commonly used on concrete, wood, or even metal surfaces to enhance their appearance and improve functionality.

While stippling polymer can be a great way to add character and durability to your home, it is important to consider the potential health risks associated with the process. The release of volatile organic compounds (VOCs) and other airborne particles during the application and drying of the stippling polymer can have a negative impact on indoor air quality.

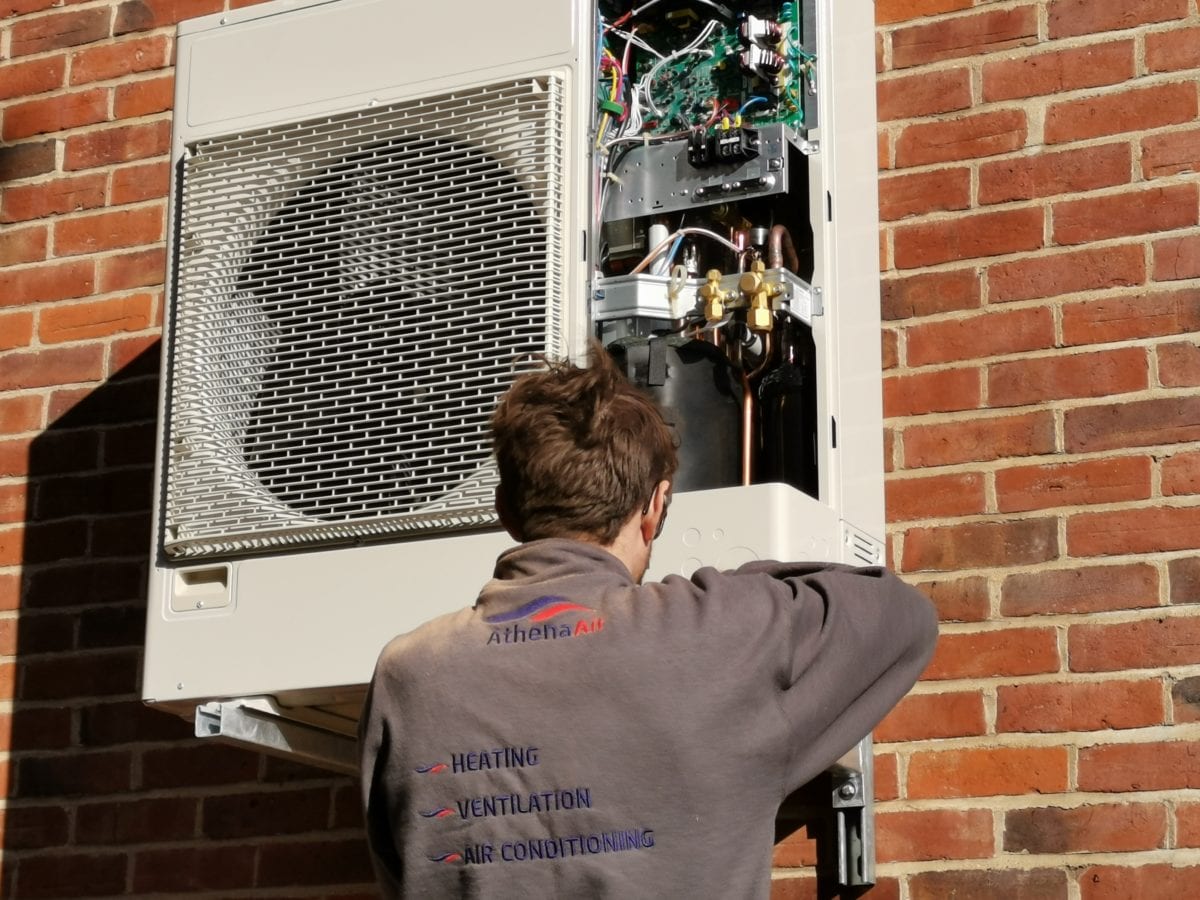

That is why ventilation plays a crucial role when undertaking any home improvement project that involves the use of stippling polymer. Proper ventilation helps to remove harmful fumes and maintain a comfortable and healthy living environment. In this article, we will explore the importance of ventilation in stippling polymer projects, as well as the pros and cons of using a ventilation system.

Key Takeaways:

- Proper ventilation is crucial when stippling polymer to remove harmful fumes and particles, ensuring a healthier and safer environment for everyone involved.

- Using a ventilation system offers benefits like improved air quality and odor control, but consider factors like cost and noise levels when making a decision.

Read more: When Should You Replace HVAC System

What is Stippling Polymer?

Stippling polymer is a type of coating or compound that is applied to surfaces to create texture and improve the grip. It is commonly used in home improvement projects such as painting, flooring, and even furniture refinishing. The application of stippling polymer involves using a brush or tool to create a pattern of raised dots or bumps on the surface, providing both aesthetic appeal and practical functionality.

Stippling polymer is available in various forms, including liquid and powder. The liquid form is typically a mixture of polymers and other additives that are applied directly to the surface. It dries and hardens to create a textured surface. The powder form, on the other hand, requires mixing with a liquid binder before application.

This technique is especially popular for surfaces that require enhanced grip, such as stairs, ramps, and outdoor walkways. The texturing provided by the stippling polymer makes these surfaces less slippery, reducing the risk of accidents and ensuring the safety of individuals using them.

In addition to improving grip, stippling polymer can also be used to enhance the appearance of surfaces. It adds depth and visual interest, making them more visually appealing. This makes stippling polymer a versatile option for homeowners looking to upgrade their spaces and create a unique aesthetic.

However, it is important to note that the application of stippling polymer can release potentially harmful fumes and particles into the air. These can have adverse effects on air quality and human health if not properly managed. That is why ventilation is crucial when working with stippling polymer.

The Importance of Ventilation

When it comes to working with stippling polymer or any other material that releases fumes and particles, proper ventilation is of utmost importance. Ventilation plays a significant role in maintaining good indoor air quality and ensuring the health and safety of those in the surrounding area. Here are some key reasons why ventilation is essential in stippling polymer projects:

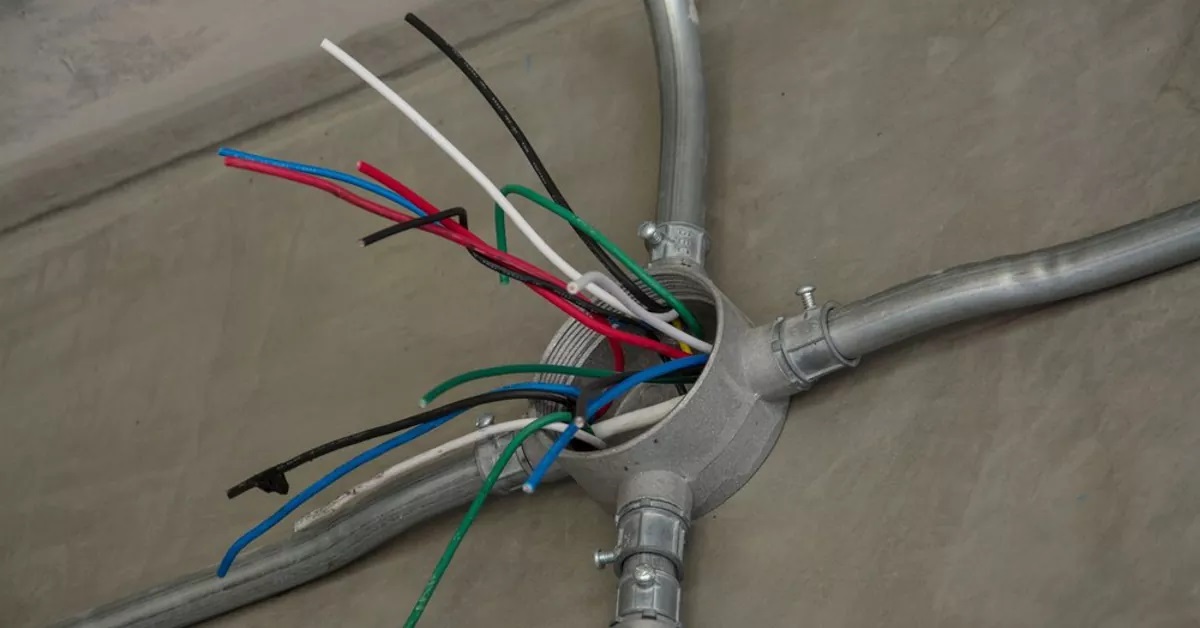

- Removal of Fumes: Stippling polymer coatings often contain volatile organic compounds (VOCs) that can evaporate into the air during application and drying. These VOCs can contribute to poor indoor air quality and may cause various health issues such as headaches, dizziness, and respiratory irritation. Ventilation helps to remove these fumes and ensure a healthier breathing environment.

- Control of Dust and Particles: The process of applying stippling polymer can also generate dust and particles that can become airborne. These particles can settle on surfaces, affecting the cleanliness of the area and potentially causing discomfort or health problems if inhaled. Ventilation helps to prevent the buildup of dust and particles by continually circulating the air and filtering out contaminants.

- Temperature and Humidity Control: Ventilation systems not only help to remove pollutants but also play a role in controlling temperature and humidity levels. Proper ventilation ensures a comfortable working environment by regulating air circulation and preventing excessive heat and humidity buildup.

- Prevention of Mold and Mildew: Stippling polymer projects often involve the use of moisture. If the moisture is not properly managed, it can lead to the growth of mold and mildew. These can not only damage the surfaces but also pose health risks. Adequate ventilation helps to remove excess moisture and prevent the growth of mold and mildew.

In summary, ventilation is essential in stippling polymer projects to remove fumes, control dust and particles, regulate temperature and humidity, and prevent the growth of mold and mildew. It is crucial to prioritize the health and well-being of both the individuals working on the project and those living in the surrounding area.

Always use a ventilation system when stippling polymer to avoid inhaling harmful fumes. This will help protect your respiratory system and ensure a safe working environment.

Pros and Cons of Using a Ventilation System

When considering whether to use a ventilation system in your stippling polymer projects, it is important to weigh the advantages and disadvantages. Here are some pros and cons to consider:

- Pro: Improved Air Quality: The primary benefit of using a ventilation system is the improved air quality it provides. The system helps to remove harmful fumes, dust, and particles from the air, ensuring a healthier breathing environment for both workers and occupants of the space.

- Pro: Odor Control: Stippling polymer coatings can emit strong odors during application and drying. A ventilation system can help to mitigate these odors by constantly extracting the air and replacing it with fresh, clean air from outside.

- Pro: Enhanced Comfort: Ventilation systems not only improve air quality but also help to regulate temperature and humidity levels, creating a more comfortable working environment. This can contribute to increased productivity and overall satisfaction during the stippling polymer project.

- Pro: Prevention of Health Issues: By removing fumes, dust, and particles, a ventilation system can help to prevent respiratory and other health issues associated with poor indoor air quality. This is especially important for individuals who may be sensitive to airborne contaminants.

- Con: Cost: Installing and operating a ventilation system can come with a financial cost. Depending on the size and complexity of the system, the initial investment and ongoing maintenance expenses may be significant.

- Con: Noise: Some ventilation systems can generate noise, especially if they are not properly designed or maintained. This can be a potential drawback for individuals who require a quiet working environment.

- Con: Energy Consumption: Ventilation systems typically require electricity to operate, which can contribute to increased energy consumption. This is an environmental consideration and can also impact utility costs.

Ultimately, the decision to use a ventilation system in your stippling polymer projects should take into account the specific needs and circumstances of the project. While there are costs and potential drawbacks associated with these systems, the benefits in terms of improved air quality, comfort, and health outcomes make them a valuable investment for many homeowners and contractors.

Factors to Consider When Choosing a Ventilation System

When selecting a ventilation system for your stippling polymer projects, it is important to consider several factors to ensure optimal performance and effectiveness. Here are some key factors to keep in mind:

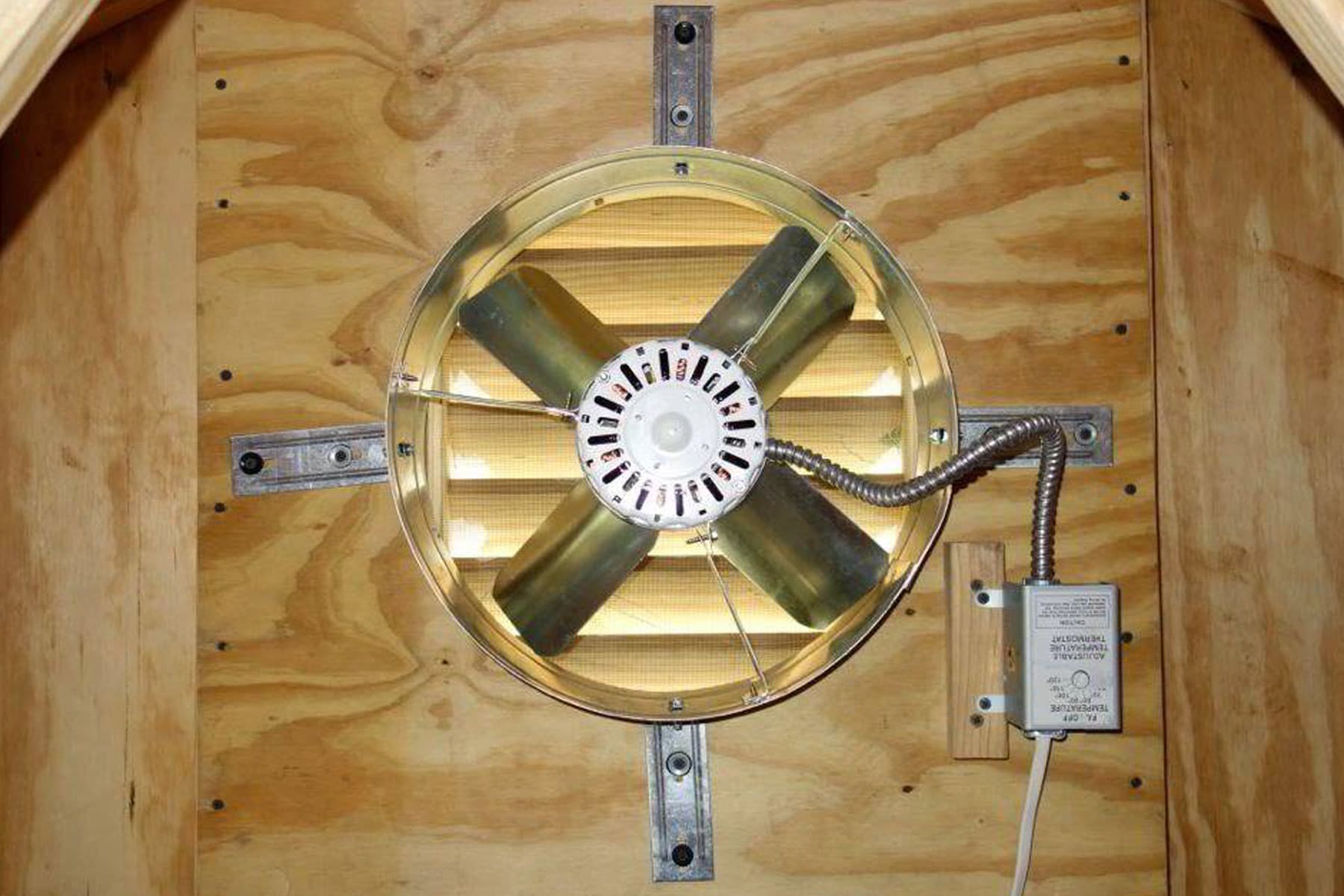

- Airflow Capacity: The airflow capacity of the ventilation system is crucial in determining its ability to effectively remove fumes, dust, and particles from the air. Consider the size of the space where the stippling polymer work will be done and choose a system with adequate airflow to cover the entire area.

- Filtration System: A good ventilation system should have a reliable filtration system to capture and remove airborne contaminants. Look for systems with high-quality filters that can efficiently trap particles and improve air quality.

- Noise Level: Consider the noise level produced by the ventilation system, especially if you require a quiet working environment. Look for systems that are designed to operate quietly, or ones that have built-in noise reduction features.

- Energy Efficiency: Energy efficiency is an important consideration to minimize your environmental impact and reduce operating costs. Look for ventilation systems that are energy-efficient and have features such as programmable timers or variable speed controls to optimize energy usage.

- Installation Requirements: Consider the installation requirements of the ventilation system. Some systems may require professional installation, while others may be easier to set up yourself. Additionally, ensure that the system is compatible with the power supply and infrastructure of your home or workspace.

- Maintenance and Cleaning: Regular maintenance and cleaning are essential to keep the ventilation system functioning effectively. Consider the accessibility and ease of maintenance, such as filter replacement and cleaning instructions provided by the manufacturer.

- Budget: Determine your budget for the ventilation system, considering both the initial cost of the system and any ongoing maintenance or operational costs. Compare different options and choose a system that offers the best balance between price and performance.

By carefully considering these factors, you can select a ventilation system that meets your specific needs and ensures a healthier and more comfortable working environment during your stippling polymer projects.

Read more: Should You Unplug Toaster When Not In Use

Conclusion

When undertaking stippling polymer projects, proper ventilation is essential to maintain good indoor air quality and promote a safe and healthy environment. The release of fumes, dust, and particles during the application and drying of stippling polymer coatings can have adverse effects on both the workers and occupants of the space. By using a ventilation system, you can effectively remove these airborne contaminants and create a more comfortable and safer working environment.

Using a ventilation system offers numerous benefits. It improves air quality, removes harmful fumes and particles, controls temperature and humidity levels, and prevents the growth of mold and mildew. This translates into better respiratory health, increased comfort, and reduced risks of potential health issues.

However, it is important to weigh the pros and cons of using a ventilation system. While it provides significant advantages such as improved air quality and odor control, there are factors to consider, including the cost of installation and operation, noise levels, and energy consumption. Nonetheless, the benefits usually outweigh the drawbacks, making a ventilation system a worthwhile investment.

When choosing a ventilation system, consider factors such as airflow capacity, filtration system quality, noise levels, and energy efficiency. Additionally, evaluate installation requirements, maintenance needs, and your budget to make an informed decision that suits your specific stippling polymer project requirements.

In conclusion, using a ventilation system when stippling polymer is crucial for the health and well-being of everyone involved. It ensures the removal of harmful fumes, dust, and particles, while creating a more comfortable and safer working environment. By carefully selecting the right ventilation system for your needs, you can enhance the overall quality of your stippling polymer projects and ensure a healthier living or working space.

Frequently Asked Questions about Should You Use A Ventilation System When Stippling Polymer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Should You Use A Ventilation System When Stippling Polymer”